Zirconia Ceramic Crucible Solutions for Demanding Industries by ADCERAX®

ADCERAX® specializes in providing zirconia ceramic crucible solutions engineered for extreme industrial conditions. With stable structure and high thermal resistance, our crucibles deliver consistent performance in metallurgy, chemical processing, and laboratory research. Clients rely on us for technical drawings support and quick turnaround on both standard and custom sizes.

As a trusted zirconia crucibles manufacturer, ADCERAX® ensures material purity, chemical stability, and long service life under repeated cycles. From yttria stabilized zirconia crucibles (YSZ) to magnesia stabilized zirconia crucibles (MSZ), we offer tailored options for research, metallurgy, and advanced ceramic applications. Every product is backed by reliable quality control and international logistics support.

Contact ADCERAX® today to discuss your zirconia crucible requirements.

5.5 g/cm³

Density uniformity

What is a Zirconia Crucible?

A zirconia crucible is a ceramic container made from stabilized zirconium oxide designed for high-temperature and corrosive environments. These zirconia ceramic crucibles withstand continuous use up to 2200°C while resisting chemical attack and thermal shock. They are widely applied in melting precious metals, sintering powders, and conducting thermal analysis.

Thanks to durability and chemical purity, Zirconia crucible tray and related forms are trusted in laboratories and industrial processes.

Technical Specifications of Zirconia Ceramic Crucibles

To guarantee consistent performance in demanding industrial and laboratory conditions, each industrial zirconia ceramic crucible from ADCERAX® is produced under strict quality control. The specifications reflect critical thermal, mechanical, and chemical properties required by global buyers.

| Technical Specification Table | ||

|---|---|---|

| Specification Item | Typical Value / Capability | |

| Maximum Working Temperature | ≈ 2200°C (continuous operation) | |

| Thermal Expansion Coefficient | 10 ×10⁻⁶/K | |

| Density | ≥ 5.5 g/cm³ | |

| Flexural Strength | > 350 MPa | |

| Compressive Strength | > 2000 MPa | |

| Vickers Hardness | ≥ 1200 HV | |

| Thermal Conductivity | 2–3 W/m·K at 1000°C | |

| Porosity | ≤ 0.1% (minimized contamination risk) | |

| Stabilizer Options | Y₂O₃ (yttria stabilized zirconia crucible, YSZ) or MgO (magnesia stabilized zirconia crucible, MSZ) | |

Core Characteristics of ADCERAX® Zirconia Ceramic Crucibles

ADCERAX® as a zirconia crucibles manufacturer delivers stable performance backed by measurable properties. These values demonstrate why we are a reliable zirconia crucibles supplier for industrial and laboratory buyers.

Mechanical Properties

ADCERAX® anti abrasion zirconia ceramic crucible variants provide long service life and strong resistance to stress.

- Flexural strength exceeds 350 MPa

- Compressive strength higher than 2000 MPa

- Vickers hardness reaches 1200 HV

Chemical Properties

ZrO2 crucibles are engineered to remain stable even in aggressive chemical environments.

- Resistant to acids and alkalis up to pH14

- Non-wetting to most molten metals

- Corrosion protection efficiency above 95%

Physical Properties

The structure of yttria stabilized zirconia crucible (YSZ) and msz crucible supports durability under repeated heating cycles.

- Continuous temperature resistance up to 2200°C

- Withstood 30 rapid cycles at 1000°C

- Thermal conductivity 2–3 W/m·K

Electrical Properties

Zirconia ceramic crucibles maintain strong insulation under extreme heat.

- Dielectric strength greater than 12 kV/mm

- Stable insulation under elevated temperature operation

- Low electrical loss in laboratory applications

ADCERAX® Industrial Zirconia Crucible Collection

ADCERAX® provides a broad range of zirconia ceramic crucibles designed for industrial and laboratory needs. Both zirconia ceramic crucibles and specialized options such as yttria stabilized zirconia crucible (YSZ) or magnesia stabilized zirconia crucible (MSZ crucible) are available with factory-direct support.

ZrO2 cylindrical crucible ensures stable containment of molten platinum and palladium.

- Tall walls support high-volume melting batches

- Resists temperatures of 2200°C continuously

- Non-wetting to noble metals, reducing losses

The arc geometry promotes uniform heating across reactor systems.

- Curved form distributes thermal stress evenly

- Proven stable in 30+ rapid heat cycles

- Reliable for continuous furnace integration use

Rectangular zirconia crucibles provide even heating surfaces for analytical labs.

- Flat geometry ensures consistent powder sintering

- Supports sample preparation under 2000°C load

- Ideal for ceramic and material science studies

Specialized tray designed for demanding lithium battery material processing.

- Resistant to corrosive lithium-containing compounds

- Maintains strength at 2000°C in furnaces

- Proven stable in anode sintering pilot lines

Round trays are widely used in dental zirconia sintering units.

- Smooth surface prevents contamination of dental blocks

- Thermal expansion matched to furnace cycles

- Extended service life with repeated dental use

Magnesia stabilized zirconia crucible is designed for extreme melting processes.

- Withstands temperatures up to 2000°C+

- Non-wetting to most molten metals

- Suitable for titanium, zirconium, and tungsten

Let’s Build Your Zirconia Crucible Solution Together!

ADCERAX® is committed to supporting your projects with reliable zirconia crucibles and engineering-backed solutions.

Whether you need cylindrical crucibles for precious metal melting, trays for laboratory sintering, or custom YSZ and MSZ crucibles for extreme processes, our team is ready to assist.

We combine factory-direct supply, technical drawing support, and no MOQ limits to ensure your requirements are fully met.

Application Scenarios of ADCERAX® Zirconia Crucibles

ADCERAX® Zirconia crucibles are adopted across industries where extreme temperatures, chemical stability, and material purity are essential. Their versatility makes them suitable for metallurgy, ceramics, glass production, and advanced research environments.

Precious Metal Refining and High-Value Alloy Processing

Refineries and foundries rely on zirconia crucibles for processing platinum, palladium, and advanced alloys. These operations demand containers that maintain stability at extreme temperatures and ensure purity of high-value materials.

- Melting platinum and palladium for jewelry and catalysts

- Alloying titanium, zirconium, and tungsten for aerospace

- Conducting refining operations in specialty metallurgy plants

Advanced Ceramics and Material Science Research

Research institutes and laboratories integrate zirconia ceramic crucibles into experiments that require high thermal stability and chemical resistance. They support both small-scale testing and pilot-scale material development.

- Sintering experimental powders for electronic substrates

- Preparing samples for DSC and TGA analysis

- Conducting structural ceramic studies in universities

Glass, Enamel, and Optical Material Production

Manufacturers of glass and optical materials use zirconia crucibles to ensure purity during melting and calcination processes. Their stability prevents contamination and guarantees consistent optical quality.

- Melting specialty glasses for optical lenses and fibers

- Calcining enamels used in electronic components

- Processing raw glass batches in research and industry

Metallurgical Furnaces and Industrial Thermal Processing

Industrial furnaces employ zirconia crucible trays and shaped designs for continuous sintering and calcination. These applications demand containers that withstand repeated cycles and varying atmospheres.

- Calcining ceramic powders for structural applications

- Thermal treatment of catalyst carriers in chemical plants

- Supporting high-temperature pilot furnaces in metallurgy

ADCERAX® as Your One-Stop Zirconia Crucible Supplier

One-Stop Services Addressing Customer Pain Points

ADCERAX® one-stop approach integrates engineering, production, quality control, and logistics into a single system. This eliminates fragmented coordination and helps customers reduce downtime, risk, and cost.

-

Tolerance Accuracy Guaranteed:

Customers report up to 15% rejection due to ±0.5 mm deviations. We provide drawing validation and precision machining to eliminate this risk. -

Batch Consistency Control:

In metallurgy, inconsistent crucibles cause process interruptions. Our one-stop QC system ensures every batch meets the same density, strength, and dimension. -

Technical After-Support:

Research labs struggle with crucible lifespan prediction. Our engineers provide usage guidance and material matching to extend cycles and lower costs.

ADCERAX® Zirconia Crucible Manufacturing Strengths

ADCERAX® integrates advanced production equipment and strict process control to guarantee consistent zirconia crucible quality. Our factory delivers precision, stability, and efficiency demanded by global industrial buyers.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | Relevance to Buyers | |

| Sintering Furnaces | Operating up to 2250°C with controlled atmosphere | Ensures crucible density and phase stability | |

| CNC Machining Precision | Dimensional tolerance within ±0.2 mm | Meets tight laboratory and metallurgy specifications | |

| Batch Consistency Testing | 100% QC on density and dimensions | Reduces rejection rates and downtime risk | |

| Polishing & Grinding Lines | Surface roughness down to Ra 0.4 μm | Prevents contamination in research and medical use | |

| Engineer Support Team | Minimum 10+ years ceramic experience | Provides drawing validation and technical consultation | |

customized zirconia crucible supplier

We specialize in custom zirconia ceramic crucibles with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

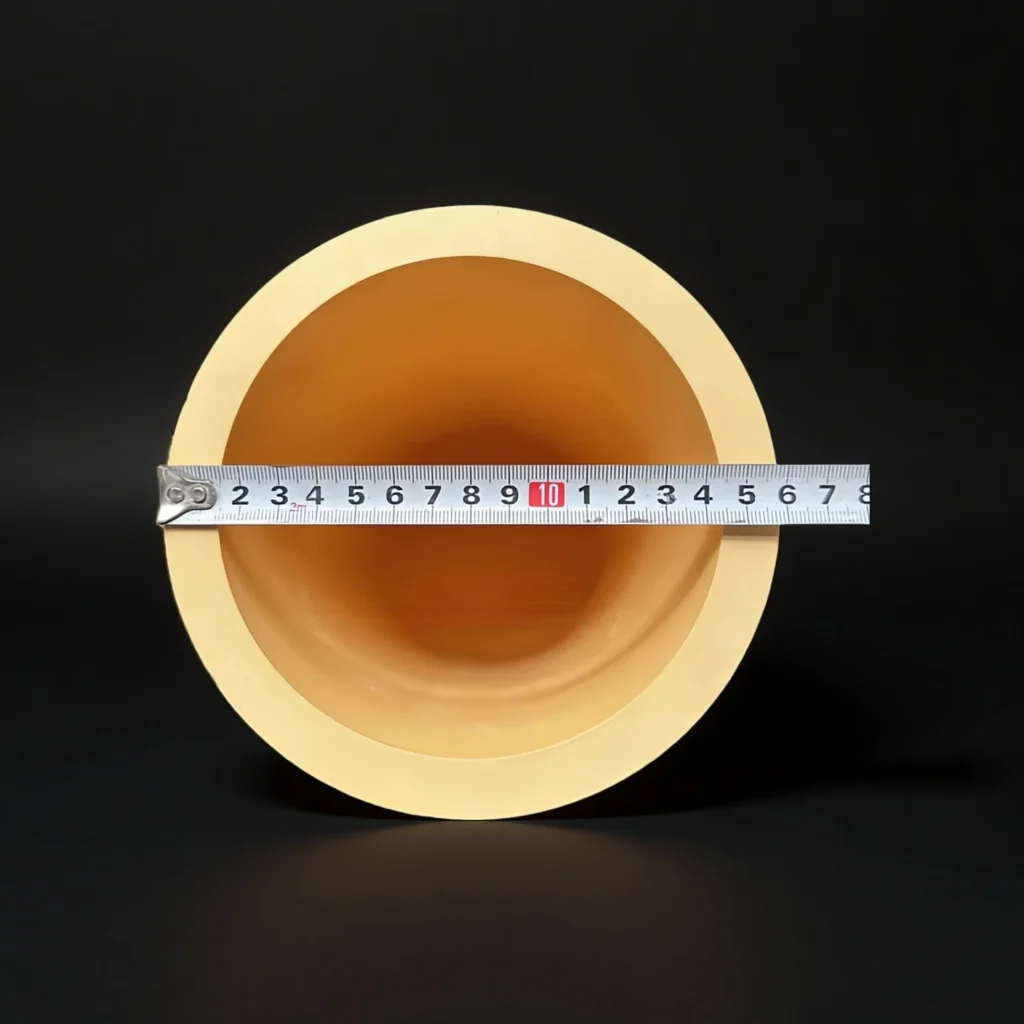

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Frequently Asked Questions About Zirconia Crucibles

A zirconia crucible maintains structural stability up to 2200°C, preventing collapse during melting cycles. It also resists wetting by noble metals, reducing material loss. This makes it reliable for platinum, palladium, and high-value alloys.

Zirconia crucibles exhibit strong thermal shock resistance, tested across 30+ cycles from room temperature to 1000°C without cracking. This performance prevents process interruptions in laboratory and industrial furnaces. It ensures long service life under repeated operations.

Yes, a zirconia crucible shows high resistance to acids, alkalis, and molten salts. Its chemical stability protects both the crucible and the sample from contamination. This feature is critical in chemical analysis and catalyst preparation.

Arc shaped crucibles are used in reactors and furnaces requiring even heat distribution. They support material sintering where curved surfaces reduce stress concentration. These are common in research-scale and pilot plants.

Rectangular crucibles provide wide, flat surfaces that ensure even powder distribution during sintering. They are favored for consistent results in material science studies. Their geometry improves heating uniformity across small samples.

Yes, zirconia crucibles resist corrosive lithium compounds at 2000°C+. They are applied in calcination of cathode powders and sintering of anode materials. This reliability supports both R&D and production lines.

Round zirconia trays are widely used in dental labs for block sintering. Their smooth surfaces prevent micro-cracks in zirconia dental crowns. This ensures high precision in restorative ceramic production.

Service life depends on cycle intensity, but zirconia crucibles can endure 100+ thermal cycles in standard use. This durability reduces replacement frequency. It lowers total cost of ownership for industrial users.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Zirconia Ceramic Crucibles

Looking for a reliable zirconia crucible supplier? Let us help you with your next project.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours