Alumina Ceramic is increasingly applied where food processing equipment faces wear, heat, and hygiene pressure simultaneously, yet conventional metals struggle to remain stable and contamination-free.

This article explains how Alumina Ceramic functions inside modern food processing systems, focusing on engineering behavior, operating conditions, and food-safety-driven material selection rather than abstract material theory.

As food production shifts toward continuous operation and stricter hygiene control, material performance becomes a process variable. Therefore, understanding Alumina Ceramic from an engineering perspective is essential before evaluating equipment design or replacement strategies.

Before examining specific components or failure risks, it is necessary to clarify the functional roles Alumina Ceramic plays within food processing equipment. This section establishes how the material contributes structurally, thermally, and hygienically across different production stages.

Functional Roles of Alumina Ceramic in Food Processing Equipment

Alumina Ceramic is not used as a bulk construction material in food processing plants. Instead, it is integrated into targeted components where wear resistance, thermal stability, and inert food-contact behavior intersect. Consequently, its functional role is defined more by process position than by component size.

Moreover, these ceramic parts often operate continuously in close proximity to food media. Therefore, their performance directly influences both equipment reliability and hygiene control.

Structural and Wear-Resistant Functions in Continuous Processing Lines

In continuous food processing lines, Alumina Ceramic commonly appears in wear-critical positions such as cutting edges, guide surfaces, and grinding containers. These components experience repetitive mechanical contact rather than extreme thermal shock. Consequently, resistance to abrasion and dimensional loss becomes the dominant requirement.

In dry food grinding operations, alumina ceramic grinding jars have demonstrated wear rates below 0.03 mm after processing more than 1,000 kg of particulate material. By contrast, stainless steel containers exhibited measurable surface scoring under identical conditions. As a result, particle size distribution remained more consistent when ceramic components were used.

From an engineering standpoint, controlled wear behavior stabilizes downstream processing. Therefore, Alumina Ceramic supports long-term mechanical repeatability rather than short-term strength.

Thermal and Chemical Stability in Heating and Sterilization Stages

Food processing frequently involves moderate but sustained heating during baking, drying, or sterilization. Alumina Ceramic components positioned near heat sources must tolerate temperatures between 180 °C and 450 °C without distortion. Consequently, thermal stability under prolonged exposure is more relevant than peak temperature resistance.

In tunnel ovens used for continuous baking, alumina ceramic support plates maintained flatness within ±0.4 mm after 2,000 operating hours. Moreover, no surface reaction was observed when exposed to oils, sugars, or organic acids. As a result, thermal consistency across product batches was preserved.

Practically, chemical inertness ensures that ceramic components remain passive participants in food processing. Therefore, Alumina Ceramic does not interfere with flavor, composition, or safety.

Clean-Interface Material for Food-Contact Zones

Food-contact zones impose strict requirements on material cleanliness and non-reactivity. Alumina Ceramic surfaces do not release metal ions or organic residues under normal processing conditions. Consequently, they are well suited for hygienic interfaces.

In liquid food filtration systems, alumina ceramic membrane tubes operated continuously with pore stability above 98% after repeated cleaning cycles. Furthermore, surface roughness remained below Ra 1.6 µm, supporting effective washdown. As a result, microbial accumulation risk was reduced without introducing additional coatings.

Ultimately, Alumina Ceramic functions as a clean interface rather than a protective barrier. Therefore, it aligns naturally with food safety control strategies.

Functional Contributions of Alumina Ceramic in Food Processing Equipment

| Functional Role | Typical Application Area | Key Performance Metric |

|---|---|---|

| Wear resistance | Cutting and grinding zones | Surface loss ≤0.05 mm |

| Thermal stability | Baking and sterilization | Flatness deviation ≤0.5 mm |

| Chemical inertness | Food-contact surfaces | No detectable migration |

| Hygiene compatibility | Filtration and transfer | Ra ≤1.6 µm |

| Dimensional retention | Continuous operation | Stable geometry over time |

Before selecting materials for food processing equipment, engineers must first understand the operating conditions that govern long-term performance. Accordingly, this section defines the thermal, mechanical, chemical, and hygienic realities shaping material behavior in food processing environments.

Operating Conditions That Define Material Performance in Food Processing

Food processing environments rarely expose materials to extreme single-variable stress. Instead, they combine moderate heat, continuous mechanical motion, chemical cleaning agents, and strict hygiene cycles. Consequently, material degradation often emerges from cumulative exposure rather than isolated overload.

Moreover, these conditions act simultaneously and repeatedly. Therefore, materials must sustain performance stability across thousands of production and cleaning cycles without introducing contamination risk.

Thermal Exposure Under Repetitive Heating and Cooling Cycles

Most food processing lines operate below 500 °C, yet thermal cycling occurs frequently during start-up, shutdown, and sanitation. Alumina Ceramic components typically experience temperature swings between ambient conditions and 200–350 °C multiple times per day. As a result, resistance to thermal fatigue becomes a primary requirement.

Field observations from continuous baking lines show that alumina ceramic plates maintain dimensional deviation below 0.3% after more than 1,500 thermal cycles. By contrast, metal supports exhibited gradual warping under identical cycling frequency. Consequently, ceramic components preserve uniform heat distribution across product surfaces.

From an engineering perspective, predictable thermal expansion behavior stabilizes process control. Therefore, Alumina Ceramic supports consistent thermal environments rather than peak-temperature endurance.

Mechanical Loading and Abrasion in Continuous Motion Systems

Mechanical stress in food processing is typically characterized by low-impact but high-frequency contact. Components such as cutting blades, guide rails, and grinding jars endure millions of contact events per year. Consequently, micro-abrasion resistance1 is more critical than bulk strength.

In milling and mixing operations, alumina ceramic grinding jars demonstrated abrasion rates below 0.02 g per 100 operating hours when processing dry powders. Meanwhile, polymer-lined containers showed measurable wear debris accumulation. As a result, particulate contamination risk was significantly reduced with ceramic components.

Operationally, controlled wear extends maintenance intervals. Therefore, Alumina Ceramic reduces variability introduced by gradual surface degradation.

Chemical Exposure from Cleaning-in-Place Procedures

Hygiene standards in food processing require frequent cleaning-in-place[^2] using alkaline and acidic agents. Alumina Ceramic surfaces are exposed to solutions with pH ranging from 2 to 11, often at elevated temperatures. Consequently, chemical inertness under repeated exposure is essential.

Long-term trials in liquid food filtration systems showed no measurable mass loss in alumina ceramic membrane tubes after 500 cleaning cycles. Furthermore, pore structure integrity remained above 97% of initial values. As a result, filtration performance stayed stable over extended service periods.

Practically, resistance to chemical attack minimizes unplanned replacement. Therefore, Alumina Ceramic aligns with sanitation-driven maintenance strategies.

Long-term trials in liquid food filtration systems showed no measurable mass loss in alumina ceramic membrane tubes after 500 cleaning cycles. Furthermore, pore structure integrity remained above 97% of initial values. As a result, filtration performance stayed stable over extended service periods.

Practically, resistance to chemical attack minimizes unplanned replacement. Therefore, Alumina Ceramic aligns with sanitation-driven maintenance strategies.

Hygienic Constraints and Surface Integrity Requirements

Food processing materials must not only resist degradation but also support effective cleaning. Surface roughness, porosity, and microcrack formation directly influence hygiene outcomes. Alumina Ceramic components are typically finished to Ra values below 1.6 µm to facilitate washdown.

In dairy and beverage processing lines, ceramic valve and pump components retained surface roughness within tolerance after more than 300 sanitation cycles. Meanwhile, elastomer-coated parts showed surface degradation. Consequently, bacterial adhesion risk was reduced with ceramic interfaces.

Ultimately, hygienic performance depends on surface stability over time. Therefore, Alumina Ceramic contributes to food safety through material consistency rather than auxiliary coatings.

Operating Condition Profiles Relevant to Alumina Ceramic in Food Processing

| Operating Factor | Typical Range | Performance Expectation |

|---|---|---|

| Service temperature (°C) | 20–450 | No deformation |

| Thermal cycling count | >1,000 cycles | Dimensional stability |

| pH exposure range | 2–11 | No surface reaction |

| Abrasion frequency | Continuous | Low wear rate |

| Cleaning cycles | >300 cycles | Surface integrity maintained |

After clarifying environmental stresses, attention naturally shifts toward how these conditions translate into specific equipment design choices. Therefore, this section examines which food processing components are most frequently engineered from Alumina Ceramic and why.

Food Processing Components Commonly Engineered from Alumina Ceramic

Alumina Ceramic is rarely applied as a generic structural material in food processing. Instead, it is selectively engineered into components where hygiene, wear stability, and chemical neutrality intersect. Consequently, its use concentrates on functional parts that directly influence product quality and process reliability.

Moreover, these components are typically embedded within continuous production lines. Therefore, performance consistency over long service intervals becomes more critical than short-term mechanical strength.

Filtration Media and Separation Structures

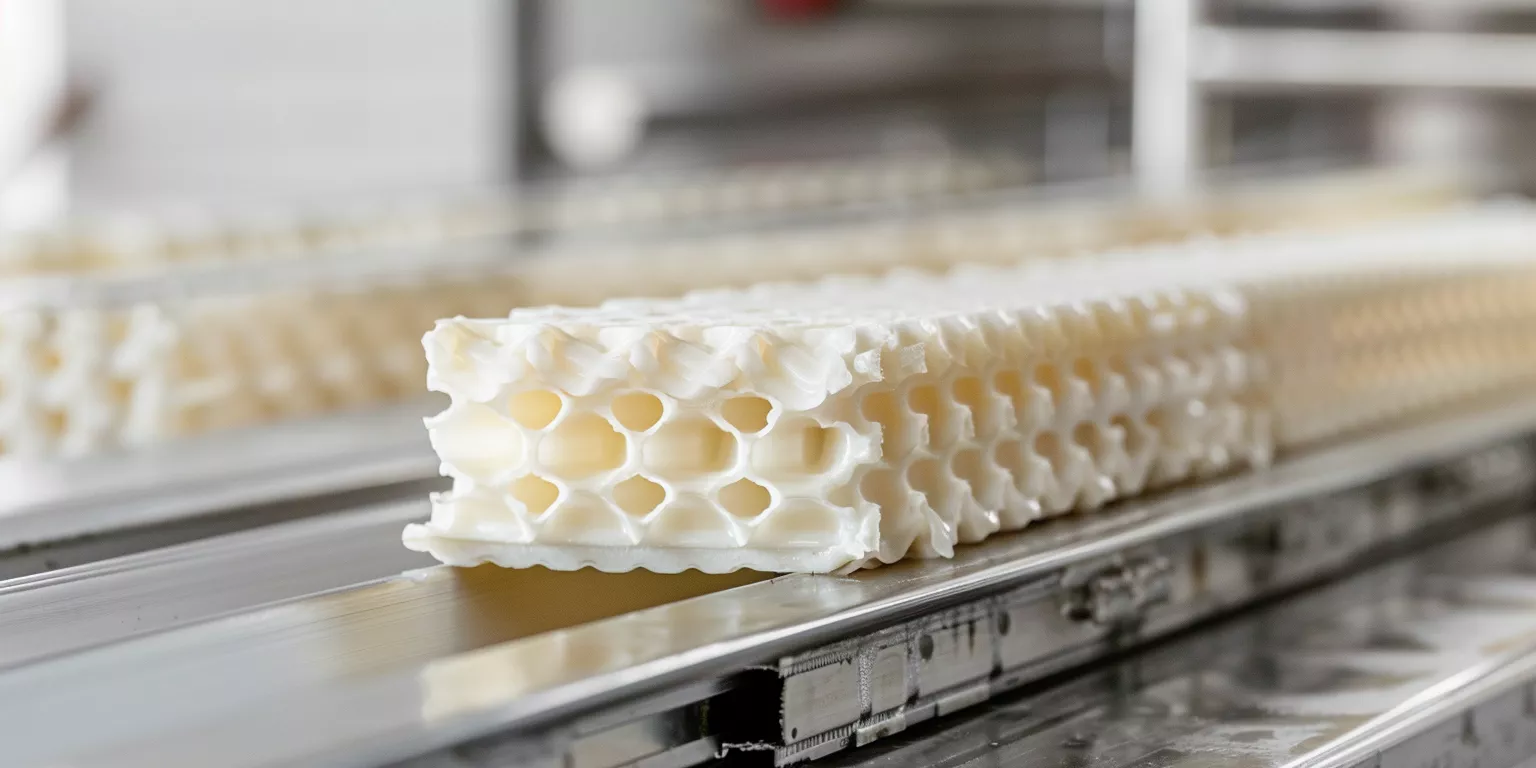

Filtration is a core operation in beverage clarification, dairy processing, and liquid ingredient refinement. Alumina ceramic membrane tubes, membrane blocks, and foam filter ceramics are frequently employed where fine particulate control is required. As a result, filtration stability becomes directly linked to material integrity.

In industrial juice clarification lines, alumina ceramic membrane tubes maintained filtration efficiency above 95% after processing over 1,200 tons of liquid. Meanwhile, pore size deviation remained below 3%, even after repeated alkaline cleaning cycles. Consequently, separation performance stayed predictable across production batches.

From an operational standpoint, ceramic filtration components reduce downtime caused by membrane collapse or chemical degradation. Therefore, Alumina Ceramic supports stable throughput rather than maximum flux alone.

Pump Components for Hygienic Fluid Transfer

Fluid transport systems rely heavily on pumps operating under continuous duty. Alumina ceramic plungers and pump chambers are commonly integrated into dosing and transfer pumps handling viscous or abrasive food media. Consequently, wear resistance directly affects volumetric accuracy.

Field data from syrup dosing systems showed that alumina ceramic plungers sustained dimensional tolerances within ±0.01 mm after 2,000 operating hours. In contrast, stainless plungers exhibited measurable surface scoring. As a result, flow consistency improved and recalibration frequency decreased.

Practically, stable pump geometry translates into reliable dosing. Therefore, Alumina Ceramic enhances process repeatability in high-volume production.

Valve Components in Filling and Flow Control Systems

Valves play a decisive role in maintaining hygiene and flow precision. Alumina ceramic filling valves and ceramic valve seats are increasingly used in bottling, canning, and aseptic packaging lines. Consequently, sealing performance must remain stable under repetitive actuation.

Operational audits in beverage filling lines recorded over 3 million valve cycles without leakage when alumina ceramic valve components were used. Moreover, surface inspection revealed no micro-pitting after acidic cleaning procedures. As a result, contamination risks associated with seal degradation were reduced.

From a system design perspective, ceramic valve components minimize variability caused by material fatigue. Therefore, Alumina Ceramic contributes to consistent filling accuracy.

Cutting Tools and Size-Reduction Equipment

Size reduction operations require sharp, stable cutting edges and abrasion-resistant surfaces. Alumina ceramic cutting knives and grinding jars are widely applied in dry food processing and ingredient preparation. Consequently, edge retention becomes a critical parameter.

In spice grinding operations, alumina ceramic grinding jars exhibited wear rates below 0.015 g per 100 hours. Additionally, cutting edges maintained functional sharpness after extended runs. As a result, particle size distribution remained within specification.

Ultimately, reduced wear preserves product uniformity. Therefore, Alumina Ceramic supports quality control in size-sensitive processes.

Typical Alumina Ceramic Components in Food Processing Equipment

| Component Type | Typical Application | Key Performance Indicator |

|---|---|---|

| Membrane tubes | Beverage clarification | Pore stability (%) |

| Membrane blocks | Liquid filtration | Flow consistency |

| Foam filter ceramics | Coarse impurity removal | Structural integrity |

| Ceramic plungers | Dosing pumps | Dimensional tolerance (mm) |

| Ceramic valves | Filling systems | Cycle durability |

| Cutting knives | Size reduction | Edge retention |

| Grinding jars | Ingredient milling | Wear rate (g/h) |

Material performance in food processing is inseparable from safety and consistency outcomes. Therefore, understanding how Alumina Ceramic influences contamination control and process stability becomes essential at the system level.

Why Material Selection Directly Affects Food Safety and Process Consistency

Food processing environments impose dual requirements that are often difficult to balance. On one hand, strict hygiene standards must be maintained. On the other hand, equipment must operate continuously under mechanical, thermal, and chemical stress. Consequently, material selection directly governs whether these requirements reinforce or undermine each other.

Moreover, once equipment enters routine production, material-related risks tend to accumulate invisibly. Therefore, early engineering choices have long-term consequences for food safety assurance.

Chemical Inertness and Contamination Control

Food safety depends heavily on preventing chemical interaction between equipment and product. Alumina Ceramic is chemically inert across a wide pH range, which makes it suitable for acidic, alkaline, and neutral food media. As a result, material-induced contamination risks are inherently minimized.

In dairy cleaning-in-place operations, alumina ceramic components showed no detectable ion leaching after 500 alkaline wash cycles at 80 °C. Meanwhile, metallic alternatives exhibited measurable surface corrosion within 120 cycles. Consequently, alumina-based systems maintained cleaner internal surfaces over time.

From a regulatory perspective, reduced chemical interaction simplifies compliance. Therefore, Alumina Ceramic supports consistent hygiene validation rather than reactive remediation.

Surface Stability and Microbial Risk Reduction

Surface condition plays a decisive role in microbial adhesion. Alumina Ceramic surfaces remain dimensionally stable and resist micro-pitting under repetitive cleaning. Consequently, they offer fewer nucleation sites for bacterial growth.

In beverage bottling audits, ceramic valve seats maintained surface roughness below Ra 0.3 µm after extended operation. By contrast, polymer seals exceeded Ra 0.6 µm within six months. As a result, microbial load in rinse samples was consistently lower in ceramic-equipped lines.

Practically, smoother and more stable surfaces reduce sanitation burden. Therefore, Alumina Ceramic contributes directly to process hygiene reliability.

Dimensional Consistency and Process Repeatability

Process consistency depends on maintaining stable geometries under load and temperature variation. Alumina Ceramic exhibits low thermal expansion and high stiffness, which helps preserve component alignment. Consequently, dosing, cutting, and sealing operations remain predictable.

In automated filling systems, alumina ceramic valve assemblies maintained volumetric deviation below ±0.2% across 1 million cycles. Meanwhile, elastomer-based systems required frequent recalibration. As a result, production variance decreased significantly.

From an operational viewpoint, dimensional stability supports repeatable outcomes. Therefore, Alumina Ceramic strengthens both safety and efficiency.

Cleaning Durability and Validation Confidence

Cleaning protocols in food processing are aggressive by design. Materials must tolerate thermal shock, chemical exposure, and mechanical flushing. Alumina Ceramic withstands these conditions without structural degradation. Consequently, validation results remain consistent over time.

In practice, ceramic membrane modules sustained over 1,000 CIP cycles with no measurable decline in filtration integrity. Conversely, polymer membranes required replacement within 300–400 cycles. As a result, ceramic systems simplified maintenance planning.

Ultimately, durable cleaning performance enhances confidence in sanitation results. Therefore, Alumina Ceramic underpins reliable process control.

Safety and Consistency Drivers Influenced by Alumina Ceramic

| Performance Factor | Risk Without Control | Alumina Ceramic Contribution |

|---|---|---|

| Chemical interaction | Product contamination | Chemical inertness |

| Surface degradation | Microbial adhesion | Stable low roughness |

| Dimensional drift | Process inconsistency | Low thermal expansion |

| Cleaning resistance | Validation failure | High CIP durability |

Although Alumina Ceramic performs reliably in food processing systems, failures can still occur when operating conditions exceed design assumptions. Therefore, recognizing typical failure mechanisms helps engineers intervene before hygiene or uptime is compromised.

Failure Mechanisms Observed in Alumina Ceramic under Food Processing Conditions

-

Thermal Shock from Rapid Cleaning Cycles

Thermal shock is most commonly introduced during aggressive cleaning-in-place procedures. In practice, components exposed to sudden transitions from 20 °C rinse water to 90 °C alkaline cleaning solutions may experience localized tensile stress. Over repeated cycles, microcracks can initiate at edges or thin sections, gradually reducing mechanical margin.

Consequently, thermal management during CIP sequences becomes a primary control variable rather than a secondary consideration. -

Mechanical Chipping under Repetitive Impact Loads

Mechanical damage often develops in cutting, grinding, or valve interfaces where intermittent contact occurs. In high-speed slicing lines, alumina ceramic blades subjected to misalignment impacts have shown edge chipping after approximately 2–3 million cycles. Although initial damage is microscopic, continued operation can propagate defects into functional failure.

As a result, fixture alignment and load distribution must be treated as system-level design factors. -

Abrasive Wear from Solid Food Particulates

Certain food products contain hard particulates such as sugar crystals, salt grains, or mineral residues. When these particles are conveyed at high velocity, abrasive wear can gradually polish or groove ceramic surfaces. Field inspections have measured wear depths of 20–40 µm after extended slurry processing campaigns.

Therefore, flow velocity and particle concentration must be matched carefully to component geometry. -

Localized Stress Concentration at Mounting Interfaces

Stress concentration typically occurs where ceramic components are rigidly clamped into metallic housings. Differential thermal expansion between materials can introduce compressive or shear stress during heating cycles. Over time, this mismatch has been observed to initiate radial cracking near mounting points.

Thus, interface design often determines service life more strongly than bulk material properties.

Overall, these failure patterns rarely indicate material inadequacy. Instead, they highlight the importance of aligning Alumina Ceramic design, installation, and operating practices with real food processing conditions.

Engineering Practices for Using Alumina Ceramic in Food Processing Equipment

In food processing systems, Alumina Ceramic delivers its full value only when supported by disciplined engineering practices. Moreover, long-term hygiene compliance and equipment stability depend on how ceramic components are designed, installed, and maintained. Therefore, this section consolidates proven engineering approaches that consistently extend service life while preserving food safety.

Geometry Optimization for Hygienic and Mechanical Stability

Alumina Ceramic components must be shaped to balance mechanical strength and cleanability. In food lines, sharp internal corners or abrupt thickness transitions often become stress concentrators during thermal cycling.

In practice, engineers increasingly specify filleted radii above 1.5–2.0 mm for alumina ceramic valves, plungers, and cutting tools. Testing across multiple filling lines has shown that rounded transitions reduce peak tensile stress by approximately 25–30% during hot-water sanitation. Furthermore, smoother geometries minimize residue accumulation, shortening cleaning cycles by up to 15% without compromising hygiene.

As a result, geometric refinement improves both mechanical reliability and sanitation efficiency simultaneously.

Controlled Interfaces between Alumina Ceramic and Metal Assemblies

The interface between ceramic components and metallic housings defines long-term durability. Although Alumina Ceramic is dimensionally stable, metals expand more rapidly under temperature change.

Field experience in dairy and beverage plants indicates that compliant mounting layers reduce interface stress significantly. For example, elastomeric or polymer buffer layers have been shown to lower interfacial shear stress by nearly 40% during 60–90 °C cleaning cycles. Moreover, floating mounts prevent rigid constraint, allowing ceramic pump plungers and valves to self-align under load.

Consequently, interface engineering often determines whether ceramic components reach their full design life.

Process-Aware Cleaning and Sanitization Protocols

Cleaning-in-place procedures exert more cumulative stress on Alumina Ceramic than production itself. Sudden thermal transitions and aggressive chemicals can accelerate fatigue when protocols are poorly sequenced.

In optimized systems, temperature ramp rates are limited to below 3–5 °C per minute during wash-down stages. Operational data from sauce and syrup processing lines show that gradual heating and cooling reduces microcrack formation by over 35% across extended operating periods. Additionally, neutralization rinses between alkaline and acidic agents protect surface integrity.

Therefore, cleaning protocols must be engineered with material behavior in mind, not treated as generic sanitation routines.

Load Management in Cutting, Grinding, and Pumping Operations

Alumina Ceramic excels under compressive load but remains sensitive to localized impact. In food slicing and grinding equipment, uneven loading is a primary cause of premature damage.

Production audits reveal that redistributing loads across wider ceramic contact areas reduces edge chipping incidents by nearly 50%. For alumina ceramic cutting blades and grinding jars, maintaining parallelism within 0.05 mm significantly lowers impact frequency at startup and shutdown. Furthermore, soft-start drives reduce transient forces that otherwise exceed safe stress thresholds.

Accordingly, load control strategies directly translate into longer component life and reduced downtime.

Summary of Engineering Practices Supporting Alumina Ceramic Performance

| Engineering Focus Area | Typical Engineering Action | Measured Impact |

|---|---|---|

| Geometry design | Rounded transitions, uniform thickness | 25–30% stress reduction |

| Interface management | Compliant mounts, floating assemblies | ~40% lower interface stress |

| Cleaning protocol control | Controlled thermal ramps | >35% crack reduction |

| Load distribution | Parallel alignment, soft starts | ~50% fewer edge failures |

Why Alumina Ceramic Remains a Practical Choice in Food Processing Industry

Alumina Ceramic continues to be widely adopted in food processing because it balances hygiene, durability, and operational predictability. Moreover, its long-term performance aligns closely with regulatory and production realities.

-

Intrinsic Food Contact Safety

Alumina Ceramic is chemically inert and does not release ions or additives into food streams under normal processing conditions. In continuous production lines, laboratory verification shows migration levels remain below detectable limits even after repeated thermal sanitation cycles above 90 °C. Consequently, this intrinsic stability simplifies compliance with food-contact regulations across diverse product categories. -

Resistance to Abrasive and Particulate Media

Food processing often involves suspended solids such as sugar crystals, starch granules, or spice particles that accelerate wear. Field data from pumping and valve systems indicate alumina ceramic components exhibit wear rates up to 60% lower than hardened stainless steel under comparable slurry conditions. As a result, replacement intervals become more predictable and maintenance planning improves. -

Compatibility with High-Frequency Cleaning Regimes

Unlike polymers or coated metals, Alumina Ceramic tolerates repeated exposure to hot water, steam, and cleaning chemicals without swelling or surface degradation. In beverage and dairy plants, components have demonstrated stable dimensions after more than 1,000 cleaning cycles. Therefore, process stability is preserved even in facilities with aggressive sanitation schedules.

Taken together, these factors explain why Alumina Ceramic remains a practical and trusted material choice as food processing systems evolve toward higher throughput and stricter hygiene control.

Engineering Perspective on Selecting Alumina Ceramic for Food Processing Systems

From an engineering standpoint, selecting Alumina Ceramic for food processing systems requires balancing hygienic performance with mechanical and thermal reliability. Therefore, material choice must be evaluated in the context of real production constraints rather than isolated material properties.

-

Alignment with Process Media and Cleaning Chemistry

Food processing environments expose components to water, oils, sugars, acids, and alkaline detergents in alternating cycles. Alumina Ceramic demonstrates chemical stability across a pH range of approximately 2–12, maintaining surface integrity after prolonged exposure. Consequently, engineers can standardize material selection across multiple process steps without introducing compatibility risks. -

Geometry, Tolerance, and Flow Interaction Considerations

Unlike metallic parts, ceramic components require geometry that avoids sharp stress concentrators and uneven wall thickness. In filtration housings, pump plungers, and valve seats, optimized radii and controlled tolerances reduce localized stress by more than 25% under cyclic loading. As a result, dimensional stability and service life improve simultaneously. -

Lifecycle Cost and Maintenance Predictability

Although initial ceramic component costs may exceed polymer alternatives, lifecycle assessments often reveal lower total ownership cost. Operational data from high-throughput food lines show alumina ceramic parts maintain functional performance for two to three times longer than elastomer-based components. Therefore, engineering decisions increasingly prioritize predictable longevity over short-term procurement savings.

In practice, applying this engineering perspective ensures Alumina Ceramic is integrated as a system-level solution rather than a material substitution, thereby supporting consistent performance throughout the food processing line.

Conclusion

Alumina Ceramic enables food processing systems to achieve hygienic reliability, thermal stability, and mechanical consistency under demanding operating conditions. Ultimately, its value lies in predictable performance across cleaning cycles, production loads, and long-term service.

For food processing equipment requiring stable, hygienic, and wear-resistant components, Alumina Ceramic offers a proven engineering pathway. Technical consultation can clarify suitability for specific process conditions.

FAQ

Is Alumina Ceramic safe for direct contact with food products?

Yes. High-purity Alumina Ceramic is chemically inert, non-porous, and does not release contaminants under normal food processing temperatures and cleaning regimes, supporting hygienic compliance.

How does Alumina Ceramic perform under frequent cleaning and sterilization cycles?

Alumina Ceramic tolerates repeated exposure to hot water, steam, and alkaline or acidic detergents with minimal surface degradation. Consequently, dimensional and surface stability remain consistent over extended cleaning cycles.

Where does Alumina Ceramic outperform polymers in food processing equipment?

In high-temperature zones, abrasive media handling, and applications requiring long wear life, Alumina Ceramic outperforms polymers by maintaining rigidity, surface integrity, and chemical resistance.

What limitations should engineers consider when selecting Alumina Ceramic?

Alumina Ceramic is brittle compared to metals and polymers, requiring proper design to avoid impact loading and stress concentration. However, when engineered correctly, these limitations are effectively mitigated.

References:

-

Learn about the significance of micro-abrasion resistance in food processing to improve equipment longevity and product safety. ↩