ADCERAX® Zirconia Ceramic Refractory Plate is engineered to support high-temperature sintering applications in dielectric ceramics, powder metallurgy, and ferrite magnetic components. With strong resistance to molten oxide corrosion and thermal shock, it ensures stability across repeated furnace cycles. The material structure of each Zirconia Ceramic Refractory Plate is optimized for industrial batch production, enabling higher throughput and fewer surface reactions. Reliable performance at up to 1600 ℃ makes it a trusted carrier platform in demanding thermal processing environments.

Features of Zirconia Ceramic Refractory Plate

- Continuous operation at 1600 ℃ enables reliable sintering cycles for dielectric ceramics and ferrite materials without structural degradation. Test data confirms shape retention after 40+ thermal cycles between 25–1500 ℃.

- The stabilized zirconia matrix maintains phase integrity under heat, allowing consistent performance across 3–5 furnace campaigns. Thermal distortion rate remains < 0.5 mm per 500 × 400 mm plate at 1550 ℃.

- Load softening temperature measured at ≥ 1600 ℃, ensuring dimensional reliability under prolonged thermal exposure and reducing deformation risk in full-load conditions.

- Resistant to molten oxides and volatile metal species, Zirconia Ceramic Refractory Plate performs well in environments with aggressive flux residues. Weight loss after 8 hr immersion in Mn-Zn oxide at 1450 ℃ is < 0.2 %.

- The calcia- and yttria-stabilized variants protect sintered components from unwanted adhesion or contamination. This reduces downstream polishing by over 35 % in ferrite applications.

- Compared to alumina plates, zirconia shows 3× longer lifespan when exposed to borate-rich melts in multilayer ceramic capacitor (MLCC) processing.

- Flexural strength of > 25 MPa (YSZ) and > 20 MPa (CSZ) allows the plate to carry heavier product loads per cycle, enabling tighter stacking in kilns and higher throughput per batch.

- It withstands > 50 thermal shock cycles (25–1500 ℃) without visible cracking, reducing breakage losses in automated sintering lines.

- With a bulk density up to 4.5 g/cm³, Zirconia Ceramic Refractory Plate minimizes porosity and extends functional service life under repetitive thermal cycling conditions.

Technical Properties for Zirconia Ceramic Refractory Plate

Zirconia Ceramic Refractory Plate is developed for high‑temperature sintering applications requiring exceptional thermal endurance, mechanical integrity, and corrosion resistance. Both yttria‑stabilized and calcia‑stabilized zirconia variants maintain stable crystalline phases under extreme furnace conditions, providing consistent reliability for industrial and laboratory use.

| Property | Specification |

|---|---|

| Material Type | Yttria‑Stabilized (YSZ) / Calcia‑Stabilized (CSZ) Zirconia |

| ZrO₂ + Stabilizer Content | ≥ 98.5 % (YSZ) / ≥ 98.2 % (CSZ) |

| Al₂O₃ Content | ≤ 0.40 % (YSZ) / ≤ 0.50 % (CSZ) |

| SiO₂ Content | ≤ 0.40 % (YSZ and CSZ) |

| TiO₂ Content | ≤ 0.20 % (YSZ and CSZ) |

| Fe₂O₃ Content | ≤ 0.10 % (YSZ and CSZ) |

| MgO Content | ≤ 0.10 % (YSZ and CSZ) |

| Maximum Operating Temperature | 1650 ℃ (YSZ) / 1600 ℃ (CSZ) |

| Bulk Density | 4.1 – 4.5 g/cm³ (YSZ) / 4.0 – 4.3 g/cm³ (CSZ) |

| Linear Expansion @ 1000 ℃ | 0.8 – 0.9 % (YSZ) / 0.9 – 1.0 % (CSZ) |

| Porosity | 23 – 28 % |

| Phase Structure | Stable cubic zirconia phase volume 70 – 80 % |

| Flexural Strength | > 25 MPa (YSZ) / > 20 MPa (CSZ) |

| Sintering Load Capacity | < 65 g/cm² |

| Thermal Shock Resistance (25–1500 ℃) | > 50 cycles (YSZ) / > 40 cycles (CSZ) |

| Softening Temperature under Load | 1650 ℃ (YSZ) / 1600 ℃ (CSZ) |

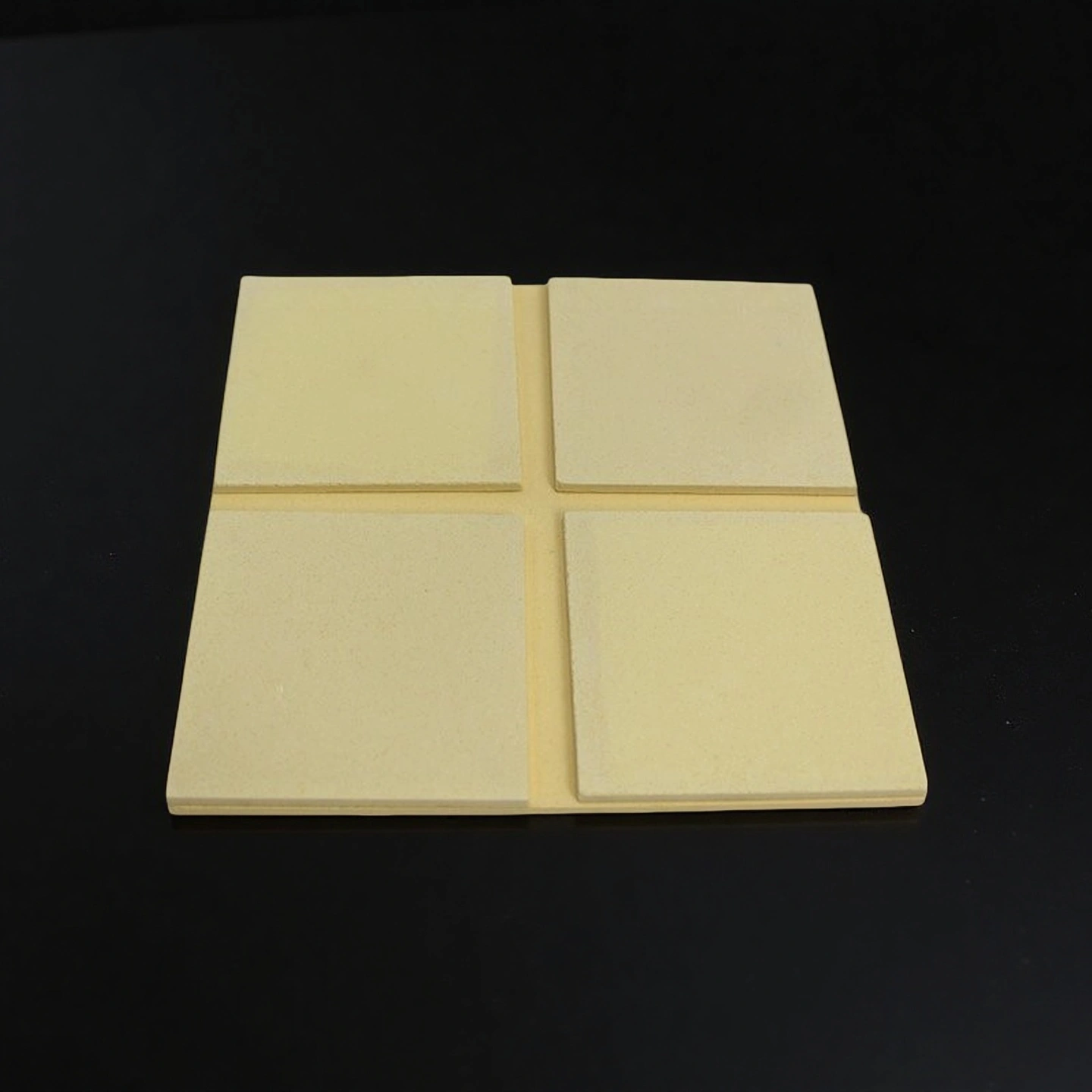

| Color Tone | Light Yellow Grade II (CSZ) / Light Yellow Grade III (YSZ) |

Specifications of Zirconia Ceramic Refractory Plate

| Zirconia Ceramic Refractory Plate | ||||

| Iten No. | Length × Width (mm) | Thickness (mm) | Slot height (mm) | Shape |

| AT-YHG-C1001 | 75×75±0.8 | 3.5±0.2 | 0 | flat plate |

| AT-YHG-C1002 | 90×72±0.8 | 3.5±0.2 | 0 | flat plate |

| AT-YHG-C1003 | 98×85±0.8 | 3.5±0.2 | 0 | flat plate |

| AT-YHG-C1004 | 98×98±0.8 | 3.5±0.2 | 0 | flat plate |

| AT-YHG-C1005 | 100×75±0.8 | 3.5±0.2 | 0 | flat plate |

| AT-YHG-C1006 | 100×100±0.8 | 3.5/4.0±0.2 | 0 | flat plate |

| AT-YHG-C1007 | 106×75±0.8 | 3.5/4.0±0.2 | 0 | flat plate |

| AT-YHG-C1008 | 115×60±0.8 | 3.5/4.0±0.2 | 0 | flat plate |

| AT-YHG-C1009 | 140×140±1.0 | 4.0±0.3 | 0 | flat plate |

| AT-YHG-C1010 | 150×150±1.0 | 4.0±0.3 | 0 | flat plate |

| AT-YHG-C1011 | Φ95±0.8 | 3.5±0.2 | 0 | flat plate |

| AT-YHG-C1012 | Φ115±0.8 | 3.5±0.2 | 0 | flat plate |

| AT-YHG-C1013 | 75×75±0.8 | 3.5±0.3 | 4.5±0.3 | Slot plate |

| AT-YHG-C1014 | 100×100±0.8 | 5.0±0.3 | 10±0.3 | Slot plate |

| AT-YHG-C1015 | 115×60±0.8 | 4.0±0.3 | 4.5±0.3 | Slot plate |

| AT-YHG-C1016 | 115×60±0.8 | 4.0±0.3 | 5.5±0.3 | Slot plate |

| AT-YHG-C1017 | 115×60±0.8 | 4.5±0.3 | 6.0±0.3 | Slot plate |

| AT-YHG-C1018 | 140×70±1.0 | 5.0±0.3 | 8.0±0.3 | Slot plate |

| AT-YHG-C1019 | 150×150±1.0 | 5.5±0.3 | 13±0.3 | Slot plate |

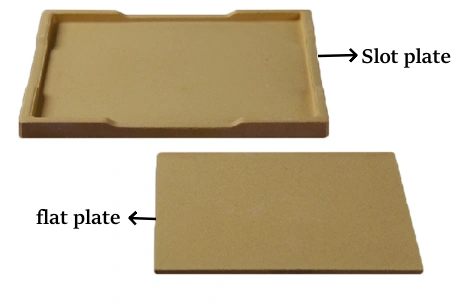

- Flat plate: for sintering of wafer ceramic capacitors and magnetic materials.

- Smoothly Slot plate: Smooth surface, tiny pores, high strength, and excellent thermal stability. Resists deformation at high temperatures. The groove design ensures smooth airflow. Ideal for high-temperature sintering of electronic components, such as ceramic capacitors and chip inductors.

- Rough Slot plate: Coarse-grain structure with high porosity, making it easy to absorb slurry. Ideal for coating and sintering low-frequency ceramic capacitors (MLCC), ensuring sufficient atmosphere during firing. Excellent thermal shock resistance and chemical stability provide an exceptionally long service life.

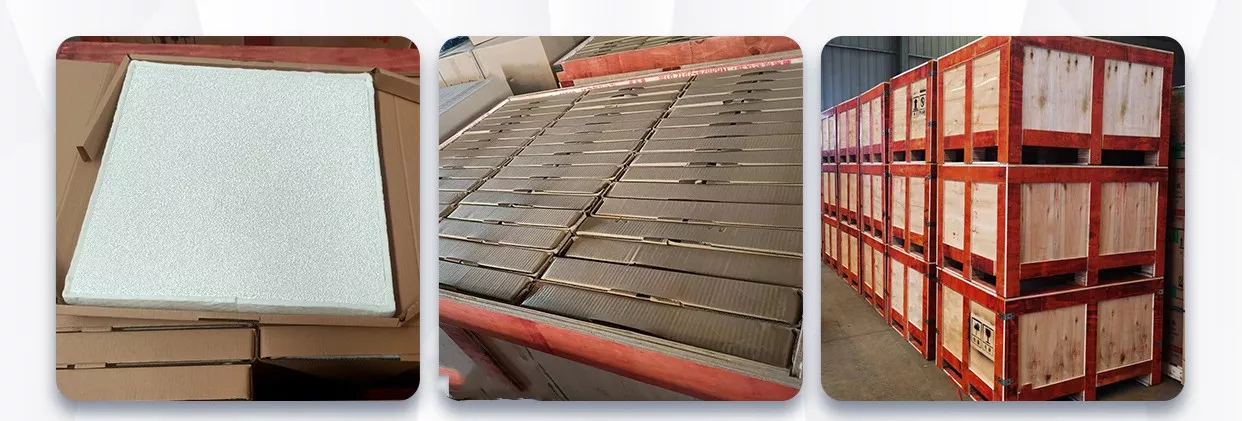

Packaging of Zirconia Ceramic Refractory Plate

Zirconia Ceramic Refractory Plate is individually cushioned with foam and packed in reinforced corrugated trays. Each batch is stacked in protective compartments to prevent edge damage during transit. Final packaging uses export-grade wooden crates for safe international shipment and forklift handling.