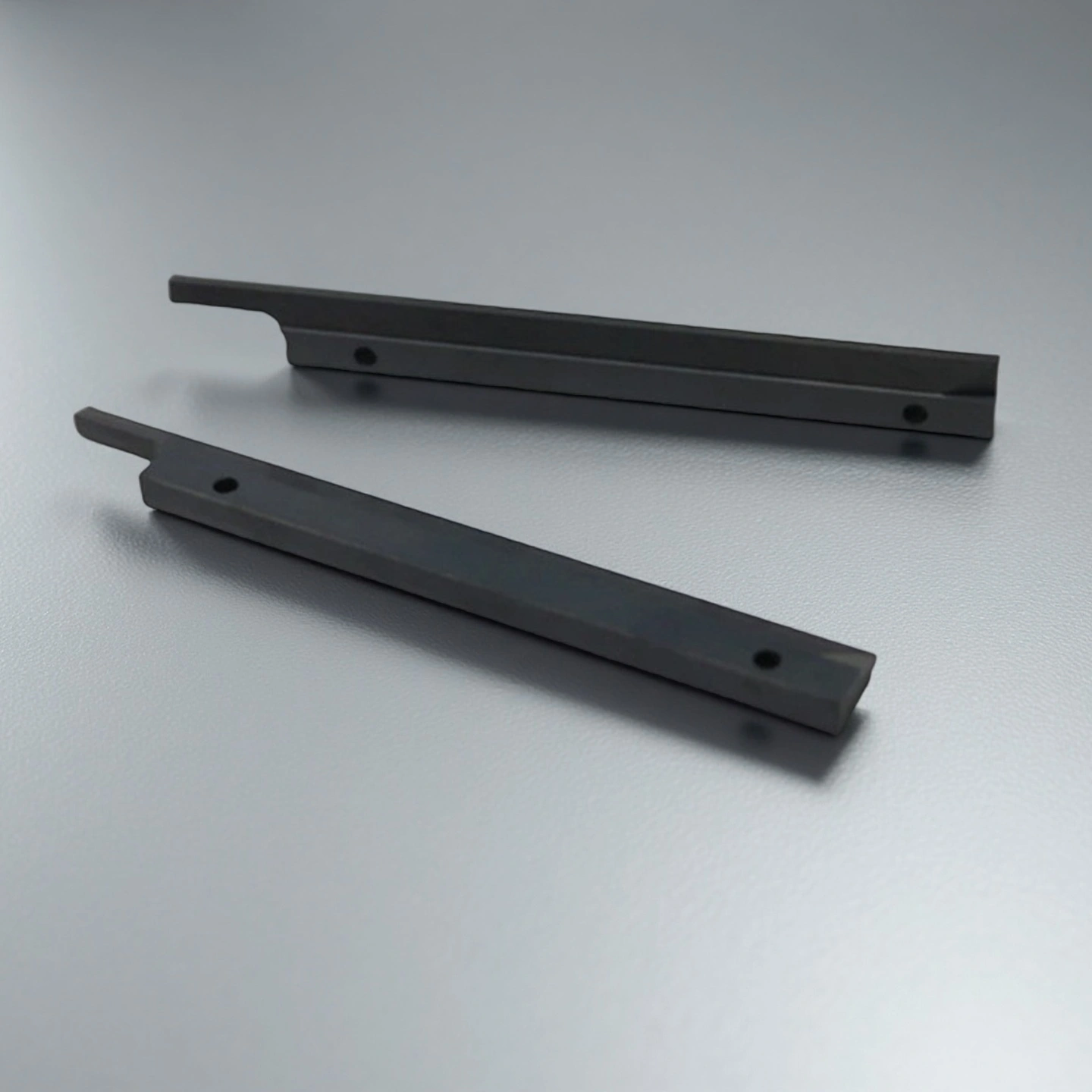

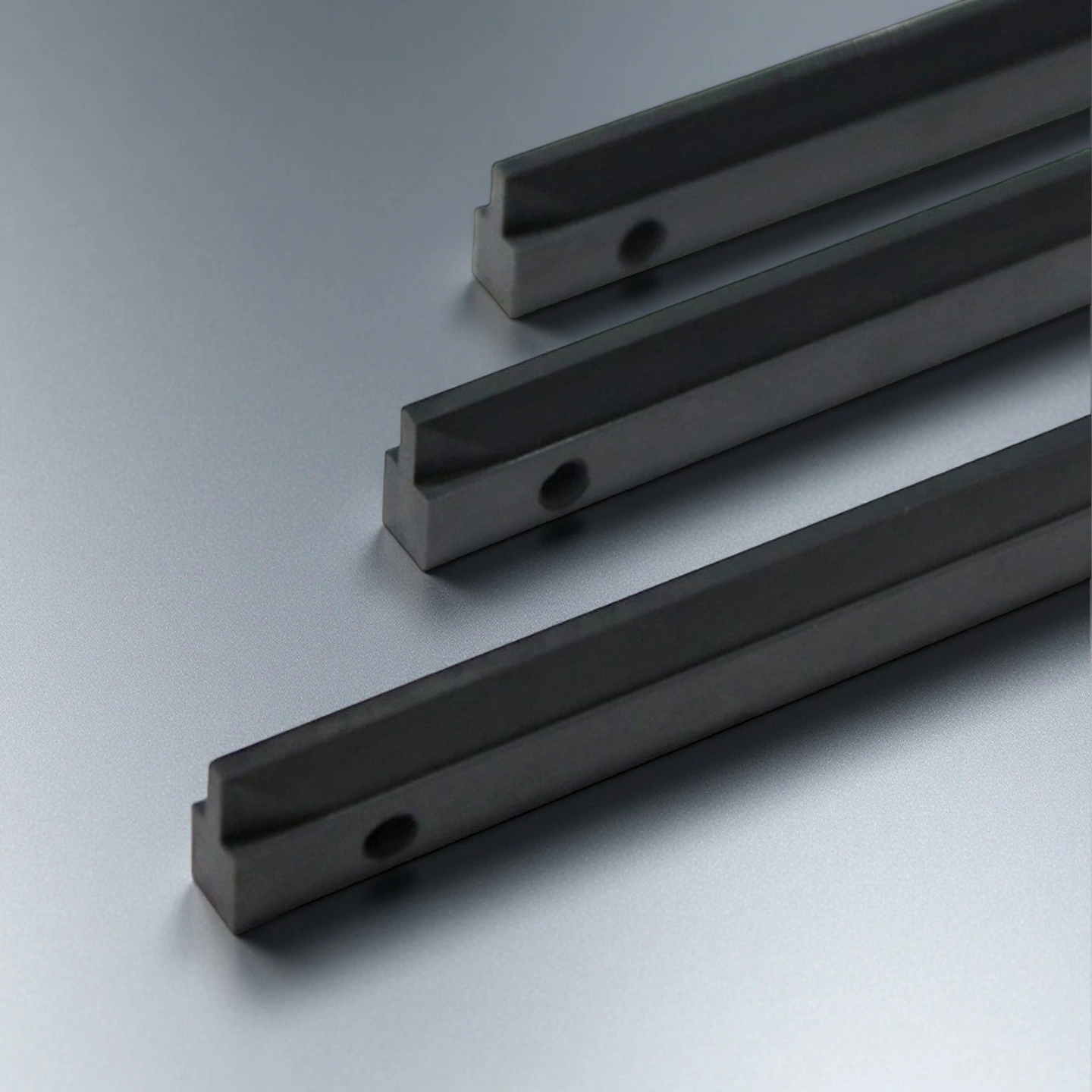

Silicon nitride 3D printer scraper is a ceramic removal tool designed for safe and efficient part removal from PEI, glass, textured steel, and resin build surfaces. Compared with metal scrapers, a Si₃N₄ blade offers high hardness, low wear, and stable geometry under repeated thermal cycles, which helps reduce build plate damage and tool replacement frequency in 3D printing environments.

Silicon Nitride 3D Printer Scraper Benefits

-

Non-scratch edge geometry for common build surfaces

The Si₃N₄ blade is ground with a controlled bevel and flatness so the scraper can slide under prints at a low angle, reducing visible scratches on PEI sheets and glass beds compared with many stamped metal scrapers. -

High wear resistance in high-cycle print farms

Silicon nitride hardness in the 13–15 GPa range allows the scraper edge to keep its profile after thousands of removal cycles, which lowers the frequency of tool replacement and maintains a consistent feel for operators. -

Stable under temperature variation

The ceramic scraper can contact warm build plates in the 60–110 °C range without significant softening or edge deformation, keeping removal behavior stable during typical FDM printing conditions. -

Chemical resistance for resin and solvent contact

The silicon nitride 3D printer scraper resists common resin printing chemicals such as photopolymer resins, isopropyl alcohol, and many water-based cleaners, making it suitable for both FDM and SLA / DLP environments. -

Customizable blade shape and thickness

Blade width, length, bevel angle, and thickness can be tailored to create rigid or slightly flexible scrapers, straight or rounded corners, and special profiles for narrow build plates or confined chambers.

Si3N4 3D Printer Scraper Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Scraper for 3d Printer Specifications

| Silicon Nitride 3D Printer Scraper | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-SIN-DG1001 | Customize | |

Silicon Nitride Ceramic 3D Scraper Packaging

- Each silicon nitride 3D printer scraper is wrapped in soft protective material to prevent chipping of the ceramic edge during transport.

![]()