ADCERAX® Silicon Carbide Bearing is engineered for operating conditions where temperature fluctuations, corrosive media, and continuous high-speed rotation place sustained demands on stability and material integrity. Its microstructure, built on dense SiC grains with low thermal expansion and high thermal conductivity, supports consistent mechanical behavior across extended cycles in chemical processing, high-temperature machinery, and precision motion systems.

Performance Characteristics of Silicon Carbide Bearing

- Hardness HV2300–2700 ensures low abrasion even under continuous particle-rich operation. It preserves bearing geometry during extended cycling.

- Elastic modulus ~410 GPa limits deformation under radial and axial loads. High stiffness maintains predictable contact patterns at varying speeds.

- Porosity <1% supports consistent load transfer across the SiC lattice. Dense microstructure prevents crack initiation during high-frequency vibration.

- Operating stability up to 1300°C prevents softening or microstructural collapse in furnace and metallurgical systems. Material phase stability remains constant.

- Thermal conductivity 80–120 W/m·K dissipates frictional heat efficiently. Heat removal lowers localized surface stress.

- Thermal expansion 4.0–4.5×10⁻⁶/K limits clearance variation during operation. Minimal expansion protects against jamming in tight-tolerance housings.

- Compatibility with strong acids and alkalis (H₂SO₄, HCl, NaOH) prevents structural loss during continuous exposure. Chemical resistance protects contact surfaces.

- Oxidation resistance >1400°C maintains surface integrity in oxidizing atmospheres. Stable oxide films reduce reaction-driven degradation.

- Wear rate significantly lower than steel under slurry conditions as demonstrated in multiple tribology studies. Reduced abrasion maintains long-term rolling quality.

Technical Specifications of Silicon Carbide Bearing

Designed for demanding thermal, mechanical, and chemical environments, Silicon Carbide Bearing exhibits stable structural behavior and predictable performance characteristics derived from its dense microstructure, high hardness, and resistance to thermal and chemical degradation.

| Material Composition | ≥98% SiC (SSiC) / Si-infiltrated SiC (RBSiC) |

| Density | 3.10–3.20 g/cm³ |

| Hardness | HV2300–2700 |

| Flexural Strength | 350–450 MPa (SSiC up to ~500 MPa) |

| Elastic Modulus | ~410 GPa |

| Thermal Conductivity | 80–120 W/m·K |

| Thermal Expansion Coefficient | 4.0–4.5×10⁻⁶/K |

| Maximum Operating Temperature | 1300°C (short excursion up to 1400°C) |

| Oxidation Resistance Threshold | >1400°C |

| Chemical Resistance | Stable in H₂SO₄, HCl, NaOH, chloride media, organic solvents |

| Porosity | <1% closed porosity |

| Wear Performance | Much lower abrasion rate than steel in slurry media |

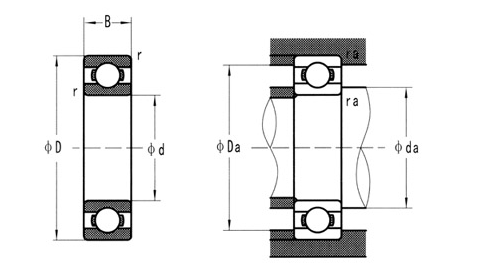

Dimensions of Silicon Carbide Bearing

| Silicon Carbide Bearing | ||||||||

| Item NO. | Product Size | r (Min) | Install Size | |||||

| d(Inner Dia) | D(Outer Dia) | B(Height) | da (Min) | Max | Max | Max | ||

| AT-SIC-ZC684CE | 4 | 9 | 2.5 | 0.1 | 4.8 | / | 8.2 | 0.1 |

| AT-SIC-ZC694CE | 4 | 11 | 4 | 0.15 | 5.2 | / | 9.8 | 0.15 |

| AT-SIC-ZC604CE | 4 | 12 | 4 | 0.2 | 5.6 | / | 10.4 | 0.2 |

| AT-SIC-ZC624CE | 4 | 13 | 5 | 0.2 | 5.6 | / | 11.4 | 0.2 |

| AT-SIC-ZC634CE | 4 | 16 | 5 | 0.3 | 6 | / | 14 | 0.3 |

| AT-SIC-ZC685CE | 5 | 11 | 3 | 0.15 | 6.2 | / | 9.8 | 0.15 |

| AT-SIC-ZC695CE | 5 | 13 | 4 | 0.2 | 6.6 | / | 11.4 | 0.2 |

| AT-SIC-ZC605CE | 5 | 14 | 5 | 0.2 | 6.6 | / | 12.4 | 0.2 |

| AT-SIC-ZC625CE | 5 | 16 | 5 | 0.3 | 7 | / | 14 | 0.3 |

| AT-SIC-ZC635CE | 5 | 19 | 6 | 0.3 | 7 | / | 17 | 0.3 |

| AT-SIC-ZC686CE | 6 | 13 | 3.5 | 0.15 | 7.2 | / | 11.8 | 0.15 |

| AT-SIC-ZC696CE | 7 | 15 | 5 | 0.2 | 7.6 | / | 13.4 | 0.2 |

| AT-SIC-ZC606CE | 8 | 17 | 6 | 0.3 | 8 | / | 15 | 0.3 |

| AT-SIC-ZC626CE | 9 | 19 | 6 | 0.3 | 8 | / | 17 | 0.3 |

| AT-SIC-ZC636CE | 10 | 22 | 7 | 0.3 | 8 | / | 20 | 0.3 |

| AT-SIC-ZC687CE | 7 | 14 | 3.5 | 0.15 | 8.2 | / | 12.8 | 0.15 |

| AT-SIC-ZC697CE | 7 | 17 | 5 | 0.3 | 9 | / | 15 | 0.3 |

| AT-SIC-ZC607CE | 7 | 19 | 6 | 0.3 | 9 | / | 17 | 0.3 |

| AT-SIC-ZC627CE | 7 | 22 | 7 | 0.3 | 9 | / | 20 | 0.3 |

| AT-SIC-ZC637CE | 7 | 26 | 9 | 0.3 | 9 | / | 24 | 0.3 |

| AT-SIC-ZC688CE | 8 | 16 | 4 | 0.2 | 9.6 | / | 14.4 | 0.2 |

| AT-SIC-ZC698CE | 8 | 19 | 6 | 0.3 | 10 | / | 17 | 0.3 |

| AT-SIC-ZC608CE | 8 | 22 | 7 | 0.3 | 10 | / | 20 | 0.3 |

| AT-SIC-ZC628CE | 8 | 24 | 8 | 0.3 | 10 | / | 22 | 0.3 |

| AT-SIC-ZC638CE | 8 | 28 | 9 | 0.3 | 10 | / | 26 | 0.3 |

| AT-SIC-ZC689CE | 9 | 17 | 4 | 0.2 | 10.6 | / | 15.4 | 0.2 |

| AT-SIC-ZC699CE | 9 | 20 | 6 | 0.3 | 11 | / | 18 | 0.3 |

| AT-SIC-ZC609CE | 9 | 24 | 7 | 0.3 | 11 | / | 22 | 0.3 |

| AT-SIC-ZC629CE | 9 | 26 | 8 | 0.3 | 11 | / | 24 | 0.3 |

| AT-SIC-ZC639CE | 9 | 30 | 10 | 0.6 | 13 | / | 26 | 0.6 |

| AT-SIC-ZC6800CE | 10 | 19 | 5 | 0.3 | 12 | 12 | 17 | 0.3 |

| AT-SIC-ZC6900CE | 10 | 22 | 6 | 0.3 | 12 | 12.5 | 20 | 0.3 |

| AT-SIC-ZC6000CE | 10 | 26 | 8 | 0.3 | 12 | 13 | 24 | 0.3 |

| AT-SIC-ZC6200CE | 10 | 30 | 9 | 0.6 | 14 | 16 | 26 | 0.6 |

| AT-SIC-ZC6300CE | 10 | 35 | 11 | 0.6 | 14 | 16.5 | 31 | 0.6 |

| AT-SIC-ZC6801CE | 12 | 21 | 5 | 0.3 | 14 | 14 | 19 | 0.3 |

| AT-SIC-ZC6901CE | 12 | 24 | 6 | 0.3 | 14 | 14.5 | 22 | 0.3 |

| AT-SIC-ZC16001CE | 12 | 28 | 7 | 0.3 | 14 | / | 26 | 0.3 |

| AT-SIC-ZC6001CE | 12 | 28 | 8 | 0.3 | 14 | 15.5 | 26 | 0.3 |

| AT-SIC-ZC6201CE | 12 | 32 | 10 | 0.6 | 16 | 17 | 28 | 0.6 |

| AT-SIC-ZC6301CE | 12 | 37 | 12 | 1 | 17 | 18 | 32 | 1 |

| AT-SIC-ZC6802CE | 15 | 24 | 5 | 0.3 | 17 | 17 | 22 | 0.3 |

| AT-SIC-ZC6902CE | 15 | 28 | 7 | 0.3 | 17 | 17 | 26 | 0.3 |

| AT-SIC-ZC16002CE | 15 | 32 | 8 | 0.3 | 17 | / | 30 | 0.3 |

| AT-SIC-ZC6002CE | 15 | 32 | 9 | 0.3 | 17 | 19 | 30 | 0.3 |

| AT-SIC-ZC6202CE | 15 | 35 | 11 | 0.6 | 19 | 20.5 | 31 | 0.3 |

| AT-SIC-ZC6302CE | 15 | 42 | 13 | 1 | 20 | 22.5 | 37 | 1 |

| AT-SIC-ZC6803CE | 17 | 26 | 5 | 0.3 | 19 | 19 | 24 | 0.3 |

| AT-SIC-ZC6903CE | 17 | 30 | 7 | 0.3 | 19 | 19.5 | 28 | 0.3 |

| AT-SIC-ZC16003CE | 17 | 35 | 8 | 0.3 | 19 | / | 33 | 0.3 |

| AT-SIC-ZC6003CE | 17 | 35 | 10 | 0.3 | 19 | 21.5 | 33 | 0.3 |

| AT-SIC-ZC6203CE | 17 | 40 | 12 | 0.6 | 21 | 23.5 | 36 | 0.6 |

| AT-SIC-ZC6303CE | 17 | 47 | 14 | 1 | 22 | 25.5 | 42 | 1 |

| AT-SIC-ZC6403CE | 17 | 62 | 17 | 1.1 | 23.5 | / | 55.5 | 1 |

| AT-SIC-ZC6804CE | 20 | 32 | 7 | 0.3 | 22 | 22.5 | 30 | 0.3 |

| AT-SIC-ZC6904CE | 20 | 37 | 9 | 0.3 | 22 | 24 | 35 | 0.3 |

| AT-SIC-ZC16004CE | 20 | 42 | 8 | 0.3 | 22 | / | 40 | 0.3 |

| AT-SIC-ZC6004CE | 20 | 42 | 12 | 0.6 | 24 | 25.5 | 38 | 0.6 |

| AT-SIC-ZC6204CE | 20 | 47 | 14 | 1 | 25 | 26.5 | 42 | 1 |

| AT-SIC-ZC6304CE | 20 | 52 | 15 | 1.1 | 26.5 | 28 | 45.5 | 1 |

| AT-SIC-ZC6404CE | 20 | 72 | 19 | 1.1 | 26.5 | / | 65.5 | 1 |

| AT-SIC-ZC6805CE | 25 | 37 | 7 | 0.3 | 27 | 27 | 35 | 0.3 |

| AT-SIC-ZC6905CE | 25 | 42 | 9 | 0.3 | 27 | 28.5 | 40 | 0.3 |

| AT-SIC-ZC16005CE | 25 | 47 | 8 | 0.3 | 27 | / | 45 | 0.3 |

| AT-SIC-ZC6005CE | 25 | 47 | 12 | 0.6 | 29 | 30 | 43 | 0.6 |

| AT-SIC-ZC6205CE | 25 | 52 | 15 | 1 | 30 | 32 | 47 | 1 |

| AT-SIC-ZC6305CE | 25 | 62 | 17 | 1.1 | 31.5 | 36 | 55.5 | 1 |

| AT-SIC-ZC6405CE | 25 | 80 | 21 | 1.5 | 33 | / | 72 | 1.5 |

| AT-SIC-ZC6806CE | 30 | 42 | 7 | 0.3 | 32 | 32 | 50 | 1 |

| AT-SIC-ZC6906CE | 30 | 47 | 9 | 0.3 | 32 | 34 | 57 | 1 |

| AT-SIC-ZC16006CE | 30 | 55 | 9 | 0.3 | 32 | 42.5 | 65.5 | 1 |

| AT-SIC-ZC6006CE | 30 | 55 | 13 | 1 | 35 | 36.5 | 53 | 1 |

| AT-SIC-ZC6206CE | 30 | 62 | 16 | 1 | 35 | 38.5 | 60 | 1 |

| AT-SIC-ZC6306CE | 30 | 72 | 19 | 1.1 | 36.5 | 42.5 | 68.5 | 1 |

| AT-SIC-ZC6406CE | 30 | 90 | 23 | 1.5 | 54 | / | 82 | 2 |

| AT-SIC-ZC6807CE | 35 | 47 | 7 | 0.3 | 37 | 37 | 45 | 0.3 |

| AT-SIC-ZC6907CE | 35 | 55 | 10 | 0.6 | 39 | 39 | 51 | 0.6 |

| AT-SIC-ZC16007CE | 35 | 62 | 9 | 0.3 | 37 | / | 60 | 0.3 |

| AT-SIC-ZC6007CE | 35 | 62 | 14 | 1 | 40 | 41.5 | 57 | 1 |

| AT-SIC-ZC6207CE | 35 | 72 | 17 | 1.1 | 41.5 | 44.5 | 65.5 | 1 |

| AT-SIC-ZC6307CE | 35 | 80 | 21 | 1.5 | 43 | 47 | 72 | 1.5 |

| AT-SIC-ZC6407CE | 35 | 100 | 25 | 1.5 | 43 | / | 92 | 1.5 |

| AT-SIC-ZC6808CE | 40 | 52 | 7 | 0.3 | 42 | 42 | 50 | 0.3 |

| AT-SIC-ZC6908CE | 40 | 62 | 12 | 0.6 | 44 | 46 | 58 | 0.6 |

| AT-SIC-ZC16008CE | 40 | 68 | 9 | 0.3 | 42 | / | 66 | 0.3 |

| AT-SIC-ZC6008CE | 40 | 68 | 15 | 1 | 45 | 47.5 | 63 | 1 |

| AT-SIC-ZC6208CE | 40 | 80 | 18 | 1.1 | 46.5 | 50.5 | 73.5 | 1 |

| AT-SIC-ZC6308CE | 40 | 90 | 23 | 1.5 | 48 | 53 | 80 | 1.5 |

| AT-SIC-ZC6408CE | 40 | 110 | 27 | 2 | 49 | / | 101 | 2 |

| AT-SIC-ZC6809CE | 45 | 58 | 7 | 0.3 | 47 | 47.5 | 56 | 0.3 |

| AT-SIC-ZC6909CE | 45 | 68 | 12 | 0.6 | 49 | 50 | 64 | 0.6 |

| AT-SIC-ZC16009CE | 45 | 75 | 10 | 0.6 | 49 | / | 71 | 0.6 |

| AT-SIC-ZC6009CE | 45 | 75 | 16 | 1 | 50 | 53.5 | 70 | 1 |

| AT-SIC-ZC6209CE | 45 | 85 | 19 | 1.1 | 51.5 | 55.5 | 78.5 | 1 |

| AT-SIC-ZC6309CE | 45 | 100 | 25 | 1.5 | 53 | 61.5 | 92 | 1.5 |

| AT-SIC-ZC6409CE | 45 | 120 | 29 | 2 | 54 | / | 111 | 2 |

| AT-SIC-ZC6810CE | 50 | 65 | 7 | 0.3 | 52 | 52.5 | 63 | 0.3 |

| AT-SIC-ZC6910CE | 50 | 72 | 12 | 0.6 | 54 | 55 | 68 | 0.6 |

| AT-SIC-ZC16010CE | 50 | 80 | 10 | 0.6 | 54 | / | 76 | 0.6 |

| AT-SIC-ZC6010CE | 50 | 80 | 16 | 1 | 55 | 58.5 | 75 | 1 |

| AT-SIC-ZC6210CE | 50 | 90 | 20 | 1.1 | 56.5 | 60 | 83.2 | 1 |

| AT-SIC-ZC6310CE | 50 | 110 | 27 | 2 | 59 | 68 | 101 | 2 |

| AT-SIC-ZC6410CE | 50 | 130 | 31 | 2.1 | 61 | / | 119 | 2 |

| AT-SIC-ZC6811CE | 55 | 72 | 9 | 0.3 | 57 | 59 | 70 | 0.3 |

| AT-SIC-ZC6911CE | 55 | 80 | 13 | 1 | 60 | 61.5 | 75 | 1 |

| AT-SIC-ZC16011CE | 55 | 90 | 11 | 0.6 | 59 | / | 86 | 0.6 |

| AT-SIC-ZC6011CE | 55 | 90 | 18 | 1.1 | 61.5 | 64 | 83.5 | 1 |

| AT-SIC-ZC6211CE | 55 | 100 | 21 | 1.5 | 63 | 66.5 | 92 | 1.5 |

| AT-SIC-ZC6311CE | 55 | 120 | 29 | 2 | 64 | 72.5 | 111 | 2 |

| AT-SIC-ZC6411CE | 55 | 140 | 33 | 2.1 | 66 | / | 129 | 2 |

| AT-SIC-ZC6812CE | 60 | 78 | 10 | 0.3 | 62 | 64 | 76 | 0.3 |

| AT-SIC-ZC6912CE | 60 | 85 | 13 | 1 | 65 | 66 | 80 | 1 |

| AT-SIC-ZC16012CE | 60 | 95 | 11 | 0.6 | 64 | / | 91 | 0.6 |

| AT-SIC-ZC6012CE | 60 | 95 | 18 | 1.1 | 66.5 | 69 | 88.5 | 1 |

| AT-SIC-ZC6212CE | 60 | 110 | 22 | 1.5 | 68 | 74.5 | 102 | 1.5 |

| AT-SIC-ZC6312CE | 60 | 130 | 31 | 2.1 | 71 | 79 | 119 | 2 |

| AT-SIC-ZC6412CE | 60 | 150 | 35 | 2.1 | 71 | 139 | 2 | |

| AT-SIC-ZC6813CE | 65 | 85 | 10 | 0.6 | 69 | 69 | 81 | 0.6 |

| AT-SIC-ZC6913CE | 65 | 90 | 13 | 1 | 70 | 71.5 | 85 | 1 |

| AT-SIC-ZC16013CE | 65 | 100 | 11 | 0.6 | 69 | / | 96 | 0.6 |

| AT-SIC-ZC6013CE | 65 | 100 | 18 | 1.1 | 71.5 | 73 | 93.5 | 1 |

| AT-SIC-ZC6213CE | 65 | 120 | 23 | 1.5 | 73 | 80 | 112 | 1.5 |

| AT-SIC-ZC6313CE | 65 | 140 | 33 | 2.1 | 76 | 85.5 | 129 | 2 |

| AT-SIC-ZC6814CE | 70 | 90 | 10 | 0.6 | 74 | 74.5 | 86 | 0.6 |

| AT-SIC-ZC6914CE | 70 | 100 | 16 | 1 | 75 | 77.5 | 95 | 1 |

| AT-SIC-ZC16014CE | 70 | 110 | 13 | 0.6 | 74 | / | 106 | 0.6 |

| AT-SIC-ZC6014CE | 70 | 110 | 20 | 1.1 | 76.5 | 80.5 | 103.5 | 1 |

| AT-SIC-ZC6214CE | 70 | 125 | 24 | 1.5 | 78 | 84 | 117 | 1.5 |

| AT-SIC-ZC6314CE | 70 | 150 | 35 | 2.1 | 81 | 92 | 139 | 2 |

| AT-SIC-ZC6815CE | 75 | 95 | 10 | 0.6 | 79 | 79.5 | 91 | 0.6 |

| AT-SIC-ZC6915CE | 75 | 105 | 16 | 1 | 80 | 82 | 100 | 1 |

| AT-SIC-ZC16015CE | 75 | 115 | 13 | 0.6 | 79 | / | 111 | 0.6 |

| AT-SIC-ZC6015CE | 75 | 115 | 20 | 1.1 | 81.5 | 85.5 | 108.5 | 1 |

| AT-SIC-ZC6215CE | 75 | 130 | 25 | 1.5 | 83 | 90 | 122 | 1.5 |

| AT-SIC-ZC6816CE | 80 | 100 | 10 | 0.6 | 84 | 84.5 | 96 | 0.6 |

| AT-SIC-ZC6916CE | 80 | 110 | 16 | 1 | 85 | 87.5 | 105 | 1 |

| AT-SIC-ZC16016CE | 80 | 125 | 14 | 0.6 | 84 | / | 121 | 0.6 |

| AT-SIC-ZC6016CE | 80 | 125 | 22 | 1.1 | 86.5 | 91 | 118.5 | 1 |

| AT-SIC-ZC6216CE | 80 | 140 | 26 | 2 | 89 | 95.5 | 131 | 2 |

| AT-SIC-ZC6817CE | 85 | 110 | 13 | 1 | 90 | 90.5 | 105 | 1 |

| AT-SIC-ZC6917CE | 85 | 120 | 18 | 1.1 | 91.5 | 94.5 | 113.5 | 1 |

| AT-SIC-ZC16017CE | 85 | 130 | 14 | 0.6 | 89 | / | 126 | 0.6 |

| AT-SIC-ZC6017CE | 85 | 130 | 22 | 1.1 | 91.5 | 96 | 123.5 | 1 |

| AT-SIC-ZC6217CE | 85 | 150 | 28 | 2 | 94 | 102 | 141 | 2 |

| AT-SIC-ZC6818CE | 90 | 115 | 13 | 1 | 95 | 95.5 | 110 | 1 |

| AT-SIC-ZC6918CE | 90 | 125 | 18 | 1.1 | 96.5 | 98.5 | 118.5 | 1 |

| AT-SIC-ZC16018CE | 90 | 140 | 16 | 1 | 95 | / | 135 | 1 |

| AT-SIC-ZC6018CE | 90 | 140 | 24 | 1.5 | 98 | 103 | 132 | 1.5 |

| AT-SIC-ZC6819CE | 95 | 120 | 13 | 1 | 100 | 102 | 115 | 1 |

| AT-SIC-ZC6919CE | 95 | 130 | 18 | 1.1 | 101.5 | 104 | 123.5 | 1 |

| AT-SIC-ZC16019CE | 95 | 145 | 16 | 1 | 100 | / | 140 | 1 |

| AT-SIC-ZC6019CE | 95 | 145 | 24 | 1.5 | 103 | 109 | 137 | 1.5 |

| AT-SIC-ZC6820CE | 100 | 125 | 13 | 1 | 105 | 106 | 120 | 1 |

| AT-SIC-ZC6920CE | 100 | 140 | 20 | 1.1 | 106.5 | 111 | 133.5 | 1 |

| AT-SIC-ZC16020CE | 100 | 150 | 16 | 1 | 105 | / | 145 | 1 |

| AT-SIC-ZC6020CE | 100 | 150 | 24 | 1.5 | 108 | 113 | 142 | 1.5 |

| AT-SIC-ZC6821CE | 105 | 130 | 13 | 1 | 110 | 111 | 125 | 1 |

| AT-SIC-ZC6921CE | 105 | 145 | 20 | 1.1 | 111.5 | 116 | 138.5 | 1 |

| AT-SIC-ZC6822CE | 110 | 140 | 16 | 1 | 115 | 117 | 135 | 1 |

| AT-SIC-ZC6922CE | 150 | 20 | 1.1 | 116.5 | 121 | 143.5 | 1 | |

| AT-SIC-ZC6824CE | 120 | 150 | 16 | 1 | 125 | 127 | 145 | 1 |

| AT-SIC-ZC6924 | 120 | 165 | 22 | 1.1 | ||||

| AT-SIC-ZC16024 | 120 | 180 | 19 | 1 | ||||

| AT-SIC-ZC6024 | 120 | 180 | 28 | 2 | ||||

| AT-SIC-ZC6224 | 120 | 215 | 40 | 2.1 | ||||

| AT-SIC-ZC6324 | 120 | 260 | 55 | 3 | ||||

| AT-SIC-ZC6826 | 130 | 165 | 18 | 1.1 | ||||

| AT-SIC-ZC6926 | 130 | 180 | 24 | 1.5 | ||||

| AT-SIC-ZC16026 | 130 | 200 | 22 | 1.1 | ||||

| AT-SIC-ZC6026 | 130 | 200 | 33 | 2 | ||||

| AT-SIC-ZC6226 | 130 | 230 | 40 | 3 | ||||

| AT-SIC-ZC6326 | 130 | 280 | 58 | 4 | ||||

| AT-SIC-ZC6828 | 140 | 175 | 18 | 1.1 | ||||

| AT-SIC-ZC6928 | 140 | 190 | 24 | 1.5 | ||||

| AT-SIC-ZC16028 | 140 | 210 | 22 | 1.1 | ||||

| AT-SIC-ZC6028 | 140 | 210 | 33 | 2 | ||||

| AT-SIC-ZC6228 | 140 | 250 | 42 | 3 | ||||

| AT-SIC-ZC6328 | 140 | 300 | 62 | 4 | ||||

| AT-SIC-ZC6830 | 150 | 190 | 20 | 1.1 | ||||

| AT-SIC-ZC6930 | 150 | 210 | 28 | 2 | ||||

| AT-SIC-ZC16030 | 150 | 225 | 24 | 1.1 | ||||

| AT-SIC-ZC6030 | 150 | 225 | 35 | 2.1 | ||||

| AT-SIC-ZC6230 | 150 | 270 | 45 | 3 | ||||

| AT-SIC-ZC6330 | 150 | 320 | 65 | 4 | ||||

| AT-SIC-ZC60/22 | 22 | 44 | 12 | 0.6 | ||||

| AT-SIC-ZC62/22 | 22 | 50 | 14 | 1 | ||||

| AT-SIC-ZC63/22 | 22 | 56 | 16 | 1.1 | ||||

| AT-SIC-ZC60/28 | 28 | 52 | 12 | 0.6 | ||||

| AT-SIC-ZC62/28 | 28 | 58 | 16 | 1 | ||||

| AT-SIC-ZC63/28 | 28 | 68 | 18 | 1.1 | ||||

| AT-SIC-ZC60/32 | 33 | 58 | 13 | 1 | ||||

| AT-SIC-ZC62/32 | 33 | 65 | 17 | 1 | ||||

| AT-SIC-ZC63/32 | 33 | 75 | 20 | 1.1 | ||||

| AT-SIC-ZC603CE | 3 | 9 | 3 | |||||

| AT-SIC-ZC606CE | 6 | 17 | 6 | |||||

| AT-SIC-ZCMR117 | 7 | 11 | 3 | |||||

| AT-SIC-ZCMR128 | 8 | 12 | 3.5 | |||||

| AT-SIC-ZCMR85 | 5 | 8 | 2.5 | |||||

| AT-SIC-ZCMR63-1 | 3 | 6 | 2.5 | |||||

| AT-SIC-ZCMR85-1 | 5 | 8 | 2 | |||||

| AT-SIC-ZCMR148 | 8 | 14 | 4 | |||||

| AT-SIC-ZCMR84 | 4 | 8 | 2 | |||||

| AT-SIC-ZCMR126 | 6 | 12 | 4 | |||||

| AT-SIC-ZCMR74-1 | 4 | 7 | 2 | |||||

| AT-SIC-ZCMR84-1 | 4 | 8 | 3 | |||||

| AT-SIC-ZCMR74 | 4 | 7 | 2.5 | |||||

| AT-SIC-ZCMR148 | 8 | 14 | 3.5 | |||||

| AT-SIC-ZCMR63 | 3 | 6 | 2 | |||||

| AT-SIC-ZCMR103 | 3 | 10 | 4 | |||||

| AT-SIC-ZCMR104 | 4 | 10 | 4 | |||||

| AT-SIC-ZCMR105 | 5 | 10 | 3 | |||||

| AT-SIC-ZCMR105-1 | 5 | 10 | 4 | |||||

| AT-SIC-ZCMR106 | 6 | 10 | 2.5 | |||||

| AT-SIC-ZCMR106-1 | 6 | 10 | 3 | |||||

| AT-SIC-ZCMR115 | 5 | 11 | 4 | |||||

| AT-SIC-ZCMR52 | 2 | 5 | 2.5 | |||||

| AT-SIC-ZCMR62 | 2 | 6 | 2.5 | |||||

| AT-SIC-ZCMR94 | 4 | 9 | 3 | |||||

| AT-SIC-ZCMR95 | 5 | 9 | 3 | |||||

| AT-SIC-ZCR188 | 6.35 | 12.7 | 4.763 | |||||

| AT-SIC-ZCR6 | 9.525 | 22.225 | 5.556 | |||||

Packaging Method for Silicon Carbide Bearing

Silicon Carbide Bearing is packed through a controlled multi-layer process to protect the components from moisture, impact, and contamination during long-distance transport. Each unit is sealed in protective film, placed into reinforced inner cartons, and consolidated into export-grade outer boxes. The boxed goods are then palletized and wrapped for stability, ensuring consistent handling quality for international shipments.

![]()