ADCERAX® Rectangular Zirconia Crucible is designed for laboratories and material science applications requiring high thermal stability and chemical resistance. Its flat geometry ensures uniform heating, efficient sample handling, and compatibility with analytical furnaces. The material composition provides excellent durability under repeated use and resistance against aggressive acids or alkalis. Research institutes and ceramic manufacturers rely on Rectangular Zirconia Crucible to achieve consistent results in sample preparation and sintering.

Features of Rectangular Zirconia Crucible

- Operating safely up to 2200 °C, the crucible maintains structural integrity under repeated cycles. It supports consistent heating processes in laboratory and pilot-scale furnaces.

- Composed of ≥92% ZrO₂, the crucible resists contamination from chemical interactions. This ensures accurate testing in sensitive material environments.

- Low Fe₂O₃ and SiO₂ content (≤0.5%) protects samples from unwanted impurities. Research projects requiring high-purity outputs benefit from reliable results.

- With a density ≥4.5 g/cm³, the crucible achieves exceptional hardness and wear resistance. This makes it suitable for frequent laboratory use.

- Low porosity (≤0.5%) prevents liquid absorption and structural weakening. This minimizes sample contamination and maintains crucible longevity.

Technical Properties for Rectangular Zirconia Crucible

The Rectangular Zirconia Crucible is engineered for high-temperature laboratory and industrial applications where measurable performance data is critical.

| Property | Specification |

| ZrO₂ Purity | ≥ 92% (stabilized zirconia) |

| Bulk Density | ≥ 4.50 g/cm³ |

| Apparent Porosity | ≤ 0.50% |

| Maximum Service Temperature | 2200 °C |

| Flexural Strength | ≥ 350 MPa |

| Compressive Strength | ≥ 2000 MPa |

| Thermal Conductivity (1000 °C) | 2.2–2.5 W/m·K |

| Thermal Expansion Coefficient | 10.5 × 10⁻⁶ /K (RT–1000 °C) |

| Acid/Alkali Resistance | Stable in HCl, H₂SO₄, NaOH |

| Electrical Resistivity | >10¹² Ω·cm at 25 °C |

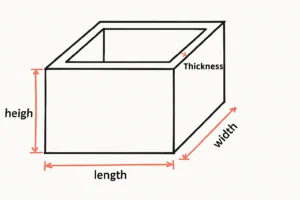

Dimensions of Rectangular Zirconia Crucible

| Rectangular Zirconia Crucible | ||||||

| Item No. | Volume(ml) | Length(mm) | Width(mm) | Height(mm) | Wall Thickness(mm) | Purity(%) |

| AT-YHG-F001 | 19 | 50 | 50 | 15 | 3 | 95 |

| AT-YHG-F002 | 25 | 60 | 30 | 20 | 3 | 95 |

| AT-YHG-F003 | 34 | 64 | 53 | 17 | 3 | 92 |

| AT-YHG-F004 | 36 | 66 | 55 | 16.8 | 3 | 92 |

| AT-YHG-F005 | 39 | 70 | 45 | 20 | 3 | 95 |

| AT-YHG-F006 | 62 | 70 | 70 | 20 | 3.5 | 95 |

| AT-YHG-F007 | 48 | 75 | 50 | 20 | 3 | 95 |

| AT-YHG-F008 | 72 | 98 | 39 | 29 | 3.5 | 92 |

| AT-YHG-F009 | 43 | 100 | 49 | 16 | 4 | 92 |

| AT-YHG-F010 | 55 | 100 | 40 | 20 | 3 | 95 |

| AT-YHG-F011 | 20 | 100 | 35 | 10 | 3.5 | 95 |

| AT-YHG-F012 | 138 | 110 | 110 | 18 | 4 | 95 |

| AT-YHG-F013 | 19 | 120 | 22 | 16 | 4 | 92 |

| AT-YHG-F014 | 236 | 135 | 135 | 20 | 5 | 95 |

| AT-YHG-F015 | 96 | 160 | 80 | 14 | 5 | 92 |

| AT-YHG-F016 | 475 | 164 | 164 | 25 | 5 | 95 |

| AT-YHG-F017 | 105 | 84 | 84 | 23 | 4 | 95 |

| AT-YHG-F018 | 152 | 67 | 67 | 48 | 4 | 95 |

| AT-YHG-F019 | 98 | 88 | 62 | 27 | 4 | 95 |

| AT-YHG-F020 | 35 | 64 | 53 | 17 | 3 | 92 |

| AT-YHG-F021 | 37 | 66 | 55 | 16.8 | 3 | 92 |

| AT-YHG-F022 | 72 | 98 | 39 | 29 | 3.5 | 92 |

| AT-YHG-F023 | 43 | 100 | 49 | 16 | 4 | 92 |

| AT-YHG-F024 | 19 | 120 | 22 | 16 | 4 | 92 |

Packaging for Rectangular Zirconia Crucible

Each Rectangular Zirconia Crucible is individually wrapped with protective film to prevent surface damage during transit. The crucibles are then packed in strong cartons and secured in reinforced wooden cases. This multi-layer protection ensures that every Rectangular ZrO2 Crucible reaches the customer safely and ready for immediate laboratory use.