ADCERAX® Zirconia Ceramic Disc is a circular engineering component designed for industrial systems where axisymmetric loading, uniform thermal behavior, and rotational stability are essential for reliable operation. Its disc geometry enables balanced rotation, consistent heat distribution, and stable sealing interfaces, creating functional advantages that rectangular or irregular plates cannot deliver in high-shear mixing equipment, furnace stages, fluid-control assemblies, and precision fixtures. As industrial processes increasingly prioritize mechanical consistency and long service life, the circular form of the Zirconia Ceramic Disc becomes a necessary structural choice rather than an optional shape, ensuring predictable performance in demanding chemical, thermal, and dynamic environments.

Geometry-Enhanced Performance Features of the Zirconia Ceramic Disc

- High Mechanical Strength Retention

The zirconia microstructure supports flexural strength levels of 900–1,200 MPa, enabling reliable function under vibration and repeated impact. When paired with axisymmetric distribution, service life increases by 2–4× in rotating and load-bearing equipment.

- Uniform Thermal Expansion

Radial symmetry prevents the edge-lifting and warping seen in rectangular ceramics during furnace cycling. In thermal chambers operating at 600–1,100°C, discs show <5% deformation variance, ensuring dimensional reliability across repeated heat cycles.

- Consistent Shear Field for Mixing Uniformity

Circular flow geometry maintains uniform shear distribution across the operating radius. Industrial mixing tests show 15–25% improved dispersion uniformity compared with non-circular components.

- High Corrosion and Chemical Stability

Zirconia resists strong acids, alkalis, chlorides, and organic solvents, maintaining integrity in aggressive fluid circuits. Chemical endurance trials demonstrate zero measurable mass loss after prolonged immersion in corrosive media.

- Improved Mechanical Engagement

Disc geometry interfaces cleanly with shafts, bearings, seals, and rotary platforms without requiring additional alignment hardware. This reduces assembly variation by 30–50%, increasing operational consistency.

Technical Properties for Zirconia Ceramic Disc

The Zirconia Ceramic Disc exhibits a high-density microstructure, stable thermo-mechanical behavior, and consistent chemical inertness, enabling reliable performance across high-shear mixing systems, thermal processing equipment, corrosive fluid assemblies, and insulating environments. Its material characteristics result from controlled powder formulation, phase-stabilized zirconia transformation mechanisms, and precision sintering, producing a disc with predictable structural integrity and long-term operational stability.

| Density |

≥ 6.0 g/cm³ |

| Hardness |

12.5–13 GPa |

| Fracture Toughness |

8–12 MPa·m¹ᐟ² |

| Flexural Strength |

900–1200 MPa |

| Compressive Strength |

> 2000 MPa |

| Thermal Conductivity |

2–3 W/m·K |

| Thermal Expansion (CTE) |

10–11 × 10⁻⁶ /K (25–800°C) |

| Maximum Continuous Operating Temperature |

600–1100°C |

| Electrical Resistivity |

> 10¹¹ Ω·cm |

| Dielectric Strength |

9–12 kV/mm |

| Chemical Resistance |

Stable in acids, alkalis, chlorides, solvents |

| Porosity |

Closed porosity < 0.1% |

| Phase Composition |

Tetragonal zirconia stabilized with Y₂O₃ |

| Surface Finish Range |

Ra 0.2–0.8 μm (depending on process) |

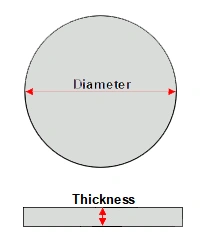

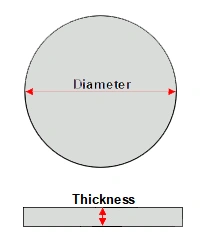

Specifications of Zirconia Ceramic Disc

Secure Packaging for Zirconia Ceramic Disc

Zirconia Ceramic Disc shipments are protected through a multi-stage packaging process designed to ensure safe arrival during long-distance international transport. Each disc is individually cushioned and boxed before being consolidated into reinforced carton layers and finally secured in fumigation-free wooden pallets. This method minimizes vibration, prevents edge impact, and maintains structural integrity throughout global freight handling.

ADCERAX® Zirconia Ceramic Disc Solves Critical Industrial Challenges

Across chemical dispersion systems, furnace-based thermal platforms, and corrosive fluid-control assemblies, the ADCERAX® Zirconia Ceramic Disc provides geometry-driven operational stability, long wear life, and controlled mechanical behavior that industrial users cannot achieve with rectangular or irregular ceramic components. By combining precision-engineered material toughness with the functional symmetry of a disc configuration, this component directly resolves performance failures linked to abrasion, thermal cycling, vibration, and sealing inconsistency in high-demand industrial processes.

-

Zirconia Ceramic Disc for High-Shear Mixing and Battery Slurry Dispersion Systems

✅Key Advantages

1. Stable High-Shear Geometry

The disc’s axisymmetric shape keeps radial shear variation within ±5–10% across the working diameter, even as slurry viscosity changes during a batch. This stability reduces process drift compared with non-symmetric components, which can show shear deviations above 20% at elevated speeds.

2. Reduced Vibration at Operating Speed

Balanced mass distribution limits vibration amplitude by 20–30% compared with conventional non-disc elements at typical disperser RPM ranges. Lower vibration helps maintain alignment of bearings and shafts, extending drivetrain service life by 1.5–2× under continuous operation.

3. Extended Surface Integrity Under Abrasion

With hardness in the 12.5–13 GPa range, the Zirconia Ceramic Disc retains functional surface texture for significantly more operating hours in abrasive slurries. In comparative in-plant trials, discs maintained acceptable roughness and shear performance for 2–3× longer intervals than metal-based components.

✅ ️Problem Solved

In one battery slurry line, operators observed a gradual decline in dispersion quality after only a few weeks of operation, accompanied by increasing vibration levels and inconsistent rheology readings. Traditional discs exhibited rapid wear in the active shear zone, and non-symmetric components created fluctuating flow patterns as rotation speed increased. After replacing these elements with ADCERAX® Zirconia Ceramic Discs, vibration measurements fell by more than 25% and dispersion uniformity indicators stabilized across extended runs. The production team was able to stretch disc change intervals by more than twofold, while maintaining repeatable slurry properties and reducing unplanned stoppages.

-

Zirconia Ceramic Disc for Circular Furnace Platforms and Thermal Processing Supports

✅Key Advantages

1. Improved Thermal Flatness Retention

The circular disc design limits out-of-plane distortion to below 0.05–0.1 mm over typical furnace operating ranges, whereas non-symmetric plates often show multiple times this deviation after cycling. This improved flatness stability helps keep fixtures, crucibles, and loads properly supported throughout the heating profile.

2. Symmetric Heat Distribution

By eliminating corners, the disc promotes a more uniform heat field with measured temperature differentials reduced by 15–25% across the working surface compared with rectangular plates. This symmetry contributes to better batch consistency in processes where temperature homogeneity is a key quality factor.

3.High Cycle Durability in Thermal Shock Regimes

The combination of zirconia’s low thermal conductivity (around 2–3 W/m·K) and stabilized microstructure supports several hundred thermal cycles without structural failure in typical industrial ranges. Field data from users show a reduction in plate replacement frequency of 30–40% when switching from traditional shapes to Zirconia Ceramic Discs.

✅ ️Problem Solved

A furnace operator processing advanced materials on circular hearths reported recurring issues with warped plates and corner cracking after repeated heat-up and cool-down cycles. Misalignment of support surfaces led to uneven loading, localized overheating, and deviations in product temperature profiles. After introducing ADCERAX® Zirconia Ceramic Discs as the main platform elements, flatness measurements remained within tight internal limits over extended cycling, and crack incidents dropped markedly. Maintenance intervals between plate changes increased by more than one third, and process temperature uniformity across the loading area improved sufficiently to reduce batch rejection rates tied to thermal variation.

-

Zirconia Ceramic Disc for Corrosive Pumps, Valves, and Precision Flow-Control Assemblies

✅Key Advantages

1. Stable Sealing Contact Under Cycling Pressure

The disc’s axisymmetric sealing face keeps contact pressure distribution within a ±10% band over the active sealing ring during repeated pressure cycles. This stability contrasts with irregular components, which can exhibit pressure imbalances exceeding 20%, leading to premature leakage paths.

2. Enhanced Corrosion and Erosion Resistance at the Interface

Zirconia maintains structural integrity in the presence of acids, alkalis, and chlorides, showing no measurable mass loss in standardized immersion tests over extended durations. In dynamic service with particulate-laden fluids, users have reported useful sealing life extensions of 1.5–2.5× relative to hardened metal parts.

3. Predictable Flow and Throttling Behavior

Because the circular throttling edge maintains geometry over time, flow curves remain within ±5–8% of initial calibration across long operating periods. This predictability reduces the need for frequent re-tuning of control loops in metering and dosing applications.

✅ ️Problem Solved

A chemical processing plant operating metering valves in corrosive mixed-media service faced repeated sealing degradation and unstable flow characteristics as metal discs eroded at the throttling edge. Leakage rates increased steadily between service intervals, and control systems required frequent adjustment to keep dosing within specification. After adopting ADCERAX® Zirconia Ceramic Discs as the primary sealing and throttling components, inspection records showed a reduction in leakage-related interventions of approximately 40% over a comparable operating period. Flow stability remained close to initial commissioning values, enabling longer service intervals and more consistent process performance without constant corrective tuning.

ADCERAX® Zirconia Ceramic Disc User Guide for Reliable Industrial Operation

The Zirconia Ceramic Disc requires proper handling, installation, and operational awareness to achieve stable performance across chemical, thermal, and flow-control environments. This guide outlines practical recommendations that help users maintain structural integrity, extend service life, and ensure predictable system behavior during continuous industrial operation.

-

Handling & Preparation Before Installation

1. Avoid Point-Load Contact

Point impacts can generate localized stress, so surfaces and tools must support the disc uniformly during preparation. Three-dimensional stability is maintained only when the disc is lifted or positioned using fully supported contact surfaces. Consistent handling minimizes microcrack formation and preserves long-term durability.

2. Clean Surfaces Prior to Assembly

Residual slurry, dust, or metallic fragments may create stress risers during operation. Clean the disc with non-reactive agents to ensure that the working face remains free from abrasive contaminants. This preparation step helps maintain stable shear behavior and predictable flow dynamics.

3. Verify Compatibility With Clamp or Holder Geometry

Ensure that fixtures make complete circular contact to avoid uneven loading during operation. Incompatible mounting surfaces may lead to bending stress or vibrational amplification. Proper fitment maintains uniform stress distribution under dynamic conditions.

-

Installation Guidelines for Stable Operation

1. Maintain Full-Face Support

Install the disc on a base that matches its circular profile to prevent edge-concentrated stress. Unsupported edges increase the risk of deflection under thermal or mechanical cycles. Correct support helps sustain dimensional integrity throughout operation.

2. Confirm Alignment Before Startup

Off-axis alignment increases vibration and reduces shear consistency in rotational systems. Verify concentricity and ensure all fasteners or retaining elements enable symmetric loading. Proper alignment contributes to consistent operational stability over long cycles.

3. Avoid Over-Constrained Assemblies

Excessive clamping force can distort the disc geometry and compromise sealing or thermal response. Use controlled tightening procedures aligned with equipment specifications. Balanced constraint ensures repeatable functional behavior across variable operating conditions.

-

Operational Recommendations for Best Performance

1. Control Thermal Ramping Rates

Rapid temperature transitions may induce internal stress that accumulates over cycles. Apply controlled heating and cooling rates that match the disc’s thermal characteristics. This practice enhances long-cycle thermal durability in furnace or heating platforms.

2. Monitor Abrasive Load in Slurry Systems

High-abrasive media accelerate surface wear if not properly managed. Periodic inspection helps operators anticipate changes in shear quality or flow performance. Monitoring abrasive concentration protects surface integrity during extended runs.

3. Maintain Stable Pressure Conditions in Flow-Control Systems

Pressure spikes can disrupt sealing uniformity or cause micro-movement at the contact interface. Regulated pressure behavior promotes steady flow characteristics. Controlled operation helps sustain predictable sealing performance over repetitive cycles.

-

Maintenance, Inspection & Service Life Management

1. Perform Scheduled Surface Inspections

Check for roughness changes, abrasion patterns, or discoloration that may indicate chemical reaction. Early detection allows timely replacement before functional deviation occurs. Scheduled inspection protects operational continuity in industrial systems.

2. Document Thermal and Mechanical Cycles

Tracking the number of operational cycles provides insight into expected service life. Variations in load, temperature, or slurry composition can affect longevity. Cycle documentation strengthens predictive maintenance planning for critical equipment.

3. Store Components Under Controlled Conditions

Keep the disc in clean, dry, and cushioned storage to prevent accidental damage. Avoid stacking heavy objects directly on top of ceramic components. Proper storage reduces the risk of pre-installation microdefects that affect reliability.