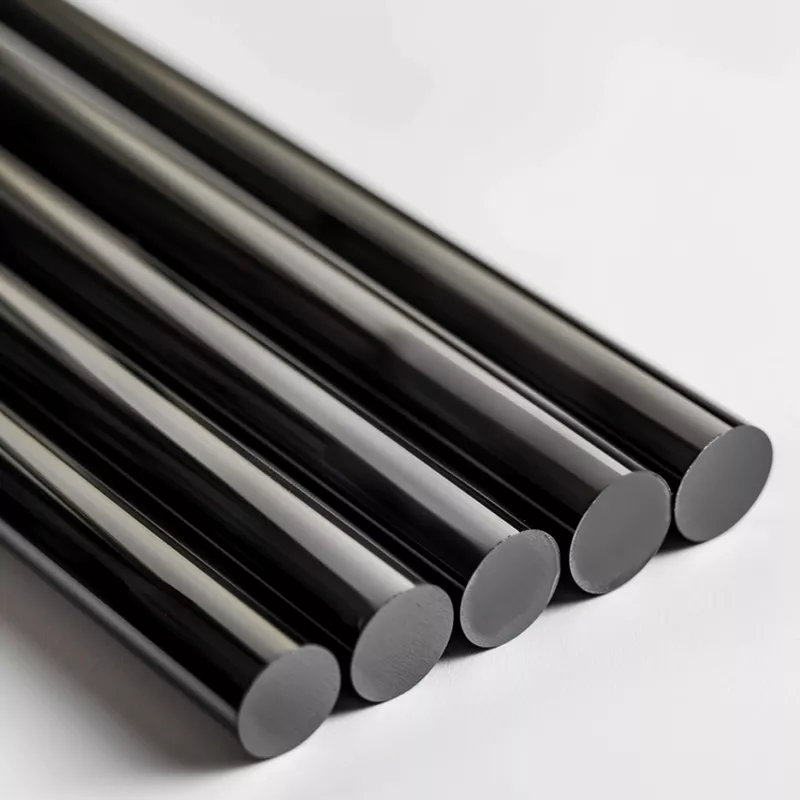

ADCERAX® Black zirconia ceramic rods are structural ceramic designed for heavy-load, high-wear industrial systems. Its combination of hardness, flexural strength above 1000 MPa, and resistance to acids, alkalis, and high temperature ensures long service in demanding environments. The black zirconia ceramic rod replaces steel components in machinery, metallurgy, and chemical equipment where durability and corrosion stability are critical. It provides reliable performance for engineers seeking long-term efficiency and maintenance reduction.

Features of Black Zirconia Ceramic Rods

- High load tolerance: Withstand forces up to 1000 MPa in bending, based on ISO 14704 4-point testing.

- Fatigue resistance: Maintains structural integrity across millions of cycles under dynamic conditions.

- Structural stability: Suitable for load-bearing applications in chemical reactors and gear shafts.

- Abrasive protection: Outlasts stainless steel by a factor of 3–5× in rotating shafts and drive rods.

- Fine grain advantage: Microstructure < 0.5 µm improves surface density and delays wear onset.

- Consistent dimension retention: Surface Ra ≤ 0.2 µm minimizes friction and precision loss.

- Acid durability: Retains >95% mass after 72h exposure to H₂SO₄ at 90 °C.

- Alkali resistance: No degradation in NaOH <10% and industrial caustic flows.

- Oxidation resistance: Performs without visible change after 100h at 800 °C in air atmosphere.

Technical Properties of Black Zirconia Ceramic Rods

The black zirconia ceramic rods deliver consistent performance across mechanical, thermal, and chemical domains, making it suitable for use in demanding industrial environments such as high-load drive systems, corrosive process lines, and thermal assemblies.

| Property |

Specification |

| Material Composition |

≥94% ZrO₂ + Y₂O₃ stabilizer + black pigment |

| Crystal Phase |

Tetragonal phase (fully stabilized) |

| Density |

≥6.0 g/cm³ |

| Flexural Strength |

≥1000 MPa (ISO 14704) |

| Compressive Strength |

≥2000 MPa (ASTM C773) |

| Vickers Hardness |

1250–1350 HV10 (ASTM C1327) |

| Fracture Toughness |

8–10 MPa·m½ (ASTM C1421) |

| Thermal Conductivity |

2.5 W/m·K |

| Thermal Expansion Coefficient |

10.5 × 10⁻⁶/K (25–1000 °C) |

| Maximum Service Temperature |

1100 °C (continuous in air/inert) |

| Electrical Resistivity |

>10¹² Ω·cm @ 25 °C |

| Acid Resistance |

>95% mass retention (72h in H₂SO₄ @ 90 °C) |

| Alkali Resistance |

Stable in NaOH <10% |

| Grain Size |

<0.5 µm (dense fine-grain structure) |

| Surface Finish (polished) |

Ra ≤ 0.2 µm |

Specifications of Black Zirconia Ceramic Rods

|

Black Zirconia Ceramic Rods |

|

Model |

Size |

|

AT-HG-B1001 |

Customized |

Packaging of Black Zirconia Ceramic Rods

Black zirconia ceramic rods are securely packed in foam-lined wooden crates to prevent impact and abrasion during transport. Each rod is individually wrapped in protective film and isolated within a shock-absorbing cavity. The packaging ensures stability, minimizes vibration, and supports long-distance international shipping.

Solving High-Load and Harsh-Condition Challenges with ADCERAX® Black Zirconia Ceramic Rods

ADCERAX® black zirconia ceramic rods address critical issues in demanding industrial environments where mechanical stress, corrosion, and thermal exposure shorten the lifespan of conventional materials. By replacing metal and lower-grade ceramics, it ensures long-term stability and minimal downtime across high-impact operational sectors.

-

CNC Machining Spindle Assemblies with Black Zirconia Ceramic Rods

✅Key Advantages

1. High-Speed Dimensional Stability

The black zirconia ceramic rod maintains micro-tolerance under speeds exceeding 12,000 rpm, resisting thermal expansion that typically causes spindle drift. Its thermal expansion coefficient of 10.5 × 10⁻⁶/K ensures stable geometry during extended machining cycles.

2. Superior Fatigue Resistance

Tested over 5 million stress cycles, the rod preserved its flexural integrity above 1000 MPa, preventing microcracks and resonance failures common in metal shafts. This provides long-term spindle balance and reduced tool chatter.

3. Low Friction, Extended Bearing Life

With a surface roughness of Ra ≤ 0.2 µm, it minimizes wear at contact interfaces, lowering bearing friction torque by 30–40% in precision assemblies. This results in smoother rotational response and less lubrication dependency.

✅ ️Problem Solved

A German CNC equipment manufacturer reported frequent spindle shaft replacements every 8 months due to thermal deformation in alloy steel rods. After switching to ADCERAX® black zirconia ceramic rods, spindle alignment deviation was reduced by 0.015 mm, extending operational intervals to 36 months without unscheduled shutdowns. Production scrap caused by vibration-induced tool drift dropped by 22%, confirming long-term stability in high-speed precision systems.

-

Corrosive Fluid Stirring Systems in Chemical Reactors Using Black Zirconia Ceramic Rods

✅Key Advantages

1. Outstanding Acid Endurance

The black zirconia ceramic rod retains >95% mass after 72 h exposure to H₂SO₄ (90 °C), allowing stable operation in reactors processing acidic or mixed solutions. Its fully stabilized tetragonal phase prevents grain-boundary corrosion and particle release.

2. Inert Surface Chemistry

The non-porous microstructure (< 0.5 µm grain size) eliminates ion leaching, avoiding contamination in sensitive reactions. This ensures consistent chemical purity even after prolonged immersion in 10% NaOH solutions.

3. High-Temperature Corrosion Resistance

Tested at 1100 °C in oxidizing atmospheres, the material showed no measurable mass loss or phase shift, securing chemical stability under hot solvent and vapor agitation conditions.

✅ ️Problem Solved

A Japanese specialty chemicals producer faced recurring contamination during acid neutralization processes caused by stainless steel stirrers leaching Fe ions. After adopting ADCERAX® black zirconia ceramic rods, analytical results confirmed 0 ppm metal ion contamination across 200 batch cycles, and equipment cleaning frequency dropped by 65%. The plant achieved uninterrupted reactor uptime for over 18 months, demonstrating consistent inertness and corrosion control under aggressive chemical exposure.

-

Metallurgical Billet Pusher Mechanisms Fitted with Black Zirconia Ceramic Rods

✅Key Advantages

1. Thermal Fatigue Resistance Above 800 °C

The black zirconia ceramic rod endures repeated thermal cycling with no microcrack propagation after 100 h exposure at 800 °C. This prevents scaling or flaking commonly seen on high-chromium steels in reheating furnaces.

2. High Compressive Strength for Shock Loads

With a compressive strength ≥ 2000 MPa, it withstands billet impacts and maintains geometric precision under continuous heavy-load motion. This stability ensures consistent billet guidance and alignment accuracy.

3. Anti-Oxidation Surface Integrity

The rod’s dense, oxygen-impermeable surface forms no oxide layer during heat cycles, reducing surface deterioration by >70% compared with standard tool steels. This eliminates regrinding or recoating maintenance.

✅ ️Problem Solved

A South Korean steel mill reported repeated pusher shaft failures every 5 weeks due to oxide scaling and bending in carbon steel components. After integrating ADCERAX® black zirconia ceramic rods, operational life extended to 28 weeks per shaft, reducing line stoppage frequency by 80%. The rods maintained alignment precision within ±0.02 mm even after 5000 billet pushes, ensuring uninterrupted production in the high-temperature furnace zone.

User Guide for Black Zirconia Ceramic Rods in Demanding Industrial Applications

To maximize performance and longevity, the black zirconia ceramic rods should be handled, installed, and maintained with consideration to its high mechanical strength and ceramic microstructure. The following usage guidelines help prevent failure, optimize alignment, and ensure safety across varied operating environments.

-

Handling Precautions for black zirconia ceramic rods

1. Avoid edge impact during unpacking or transport. Although mechanically strong, localized impact on sharp edges may cause micro-cracking. Always support the rod fully with cushioned material when moving.

2. Do not clamp directly with metal jaws. Direct metal contact can cause surface indentation or stress risers. Use compliant soft pads or torque-limited clamping devices.

3. Store in a clean, vibration-free area. Avoid stacking without dividers. Sudden shifts or repeated minor vibrations can induce unseen fatigue over time.

-

Installation Guidelines for black zirconia ceramic rods

1. Ensure axial alignment before torque transfer. Misalignment increases bending moments and may exceed the rod’s flexural limits. Use calibration tools to verify coaxial fit.

2. Accommodate thermal expansion differences. Avoid over-constraining in multi-material assemblies. Support structures must allow for minor differential movement.

3. Use dry-fit or chemically inert couplings. Avoid thread-lockers or epoxies with metal ions. Use PTFE-based fittings for chemically sensitive environments.

-

Maintenance and Monitoring of black zirconia ceramic rods

1. Inspect monthly for wear or surface abrasion. Focus on contact zones and mating surfaces. Use magnification to identify early signs of scoring or erosion.

2. Monitor operational temperature and vibration trends. Excessive rise may indicate mounting issues or system overload. Install sensors for early warning in high-value systems.

3. Keep the rod free from abrasive dust or sludge. Accumulated particles may act as third-body abrasives. Clean using isopropyl alcohol or air-drying solvents only.

-

Storage and Replacement Best Practices for black zirconia ceramic rods

1. Store horizontally in padded racks. Avoid point contacts or vertical placement. Pressure points may lead to warping under long-term weight.

2. Label by batch and application type. Always track rods by project or use-case to align with mechanical test records. Keep usage logs in critical applications.

3. Replace based on duty cycles, not just breakage. Even without visual damage, microfatigue accumulates over time. Schedule proactive replacements every 18–24 months in continuous operations.