ADCERAX® Square Zirconia Sagger is engineered for high-temperature sintering and calcination where consistent performance is critical. Made from dense zirconia with high purity, it maintains stability under repeated furnace cycles above 1,400 °C. The sagger resists corrosion from aggressive environments and ensures powders or green bodies are processed without contamination. Its flat base and strong thermal reliability make Square Zirconia Sagger a trusted choice in metallurgy, advanced alloys, and material science applications.

Features of Square Zirconia Sagger

- Withstands continuous use above 1,400 °C, ensuring safe performance in repeated furnace cycles. This stability supports long production runs without structural damage.

- Thermal expansion coefficient around 10.3 × 10⁻⁶/K keeps sagger s dimensionally consistent. This prevents deformation that could disrupt powder sintering processes.

- Purity above 99.5% ZrO₂ reduces risk of reaction with lithium salts or transition metal oxides. This ensures high-quality output in demanding environments.

- Low porosity structure minimizes absorption of chemical vapors. This maintains cleanliness inside high-temperature processing chambers.

- Dense construction provides mechanical strength to carry heavy powder loads. This reduces risk of cracking under industrial-scale sintering.

- Flat base and shallow wall design promote uniform heat distribution. This minimizes uneven densification of powders during calcination.

Technical Properties for Square Zirconia Sagger

Square Zirconia Sagger is designed for demanding sintering environments where performance consistency is critical.

| Property |

Specification |

| Purity (ZrO₂) |

≥ 99.5% |

| Max Working Temperature |

≥ 1,400 °C |

| Thermal Expansion |

10.3 × 10⁻⁶ /K |

| Bulk Density |

~6.0 g/cm³ |

| Thermal Conductivity |

2.5 W/m·K |

| Water Absorption |

<0.1% |

| Flexural Strength |

≥ 350 MPa |

| Compressive Strength |

≥ 2,000 MPa |

| Fracture Toughness |

8–10 MPa·m¹ᐟ² |

| Hardness |

~1,200 HV |

| Thermal Emissivity |

0.90–0.95 |

| Porosity |

<1% |

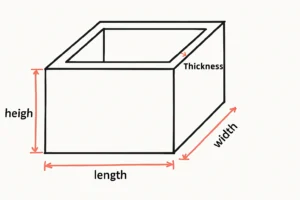

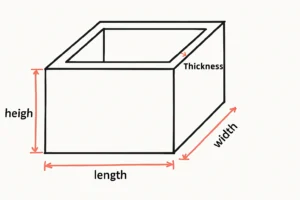

Dimensions of Square Zirconia Sagger

|

Item |

Capacity(ml) |

Length(mm) |

Width(mm) |

Height(mm) |

Thickness(mm) |

Purity(%) |

|

AT-YHG-XB036 |

56 |

100 |

100 |

12 |

5 |

92-95 |

|

AT-YHG-XB037 |

507 |

150 |

150 |

50 |

10 |

92-95 |

|

AT-YHG-XB038 |

350 |

200 |

100 |

30 |

8.5 |

92-95 |

|

AT-YHG-XB039 |

6000 |

300 |

300 |

175 |

12 |

92-95 |

|

AT-YHG-XB040 |

5400 |

300 |

300 |

110 |

12 |

92-95 |

|

AT-YHG-XB041 |

8000 |

300 |

300 |

150 |

12.5 |

92-95 |

|

AT-YHG-XB042 |

2800 |

320 |

320 |

48 |

14 |

92-95 |

Packaging for Square Zirconia Sagger

Each Square Zirconia Sagger is carefully packed with bubble wrap and placed in protective cartons before palletization. For long-distance or fragile shipments, trays are reinforced with sealed wooden cases. This ensures every ZrO2 Square Sagger arrives safely without damage during international transport.

Addressing Powder Sintering Challenges with ADCERAX® Square Zirconia Sagger

Zirconia Ceramic Tray is not only a container but a critical tool for industries where powder sintering defines product quality. Its material properties directly respond to technical pain points in metallurgy, advanced alloy production, and material research, ensuring reliable results under harsh furnace conditions.

-

Metallurgical Powder Compaction

✅Key Advantages

1. Cycle-Proof Thermal Stability — Operates ≥1,400 °C for >100 thermal cycles without measurable warpage. This protects powder packing quality during long production runs.

2. Load-Bearing Flex Strength — Flexural strength ≥350 MPa resists bending under dense powder loads. Bulk density ~6.0 g/cm³ improves stiffness at temperature.

3. Uniform Heat Field Emissivity — Thermal emissivity 0.90–0.95 promotes even IR absorption. This limits local sintering gradients across wide trays.

✅ ️Problem Solved

A European powder-metallurgy line processing Fe-based blends replaced alumina supports with ADCERAX® Square Zirconia Sagger. Over an 8-week trial at 1,250–1,320 °C, scrap rate fell from 7.2% to 4.1%, and tray change intervals extended from ~120 to ~320 cycles. Furnace micro-thermocouple mapping showed ≤±12 °C across the charge vs ±25 °C previously, stabilizing densification. Unplanned downtime dropped by ~18 hours/month, improving throughput without recipe changes.

-

Advanced Alloy Powder Processing

✅Key Advantages

1. High-Purity Inert Contact — ZrO₂ purity ≥99.5% minimizes interfacial reactions with Ni/Co/rare-element powders. Low reactivity preserves alloy chemistry through peak hold.

2. Low-Porosity Surface Uptake — Porosity <1% reduces vapor absorption and re-release of oxides. This limits batch-to-batch contamination during long holds.

3. Chemical Resistance Window — Strong resistance to most acids/alkalis (except HF) under furnace atmospheres. Suitable for oxidative or inert cycles up to ≥1,400 °C.

✅ ️Problem Solved

A cathode-grade Ni-Co alloy program saw frequent batch rejections due to trace surface contamination from legacy trays. After switching to ADCERAX® Square Zirconia Sagger, rejection rate declined from 5.5% to 2.2% over six campaigns at 1,100–1,350 °C. Post-sinter tensile variability narrowed by ~35%, attributed to cleaner interfaces and reduced vapor uptake. Production cadence recovered a full shift/week, with no recipe alteration.

-

Materials Science Research Laboratories

✅Key Advantages

1. Repeatable Thermal Cycling — Service life >100 cycles with stable thermal behavior. This supports Design-of-Experiments without tray-induced drift.

2. Fracture-Resistant Mechanics — Fracture toughness 8–10 MPa·m¹ᐟ² and flexural strength ≥350 MPa reduce crack initiation in tight ramp profiles.

3. Clean, Stable Contact — Low porosity and high purity sustain uncontaminated surfaces. This protects analytical integrity in small-batch studies.

✅ ️Problem Solved

A university lab running DoE on advanced alloy powders reported inconsistent shrinkage due to support variability. With ADCERAX® Square Zirconia Sagger, repeat runs at 1,200–1,450 °C produced consistent shrinkage curves and eliminated repeat tests across 50 specimens. Rework cycles dropped by ~40%, and the campaign finished two weeks earlier. Data quality improved without modifying furnace hardware or scripts.

User Guide for Square Zirconia Sagger

Correct handling and operation of Square Zirconia Sagger ensure long service life and stable results in powder sintering. This guide provides essential reminders for customers, covering pre-use preparation, heating cycles, operational safety, and storage practices. Following these guidelines helps minimize risk, improve efficiency, and reduce overall operating costs.

-

Pre-Use Preparation

1. Before the first use, the tray should be preheated in an oven at 105 °C for 120 minutes. This process removes residual moisture and prevents sudden cracking during the first heating cycle.

2. Avoid exposing the tray to direct flames from tools such as gasoline torches or alcohol burners. Sudden localized heating can create stress fractures in the ceramic body.

3. Inspect the surface and edges of the tray prior to loading powders. Small cracks or chips can expand rapidly under heat, leading to unexpected breakage.

-

Heating and Cooling Cycles

1. Maintain controlled heating and cooling rates for best results. Below 1,200 °C, do not exceed 5 °C per minute, while above 1,200 °C, limit to 4 °C per minute.

2. Place the Zirconia Ceramic Tray at least 2 cm away from heating elements such as silicon carbide rods or heating wires. This reduces uneven radiation and prevents hot spots.

3. Always allow the furnace to return gradually to room temperature after operation. Rapid cooling may cause internal stress that shortens the tray’s usable life.

-

Operational Safety

1. Load powders evenly across the flat base of the tray. Uneven distribution can lead to localized stress points and reduce the quality of sintered products.

2. Do not exceed the recommended capacity of the tray during each furnace cycle. Overloading can cause distortion and premature failure under high mechanical stress.

3. Handle the tray with proper tools such as ceramic tongs or heat-resistant gloves. Direct contact during operation increases the risk of accidents and contamination.

-

Storage and Maintenance

1. Store Zirconia Ceramic Trays in a dry, clean area away from corrosive chemicals. Long-term exposure to reactive vapors may degrade the tray surface.

2. After each use, clean the tray gently with non-abrasive tools. Harsh cleaning methods can scratch the dense surface and weaken its integrity over time.

3. Keep trays stacked with protective layers between them when not in use. This prevents accidental chipping of edges and ensures readiness for the next production cycle.