ADCERAX® Zirconia Ceramic Setting Ring Gauge is designed as a stable master reference for calibrating bore gages and inside micrometers across demanding industries. It combines high hardness, resistance to corrosion, and thermal stability to support long service life in production metrology. By maintaining consistent performance in automotive, aerospace, and precision manufacturing environments, it reduces downtime and ensures reliable measurement baselines. This makes it a preferred choice for engineers seeking durability and traceable calibration standards.

Features of Zirconia Ceramic Setting Ring Gauge

- With a thermal expansion coefficient of ~10.5 × 10⁻⁶/K, Zirconia Ceramic Setting Ring Gauge resists temperature-induced drift on shop floors. This keeps bore calibration precise during ±15 °C fluctuations.

- Roundness tolerance of ≤0.2 µm ensures consistent reference performance for advanced metrology setups, even after repeated use.

- Comparative testing indicates recalibration intervals improve by 30–50% versus hardened steel, reducing downtime across production lines.

- Zirconia achieves >1200 HV hardness, maintaining dimensional integrity where steel rings fail. Each ring can last over 10× longer than hardened steel alternatives, reducing replacement frequency.

- Zirconia resists weak acids, coolants, and cleaning solvents, eliminating rust and reducing handling care. In environments where steel corrodes within months, ceramic remains unaffected.

- Density values of 5.65–6.05 g/cm³ combined with non-magnetic behavior make gauges suitable for sensitive aerospace and electronics calibration labs.

- Industry case reports confirm failure rate reduction by 20–25% when switching from steel to zirconia, lowering operational risk and ensuring safer calibration routines.

- Testing data shows wear depth below 0.1 µm after 10,000 cycles, preserving measurement reliability in continuous production.

- Independent studies confirm service life extension of more than 5 years under normal calibration cycles, helping plants save thousands in maintenance cost.

Technical Properties for Zirconia Ceramic Setting Ring Gauge

Zirconia Ceramic Setting Ring Gauge is engineered for demanding calibration environments where laboratories and inspection agencies require stable performance benchmarks. Its material composition and mechanical behavior combine durability, resistance to harsh conditions, and consistency under thermal or chemical stress, making it suitable for advanced industrial metrology.

| Property |

Specification |

| Density |

5.65–6.05 g/cm³ |

| Hardness (Vickers HV1) |

1200–1450 HV |

| Fracture Toughness |

6–8 MPa·m½ |

| Bending Strength |

480–1000 MPa |

| Compressive Strength |

1600–2300 MPa |

| Thermal Conductivity |

~3 W/m·K |

| Thermal Expansion Coefficient |

~10.5 × 10⁻⁶/K |

| Maximum Service Temperature |

1000 °C |

| Temperature Resistance |

Up to 1000°C |

| Chemical Resistance |

Stable in coolants, weak acids, and alkalis |

| Dimensional Stability |

Maintains reference accuracy; calibration cycles extended by 30–50% |

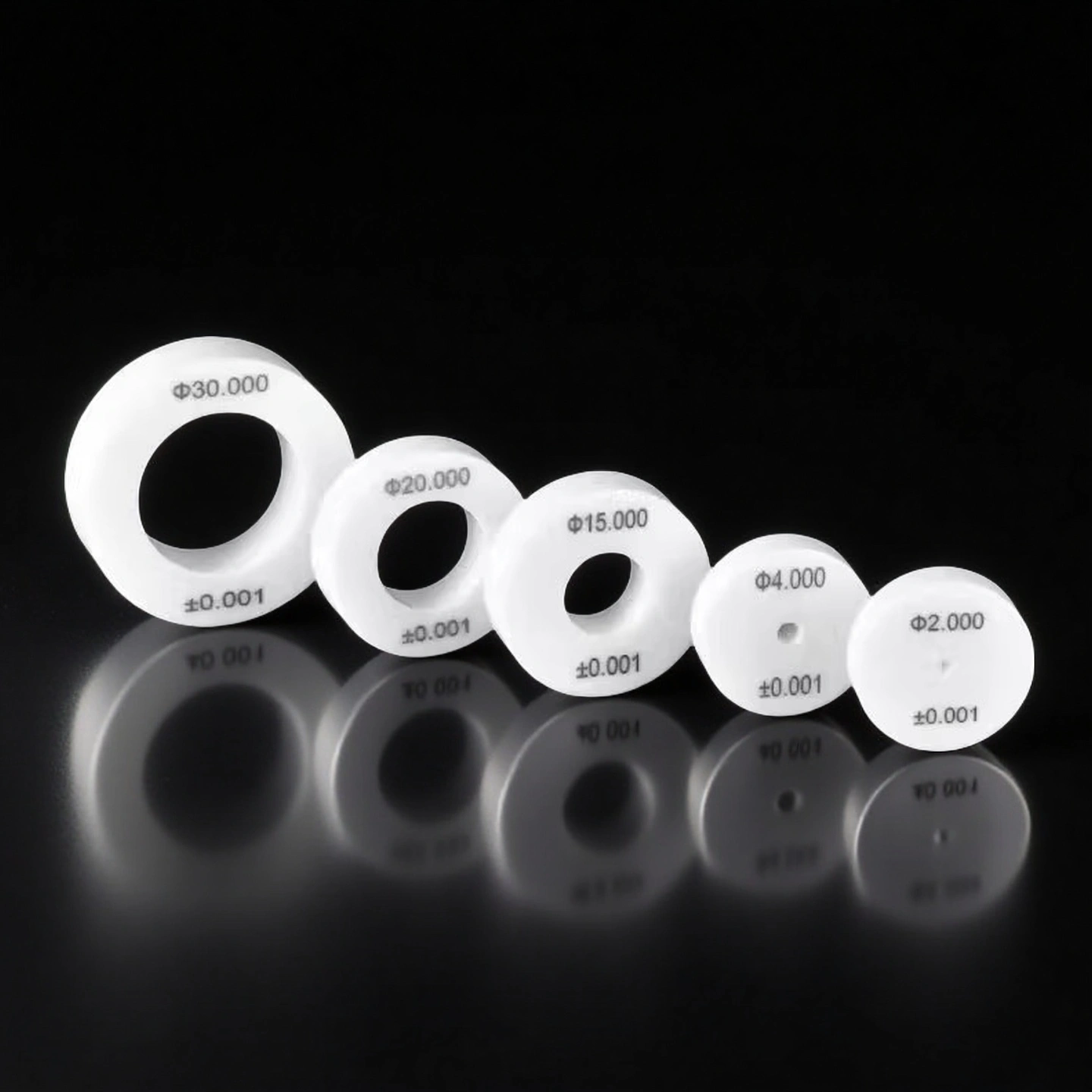

Specifications of Zirconia Ceramic Setting Ring Gauge

|

Zirconia Ceramic Gauge Ring |

|

Item NO. |

Outer Diameter (mm) |

Thickness (mm) |

Measurement Range |

|

AT-YHG-HG001 |

32 |

8 |

3-10mm |

|

AT-YHG-HG002 |

38 |

10 |

10-15mm |

|

AT-YHG-HG003 |

45 |

14 |

20-25mm |

|

AT-YHG-HG004 |

53 |

16 |

25-32mm |

|

AT-YHG-HG005 |

71 |

18 |

32-40mm |

Packaging of Zirconia Ceramic Setting Ring Gauge

Each Zirconia Ceramic Setting Ring Gauge is individually packed in a protective plastic case with foam to prevent surface damage during transport. For bulk orders, the units are organized in secure wooden boxes with numbered slots for easy identification. This packaging ensures that every one of them arrives in stable condition and ready for immediate calibration use.

Solving Application Challenges with ADCERAX® Zirconia Ceramic Setting Ring Gauge

ADCERAX® Zirconia Ceramic Setting Ring Gauge is widely adopted in sectors where repeatable calibration and long-term stability are critical. By combining high hardness, low thermal expansion, and chemical inertness, it directly addresses issues faced in high-precision inspection. The following examples highlight specific industries and the challenges solved by applying Zirconia Ceramic Setting Ring Gauge.

-

Fuel Injector Bore Calibration

✅Key Advantages

1. Coolant-safe reference — Zirconia Ceramic Setting Ring Gauge is inert to oils, coolants, and weak acids. Plants report calibration intervals extending 30–50% in wet lines.

2. High-cycle wear stability — Vickers hardness 1200–1450 HV resists micro-abrasion under continuous checks. Service life exceeds steel by >10×, cutting replacements.

3. Sub-micron repeatability — Roundness error control ≤0.2 µm maintains a stable zero. Thermal expansion ~10.5×10⁻⁶/K suppresses drift during ±15 °C shifts.

✅ ️Problem Solved

On a multi-station injector line running coolant flood, steel rings drove weekly re-zeros and unplanned checks. After adopting ADCERAX® Zirconia Ceramic Setting Ring Gauge, required recalibrations fell within the 30–50% reduction band. Reference stability held under oil and solvent exposure with roundness error ≤0.2 µm. Replacement frequency dropped thanks to >10× wear life, improving uptime and inspection throughput.

-

Aerospace Hydraulic Valve Inspection

✅Key Advantages

1. Low-CTE baseline — Coefficient ~10.5×10⁻⁶/K limits thermal drift across soak and ambient transitions. Bore verification remains stable through multi-temperature audits.

2. Traceable stability — Roundness control ≤0.2 µm supports consistent master values. ISO 17025 traceable certification aligns with aerospace QA gates.

3. Sensor-safe material — Non-magnetic, non-conductive zirconia avoids interference near transducers. Chemical inertness protects the reference in cleaning cycles.

✅ ️Problem Solved

A valve housing program saw false rejects during 20–60 °C inspections when using steel masters. Swapping to ADCERAX® Zirconia Ceramic Setting Ring Gauge stabilized readings, cutting recalibration load by 30–50% across shifts. Traceable certificates and ≤0.2 µm form control satisfied audit sampling without extra rework. Lines passed temperature-sweep checks without schedule slips.

-

Bearing Seat Metrology

✅Key Advantages

1. Abrasion-resistant master — Hardness 1200–1450 HV endures repetitive gauge contact. Service life >10× versus steel sustains stable references in high-volume cells.

2. Oil-line stability — Chemical inertness prevents corrosion in lubricant and solvent exposure. Roundness ≤0.2 µm preserves a consistent zero through daily cycles.

3. Fewer interruptions — Extended intervals by 30–50% reduce metrology stoppages. Non-magnetic behavior keeps readings consistent near rotating equipment.

✅ ️Problem Solved

A bearing seat line with hourly ID checks faced drift and frequent ring changes using steel tools. With ADCERAX® Zirconia Ceramic Setting Ring Gauge, metrology interruptions fell as recalibration frequency moved into the 30–50% reduction range. The master maintained sub-micron form (≤0.2 µm) despite oil carryover. Longer life (>10×) lowered changeouts and stabilized inspection cadence.

User Guide for Zirconia Ceramic Setting Ring Gauge

Zirconia Ceramic Setting Ring Gauge is a master reference tool that supports long service life when handled correctly. To help engineers, quality managers, and technicians achieve consistent results, the following guidance highlights practical steps in daily use, maintenance, and calibration. Clear instructions reduce the risk of premature wear and ensure reliable measurement performance across demanding industrial environments.

-

Handling and Preparation

1. Always inspect the gauge surface before use. Cleanliness is critical, and any dust, oil, or metal residue can affect reference accuracy. Wipe gently with lint-free cloths to keep the gauge ready for calibration.

2. Do not apply excessive mechanical force when placing instruments on the gauge. Avoid sudden impacts that could compromise roundness stability. Consistent handling helps maintain the form error within ≤0.2 µm.

3. Store each unit in its protective case when not in use. This prevents accidental scratches and shields the Zirconia Ceramic Setting Ring Gauge from environmental contaminants.

-

Usage During Calibration Tasks

1. Position the gauge in a stable temperature environment to reduce expansion drift. Fluctuations of ±15 °C can affect repeatability, so avoid calibration in unstable conditions.

2. When zeroing bore gages or micrometers, apply consistent seating pressure. Uneven loading introduces error, and calibration tools should be aligned carefully to the gauge surface.

3. Follow a standard calibration schedule to ensure traceability. Document each cycle with records of reference values and traceable certificates where applicable.

-

Maintenance and Cleaning

1. Use only approved solvents or alcohol-based cleaners. Harsh chemicals should be avoided, as they may leave residues that interfere with dimensional integrity.

2. After cleaning, dry the gauge completely before returning it to storage. Moisture can promote contamination of calibration setups even though the ceramic itself is corrosion-proof.

3. Schedule visual inspections for chipping or edge wear every 500–1000 uses. Preventive checks lower the risk of introducing inaccurate references into production.

-

Storage and Long-Term Care

1. Keep gauges in a controlled humidity environment, ideally below 60% RH, to avoid long-term exposure to condensation or aggressive shop-floor atmospheres.

2. Organize gauges in labeled protective boxes. This ensures easy identification and reduces handling errors during high-volume production.

3. Rotate gauges in use if multiple sets are available. Balanced utilization helps extend calibration intervals by up to 30–50% and distributes wear evenly across the fleet.