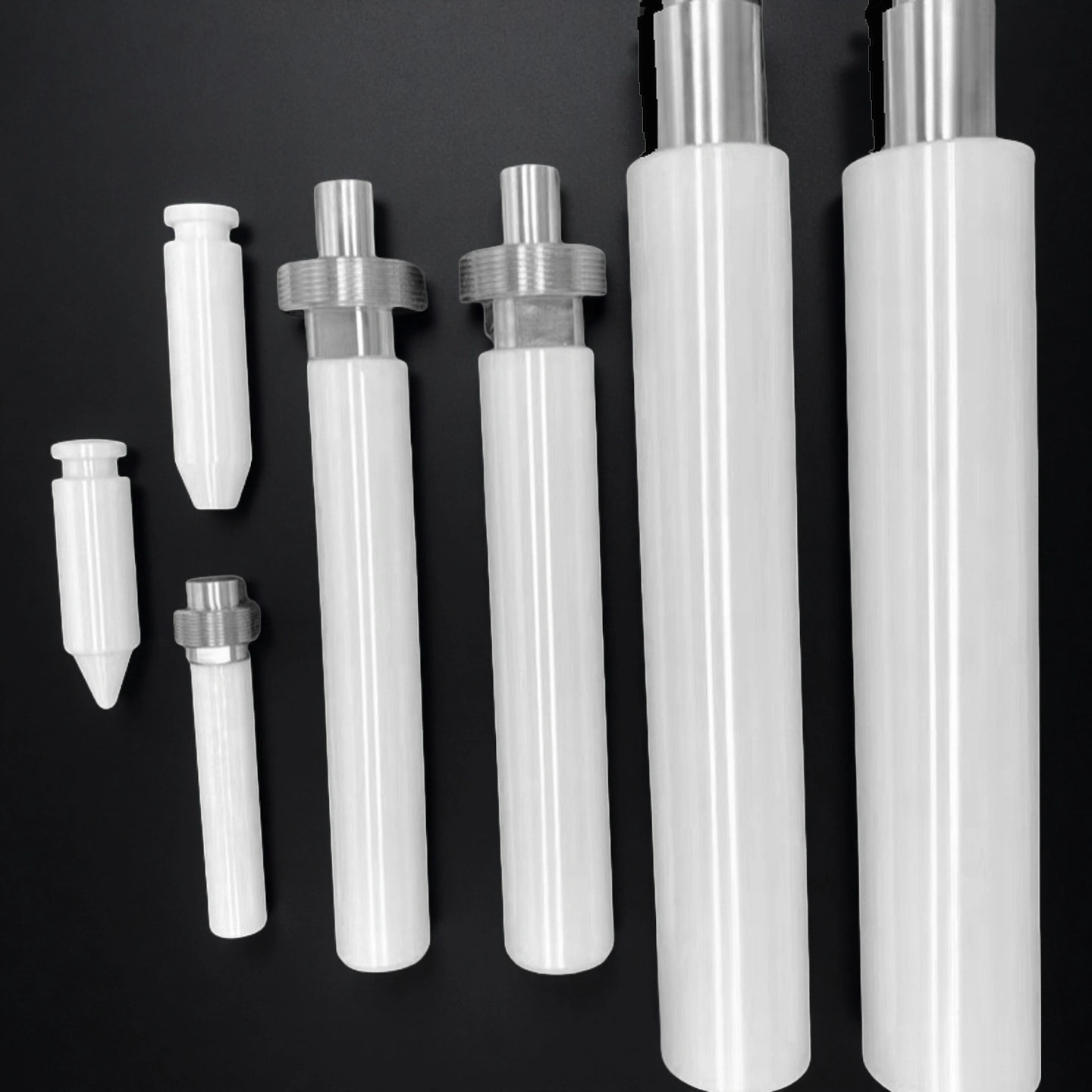

ADCERAX® Zirconia Ceramic Piston is engineered for long‑cycle, high‑precision fluid control in metering and dosing pumps. It combines high mechanical strength, wear resistance, and chemical stability to maintain consistent flow under demanding conditions. The mirror‑polished surface reduces friction and leakage, enabling smooth reciprocation with minimal maintenance. This product is widely applied in pharmaceutical equipment, water treatment systems, fine‑chemical dosing, and automated industrial filling lines.

Performance Features of Zirconia Ceramic Piston

- Stable up to 1000 °C in dry operation, and continuously operates at ≤ 600 °C under fluid load, ensuring dimensional reliability during thermal cycling.

- Immune to 5% HCl and 10% NaOH exposure for 72 hours with no measurable mass loss, supporting long-term compatibility with acidic and basic chemicals.

- Thermal expansion coefficient of 10.5 × 10⁻⁶/K, matched to stainless steel, prevents thermal shock and mismatch failure in hybrid assemblies.

- Vickers hardness of 1250–1350 HV0.5 delivers exceptional abrasion resistance against slurries or solid-loaded fluids in continuous dosing.

- Flexural strength exceeds 1200 MPa, allowing the piston to withstand internal pump pressures without deformation or failure.

- Fracture toughness reaches 6–10 MPa·m¹ᐟ², enabling resistance to chipping and sudden mechanical impacts during high-speed stroke applications.

- Surface roughness as low as Ra ≤ 0.02 µm minimizes fluid drag and ensures high dynamic sealing with polymer or ceramic liners.

- Friction coefficient as low as μ ≈ 0.1 (dry contact) eliminates the need for external lubrication in sterile or food-grade processes.

- Roundness deviation ≤ 0.003 mm guarantees uniform pressure distribution during reciprocation, reducing seal wear and start-up resistance.

Technical Properties of Zirconia Ceramic Piston

Zirconia Ceramic Piston is developed for precision fluid transfer systems that demand high mechanical integrity, thermal endurance, and chemical stability. The engineered microstructure and controlled sintering process ensure consistent performance under dynamic and corrosive working conditions.

| Property |

Specification |

| Material Composition |

3Y-TZP Zirconia |

| Density |

≥ 6.05 g/cm³ |

| Flexural Strength |

≥ 1200 MPa |

| Compressive Strength |

≥ 2000 MPa |

| Fracture Toughness |

6–10 MPa·m¹ᐟ² |

| Vickers Hardness |

1250–1350 HV0.5 |

| Surface Roughness (Ra) |

≤ 0.02 µm |

| Roundness Deviation |

≤ 0.003 mm |

| Thermal Conductivity |

2.5 W/m·K |

| Maximum Working Temperature |

≤ 600 °C continuous / ≤ 1000 °C peak |

| Thermal Expansion Coefficient |

10.5 × 10⁻⁶ /K |

| Acid Resistance (5% HCl, 72h) |

No mass loss |

| Alkali Resistance (10% NaOH, 72h) |

No mass loss |

| Electrical Resistivity |

>10¹² Ω·cm |

| Water Absorption |

0% |

Specifications of Zirconia Ceramic Piston

|

Zirconia Ceramic Pistons |

|

Item NO. |

Diameter (mm) |

Width(mm) |

|

AT-YHG-HS1001 |

Customize |

Packaging of Zirconia Ceramic Piston

Zirconia Ceramic Piston is securely packed in layered protective boxes, ensuring maximum shock absorption during transit. Each unit is first sealed in individual cartons, then consolidated into foam-lined wooden crates. Final export packaging is reinforced with straps and a moisture-resistant outer layer for international shipping.

Solving Fluid Control Challenges in Critical Systems with ADCERAX® Zirconia Ceramic Piston

ADCERAX® Zirconia Ceramic Piston addresses persistent failures in high-precision reciprocating equipment, where aggressive fluids, thermal cycling, and tight tolerance sealing present performance and maintenance risks. Its advanced ceramic properties enable consistent dosing, longer service life, and reduced downtime across complex process environments.

-

Zirconia Ceramic Piston in High-Purity Pharmaceutical Micro-Dosing Systems

✅Key Advantages

1. Ion-Free Chemical Inertness

Zirconia Ceramic Piston contains <0.001% metallic impurities, ensuring zero ion migration during high-temperature CIP/SIP sterilization. Its chemical stability prevents contamination of drug formulations, maintaining pharmaceutical-grade purity in micro-dosing lines.

2. Mirror-Polished Aseptic Surface

The Ra ≤ 0.02 µm optical finish minimizes bacterial adhesion and media retention. This smooth surface allows complete cleaning during CIP cycles, reducing residue detection in validation tests to below 0.2 CFU/cm².

3. Dimensional Stability Under Sterilization Stress

With a thermal expansion coefficient of 10.5 × 10⁻⁶/K, the piston retains geometry across repeated 121 °C steam sterilization cycles. It eliminates micro-deformation, ensuring stable volumetric displacement and flow consistency.

✅ ️Problem Solved

A European injectable drug manufacturer reported metal ion contamination and dosing drift after 200 CIP/SIP sterilizations using stainless plungers. By replacing them with ADCERAX® Zirconia Ceramic Pistons, contamination levels dropped to non-detectable limits, and volumetric deviation decreased from ±1.8% to ±0.3%. After six months of continuous use, no dimensional wear or residue accumulation was observed, validating compliance with EN ISO 13408-2 aseptic processing standards.

-

Zirconia Ceramic Piston in Alkaline Polymer Metering for Wastewater Coagulation

✅Key Advantages

1. Extended Life in High-pH Media

Tested in 10% NaOH solution for 72 hours, Zirconia Ceramic Piston exhibited 0% measurable mass loss, proving full resistance to alkaline attack. This endurance extends maintenance cycles by up to 6× compared to 316L plungers.

2. Structural Integrity Under Continuous Flow Stress

With a compressive strength ≥ 2000 MPa, the piston maintains form during high-pressure coagulant injection. Dimensional precision ensures consistent dosing pressure without pulse fluctuation even after 10⁷ cycles.

3. Reduced Downtime Through Surface Durability

Surface hardness of 1250–1350 HV0.5 prevents abrasive polymer slurry wear. The result is a 45% reduction in seal replacements per operating year, improving system uptime in flocculant dosing units.

✅ ️Problem Solved

A German wastewater treatment plant observed severe wear on stainless pistons, requiring replacement every 14 days. After adopting ADCERAX® Zirconia Ceramic Pistons, operational life exceeded 12 weeks per piston, maintaining dosing pressure stability within ±0.4 bar. System downtime due to maintenance fell by 52%, while polymer usage efficiency increased by 8%, verified through process analytics from the plant’s SCADA system.

-

Zirconia Ceramic Piston in Lithium Battery Slurry Dispersion Systems

✅Key Advantages

1. High Abrasion Resistance for Particle-Laden Slurries

Zirconia Ceramic Piston shows wear loss < 0.005 mm after 300 hours of NMC slurry circulation, maintaining metering accuracy. Its Vickers hardness 1350 HV0.5 ensures uniform flow delivery under particle erosion.

2. Stable Geometry in High-Stroke Operation

Flexural strength of ≥ 1200 MPa allows sustained reciprocation under >25 MPa injection pressure. Dimensional stability limits dosing deviation to <0.5%, critical for cathode material homogeneity.

3. Anti-Contamination Performance

The non-reactive zirconia matrix prevents metallic contamination from affecting lithium-ion chemistry. Trace analysis confirmed zero Fe/Ni inclusion after extended slurry exposure, preserving electrode quality and cycle life.

✅ ️Problem Solved

A Korean cathode manufacturer faced irregular flow and rapid plunger erosion during NMC slurry dosing, causing 3% batch composition drift and premature cell failures. After integration of ADCERAX® Zirconia Ceramic Pistons, dosing uniformity improved to within ±0.4%, and equipment lifespan extended from 2 weeks to 4 months. The change reduced slurry waste by 12%, confirmed through downstream coating thickness analysis and SEM inspection results.

Safe Handling and Operational Guidelines for Zirconia Ceramic Piston

To ensure optimal service life and precision performance, all users of Zirconia Ceramic Piston should follow structured handling, installation, and maintenance protocols. The following guidelines help minimize wear, prevent sealing issues, and avoid damage caused by improper alignment or fluid contamination.

-

Pre-Installation Inspection and Preparation

1. Visual inspection is essential before use. Check the Zirconia Ceramic Piston for surface defects, chipping, or dimensional mismatch. Any visible cracks or irregularities must be reported before assembly.

2. Cleanroom-grade cleanliness should be maintained. Ensure that the piston, liner, and associated pump components are free of dust, grease, or metallic particles prior to installation.

3. Use only approved cleaning fluids. Do not expose the piston to alcohol-based or acidic agents outside its tested chemical resistance range. Neutral detergents or DI water are recommended.

-

Installation into Pump Systems

1. Avoid excessive insertion force. The Zirconia Ceramic Piston should slide smoothly into the liner or housing with a gap tolerance-controlled fit; forced fitting may cause microfractures.

2. Align piston and liner concentricity. Misalignment leads to seal wear and uneven stroke resistance, especially in reciprocating pump configurations.

3. Secure piston ends without torsion. When using clamping interfaces or thread connectors, do not apply twisting force directly to ceramic components. Use compliant couplings if necessary.

-

Operating Conditions and Environmental Limits

1. Monitor stroke frequency and pressure. Zirconia Ceramic Piston is rated for operation under ≤ 600 °C and up to 25 MPa, but excessive cycling can accelerate wear if outside recommended limits.

2. Avoid sudden temperature transitions. Thermal shock may result if cold fluids are introduced rapidly after high-temp cycles. Allow natural cooling to ambient before flushing.

3. Prevent dry-run conditions. Continuous dry movement increases friction and can lead to micro-abrasion on contact surfaces. Always pre-fill fluid channels before pump activation.

-

Routine Maintenance and Replacement Triggers

1. Schedule wear assessments regularly. Check for Ra deviation, stroke noise, or sealing pressure changes every 3–6 months, depending on system load.

2. Replace upon sealing failure or dimensional drift. If flow deviation exceeds ±0.5%, or if piston surface shows wear >0.01 mm, initiate replacement protocol.

3. Store unused pistons properly. Keep in dry, anti-static packaging away from direct sunlight or corrosive fumes. Avoid stacking bare ceramics to prevent surface damage.