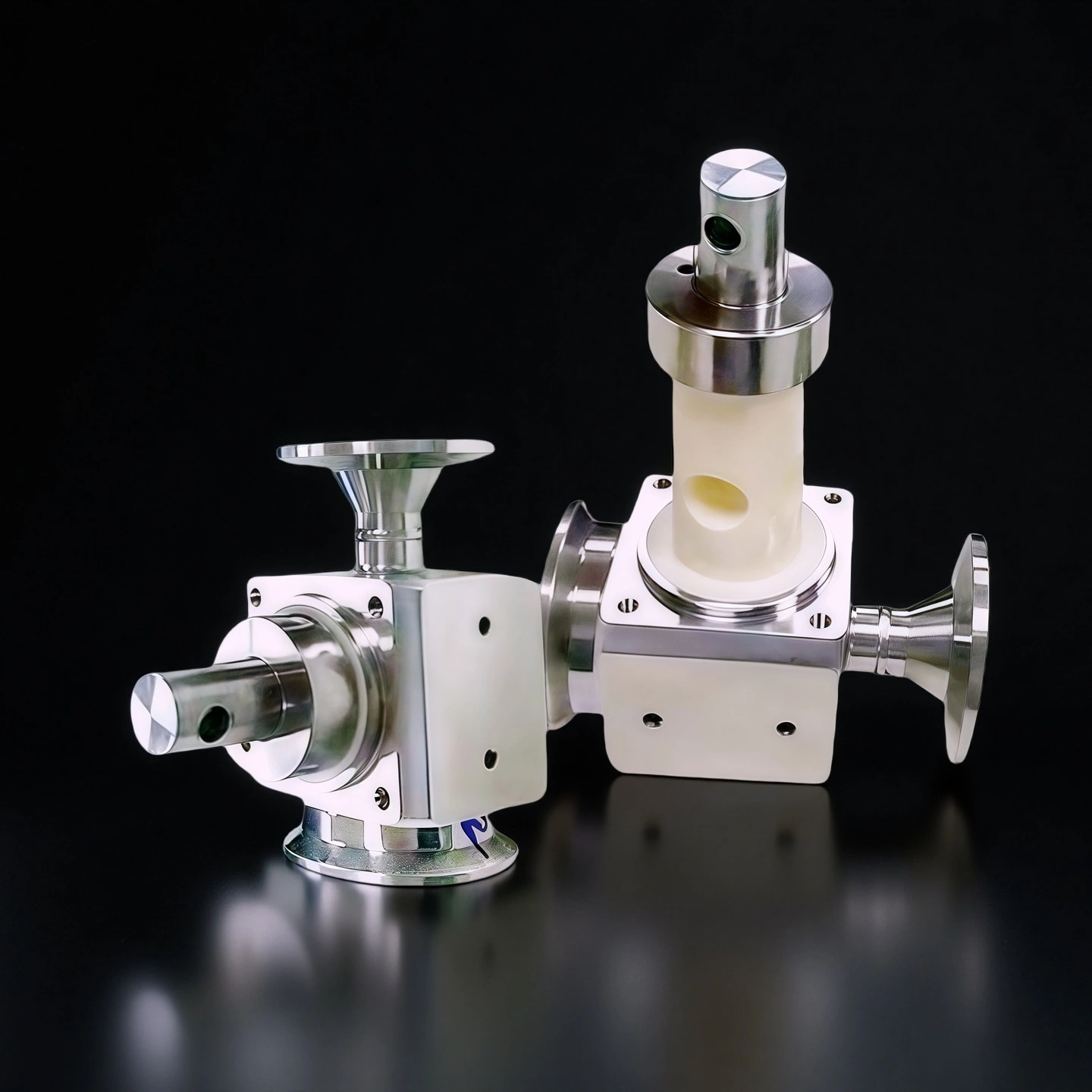

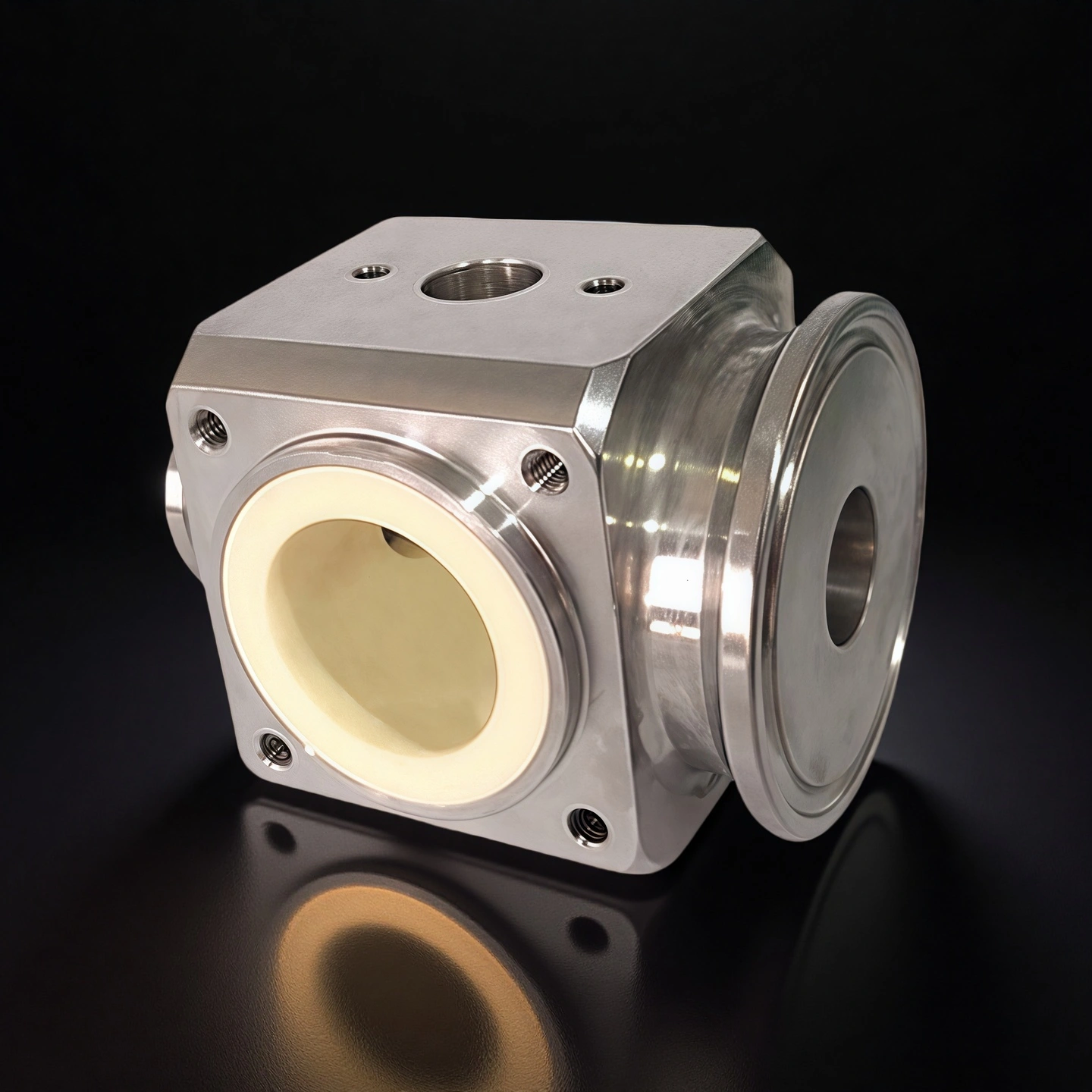

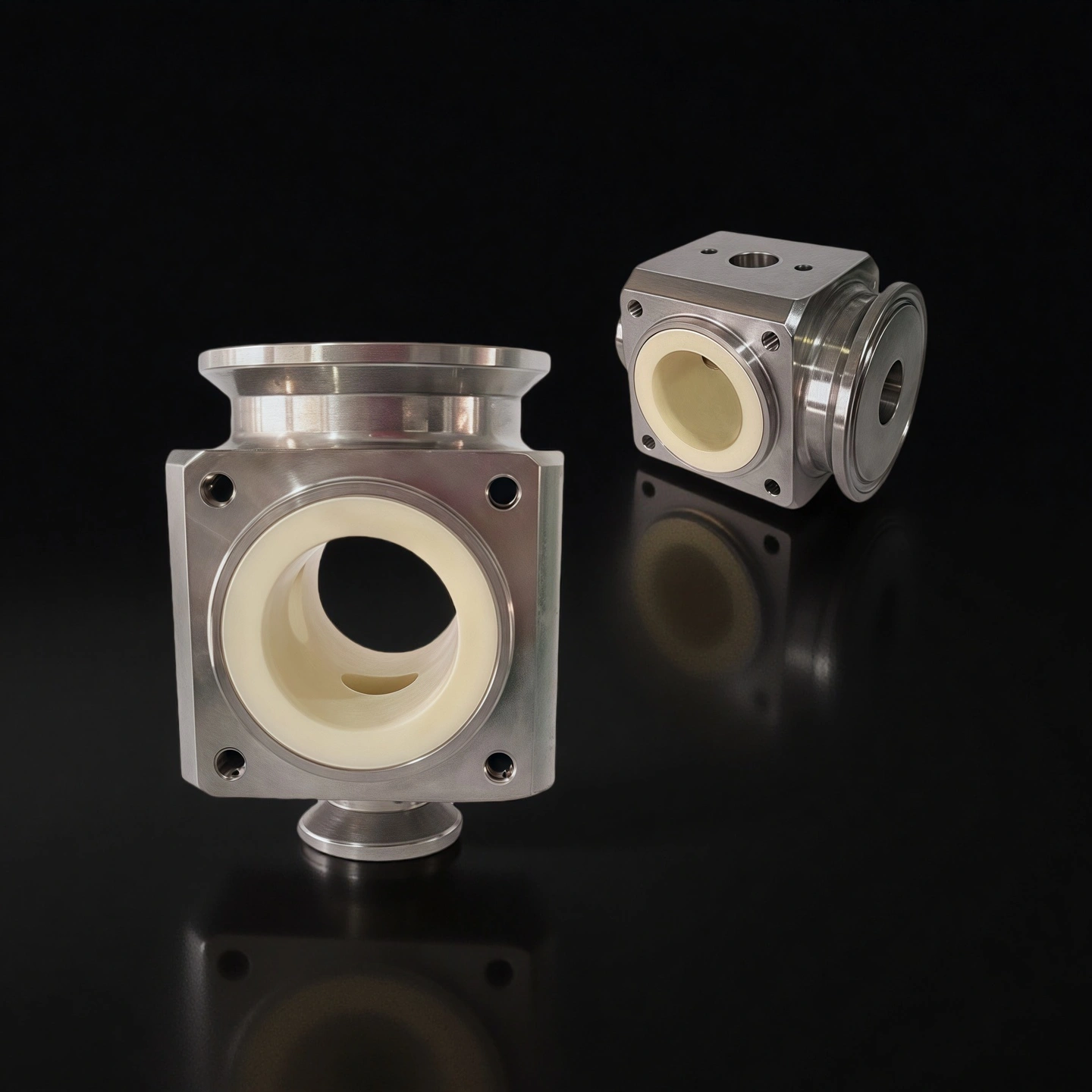

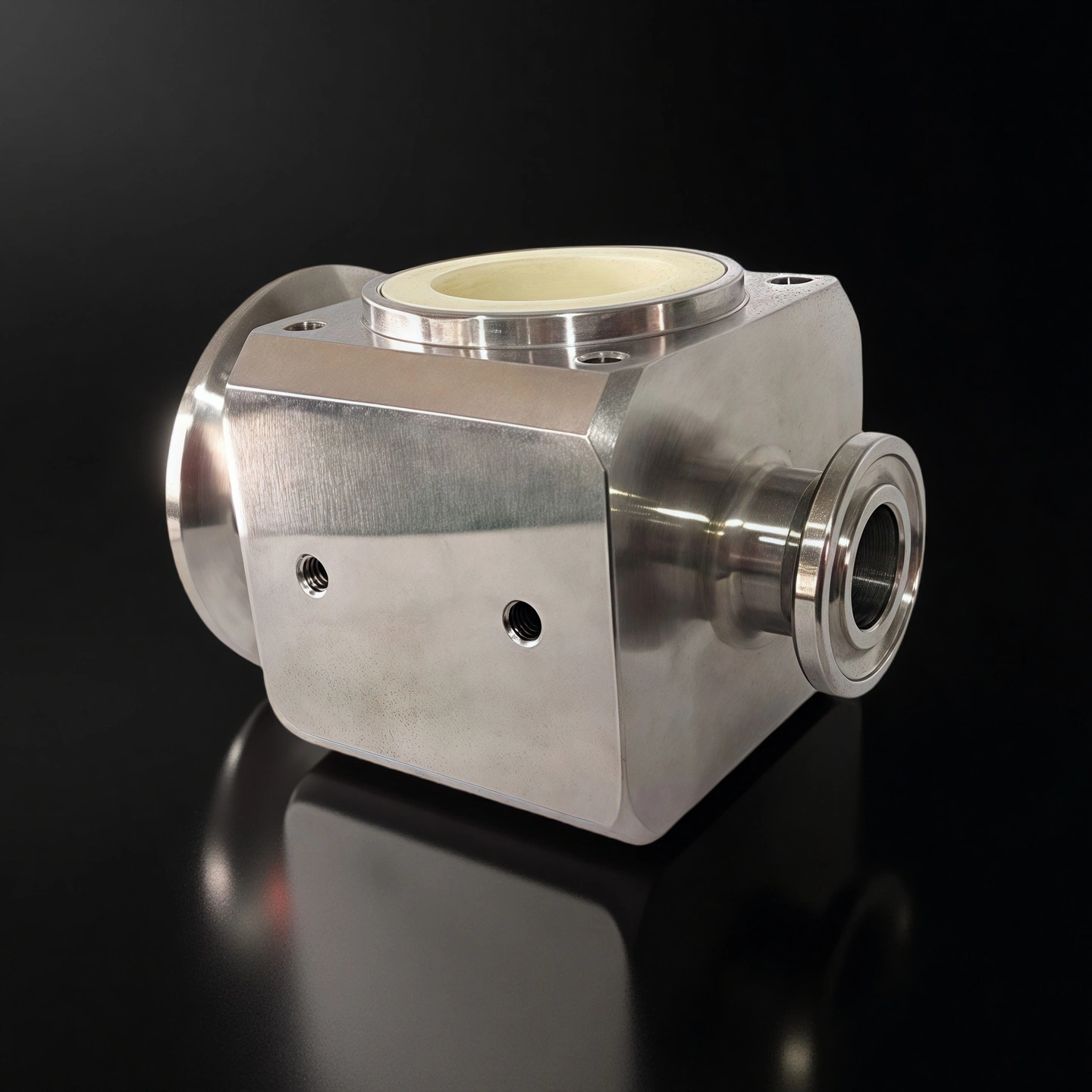

Alumina Ceramic Filling Valve is a precision-engineered component used in liquid dosing and filling systems to control the flow, sealing, and metering of viscous or corrosive media such as creams, gels, flavour concentrates, chemical slurries, or electrolytes.It is typically composed of a ceramic valve core, seat, sleeve, and plunger, made from high-purity alumina (Al₂O₃ ≥99.5%).

Alumina Ceramic Filling Valve Benefits

- Face-lapped ceramic seal pair reduces micro-leakage drift over long duty cycles.

- Tight-tolerance plunger/sleeve supports small stroke volumes without stick-slip.

- High-purity alumina limits ionic contamination into sensitive formulations.

- Custom port geometry & seat profile to match media viscosity and particle loads.

- Thermal stability of the valve stack maintains clearance under CIP/SIP cycles.

Alumina Ceramic Filling Valve Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Filling Valve Specifications

| Item No. | Diameter (mm) | Thickness (mm) | Purity |

| AT-CVC-01 | Customize | ||

Alumina Ceramic Filling Valve Packaging

- Matched valve core + seat sets in protective EPE foam