ADCERAX® Silicon Carbide Ball Valve is designed for industrial systems that require stable flow control under corrosive, abrasive, and high-temperature operating conditions. Its dense SiC microstructure, combined with polished sealing surfaces, enables consistent performance in applications ranging from chemical processing and power-plant slurry loops to desalination and high-salinity water treatment lines. As equipment in these sectors faces increasing demands for reliability and reduced downtime, the valve supports long service cycles and maintains sealing stability even under fluctuating loads and aggressive media exposure.

Performance Characteristics of Silicon Carbide Ball Valve in Demanding Industrial Environments

-

Dense SiC Matrix

Achieves a porosity level below 0.5%, improving resistance to chemical attack and ensuring sealing stability under aggressive media.

-

Thermal Shock Endurance

Withstands rapid temperature changes exceeding 300°C/min, maintaining shape integrity in fluctuating thermal cycles.

-

Chemical Inertness

Demonstrates zero measurable mass loss in pH 0–14 exposure tests, supporting long-term operation in corrosive chemical environments.

-

Surface Hardness Retention

Maintains hardness above HV 2500, preventing degradation in gypsum, ash, and catalyst-fines applications.

-

Reduced Torque Variation

Shows torque drift below 5% after 100,000 opening–closing cycles, improving actuator efficiency and reliability.

-

Low Friction Sealing

Offers a polished sealing surface below Ra 0.04 μm, minimizing turbulence and maintaining predictable throttling behavior.

-

Leakage Rate Stability

Maintains leakage class performance degradation under 1% over extended cycles, reducing unscheduled shutdowns.

Technical Specifications of Silicon Carbide Ball Valve

The Silicon Carbide Ball Valve is defined by the physical, chemical, and thermal characteristics of its SiC ceramic core, which enables reliable operation in corrosive liquids, abrasive slurries, and high-temperature flow-control environments.

| Property |

Specification |

| Material Grade |

RBSiC / SSiC |

| Density |

3.10–3.15 g/cm³ |

| Open Porosity |

<0.5% |

| Hardness |

HV 2400–2500 |

| Flexural Strength |

380–420 MPa |

| Compressive Strength |

>2000 MPa |

| Thermal Conductivity |

95–120 W/m·K |

| Coefficient of Thermal Expansion |

4.0–4.5 ×10⁻⁶ /K |

| Maximum Service Temperature |

≥1300°C |

| Thermal Shock Resistance |

>300°C/min |

| Acid Resistance |

Mass loss <0.05% in H₂SO₄/HCl |

| Alkali Resistance |

Mass loss <0.03% in NaOH |

| Erosion Resistance |

Wear rate <1.2×10⁻⁶ mm³/N·m |

| Electrical Resistivity |

>10⁵ Ω·cm |

| Surface Roughness (Valve Core) |

Ra 0.02–0.05 μm |

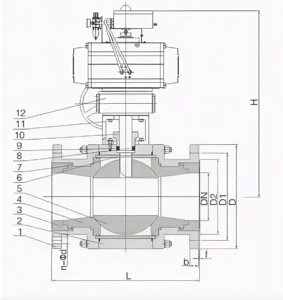

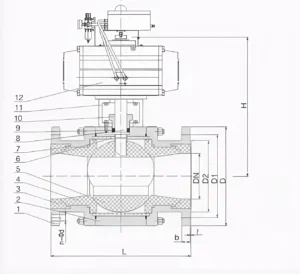

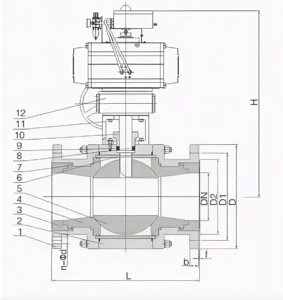

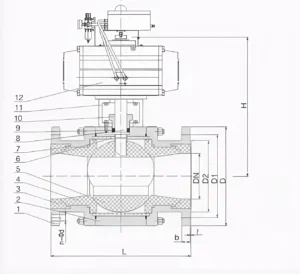

Dimensions of Silicon Carbide Ball Valve

Ceramic Ball Valve Corrosion Resistance Performance Table

| Medium |

Temperature |

95% Alumina |

Silicon Carbide |

Zirconia |

| 20% HCl |

60℃ |

A |

A |

A |

| 95℃ |

A |

A |

A |

| 90% H2SO4 |

60℃ |

A |

A |

A |

| 95℃ |

A |

A |

A |

| 60% H2SO4 |

60℃ |

A |

A |

A |

| 95℃ |

A |

A |

A |

| 10% HF |

60℃ |

N/A |

A |

C |

| 95℃ |

C |

A |

C |

| 60% HNO3 |

60℃ |

N/A |

A |

A |

| 95℃ |

C |

A |

A |

| 30% NaOH |

60℃ |

C |

A |

A |

| 95℃ |

C |

A |

B |

Explanation:

A: < 0.1 mg/cm²/day, indicates that the material is non-corrosive or negligible in the medium, recommended for use.

B: 0.1 ~ 0.3 mg/cm²/day, indicates slight or minor corrosion in the medium, suitable for use.

C: > 0.3 mg/cm²/day, indicates moderate or significant corrosion in the medium, not recommended for use.

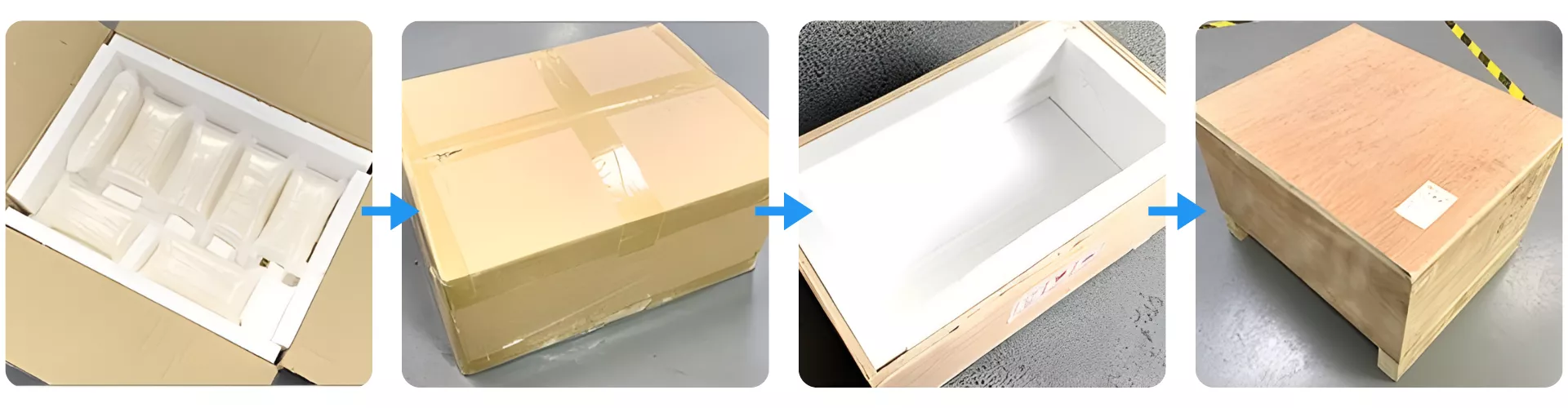

Protective Packaging for Silicon Carbide Ball Valve

The Silicon Carbide Ball Valve is secured using multi-layer packaging designed for international transport and vibration-sensitive logistics. Each unit is first stabilized in a fitted foam chamber, then sealed in a reinforced carton before being placed into a lined wooden crate to prevent impact or moisture intrusion. This packaging method ensures safe arrival for both small-batch shipments and large engineering orders.

ADCERAX® Silicon Carbide Ball Valve Eliminates Industrial Flow-Control Failures in Corrosive, Abrasive, and High-Temperature Systems

ADCERAX® Silicon Carbide Ball Valve supports stable operation in equipment where corrosive chemicals, solids-laden slurries, or rapid thermal fluctuations create severe failure risks for metallic or polymeric valves. These application environments demand long life cycles, predictable sealing stability, and material resilience under aggressive operating conditions, which are consistently achieved through ADCERAX®’s engineered SiC microstructure and surface-finished sealing interfaces.

-

Silicon Carbide Ball Valve in Chloride-Rich Chemical Circulation Loops

✅Key Advantages

1. Pitting-Resistant SiC Surface

The SiC ball and seat maintain a smooth sealing interface with total mass loss kept below 0.05% in accelerated chloride exposure testing. This stability limits surface roughening and helps keep torque growth within 10% over extended operation.

2. Stable Sealing Under Thermal Cycling

In simulated reactor conditions, the valve endures more than 500 temperature cycles between low and elevated operating temperatures without a measurable change in leakage class. This behavior reduces the risk of seal deformation that typically appears in metal valves under repeated thermal swings.

3. Controlled Torque Growth Over Long Campaigns

Cycle-testing shows that actuation torque increase can be restricted to 5–8% after 50,000 open–close cycles in chloride-intensive service. This performance contrasts with metal valves, where torque escalation often exceeds 30%, leading to inconsistent modulation and actuator overload.

✅ ️Problem Solved

In a chlorinated solvent and inorganic salt loop, metal ball valves had to be inspected every few weeks due to pitting, with torque drift and leakage becoming evident after a few thousand cycles. Chloride concentration and oxidizing agents accelerated surface attack, and thermal cycling between reaction and standby states pushed sealing faces out of shape. After replacing these units with ADCERAX® Silicon Carbide Ball Valves, inspection intervals were extended to more than six months, while recorded torque variation stayed below 10% across comparable operating hours. Leakage incidents dropped sharply, and batch sequence interruptions caused by valve instability were reduced by more than 50% over the next production campaign.

-

Silicon Carbide Ball Valve for Limestone–Gypsum Slurry in FGD and Ash-Handling Systems

✅Key Advantages

1. Low Erosion Depth in High-Solids Slurry

Erosion tests with limestone–gypsum slurry show surface wear depths remaining under 0.10 mm after the equivalent of 1,000 operating hours. This performance delays groove formation that would otherwise disturb flow and compromise shut-off capability.

2. Stable Cv Under Particle Impact

Flow-coefficient measurements indicate Cv drift within ±3% after prolonged exposure to slurry streams containing more than 10% suspended solids. This allows absorber and recirculation loops to maintain predictable pressure profiles without frequent recalibration.

3. Extended Cycle Life in FGD Duty

Endurance trials in simulated FGD conditions demonstrate that the SiC ball and seat can sustain over 100,000 cycles without visible edge chipping or loss of sealing line. Compared with conventional metal valves, which often require replacement after a fraction of that duty, this extends planned maintenance windows by a factor of 3–4.

✅ ️Problem Solved

In a wet FGD installation handling limestone–gypsum slurry, metal valves in the recirculation loop developed deep erosion grooves within one heating season, causing unstable throttling and difficulty reaching target absorber pressure. As solids loading increased, differential pressure across the valves rose and shut-off performance deteriorated, forcing unscheduled maintenance stops. After the plant introduced ADCERAX® Silicon Carbide Ball Valves in the high-solids sections, Cv drift stayed within ±3% over the same operating period, and visual inspection showed only shallow surface wear. Maintenance intervals for these positions were extended to span multiple seasons, and the number of slurry-related valve replacements was reduced by more than 60%.

-

Silicon Carbide Ball Valve in Desalination Brine Management and High-Salinity Wastewater Lines

✅Key Advantages

1. Chloride-Resistant Sealing in Concentrated Brine

Tests in high-salinity brine show no detectable pitting on SiC sealing faces after more than 1,000 hours of immersion under circulation conditions. This stability preserves smooth actuation and prevents the localized damage that often initiates bypass flow in alloy-based valves.

2. Dimensional Stability Under Thermal and Chemical Cleaning Cycles

Thermal and chemical cycling, including exposure to oxidizing cleaning agents, results in negligible dimensional change with axial distortion kept below 0.01 mm on critical sealing zones. This supports consistent shut-off and avoids the progressive misalignment observed in polymer valves subjected to elevated temperature and aggressive cleaning regimes.

3. Reduced Replacement Frequency in Brine Service

Field-simulated duty with concentrated brine and intermittent solids shows that SiC-based units can operate for more than 12 months without functional degradation, whereas previous metal or polymer valves required changeout within a fraction of that time. This longevity directly lowers the count of annual valve interventions in desalination and wastewater modules.

✅ ️Problem Solved

In a large thermal desalination facility, concentrated brine and cleaning chemicals caused rapid surface degradation of alloy valves, while polymer units softened after repeated high-temperature cycles. Operators reported that several critical positions needed replacement within half a year, and increasing bypass incidents disrupted stable brine management. After introducing ADCERAX® Silicon Carbide Ball Valves on key brine and concentrate lines, visual inspections after 12 months showed intact sealing faces and unchanged actuation behavior. Recorded replacement events for those locations dropped by more than 50%, and the plant reported more stable control of brine circulation under the same salinity and operating-hour conditions.

ADCERAX® Silicon Carbide Ball Valve User Guide for Stable Operation in Industrial Systems

The Silicon Carbide Ball Valve supports demanding flow-control environments, and its performance relies on proper installation, media assessment, and routine inspection to ensure long service cycles and consistent sealing behavior.

-

System Preparation and Pre-Installation Checks

1. Confirm media compatibility

The valve should be assessed against the chemical profile of the circulating fluid to ensure long-term stability. SiC responds predictably to corrosive, abrasive, and mixed-phase environments when properly matched. Incorrect media pairing may accelerate wear or increase torque drift.

2. Verify upstream and downstream cleanliness

Piping should be flushed to remove debris that may scratch the sealing surface during initial operation. This step is especially important for slurry or recycled-liquid circuits. Residual particles at commissioning can shorten the cycle life of the sealing interface.

3. Evaluate temperature variation within the line

Thermal fluctuations must be identified to ensure the valve is introduced into a predictable thermal envelope. Sudden temperature differences can affect mounting hardware and surrounding components. Stabilizing temperature transitions reduces startup stress on the SiC ball and seat.

-

Installation Best Practices for Optimal Performance

1. Ensure proper valve orientation

Flow direction should match the designated installation markings to optimize seat engagement and reduce turbulence. Misalignment can influence pressure balance across the valve body. Correct positioning improves actuation smoothness and helps maintain sealing stability.

2. Support the pipeline during installation

External loads from misaligned piping can apply stress to the valve housing and connection interfaces. These loads accumulate during vibration or thermal expansion cycles. A supported pipeline minimizes strain and protects the internal ceramic core from unintended force.

3. Tighten mounting fasteners evenly

Uneven torque on flanges or threaded interfaces may shift the ball–seat geometry and affect sealing quality. Controlled tightening distributes load uniformly across the assembly. Balanced tightening helps preserve the concentricity essential for low-leakage operation.

-

Operational Guidelines for Consistent Sealing and Control

1. Monitor early-cycle torque readings

Initial actuation cycles help reveal how fluid composition interacts with the sealing surface. Early changes in torque patterns can indicate improper media compatibility or upstream contamination. Tracking these readings helps prevent long-term drift and avoids unnecessary shutdowns.

2. Observe pressure changes across the valve

Pressure spikes can occur in slurry, brine, or chemically reactive systems, influencing the valve’s closing behavior. A stable differential pressure supports predictable throttling. Unusual pressure trends should be addressed promptly to protect the seat surface from accelerated wear.

3. Limit rapid cycling in unstable media

Abrasive or highly reactive media require controlled cycling frequency to maintain surface integrity. Excessive cycling in these environments increases the risk of micro-abrasion. Moderating valve actuation during process upset conditions extends operational life.

-

Maintenance and Long-Cycle Care

1. Inspect sealing surfaces at planned intervals

Visual checks help identify early surface dulling or localized wear patterns. These indicators reflect upstream media behavior and system consistency. Scheduled inspections allow intervention before performance decline becomes significant.

2. Flush the line before restarting after downtime

Settled solids or concentrated chemicals can accumulate when systems remain idle. A controlled flush returns the pipeline to a stable process state before the valve resumes operation. This step reduces abrupt load changes on the ceramic interface.

3. Document operational history

Logs of torque values, pressure variations, and cycling frequency provide insight into long-term performance trends. These records support predictive maintenance and help diagnose evolving process conditions. Stable documentation enhances reliability planning for continuous-duty operations.

![]()