ADCERAX is a China manufacturer of ceramic sleeves, including ceramic shaft sleeves, sleeve bushings, insulation sleeves, and related sleeve components. We produce parts in alumina, zirconia, silicon carbide, silicon nitride, and aluminum titanate, with standard sizes and custom-to-drawing support.

These ceramic sleeves help engineers control wear, corrosion, heat exposure, and fit stability in pumps, furnaces, kilns, and rotating equipment. ADCERAX adds value with fast engineering response, flexible small-batch customization, and export-ready supply.

A ceramic sleeve is a rigid, precision ceramic tube/bushing-style component used to protect shafts, isolate wear interfaces, stabilize alignment, and reduce corrosion-driven dimensional drift.

Typical reasons buyers switch to ceramic

🛡️ Reduce wear scoring on shafts and mating parts

🧪 Improve resistance to corrosive liquids and aggressive media

🎯 Maintain tighter fit stability where metal sleeves deform, gall, or corrode

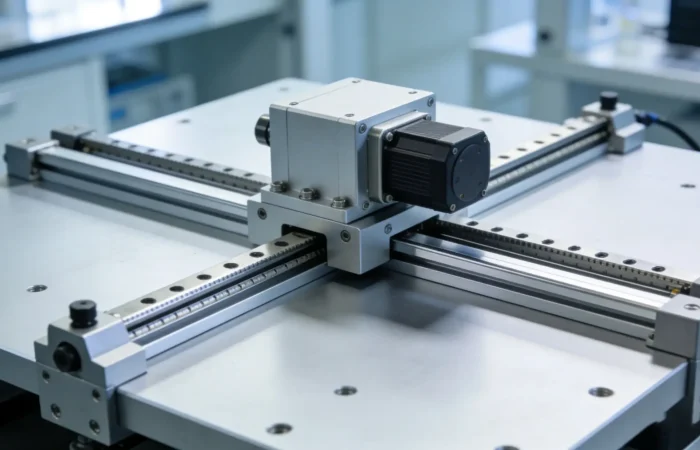

⚙️ Improve repeatability for rotating interfaces and guided motion

Precision ceramic sleeves deliver stable performance in wear, heat, and corrosive service. High hardness and low wear help extend replacement intervals, while thermal and chemical resistance keep clearances consistent and reduce deformation in harsh duty.

Alumina ceramic sleeves offer hard wear resistance with dependable electrical insulation. They keep stable dimensions in heat and corrosive service for general industrial sleeves.

| Property | Unit | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Flexural strength | MPa | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.2 | 8.4 | – | – | – | – | – |

| Melting point | °C | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 |

Zirconia ceramic sleeves add higher toughness to reduce chipping in fit-critical parts. They hold tight clearances in compact, high-load mechanisms.

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Silicon carbide ceramic sleeves excel in abrasion and chemical resistance for harsh media. They maintain geometry in slurry and corrosive process duty.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

Magnesia stabilized zirconia ceramic sleeves suit abrasive slurries, hot gas, and corrosive liquids. They help keep clearances consistent in harsh media.

| Property | Specification |

|---|---|

| Material Composition | MgO-Stabilized ZrO₂ (MSZ) |

| Density | 5.60 – 5.85 g/cm³ |

| Vickers Hardness | >1200 HV |

| Compressive Strength | >2,000 MPa |

| Flexural Strength | 800 – 1000 MPa |

| Fracture Toughness | 9 – 10 MPa·m¹ᐟ² |

| Maximum Working Temperature | >1000°C |

| Thermal Conductivity | 2.0 – 2.3 W/m·K @ RT |

| Thermal Expansion Coefficient | 10.3 ×10⁻⁶/K (25–1000°C) |

| Electrical Resistivity | >10¹² Ω·cm @ RT |

| Chemical Resistance | Stable in H₂SO₄, NaOH, chlorides, oxidizers |

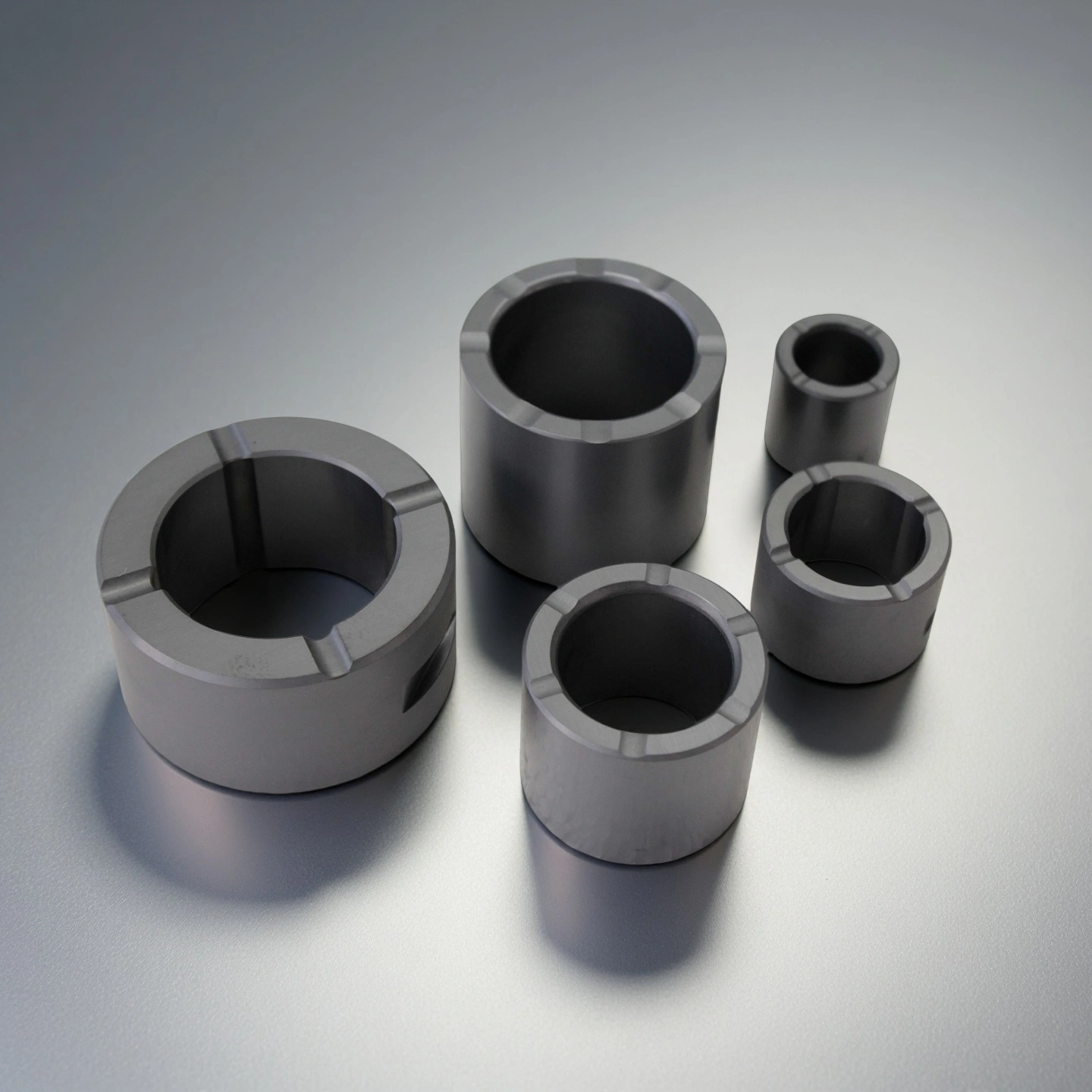

Ceramic sleeve products include ceramic shaft sleeves, ceramic sleeve bushings, ceramic wear sleeves, ceramic insulation sleeves, ceramic sleeve washers, and special designs such as split sleeves and taper sleeves. ADCERAX supplies both standard sizes and custom-to-drawing sleeves with controlled ID/OD finishing for consistent fit.

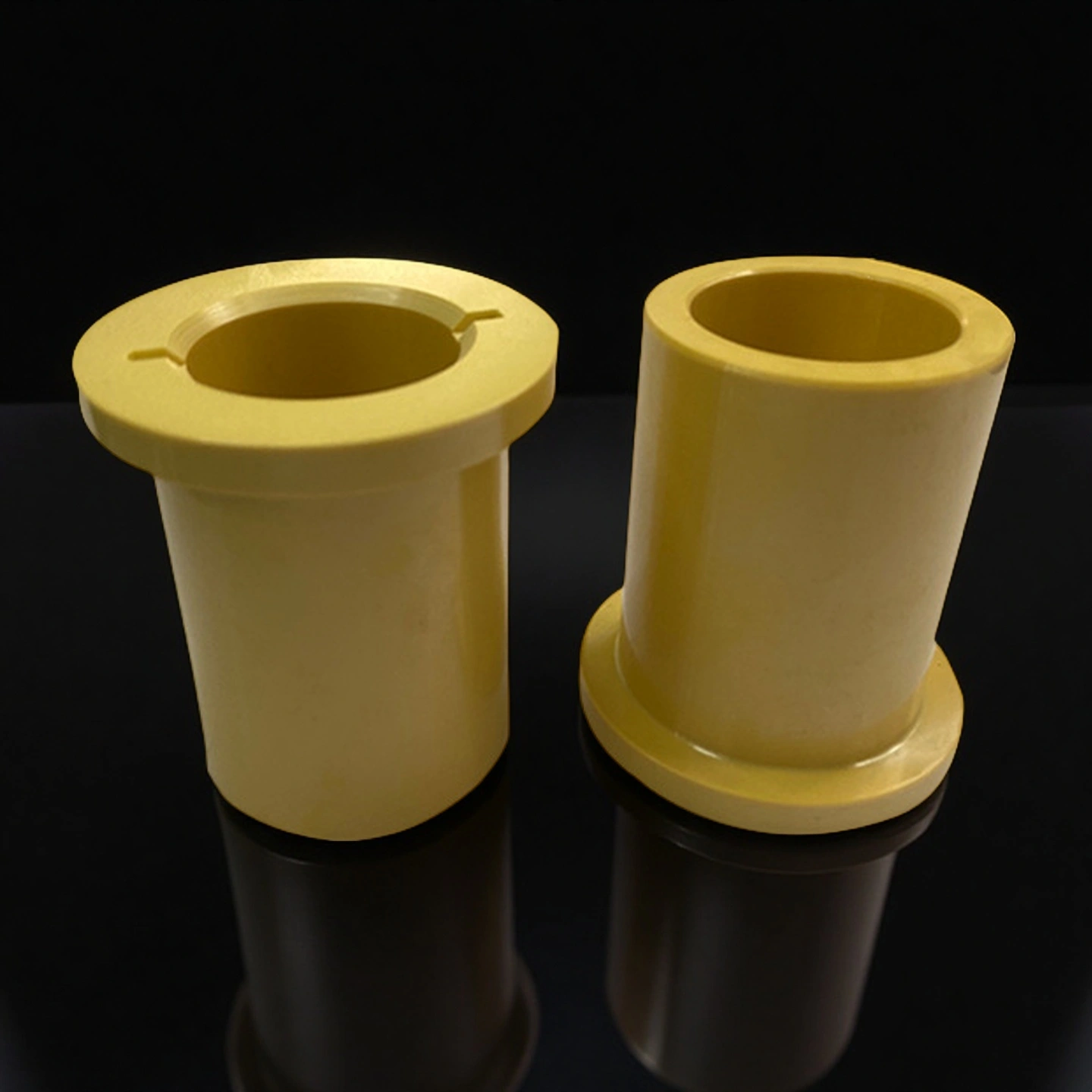

Al2O3 Sleeve is the go-to choice for cost-effective electrical insulation in furnaces, kilns, and lab fixtures—keeping assemblies clean, stable, and easy to replace.

Zro2 Sleeve is chosen for compact mechanisms under high load or impact—precision guides, bushes, and wear inserts that must stay tight and run longer.

Si3N4 Sleeve is preferred in high-speed or thermal-shock service—rotor parts, rollers, and tooling where lower mass and long service life reduce downtime.

Magnesia Stabilized zirconia sleeve suits abrasive slurries, hot gas, and corrosive liquids—nozzles, seal faces, and parts needing clearance in harsh media.

Silicon Carbide Sleeve is a solid pick for slurry pumps, burners, and kiln hardware—keeping clearances consistent in abrasive, high-load process lines.

Aluminum Titanate Sprue Bushing is a go-to option for insulating parts in furnaces, kilns, and lab equipment—keeping fixtures clean, stable, and easy to replace.

Ceramic Cylinder Sleeve is a go-to option for insulating and wear-resistant parts in furnaces, kilns, and industrial equipment—keeping fixtures clean, stable, and easy to replace.

Ceramic Sleeve Bushing is chosen for compact mechanisms under high load or impact—precision guides, bushes, and wear inserts that must stay tight and run longer.

Fiber Optic Ceramic Sleeve is preferred for high-precision optical alignment—connectors and assemblies where tight tolerances and long-term signal stability matter most.

Ceramic Insulation Sleeve is designed for electrical isolation in hot or corrosive zones—protecting leads and assemblies while staying dimensionally stable under heat and vibration.

Ceramic Shaft Sleeve is built to shield shafts from wear and corrosion—holding tight fits and smoother interfaces to extend service life in demanding rotating equipment.

Ceramic Sleeve Washer is used for load spread and electrical isolation—keeping fasteners stable, reducing galling, and maintaining clean contact surfaces in harsh duty.

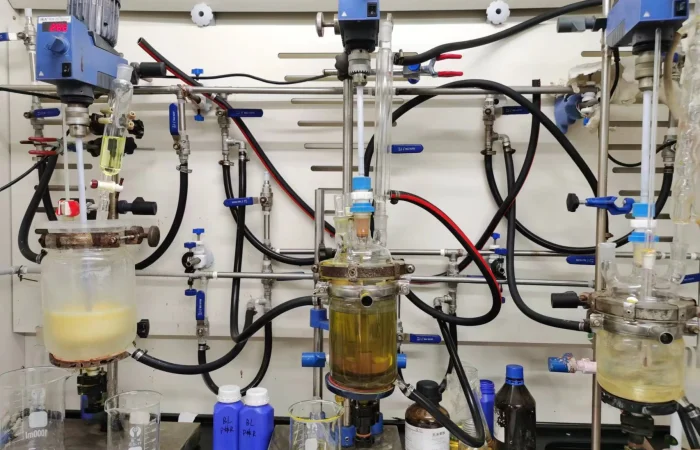

Ceramic sleeving is used in industrial, mining, chemical, and mechanical equipment to control wear, corrosion, heat stress, and fit drift at critical interfaces. It helps reduce clearance growth, scoring, and leakage risk for longer, more stable service.

💠Where ceramic sleeves are used

💠Why buyers choose ceramic sleeves

Ceramic sleeves significantly extend shaft life, stabilize seal performance, and reduce unplanned downtime. They are easy to replace and ideal for OEM standardization and MRO stocking.

💠Where ceramic sleeves are used

💠Why buyers choose ceramic sleeves

Ceramic sleeves slow erosion rates, lengthen maintenance intervals, and help operators plan predictable replacement cycles instead of emergency shutdowns.

💠Where ceramic sleeves are used

💠Why buyers choose ceramic sleeves

Ceramic sleeves maintain dimensional stability and chemical integrity, reducing corrosion-driven failures and re-machining costs during maintenance.

💠Where ceramic sleeves are used

💠Why buyers choose ceramic sleeves

Ceramic sleeves help maintain tight clearances, smooth motion, and lot-to-lot consistency, making them ideal for repeat orders and interchangeable replacement parts.

ADCERAX custom ceramic sleeves are made to your drawing or fit requirements, with material options matched to your duty. Share your key dimensions, tolerance targets, and quantity for a fast review. Typical custom lead time is 2–9 weeks, depending on complexity.

Define the duty first—abrasion level, corrosion exposure, temperature, and load. Clear matching helps the sleeve hold fit and wear performance, avoiding premature scoring or drift.

Share your key fit points—ID/OD/length and how the sleeve interfaces with the shaft or housing. Controlled geometry supports consistent clearance and makes replacement straightforward.

Focus on the contact behavior—sliding, rotation, particles, and lubrication conditions. Proper sleeve design helps slow clearance growth and keeps assemblies running smoothly for longer intervals.

Specify where finish matters—ID, OD, and end faces—plus your acceptance criteria. The right finishing and inspection focus improve repeatability and reduce assembly variation across batches.

Share drawing or key dimensions (ID/OD/length), quantity, tolerance target, and duty conditions.

We confirm material, fit intent, and critical surfaces with you before production.

We make sleeves to spec and inspect key dimensions for batch consistency.

Parts are protected, labeled, and shipped with export-ready documents.

ADCERAX is a China ceramic sleeve manufacturer, supplying ceramic shaft sleeves, sleeve bushings, wear sleeves, and insulation sleeves with controlled production and batch inspection for consistent quality. Fast engineering support helps match materials to duty and keep supply reliable for repeat orders.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX is a factory-direct ceramic sleeve manufacturer in China with 20+ years of advanced ceramics experience, supplying ceramic sleeves in alumina, zirconia, silicon carbide, silicon nitride, and aluminum titanate for harsh-duty service.

Standard sleeves are available for fast replacement, and custom-to-drawing orders are supported for fit-critical builds. With batch inspection, traceable records, and export-ready packing, ADCERAX helps buyers keep supply stable, reduce scrap, and maintain predictable maintenance cycles.

Ceramic powders are selected by duty, mixed with binders to form a feedstock.

Parts are dried and then debound to remove binders without warpage or hidden defects.

ID/OD and end faces are ground to achieve repeatable fit and assembly performance consistently.

Sleeve bodies are shaped by extrusion or pressing, depending on size and geometry.

High-temperature firing densifies the ceramic and sets final material performance.

Key dimensions are inspected by batch, then cleaned, labeled, and packed for export.

Start with the duty conditions, then match the material:

Abrasion level (particle wear, sliding wear)

Corrosion exposure (chemical type + concentration)

Temperature profile (steady vs. thermal cycling)

Load / impact (radial load, shock, edge loading)

Material selection guidelines:

Alumina: a strong general-purpose choice with reliable insulation and wear resistance.

Zirconia / MSZ: adds toughness for better edge strength and reduced chipping risk.

Silicon carbide (SiC): preferred for severe abrasion and corrosive media duty.

Silicon nitride (Si₃N₄): often chosen for high-speed or thermal-shock–sensitive assemblies.

To recommend the best option quickly, share: media + temperature + load type.

Most dense SiC is not a reliable electrical insulator because it can be semiconductive, and conductivity can increase with temperature and grade. If electrical isolation is required, alumina, zirconia, aluminum titanate, or other insulating ceramics are safer defaults, depending on duty.

Material preference (or duty conditions), key dimensions (ID/OD/length), quantity, and the critical fit surfaces. If you have a drawing, include it; if not, provide the mating shaft/housing sizes and any assembly constraints. This prevents mis-selection and speeds lead time confirmation.

Commonly finished areas include the ID (for shaft fit), OD (for housing fit), and end faces (for squareness and assembly seating). If the sleeve acts as a wear interface, a controlled surface finish can materially impact wear behavior and stability across batches.

Ceramics are strong in compression but can be sensitive to impact and sharp stress concentrators. If impact or edge loading is present, tougher ceramics (such as zirconia/MSZ) and conservative edge design (chamfers/radii) reduce chipping risk. Installation method and alignment often matter as much as material choice.

Thermal shock cracking occurs when heating/cooling rates create high internal stress. Aluminum titanate and certain zirconia grades can be more tolerant in rapid cycling, while geometry (wall thickness) and installation constraints also drive risk. If cycling is frequent, “thermal profile” is a critical input.

Common modes include chipping from installation or misalignment, cracking from impact/thermal shock, and gradual wear/erosion that increases clearance. Many “ceramic failures” are actually interface or assembly issues, so confirming load path, alignment, and mounting approach matters.

Avoid point loading and misalignment during pressing or assembly. Use proper fixtures, clean mating surfaces, controlled press forces, and edge protection where needed. If interference fits are involved, material choice, surface finish, and assembly method should be confirmed together.

Yes. ADCERAX can custom-make solid ceramic sleeves for your application.

Share a drawing or key dimensions, duty media, temperature, and quantity, and we will recommend a suitable material and quote accordingly.

Yes. ADCERAX offers ceramic sleeve for sale options for pump duty, including ceramic shaft sleeves and wear sleeves for abrasive or corrosive service. Share your key dimensions, media, temperature, and quantity, and we will match the material and provide a fast quote.

Ceramic sleeving is a separate ceramic sleeve part installed over a shaft or inside a bore to provide wear resistance, corrosion resistance, heat stability, or electrical insulation. It is typically replaced as a unit when worn.

A ceramic coating sleeve is usually a metal sleeve with a ceramic coating on the surface to improve wear or corrosion performance while keeping the metal core’s toughness. Performance depends heavily on coating adhesion and surface damage risk.

Quick choice: pick ceramic sleeving for a replaceable ceramic component, and pick a ceramic coating sleeve when you want a metal base with added surface protection.

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

WhatsApp us

The more details you provide, the faster we can respond.

*We respond within 24 hours. All inquiries are confidential.

The more details you provide, the faster we can quote.

*We respond within 24 hours. All inquiries are confidential.