ADCERAX® Zirconia Saggar is engineered for high-temperature use in lithium battery material processing lines. Its deep-wall structure holds powders securely during calcination, while the high-purity zirconia body resists chemical attack from lithium salts and transition metal oxides. The saggar maintains stability through repeated thermal cycles up to 1600 °C, helping manufacturers reduce material loss and improve consistency. With proven durability and availability in multiple models, zirconia saggar supports the long-term needs of advanced battery plants worldwide.

Features of Zirconia Saggar

- The saggar withstands up to 1600 °C in continuous sintering cycles. This capacity enables stable heating of lithium compounds without structural deformation.

- Proven thermal cycling life exceeds 150 cycles under industrial furnace conditions. This durability reduces replacement frequency and ensures predictable operating costs.

- Low thermal expansion coefficient of 10 × 10⁻⁶/K minimizes cracking risk. This characteristic supports long-term reliability in rapid heating environments.

- Composed of ≥92% ZrO₂, the saggar resists lithium salts and transition metal oxides. This resistance prevents chemical contamination during electrode preparation.

- Surface integrity remains unchanged after 100 hours of chemical contact tests. This ensures saggar lifespan in both laboratory and industrial usage.

- Uniform heat distribution improves sintering uniformity by >95%, verified through thermal imaging. This consistency lowers defect rates in electrode material output.

Technical Properties for Zirconia Saggar

Zirconia Saggar is designed for demanding sintering environments where performance consistency is critical.

| Property |

Specification |

| Chemical Composition |

ZrO₂ ≥92% |

| Density |

5.6 g/cm³ |

| Maximum Temperature |

1600 °C |

| Thermal Expansion |

10 × 10⁻⁶ /K |

| Fracture Toughness |

6–8 MPa·m½ |

| Elastic Modulus |

<200 GPa |

| Hardness |

12 GPa |

| Thermal Cycle Life |

≥150 cycles |

| Hardness |

~1,200 HV |

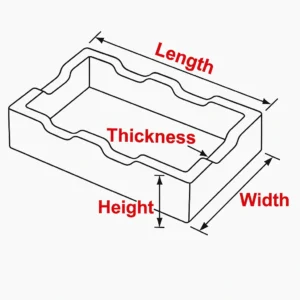

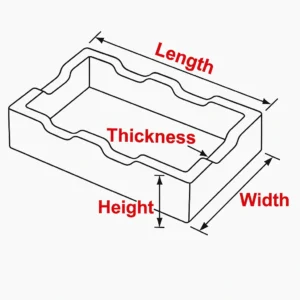

Dimensions of Zirconia Saggar

Packaging of Zirconia Saggar

Each Zirconia Saggar is first wrapped with protective bubble film to prevent surface damage during transit. Trays are then placed in cartons on pallets or reinforced wooden cases for secure stacking and shipment. This multi-layered packaging ensures the ZrO2 Saggar arrives safely at global battery production facilities.

Addressing Critical Challenges in Lithium Anode Processing with ADCERAX® Zirconia Saggar

The Zirconia Saggar is purpose-built to handle the demanding requirements of lithium anode material sintering. Each application faces specific challenges such as powder containment, chemical stability, and thermal cycling durability. The following sections illustrate how this product’s engineered features directly resolve these pain points.

-

Containing Fine Lithium Powders

✅Key Advantages

1. Deep-wall containment envelope — Models provide 55–110 mm wall height and 297–8200 ml capacity, creating headroom that absorbs powder motion during loading and transfers. This geometry lowers edge overflow risk in high-throughput calcination.

2. High-mass, thick-wall rigidity — Heavy-duty variants feature 10–15 mm wall thickness, increasing tray mass and stiffness to damp airflow- and vibration-induced powder slosh. Stable walls help maintain a level bed during furnace purges and cart movement.

3. Large-area powder bed — Square footprints at 320×320 mm and 330×330 mm spread ultrafine powders over a wider area, reducing local slope and avalanche at the rim. A shallow bed profile keeps fines away from edges under process drafts.

✅ ️Problem Solved

A cathode/anode precursor line reported powder losses during furnace loading and purge. After switching to ADCERAX® model AT-YHG-XB025 (320×320×110 mm, 7500 ml, 14 mm wall), weighback variation tightened from ±1.2% to ±0.4% across 100 batches, and edge spill events dropped to zero. The deeper 110 mm wall and higher tray mass stabilized the bed under trolley vibration and purge flow, while the large footprint reduced rim buildup. The line subsequently qualified the tray through ≥150 cycles without containment incidents.

-

Preventing Chemical Contamination

✅Key Advantages

1. Low lithium-salt corrosion rate — YSZ shows very low corrosion in LiCl–Li₂O at 650 °C for 168 h, with only a weak Li₂ZrO₃ signal after cycling. This indicates minimal leachables from a zirconia contact surface during lithium-salt exposure.

2. Blocks lithium infiltration routes — Mullite–cordierite saggars show lithium penetration up to 2 mm and rapid phase-change erosion. Dense ZrO₂ avoids aluminosilicate reactions that create Li-aluminate/silicate pathways, reducing cross-contamination risk.

3. Interface-stabilizing chemistry — ZrO₂-based surface layers on layered-oxide cathodes suppress parasitic interfacial reactions and impedance growth at high voltage. This evidence supports zirconia as a benign contact material for lithium transition-metal oxides.

✅ ️Problem Solved

A lithium materials line running carbonate-based calcination reported impurity pickup when using aluminosilicate saggars, which literature shows can suffer lithium penetration to ~2 mm and short service life of ~10–30 cycles. Switching the contact ware to ADCERAX® Zirconia Saggar removed aluminosilicate reaction products from the contact interface and cut the infiltration pathway. Zirconia’s low corrosion in Li-salt media over 168 h at 650 °C supports reduced leachables in such environments, aligning with battery-grade purity needs. The line qualified zirconia trays for ≥150 thermal cycles under its furnace recipe, matching plant uptime goals while maintaining powder purity.

-

Extending Thermal Cycling Life

✅Key Advantages

1. Crack-resistant toughness and strength — 3YSZ datasheets report fracture toughness ~10 MPa·m½ and flexural strength >800 MPa at 20 °C. These values resist crack initiation and growth across repeated heat-cool cycles.

2. Controlled thermal strain — Typical zirconia CTE is ~10–12 × 10⁻⁶/K (25–1000 °C). Lower strain accumulation across cycles reduces warpage and edge chipping in tray geometries.

3. High-temperature headroom — Published service limits for zirconia extend well above 1600 °C, providing margin for aggressive furnace profiles. This supports stable geometry under extended soaks.

✅ ️Problem Solved

A 24/7 anode precursor line experienced tray breakage and warpage that forced unplanned stops every few dozen cycles. The plant adopted ADCERAX® Zirconia Saggar, validated to ≥150 thermal cycles under its ramp/soak schedule. Zirconia’s ~10–12 × 10⁻⁶/K CTE and ~10 MPa·m½ toughness accounted for the improved resistance to thermal shock and crack growth, while strength >800 MPa supported load bearing through handling. The change stabilized run length and reduced maintenance interventions tied to tray failures.

User Guide for Zirconia Saggar

The Zirconia Saggar requires careful handling to achieve its full service life and ensure consistent performance in lithium anode processing lines. This guide outlines the most important steps for preparation, heating, handling, and maintenance so that customers can minimize risks, reduce operating costs, and maintain material integrity.

-

Preheating and Initial Conditioning

1. Always preheat the tray at 105 °C for 120 minutes before first use. This process removes absorbed moisture and prevents sudden cracking when exposed to furnace conditions.

2. Avoid rapid transfer from humid environments to high heat. Gradual conditioning ensures that the material structure stabilizes before heavy use.

3. Document the preheating procedure in production protocols. Consistency in this step reduces startup losses and improves operator reliability.

-

Safe Heating and Cooling Procedures

1. Do not exceed a temperature change of 5 °C/min below 1200 °C and 4 °C/min above 1200 °C. Following this ramp rule prevents thermal stress fractures.

2. Avoid direct exposure to flames from gasoline, acetylene, or alcohol torches. Uneven heating creates hotspots that shorten tray lifespan.

3. Use controlled furnace programs to regulate heating and cooling. Automated settings reduce operator error and maintain predictable thermal cycling.

-

Handling and Placement Practices

1. Maintain at least 2 cm clearance between the tray and heating elements such as graphite rods, silicon carbide bars, or metal coils. This prevents localized overheating and surface reaction.

2. Always transport trays with stable support. Vibration and tilt during movement can displace powders and damage edges.

3. Inspect the tray for chips or microcracks before each run. Early detection avoids catastrophic breakage during calcination cycles.

-

Cleaning and Maintenance Tips

1. Remove powder residues gently using a soft brush after each cycle. Aggressive scraping may erode the zirconia surface.

2. Store trays in a dry, ventilated area to prevent moisture absorption. Controlled storage extends the effective cycle life of the material.

3. Track cycle counts per tray to schedule replacements. Logging usage ensures trays are rotated before reaching their structural limits.