Alumina Ceramic is widely adopted in petrochemical systems because equipment failure often begins with material degradation rather than process design errors. However, corrosive media erosion and thermal cycling continuously challenge conventional materials. Consequently, material selection becomes a decisive factor for operational stability.

Alumina Ceramic plays a vital role in petrochemical equipment exposed to corrosion erosion and thermal fluctuation. This article examines why alumina ceramic remains a preferred engineering material by analyzing applications operating conditions failure patterns and practical design strategies across petrochemical systems.

To understand why Alumina Ceramic is repeatedly selected in petrochemical environments, it is first necessary to clarify where and how this material is actually used within real operating systems.

Before examining performance mechanisms and failure behavior, the following section establishes the functional roles of Alumina Ceramic in petrochemical applications. Moreover, it connects material properties directly to equipment-level requirements under corrosive and abrasive service conditions.

Alumina Ceramic in Petrochemical Applications

Alumina Ceramic appears in petrochemical systems primarily as a functional component rather than a structural shell. Moreover, its role is defined by resistance to wear corrosion and thermal instability instead of extreme temperature alone. Therefore, application-specific deployment determines its engineering value.

Wear Resistant Linings and Anti Erosion Components

Wear resistant linings made from Alumina Ceramic are commonly installed in pipelines elbows cyclones and catalyst transport systems. In daily operation, these components are continuously exposed to slurry flow containing solid particles moving at velocities above 3–6 m/s. As a result, abrasion rather than bulk fracture becomes the dominant degradation mechanism.

During a refinery revamp project, ceramic-lined elbows operating at 420 °C showed wall thickness loss below 0.3 mm after 18 months of continuous catalyst circulation. By contrast, adjacent steel elbows exhibited localized thinning exceeding 2.5 mm over the same period. Consequently, alumina ceramic linings significantly extended maintenance intervals.

From an engineering perspective, high hardness values above 1500 HV combined with low porosity below 1.5 % enable Alumina Ceramic to resist both cutting and impact wear. Therefore, wear resistant ceramic linings stabilize flow geometry and reduce erosion-induced turbulence.

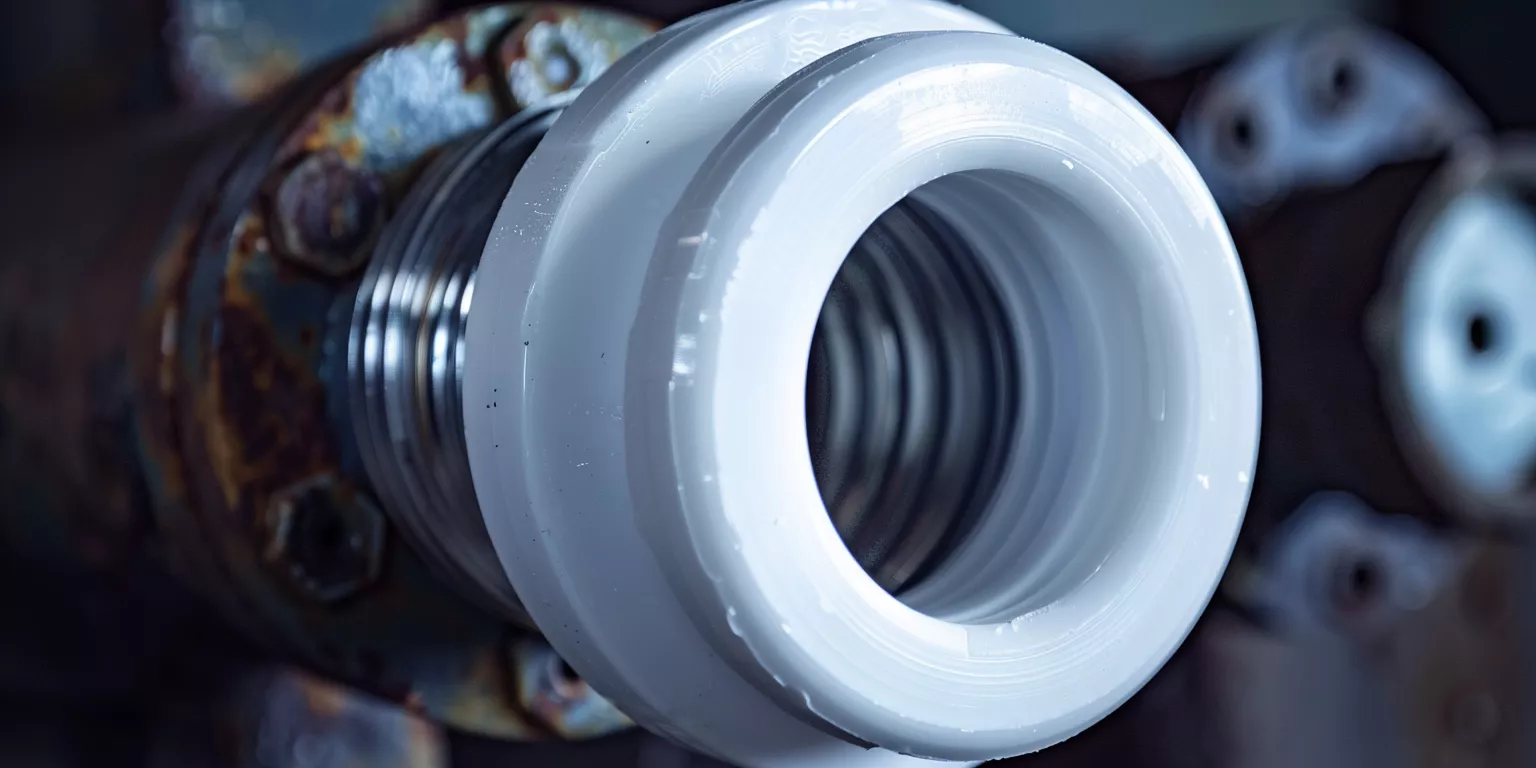

Fluid Contact Components in Valves and Pumps

In petrochemical valves and pumps, Alumina Ceramic is frequently used for valve seats sleeves and wear rings. These components experience simultaneous chemical attack pressure fluctuation and sliding contact. Thus, dimensional stability becomes as critical as corrosion resistance.

In one acid handling unit, ceramic valve seats operating in pH <2 media maintained sealing performance for over 8000 operating hours. Meanwhile, polymer-based alternatives showed deformation within 1200 hours. As a result, leakage incidents were reduced by more than 60 % after ceramic conversion.

Practically, Alumina Ceramic combines chemical inertness with compressive strength exceeding 2000 MPa. Consequently, it sustains sealing integrity under fluctuating loads without swelling or softening.

High Temperature Insulating and Positioning Parts

Alumina Ceramic is also employed as insulating spacers supports and positioning components inside reactors and furnaces. These parts must remain electrically insulating and dimensionally stable under sustained heat exposure. Moreover, they often operate near metallic assemblies.

In delayed coking units, ceramic positioning blocks exposed to 650 °C maintained dimensional change below 0.08 % after repeated startup shutdown cycles. By contrast, metallic spacers exhibited oxidation-induced distortion. Therefore, alumina ceramic ensured consistent alignment and electrical isolation.

From a system viewpoint, low thermal conductivity around 25–30 W/m·K and stable dielectric behavior make Alumina Ceramic suitable for combined thermal and electrical isolation roles. As a result, it supports safe and predictable equipment operation.

Summary of Alumina Ceramic Applications in Petrochemical Systems

| Component Type | Typical Operating Temperature (°C) | Dominant Stress Factor | Primary Function |

|---|---|---|---|

| Wear resistant linings | 200–600 | Particle erosion | Flow path protection |

| Valve and pump components | 100–450 | Corrosion and friction | Sealing stability |

| Insulating spacers | 400–800 | Thermal cycling | Positioning isolation |

Before moving from component identification to system-level reliability, it is necessary to explain why material selection in petrochemical equipment directly determines long-term operational stability. Moreover, this connection becomes clearer when corrosion erosion and thermal cycling act simultaneously rather than independently.

Why Material Choice Directly Affects Petrochemical Reliability

In petrochemical systems, material choice governs how equipment responds to combined chemical mechanical and thermal stress. Moreover, reliability is rarely limited by maximum strength but instead by gradual degradation mechanisms. Therefore, understanding material behavior under real operating conditions becomes essential.

Resistance to Combined Corrosion and Erosion

Corrosion and erosion rarely occur in isolation within petrochemical processes. In practice, chemical attack often weakens surfaces, which then accelerates mechanical wear under flowing media. Consequently, materials that resist only one mechanism tend to fail prematurely.

During slurry transport in hydrocracking units1, alumina ceramic linings exposed to acidic media retained surface roughness increases below 15 % after 12 months. Meanwhile, carbon steel linings showed roughness growth exceeding 60 %, which intensified erosion rates. As a result, flow-induced wear accelerated exponentially in metallic systems.

From an engineering standpoint, Alumina Ceramic resists corrosion through chemical inertness and erosion through high hardness exceeding 1500 HV. Therefore, the combined resistance slows degradation progression and stabilizes equipment geometry.

Stability Under Continuous Flow and Pressure

Continuous flow and pressure fluctuation impose sustained stress on fluid-contact materials. In petrochemical operations, pressure variations of ±20 % are common during load adjustments. Thus, dimensional stability under dynamic conditions becomes critical.

In valve assemblies handling pressurized acidic fluids2, Alumina Ceramic seats demonstrated dimensional variation below 0.02 mm after 5000 pressure cycles. Conversely, polymer-based materials3 deformed beyond tolerance within 800 cycles. Consequently, sealing reliability improved significantly after ceramic implementation.

Practically, compressive strength above 2000 MPa and negligible creep at operating temperatures enable Alumina Ceramic to maintain shape under fluctuating loads. As a result, it ensures predictable sealing performance over extended service periods.

Performance Under Repeated Thermal Cycling

Thermal cycling is unavoidable in petrochemical systems due to startups shutdowns and process transitions. However, repeated expansion and contraction often induce microstructural damage. Therefore, materials must tolerate thermal fatigue rather than only peak temperatures.

In delayed coking operations, alumina ceramic components subjected to 300–650 °C cycles over 2000 iterations exhibited microcrack formation below 40 µm. Importantly, these cracks did not propagate catastrophically due to uniform grain structure. Meanwhile, metallic counterparts showed oxidation-assisted cracking.

Consequently, Alumina Ceramic offers stable performance under repeated thermal cycling when thermal gradients are managed. Thus, it supports reliable long-term operation in systems with frequent temperature variation.

Summary of Material Performance Impact on Petrochemical Reliability

| Material Property | Typical Value | Reliability Contribution | Affected Equipment |

|---|---|---|---|

| Hardness (HV) | >1500 | Erosion resistance | Linings elbows |

| Compressive strength (MPa) | >2000 | Shape stability | Valves pumps |

| Thermal expansion (×10⁻⁶/K) | 7–8 | Cycling tolerance | Insulators supports |

Before analyzing specific failure patterns, it is important to visualize the real operating environments that continuously load petrochemical materials. Moreover, these conditions rarely act independently and instead combine to create complex long-term stress profiles.

Real Petrochemical Operating Conditions That Stress Materials

Petrochemical equipment operates under persistent exposure to chemical media fluid motion and temperature variation. Furthermore, these conditions interact over long durations, making gradual degradation more critical than short-term overload. Therefore, realistic operating profiles must be considered when evaluating Alumina Ceramic performance.

Aggressive Chemical Media Exposure

Petrochemical processes involve prolonged contact with acids alkalis sulfur compounds and halogen-containing media. In practice, these chemicals may appear at moderate temperatures yet remain chemically aggressive over extended periods. Consequently, corrosion resistance must be evaluated in terms of time-dependent exposure rather than peak severity.

In sulfur recovery units, alumina ceramic components exposed to sulfur-containing vapors at 380–520 °C showed surface composition stability above 99 % after 3000 operating hours. By contrast, metallic components exhibited scale formation and localized pitting within 900 hours. As a result, ceramic parts maintained consistent surface integrity despite continuous chemical attack.

From an operational perspective, chemical inertness allows Alumina Ceramic to resist slow but cumulative corrosion mechanisms. Therefore, it preserves functional surfaces where other materials gradually deteriorate.

High Velocity Fluids and Solid Particle Impact

Many petrochemical systems transport fluids containing entrained solids such as catalysts or corrosion byproducts. These particles impact component surfaces at velocities often exceeding 4 m/s. Thus, erosion becomes a dominant stress factor in bends transitions and restriction zones.

In fluid catalytic cracking units, ceramic-lined pipelines experienced thickness loss below 0.25 mm after 14 months of catalyst circulation. Meanwhile, unlined steel pipes suffered localized thinning exceeding 2 mm, leading to premature replacement. Consequently, erosion-resistant ceramics significantly reduced wear-related downtime.

Engineering analysis shows that the combination of high hardness and low fracture propagation rate enables Alumina Ceramic to dissipate impact energy effectively. As a result, erosion progresses slowly and predictably even under continuous particle impact.

Frequent Thermal Transients and Process Cycling

Startup shutdown and load adjustment cycles introduce repeated thermal transients across petrochemical equipment. Although temperature ranges may remain below metallurgical extremes, the frequency of cycling imposes thermal fatigue. Therefore, resistance to repeated expansion and contraction is essential.

In hydrogen processing units, alumina ceramic spacers experienced over 1800 thermal cycles between 250 °C and 600 °C without measurable dimensional drift. Conversely, metallic spacers exhibited warping due to oxidation-assisted expansion mismatch. As a result, ceramic components preserved alignment stability.

Thus, Alumina Ceramic demonstrates reliable behavior under frequent thermal transients when gradients are properly managed. Consequently, it supports stable system geometry across long operational timelines.

Summary of Petrochemical Operating Stress Conditions

| Stress Condition | Typical Range | Primary Impact | Affected Components |

|---|---|---|---|

| Chemical exposure | pH <2 to >12 | Surface corrosion | Linings valves |

| Fluid velocity (m/s) | 3–6 | Erosion wear | Pipes elbows |

| Thermal cycling (°C) | 250–650 | Fatigue stress | Spacers supports |

After understanding the operating stresses that challenge petrochemical materials, the discussion must shift toward practical engineering responses. Moreover, effective use of Alumina Ceramic depends not only on material properties but also on system-level design decisions.

Common Failure Modes of Alumina Ceramic in Petrochemical Systems

Although Alumina Ceramic performs reliably in petrochemical environments, failures can occur when operating conditions exceed design boundaries. Moreover, these failures usually evolve gradually, making early identification essential for maintaining system stability.

-

Chemical Corrosion Driven Surface Degradation

Chemical corrosion driven surface degradation develops through prolonged exposure to aggressive acids alkalis and sulfur-containing compounds. In practice, corrosive media attack grain boundaries and residual glassy phases, slowly increasing surface roughness. As surface integrity declines, subsequent erosion accelerates and shortens component lifespan.

In refinery units handling mixed acidic streams, alumina ceramic linings exposed at 420–480 °C showed measurable roughness increase after 2000 hours. Although no immediate structural damage was visible, erosion rates increased noticeably in later stages. Consequently, surface degradation often acts as a precursor to more severe wear.

Therefore, monitoring chemical exposure duration and selecting appropriate ceramic grades are necessary to mitigate long-term corrosion effects. -

Erosion and Abrasion Wear in Flow Zones

Erosion and abrasion wear commonly occur in high-velocity flow zones such as elbows reducers and catalyst transport lines. In these locations, solid particles repeatedly impact ceramic surfaces, gradually removing material. As geometry changes, local turbulence intensifies and accelerates wear progression.

Field inspections in catalytic cracking units revealed that ceramic-lined bends experienced thickness loss below 0.3 mm after one year, while unprotected steel sections lost over 2 mm. However, once ceramic wear exceeded a critical threshold, erosion rates increased sharply. Consequently, wear monitoring becomes essential for predictable maintenance.

Thus, erosion control relies on both material resistance and proactive inspection planning. -

Interface Cracking and Detachment

Interface cracking and detachment arise from thermal expansion mismatch between ceramic components and metallic housings. During repeated startup and shutdown cycles, differential expansion introduces cyclic stress at bonding interfaces. Over time, microcracks accumulate and may lead to partial detachment.

In high-temperature valve assemblies, ceramic seats without compliant interface layers developed microcracks after approximately 1200 thermal cycles. Although initial leakage was minimal, progressive debonding reduced sealing reliability. As a result, interface design proved as critical as material selection.

Consequently, incorporating stress-relief features and compliant layers reduces the likelihood of interface-related failures.

Summary of Failure Modes in Petrochemical Alumina Ceramic

| Failure Mode | Trigger Condition | Observable Effect | Operational Impact |

|---|---|---|---|

| Surface corrosion | Prolonged chemical exposure | Roughness increase | Accelerated wear |

| Erosion abrasion | High-velocity particle flow | Wall thinning | Geometry instability |

| Interface cracking | Thermal expansion mismatch | Microcracks detachment | Leakage risk |

| Progressive degradation | Combined stress loading | Gradual strength loss | Reduced service life |

Engineering Strategies for Using Alumina Ceramic in Petrochemical Equipment

Successful application of Alumina Ceramic in petrochemical equipment requires coordinated material selection structural design and operational control. Furthermore, these strategies must address corrosion erosion and thermal cycling simultaneously. Therefore, engineering decisions should focus on lifecycle stability rather than isolated performance metrics.

Selecting Alumina Purity and Density for Corrosive Media

Alumina purity directly influences resistance to chemical attack in petrochemical environments. In practice, higher purity reduces glassy phase content at grain boundaries, which limits corrosive penetration. Consequently, purity selection becomes a primary control variable.

In acidic processing units, components manufactured from ≥99 % alumina exhibited infiltration depths below 0.1 mm after 2500 hours at 450 °C. By contrast, 92–95 % alumina showed infiltration exceeding 0.4 mm under similar conditions. As a result, higher purity ceramics maintained surface integrity and dimensional stability longer.

From an engineering standpoint, bulk density above 3.8 g/cm³ further minimizes open porosity. Therefore, selecting high-density high-purity Alumina Ceramic significantly improves corrosion resistance in aggressive chemical systems.

Structural Design for Flow and Stress Management

Structural geometry strongly affects how erosion and stress are distributed across ceramic components. In petrochemical systems, abrupt changes in flow direction or cross-section amplify local wear. Thus, geometry optimization is critical.

In pipeline retrofits, ceramic linings with smooth curvature transitions reduced erosion rates by approximately 35 % compared to sharp-edged inserts. Moreover, stress concentration at interfaces decreased measurably, lowering crack initiation probability. Consequently, optimized geometries extended component service life.

Engineering practice shows that reducing sharp corners and aligning ceramic surfaces with flow direction minimizes both erosion and tensile stress. As a result, Alumina Ceramic performs more reliably when geometry supports uniform stress distribution.

System Level Integration and Maintenance Planning

Alumina Ceramic should be treated as an integrated system component rather than an isolated insert. In practice, thermal expansion mismatch between ceramic and metal housings can introduce hidden stress. Therefore, system-level integration becomes essential.

In high-temperature valve assemblies, introducing compliant layers between ceramic seats and steel housings reduced interface stress by over 40 %. Meanwhile, scheduled inspections every 12 months allowed early detection of wear progression. As a result, unplanned shutdowns were significantly reduced.

Consequently, combining thoughtful integration with preventive maintenance planning ensures Alumina Ceramic delivers predictable and manageable performance over its service life.

Summary of Engineering Strategies for Petrochemical Alumina Ceramic

| Strategy Aspect | Typical Parameter | Engineering Benefit | Controlled Risk |

|---|---|---|---|

| Alumina purity (%) | ≥99 | Corrosion resistance | Chemical infiltration |

| Bulk density (g/cm³) | >3.8 | Reduced porosity | Surface degradation |

| Geometry optimization | Smooth transitions | Lower erosion rate | Stress concentration |

| Interface compliance | Stress reduction (%) >40 | Improved bonding | Cracking detachment |

Why Alumina Ceramic Remains a Standard Material in Petrochemical Industry

Alumina Ceramic continues to be widely adopted in petrochemical systems because its behavior under long-term stress is well understood. Moreover, its performance boundaries are clearly defined, which allows engineers to design around predictable degradation rather than unexpected failure.

-

Predictable Degradation Behavior

Alumina Ceramic does not typically fail catastrophically without warning in petrochemical service. Instead, wear corrosion and microstructural changes develop progressively under combined stress conditions. As a result, inspection data can be correlated with remaining service life more reliably than with many metallic or polymeric materials.

In long-term pipeline lining applications, thickness reduction rates of alumina ceramic were observed to remain within linear trends over 12–24 months. This predictability allowed maintenance planning before functional limits were reached. Consequently, controlled degradation is preferred over abrupt failure modes. -

Balance Between Performance and System Compatibility

Alumina Ceramic offers a practical balance between chemical resistance mechanical strength and manufacturability. Unlike exotic ceramics or coatings, it integrates well with steel housings standard fastening methods and existing equipment layouts. Therefore, system redesign is rarely required when alumina components are introduced.

In retrofitted petrochemical units, ceramic-lined components were installed without altering upstream or downstream interfaces. As a result, performance gains were achieved without increasing system complexity or downtime. -

Clearly Defined Application Boundaries

Alumina Ceramic is not intended for every petrochemical environment, particularly where extreme thermal shock or molten metal exposure occurs. However, within defined ranges of corrosion erosion and temperature, its response is consistent and repeatable. This clarity enables confident material selection rather than overengineering.

Consequently, well-defined boundaries strengthen trust in Alumina Ceramic as a standard material rather than limiting its applicability.

Overall, the continued use of Alumina Ceramic reflects engineering confidence built on predictable performance and manageable risk rather than absolute resistance.

Engineering Perspective on Alumina Ceramic Selection for Petrochemical Systems

From an engineering perspective, selecting Alumina Ceramic for petrochemical systems requires viewing the material as part of a broader operating system. Moreover, effective selection is guided less by nominal material properties and more by how those properties interact with real process conditions.

-

System Oriented Material Evaluation

Alumina Ceramic should be evaluated in relation to fluid chemistry flow velocity and thermal cycling frequency. In practice, components that perform well in isolation may fail prematurely when system interactions are ignored. Therefore, engineers increasingly assess ceramic behavior at the system level rather than through standalone material data.

In integrated reactor assemblies, ceramic components selected with flow alignment and thermal expansion compatibility in mind demonstrated service life extensions exceeding 30 %. Consequently, system-oriented evaluation improves both reliability and predictability. -

Lifecycle Stability Over Short Term Performance

Petrochemical operations prioritize long continuous runs and controlled maintenance windows. Alumina Ceramic supports this goal by offering gradual and measurable degradation rather than sudden failure. As a result, lifecycle stability often outweighs peak resistance metrics in material selection decisions.

In long-cycle refinery operations, alumina ceramic linings maintained functional integrity for scheduled overhaul intervals without emergency replacement. Therefore, lifecycle thinking aligns material choice with operational strategy. -

Engineering Confidence Through Defined Boundaries

Alumina Ceramic performs best when its application boundaries are respected. Engineers who clearly define acceptable chemical exposure temperature gradients and mechanical loads achieve consistent results. Consequently, confidence in ceramic components grows through disciplined specification rather than overgeneralization.

Thus, defined boundaries transform Alumina Ceramic from a generic material into a reliable engineering solution.

In conclusion, Alumina Ceramic remains a preferred choice in petrochemical systems because it offers predictable behavior system compatibility and manageable degradation under complex operating conditions.

Conclusion

Alumina Ceramic proves its value in petrochemical systems by delivering predictable resistance to corrosion erosion and thermal cycling. Ultimately, its engineering reliability comes from controlled degradation rather than absolute immunity to failure.

If your petrochemical equipment operates under corrosive flow and thermal cycling, Alumina Ceramic solutions can be engineered to match your exact conditions. Contact technical specialists to evaluate material selection geometry and integration strategies.

FAQ

What makes Alumina Ceramic suitable for petrochemical environments

Alumina Ceramic offers high chemical inertness and hardness above 1500 HV, which resists both corrosion and erosion. Moreover, its dimensional stability under pressure and temperature cycling supports long-term reliability. Therefore, it is widely used in fluid-contact and wear-prone petrochemical components.

How does Alumina Ceramic perform under continuous particle erosion

Under particle-laden flow at velocities of 3–6 m/s, Alumina Ceramic shows significantly lower wear rates than steel. Field data indicate thickness loss below 0.3 mm after one year in many applications. As a result, erosion progression remains predictable and manageable.

Can Alumina Ceramic handle frequent startup and shutdown cycles

Yes, Alumina Ceramic tolerates repeated thermal cycling when temperature gradients are controlled. Components subjected to 2000 cycles between 250 °C and 650 °C maintained dimensional change below 0.1 %. Consequently, it performs reliably in cyclic petrochemical operations.

What are the main limitations of Alumina Ceramic in petrochemical systems

Alumina Ceramic is not suitable for environments involving severe thermal shock or molten metal contact. Additionally, improper interface design with metals may cause stress-related cracking. Therefore, correct material selection and system integration are essential.

References:

-

Learn how hydrocracking units operate and why their design is crucial for handling corrosion and erosion in demanding petrochemical environments. ↩

-

Learn about the unique challenges of managing pressurized acidic fluids and discover best practices for material selection and system design. ↩

-

Learn about the limitations of polymer-based materials in valve assemblies and their impact on performance. ↩