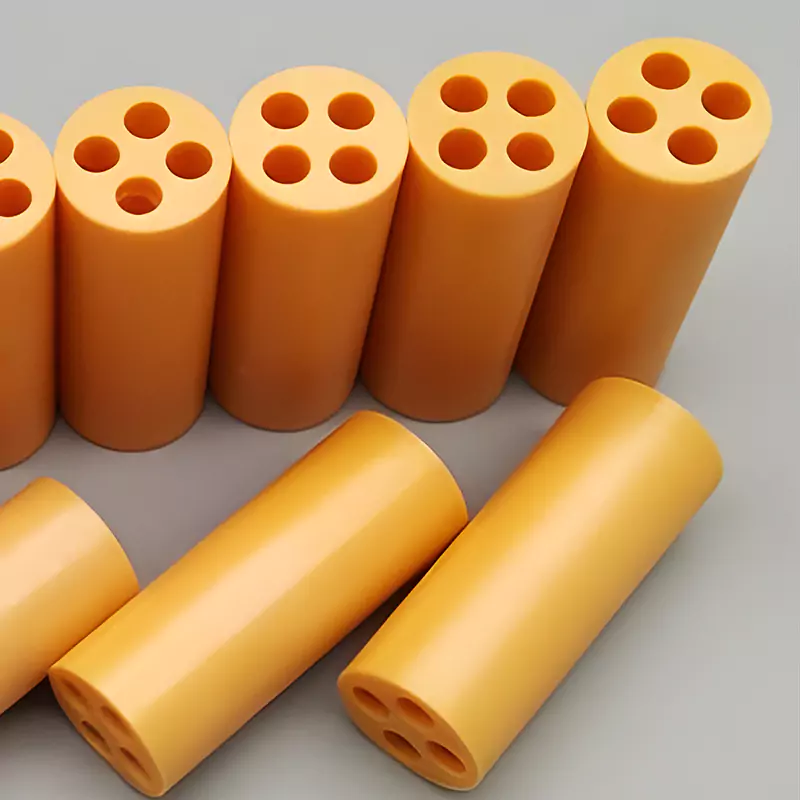

ADCERAX® Magnesia Stabilized Zirconia MSZ Tube Multi Bore is engineered for demanding industrial environments where high strength, thermal stability, and corrosion resistance are critical. The multi-bore design enables efficient gas or fluid distribution in metallurgy, chemical processing, and advanced energy systems. Its smooth surface and inherent toughness extend service life while reducing maintenance downtime. This combination of performance and durability makes it a reliable choice for customers seeking consistent operation under extreme conditions.

Features of Magnesia Stabilized Zirconia MSZ Tube Multi Bore

The Magnesia Stabilized Zirconia MSZ Tube Multi Bore provides a balance of mechanical strength, thermal shock resistance, and chemical stability required in heavy industry. Its multi-channel configuration is optimized for fluid distribution, while proven test data supports its durability and consistent performance in metallurgy, chemical plants, and energy systems.

- Resistant to acids and alkalis, excluding hydrofluoric acid, ensuring broad process use.

- Shows <2% weight loss in 48-hour sulfuric acid exposure tests.

- Retains mechanical integrity in saline or alkaline conditions for >500 cycles.

- Flexural strength exceeds 800 MPa, supporting heavy load environments.

- Fracture toughness measured around 8–10 MPa·m½, minimizing crack propagation.

- Wear resistance extends component life to 3× longer than alumina under abrasion.

Technical Properties for Magnesia Stabilized Zirconia MSZ Tube Multi Bore

ADCERAX® Magnesia Stabilized Zirconia MSZ Tube Multi Bore is defined by precise physical, chemical, optical, and mechanical properties that determine its durability and performance. This section provides an overview of the material’s key technical parameters and includes reference data relevant to the specification table and dimensional catalog.

| Property |

Specification |

| Density |

~5.7 g/cm³ |

| Flexural Strength |

>800 MPa |

| Fracture Toughness |

8–10 MPa·m½ |

| Thermal Expansion Coefficient |

~10 ×10⁻⁶ /K (room temp–1000 °C) |

| Maximum Operating Temperature |

>1000 °C continuous |

| Hardness (Vickers HV1) |

~12 GPa |

| Corrosion Resistance |

<2% weight loss, 48h H₂SO₄ exposure |

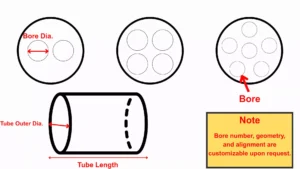

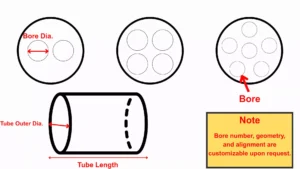

Dimensions of Magnesia Stabilized Zirconia MSZ Tube Multi Bore

Magnesia Stabilized Zirconia MSZ Tube Multi Bore

|

Model |

Tube Outer Dia.(mm) |

Bore Dia.(mm) |

Length(mm) |

Bores |

|

AT-MGO-G2001 |

5 |

1.2 |

4 |

2 |

|

AT-MGO-G2002 |

5 |

1.2 |

10 |

2 |

|

AT-MGO-G2003 |

5.3 |

1.2 |

8 |

4 |

|

AT-MGO-G2004 |

5.3 |

1.2 |

15 |

4 |

|

AT-MGO-G2005 |

6.5 |

1.2 |

15 |

6 |

|

AT-MGO-G2006 |

6.5 |

1.2 |

20 |

6 |

Packaging of Magnesia Stabilized Zirconia MSZ Tube Multi Bore

ADCERAX® Magnesia Stabilized Zirconia MSZ Tube Multi Bore is defined by precise physical, chemical, optical, and mechanical properties that determine its durability and performance. This section provides an overview of the material’s key technical parameters and includes reference data relevant to the specification table and dimensional catalog.

Solving Application Challenges with ADCERAX® Magnesia Stabilized Zirconia MSZ Tube Multi Bore

The Magnesia Stabilized Zirconia Ceramic Tube Single Bore addresses real engineering problems where conventional ceramics such as alumina fail to deliver reliable performance. By combining high fracture toughness, excellent corrosion resistance, and stability under thermal cycling, it provides practical solutions in advanced industrial sectors.

-

Metallurgical Gas Distribution Systems

✅Key Advantages

1. Uniform multi-jet diffusion (<10% flow variance) — Multi-bore geometry delivers near-even O₂/Ar injection at constant header pressure.

2. Thermal-shock endurance >1000 °C — Survives repeated heat-quench cycles near molten baths without microcracking or spall.

3. High toughness and strength — 8–10 MPa·m½ toughness and >800 MPa flexural strength resist chipping during ladle changes.

✅ ️Problem Solved

A steel plant experienced six tube-related stoppages per month from fractured injectors during tap-to-tap cycles. After switching to ADCERAX® Magnesia Stabilized Zirconia MSZ Tube Multi Bore, stoppages fell by ≈70%, and gas distribution uniformity improved (flow variance cut to <10% at the tuyere). Oxygen utilization rose by ~8–12%, stabilizing bath chemistry and heat times. The mill reported lower energy per ton and fewer corrective blows over the following quarter.

-

High-Temperature Sensor Protection

✅Key Advantages

1. Accurate sensing at heat (>1000 °C) — Maintains geometry to keep probe alignment and signal fidelity in furnace zones.

2. Mixed-gas erosion resistance — Zirconia matrix shows <2% mass change in 48 h H₂SO₄ exposure and resists alkali/sulfidation attack.

3. Crack-arrest behavior — 8–10 MPa·m½ toughness reduces failure from vibration and steep thermal gradients.

✅ ️Problem Solved

A power plant’s thermocouple shields cracked or eroded after 3–4 weeks at peak load, causing drift and unscheduled outages. With ADCERAX® Magnesia Stabilized Zirconia MSZ Tube Multi Bore shields, service intervals extended to ≈12 weeks, and unplanned downtime dropped by ~40 h/quarter. Post-run checks showed temperature drift <±3 °C after 1,000 h at high fire. Maintenance teams reduced hot-work entries and spare consumption in the same period.

-

Hydraulic Cylinder Insulation

✅Key Advantages

1. Low-friction bore finish (Ra ≤0.2 μm) — Polished MSZ bore lowers seal wear and start-up torque in hot-oil service.

2. Wear life extension (≥3× vs alumina) — PSZ microstructure resists abrasion under pressure and particulate load.

3. Chemical stability in fluids (>500 cycles) — Properties retained after repeated thermal cycling in common hydraulic oils and additives.

✅ ️Problem Solved

A forge press running ≈180 °C hydraulic circuits saw liner wear-through and leakage every 3 months, forcing pressure derates. After adopting ADCERAX® Magnesia Stabilized Zirconia MSZ Tube Multi Bore liners, changeout intervals extended to ~9 months, and leak incidents dropped by ≈80%. System pressure stability improved, cutting make-up oil and cleanup. The operator logged a ~35% reduction in maintenance spend across two consecutive quarters.

User Guide for Magnesia Stabilized Zirconia MSZ Tube Multi Bore

The Magnesia Stabilized Zirconia MSZ Tube Multi Bore requires correct handling, installation, and maintenance to ensure its full service life and stable performance. This guide provides practical recommendations for engineers and buyers to manage the product effectively in demanding industrial systems.

-

Handling and Preparation

1. Always handle tubes with clean gloves to avoid surface contamination.

2. Inspect each tube for visible cracks or chips before installation.

3. Store tubes in cushioned trays to minimize accidental impact damage.

-

Installation Practices

1. Position tubes carefully to maintain bore alignment during system setup.

2. Use compatible fittings and supports to reduce mechanical stress.

3. Avoid excessive tightening that could generate localized fractures.

-

Operating Conditions

1. Keep operating temperatures within rated service above 1000 °C.

2. Monitor chemical exposure to prevent contact with hydrofluoric acid.

3. Reduce rapid heating and cooling cycles to limit thermal stress.

-

Maintenance and Service Life

1. Conduct periodic cleaning with neutral solutions to remove buildup.

2. Replace tubes showing erosion or wear to prevent system inefficiency.

3. Keep service logs to track operational cycles and schedule replacements.