Bespoke Zirconia Plate Factory for Engineering Projects by ADCERAX®

ADCERAX® supplies custom Zirconia Plate solutions for industrial sectors requiring high dimensional consistency, chemical inertness, and thermal insulation. Each piece is engineered to adapt to dynamic technical specifications across complex operational environments.

From electronics to energy systems, ADCERAX® Zirconia Plates deliver essential support for high-precision assemblies. We combine drawing-based production, no MOQ policy, and 24h dispatch for standard stocked items to meet global sourcing demands.

Contact ADCERAX® now to discuss your Zirconia Plate specifications and receive tailored engineering support.

2200°C

Max Operating Temp

What is a Zirconia Plate?

A Zirconia Plate is a ceramic flat component made from stabilized zirconium dioxide (ZrO₂), known for its structural hardness and exceptional thermal behavior.

Zirconia Plates are typically used in high-stress environments where resistance to heat, corrosion, and mechanical impact is critical.

These plates maintain electrical insulation even in humid or high-temperature conditions.

Due to its machinability and chemical inertness, a Zirconia Plate is ideal for advanced engineering integration.

Technical Specification of ADCERAX® Zirconia Plate

ADCERAX® manufactures and supplies Zirconia Plates based on industrial-grade accuracy and materials compliance. Each plate undergoes dimensional and material inspection to ensure compatibility with global engineering systems.

| Technical Specification Table | ||

|---|---|---|

| Parameter | Specification | |

| Composition | ≥94.5% ZrO₂ + Y₂O₃ or MgO Stabilized | |

| Density | 5.95–6.05 g/cm³ | |

| Flexural Strength | ≥950 MPa | |

| Compressive Strength | ≥2000 MPa | |

| Hardness | 12–13 GPa (Vickers) | |

| Thermal Expansion Coefficient | 10.5×10⁻⁶ /K | |

| Max Operating Temperature | Up to 2200 °C | |

| Electrical Resistivity | ≥10⁸ Ω·cm | |

Key Properties of ADCERAX® Zirconia Plate

Zirconia Plates exhibit a combination of physical, chemical, and thermal traits that make them suitable across multiple industrial sectors. These properties support precision operations under extreme operating conditions.

Mechanical Strength and Toughness

Zirconia ceramic Plates offer high fracture toughness and flexural strength for structural integrity.

- Excellent resistance to crack propagation

- Maintains shape under mechanical stress

- High compressive strength up to 2000 MPa

Thermal Performance

These ZrO2 Plates perform reliably in high-temperature cycles and thermal shock conditions.

- Max. Working temperature 2200 °C

- Thermal expansion coefficient ~10.5×10⁻⁶/K

- Superior heat shock resistance

Electrical Insulation

Zirconia Plates provide strong insulation under both dry and humid conditions.

- Dielectric strength >10⁸ Ω·cm

- Suitable for high-voltage shielding

- Stable in high-temperature electronics

Corrosion and Chemical Resistance

Zirconia Plates resist degradation across acidic and basic media.

- Compatible with alkalis and strong acids

- Zero contamination to surrounding media

- Preferred in harsh chemical environments

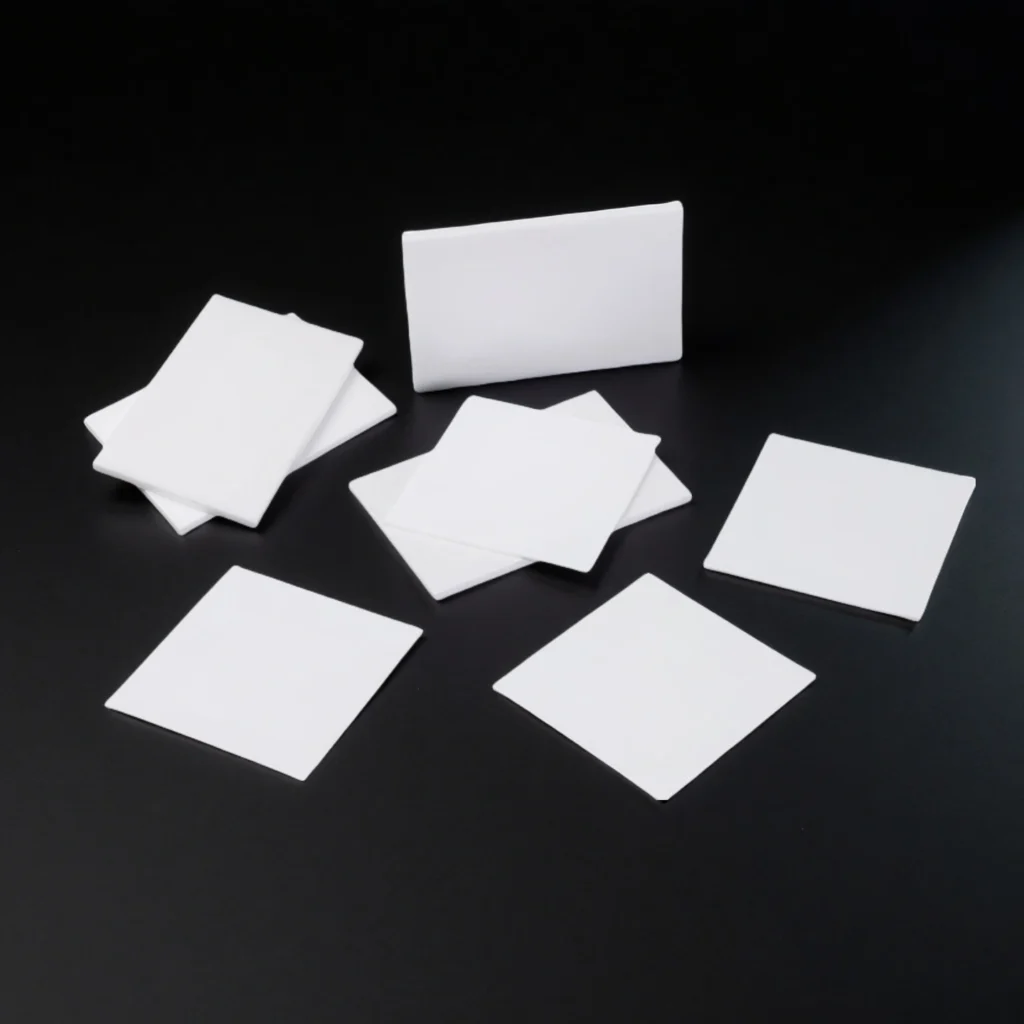

Zirconia Plate Product Range from ADCERAX®

Used in supporting, insulating, or wear-resistant systems.

- Electrical insulation under high temp

- Compatible with aggressive environments

- Available in YSZ and MSZ

Ideal for structural integration in high-wear and thermal applications.

- High flexural strength >950 MPa

- Excellent edge durability

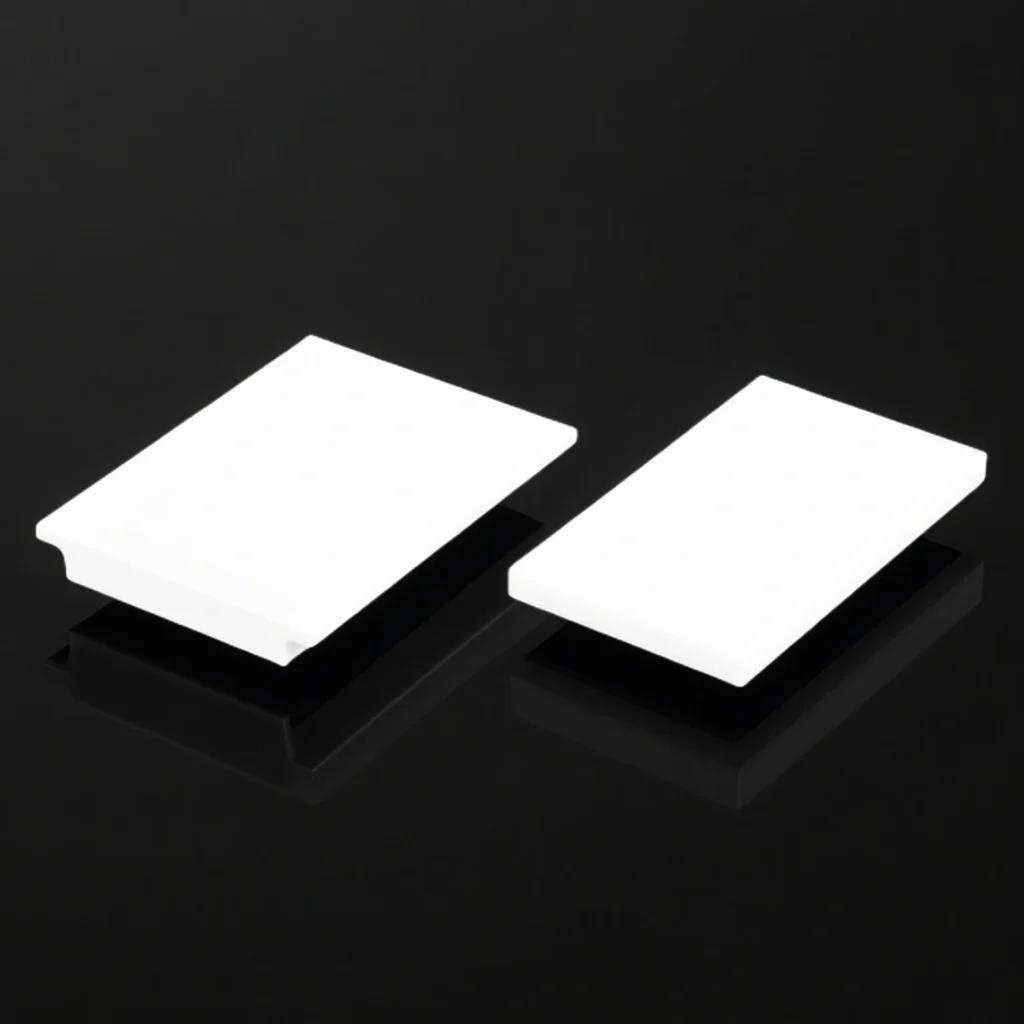

- Custom thickness and surface finish

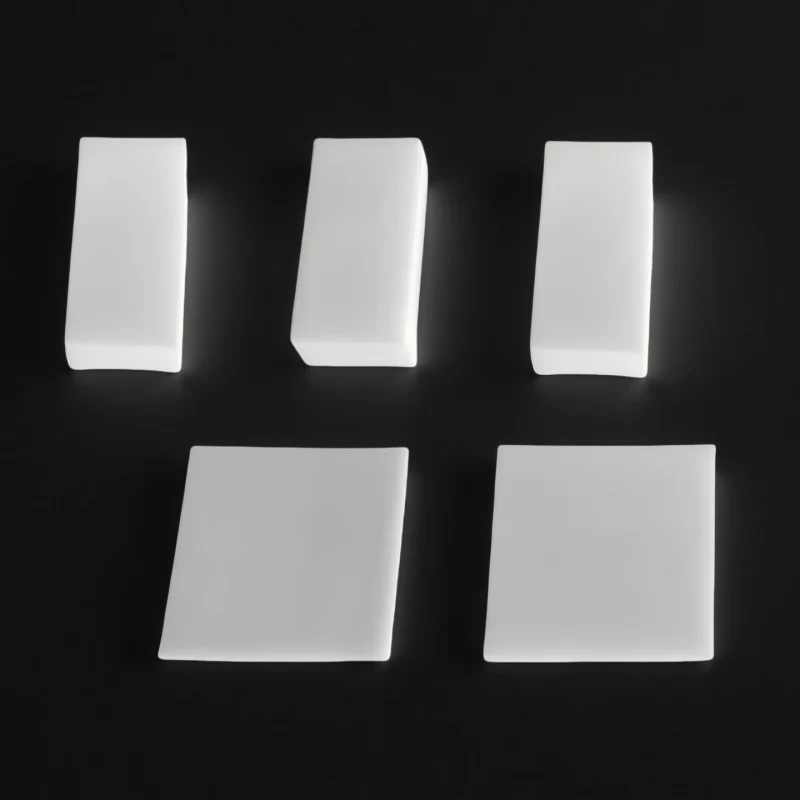

Engineered for fuel cell and sensor applications.

- Stable thermal conductivity

- Matched thermal expansion with steel

- High dielectric isolation

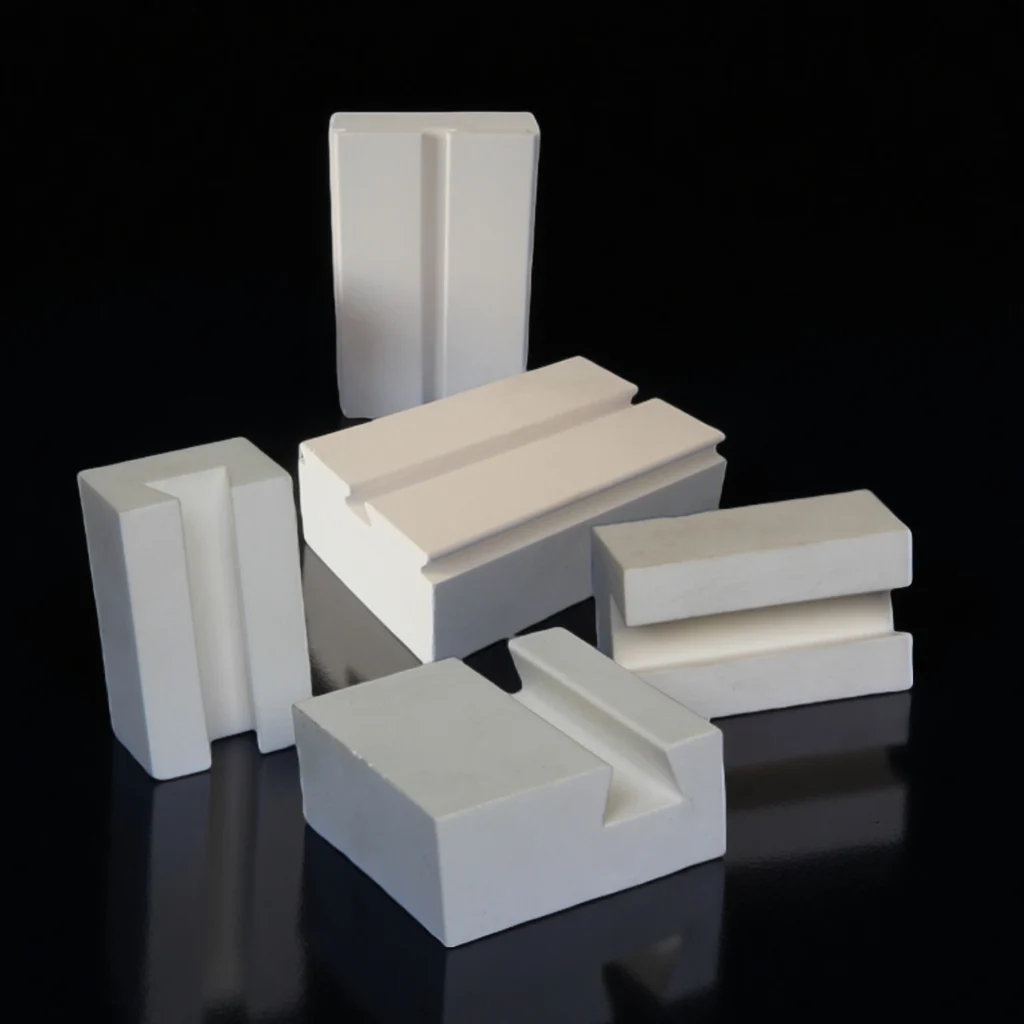

Built for abrasion zones in milling and mixing equipment.

- Impact-resistant under bulk loading

- Superior mechanical shock absorption

- Seamless interface with ceramic drums

Functions as heat barrier or structural support in kilns.

- Operates reliably above 1500 °C

- Resistant to molten oxides

- Enhanced dimensional rigidity

Designed for load-bearing insulation and thermal partitions.

- Superior thermal shock resistance

- Stable under >1000 °C thermal cycling

- Maintains insulation under pressure

Ready to Source Your Zirconia Plate Solution?

At ADCERAX®, we are committed to supporting your engineering project from drawing to delivery. Whether you require structural stability, precise insulation, or corrosion-resistant plate components, our team is ready to deliver tailored Zirconia Plate products that meet your exact specifications—without minimum order quantity.

Reach out now and receive expert support on material selection, tolerance control, and application matching.

Where Zirconia Plate Performs: Application Scenarios

ADCERAX® manufactures Zirconia Plates to serve complex and evolving demands in sectors such as high-temperature processing, electronic insulation, energy systems, and advanced material fabrication.

Zirconia Plate Applications in High-Temperature Processing Systems

Zirconia Plates are used in continuous thermal processes requiring minimal deformation. They maintain planar integrity under intense heating and repeated thermal cycling. These properties make them ideal for industrial sintering and refractory support.

- Withstands max. operating temperatures up to 2200 °C

- Thermal expansion rate ~10.5×10⁻⁶/K, minimizing shape distortion

- Retains >95% flexural strength after 10 thermal cycles at 1200 °C

ZrO2 Plate in Power Electronics and Insulation Assemblies

Zirconia Plates function as insulating platforms and spacer elements in power electronics. Their electrical resistivity remains stable across high humidity and temperature ranges. They are critical in SOFC stacks, dielectric assemblies, and voltage isolation.

- Electrical resistivity ≥ 10⁸ Ω·cm under 150 °C / 90% RH

- Dielectric strength supports devices >1000 V

- Compatible with YSZ ceramic used in high-temperature sensors and stacks

Zirconia Ceramic Plate for Corrosive Fluid Processing Environments

ZrO₂ Plates are deployed in fluid reactors, separators, and acid-base containment systems. Their inert surface resists chemical degradation across a wide pH spectrum. This ensures performance stability in extended chemical exposure.

- Corrosion rate < 0.002 mm/year in H₂SO₄, HCl, and NaOH solutions

- Effective in environments from pH 1 to pH 13

- Surface roughness ≤ Ra 0.8 µm, minimizing contaminant adhesion

Zirconia Plate for Precision Instrumentation and Non-Magnetic Tooling

Zirconia Plates are selected for structural and dimensional references in non-magnetic environments. Their thermal expansion is close to steel, allowing integration with metallic systems. Tolerances are maintained across machining and use.

- Thermal expansion coefficient ~10.3×10⁻⁶/K (close to SUS304)

- Dimensional flatness within ±0.05 mm over 100 mm length

- Non-magnetic and dielectric for EMI-sensitive equipment calibration

ZrO2 Plate for Energy Modules and YSZ Fuel Cell Applications

Yttria-stabilized zirconia substrates are central to ionic conduction and thermal isolation. These plates support temperature gradients while minimizing energy loss. Their compatibility with lithium systems and SOFC stacks enables scalable use.

- Ionic conductivity of YSZ > 0.1 S/cm at 1000 °C

- Thermal conductivity < 2.5 W/m·K at 800 °C

- Survives over 1000 charge–discharge cycles in ceramic fuel modules

ADCERAX® One‑Stop Supplier for Customized Zirconia Plate Solutions

ADCERAX® One-Stop Zirconia Plate Solutions That Eliminate Engineering Disruptions

ADCERAX®’s one-stop supply model is built to directly resolve the core pain points faced by technical buyers of zirconia ceramic Plate products. From unstable lead times to tolerance mismatch in local production, we provide full-cycle support—ensuring your sourcing plan stays on track.

- Missed lead time penalties: Standard plates ship within 24–72h; customs cleared DDP available

- Spec deviation in local supply: We meet ±0.1 mm or tighter tolerances for repeat dimensions

- Inefficient prototyping: 3D/CAD-based customization returned within 48h, even for low-volume samples

- Batch inconsistency: Our lot-controlled production ensures <2% variance in mass batches

- Certification gaps: All zirconia oxide Plate materials pass RoHS / REACH / ISO 9001 standards

ADCERAX® Factory-Level Precision That Powers Zirconia Plate Scalability

ADCERAX® operates a vertically integrated zirconia ceramic manufacturing facility designed to meet stringent global engineering demands. From ultra-flat polishing to complex non-standard shapes, every Zirconia Plate is machined with exacting repeatability, even at scale.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Manufacturing Asset | Capability & Performance Metrics | ||

| CNC Surface Grinders (12x) | Parallelism < ±0.02 mm over 200 mm; Ra ≤ 0.2 μm with mirror-polished finish | ||

| Precision Diamond Saws (6x) | Cutting accuracy within ±0.1 mm; supports complex geometries and edge tapering | ||

| Deep Hole Drilling (4x) | Ø0.5–12 mm holes on ZrO₂ plates up to 25 mm thick, position tolerance ±0.05 mm | ||

| Batch Tolerance Control | Full-run dimensional deviation < 2%; SPC report available per lot | ||

| In-House Tooling Shop | Custom jigs, fixtures, and forming dies designed and fabricated within 72 hours | ||

| Material Traceability System | QR-coded batch tracking; 100% raw material input traceable to ZrO₂ source vendor | ||

customized zirconia Plates supplier

We specialize in custom zirconia ceramic plates with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Frequently Asked Questions about Zirconia Plates

We maintain a batch deviation of less than ±0.02 mm across plates using precision grinding lines and real-time SPC monitoring. For plates over 100 mm in length, flatness control is maintained under 0.05 mm.

ADCERAX® Yttria-Stabilized Zirconia Plates can continuously operate up to 2200 °C, with MSZ variants supporting stable use beyond 1000 °C under thermal cycling. Structural integrity is retained after 10+ cycles at full load.

Yes. ADCERAX® ZrO₂ Plates show surface degradation of less than 0.002 mm/year when tested in HCl, H₂SO₄, and NaOH solutions, making them suitable for pH 1 to 13 environments in continuous contact conditions.

Yes. ZrO₂ is non-conductive and completely non-magnetic. This makes our zirconia ceramic Plate products ideal for medical devices, aerospace electronics, and calibration tools requiring zero signal interference.

We offer ground, polished, and mirror finishes with roughness as low as Ra ≤ 0.2 μm. Surface condition is selected based on friction behavior, sealing needs, or mounting requirements.

We use Y₂O₃ (yttria) and MgO (magnesia) stabilized zirconia ceramics depending on thermal and mechanical application. Material composition is ≥94.5% ZrO₂ with full RoHS & REACH compliance.

We machine Ø0.5 mm to Ø12 mm holes with positional tolerance of ±0.05 mm. Complex slots and multiple-surface machining are supported through custom jigs and multi-axis setups.

Zirconia offers up to 15x the wear resistance of alumina and far exceeds stainless steel. Vickers hardness exceeds 1200 HV, with minimal wear rates even under repeated mechanical contact.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Zirconia Plates

Looking for a reliable zirconia plates supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours