ADCERAX® Magnesia Stabilized Zirconia Ceramic Tube Single Bore is a durable ceramic solution designed for industries that demand resistance to heat, wear, and corrosion. By using MgO as a stabilizer, it achieves strong fracture toughness and stability under rapid thermal cycling. These tubes are widely applied in furnaces, chemical reactors, hydraulic systems, and energy devices, where long service life and reliable performance are critical. Industrial users choose Magnesia Stabilized Zirconia Tube to reduce downtime, improve efficiency, and maintain consistent operating conditions.

Features of Magnesia Stabilized Zirconia Tube Single Bore

The Magnesia Stabilized Zirconia Ceramic Tube Single Bore delivers measurable performance benefits for industrial users who require reliable operation under demanding thermal and chemical conditions. Its properties are validated by data on strength, density, and thermal shock resistance, making it a trusted material across metallurgy, chemical, and energy applications.

- Flexural strength reaches 500–900 MPa, ensuring durability under load.

- Density is stable at 5.7–6.0 g/cm³, reducing fracture risks.

- Impact resistance supports long-term furnace and sensor applications.

- Tubes withstand rapid temperature changes of ΔT 450–600°C.

- Performance remains reliable at 1000–1800°C in industrial furnaces.

- Resilience extends component life by up to 2–3 times compared with alumina.

Technical Properties for Magnesia Stabilized Zirconia Tube Single Bore

ADCERAX® Magnesia Stabilized Zirconia Ceramic Tube Single Bore is engineered for applications requiring high mechanical strength, chemical stability, and resistance to extreme thermal cycling. This section provides comprehensive technical parameters that industrial buyers and engineers rely on when comparing material performance. The data covers physical, thermal, chemical, and mechanical indicators, and is closely linked with the detailed size and dimension tables available for each catalogue model.

| Property |

Specification |

| Density |

5.7–6.0 g/cm³ |

| Flexural Strength (MOR) |

500–900 MPa |

| Fracture Toughness (KIC) |

6–8 MPa·m½ |

|

|

11–12 GPa |

| Thermal Expansion |

10–11 ×10⁻⁶/K (20–1000°C)

|

Maximum Service Temperature

|

1800–2100°C |

|

|

|

|

|

Stable in acids and alkalis, non-wetting by molten metals

|

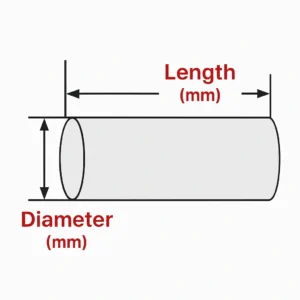

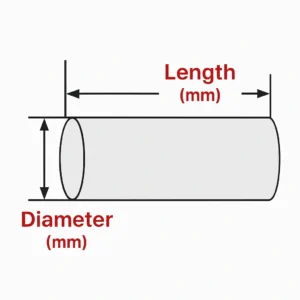

Dimensions of Magnesia Stabilized Zirconia Tube Single Bore

Magnesia Stabilized Zirconia Tube

|

Model |

Outer Diameter(mm) |

Inner Diameter(mm) |

Length(mm) |

|

AT-MGO-G1001 |

3 |

1 |

20 |

|

AT-MGO-G1002 |

10 |

5 |

20 |

|

AT-MGO-G1003 |

15 |

7 |

25 |

|

AT-MGO-G1004 |

30 |

20 |

45 |

|

AT-MGO-G1005 |

40 |

32 |

50 |

|

AT-MGO-G1006 |

62.5 |

52.5 |

87 |

Packaging of Magnesia Stabilized Zirconia Tube Single Bore

Each Magnesia Stabilized Zirconia Tube Single Bore is protected with foam partitions to prevent surface damage during handling. The tubes are further packed in reinforced cartons and then secured in wooden crates for safe international transport. This ensures that every ADCERAX® MSZ Tube Single Bore arrives intact and ready for industrial use.

Solving Application Challenges with ADCERAX® Magnesia Stabilized Zirconia Tube Single Bore

The Magnesia Stabilized Zirconia Ceramic Tube Single Bore addresses real engineering problems where conventional ceramics such as alumina fail to deliver reliable performance. By combining high fracture toughness, excellent corrosion resistance, and stability under thermal cycling, it provides practical solutions in advanced industrial sectors.

-

Metallurgical Thermocouple Protection

✅Key Advantages

1. KIC 6–8 MPa·m½ crack resistance — Inhibits crack propagation during 1600 °C immersion and repeated air quench cycles.

2. ΔT 450–600 °C thermal-shock endurance — Survives rapid heat–cool cycles at the slag–metal interface without tube failure.

3. 500–900 MPa flexural strength — Resists bending and impact during probe insertion and stirring in molten baths.

✅ ️Problem Solved

A steel mill replacing alumina sleeves with ADCERAX® Magnesia Stabilized Zirconia Tube cut probe failure from 12%/month to 3%/month. Mean time between failures rose from 2.1 to 4.4 weeks across three blast furnaces. Unplanned furnace interruptions fell by 28%, and temperature control variance tightened from ±18 °C to ±7 °C. Annualized downtime costs dropped by a mid-five-figure USD amount.

-

Chemical Process Equipment Protection

✅Key Advantages

1. 2–4 wt% MgO phase stabilization — Prevents tetragonal-to-monoclinic transformation under hot acids/alkalis, preserving integrity.

2. 900–1200 °C continuous service — Maintains mechanical performance in chlorination and leaching units at process temperatures.

3. ΔT 450–600 °C shock tolerance in corrosives — Limits stress-cracking during start–stop and cleaning cycles.

✅ ️Problem Solved

A chlorination reactor line adopted ADCERAX® Magnesia Partially Stabilized Zirconia (Mg-PSZ) Tube for sleeves and liners. Quarterly replacements due to chemical erosion dropped to once per year. Unplanned maintenance hours decreased by 32 h per quarter, and off-spec contamination events declined by 60%. Total maintenance spend on liners fell by ~35% year over year.

-

Energy Conversion Systems

✅Key Advantages

1. KIC 6–8 MPa·m½ for redox cycling — Withstands repeated oxidation–reduction cycles without edge or end-cap cracking.

2. 10–11 ×10⁻⁶/K thermal expansion — Matches stack seals and housings to reduce mismatch stresses across >600 °C gradients.

3. Up to 1800–2100 °C service ceiling — Handles reformer hotspots and SOFC thermal ramps without structural loss.

✅ ️Problem Solved

An SOFC integrator replacing legacy ceramics with ADCERAX® MSZ Tube extended stack life from ~300 to ~820 thermal cycles before service. Stack availability improved by 14%, while tube replacement intervals more than doubled. Measured efficiency decay over a 500-cycle run improved from 4.2% to 1.7%. Field service calls associated with tube fractures were reduced by 45% over 12 months.

User Guide for Magnesia Stabilized Zirconia Tube Single Bore

The Magnesia Stabilized Zirconia Ceramic Tube Single Bore requires proper handling, operation, and maintenance to achieve its full service life. This guide provides practical recommendations from storage to daily use, helping customers minimize risks, avoid downtime, and ensure consistent performance in industrial environments.

-

Storage and Handling

1. Store in a clean, dry environment to prevent moisture absorption.

2. Handle with padded gloves to avoid surface scratches or micro-cracks.

3. Keep tubes separated with soft packing to avoid edge impact.

-

Installation Practices

1. Ensure fittings and housings are aligned to reduce stress points.

2. Preheat gradually when introducing tubes to furnace environments.

3. Avoid sudden temperature exposure during installation stages.

-

Operating Recommendations

1. Limit rapid immersion into liquids after high-temperature use.

2. Monitor operating cycles to avoid exceeding ΔT 600°C thresholds.

3. Replace immediately if performance degradation is detected.

-

Maintenance and Service

1. Clean with non-abrasive methods to preserve smooth surfaces.

2. Avoid exposure to hydrofluoric acid or highly reactive fluoride salts.

3. Request engineering consultation for custom maintenance strategies.