Alumina Ceramic Parts often fail quietly before a machine alarms. Consequently, unchecked wear, contamination, and drift accumulate until throughput or product quality collapses.

Alumina Ceramic Parts support rotating, grinding, dispersing, and motion-driven equipment by offering high hardness, chemical inertia, and electrically insulating behavior. Moreover, these traits stabilize wear interfaces where metals shed debris or deform under cyclic load. This article consolidates material science, wear physics, geometry control, manufacturability, verification, and lifecycle planning for industrial teams specifying Alumina Ceramic Parts.

Fundamental Wear Mechanisms in Dynamic Alumina Ceramic Parts

Dynamic components rarely fail because alumina is “weak”; rather, they fail when wear mode and geometry interact in uncontrolled ways. Once the dominant wear mechanism is identified, tolerance and surface requirements become clearer.

Sliding Abrasion in Continuous Motion Interfaces

Sliding wear1 in Alumina Ceramic Parts is usually stable when contact conditions remain consistent. Specifically, alumina hardness commonly falls within HV 1500–1900, which limits plastic plowing and suppresses rapid adhesive wear2.

In spindle sleeves and thrust washers, I have repeatedly seen friction behavior shift once surface roughness exceeds Ra 0.6 μm, because asperity contact raises local temperature and micro-fracture risk. Under typical dry sliding against hardened steel, steady wear rates often remain below 10⁻⁶–10⁻⁵ mm³/N·m when the ceramic surface is finished near Ra 0.2–0.4 μm. Conversely, if the interface traps abrasive fines above roughly 5–20 μm, three-body abrasion dominates and the wear rate can increase by 3–8× even when hardness is unchanged.

In production lines where operators “wipe and reassemble” quickly, the most frequent mistake is leaving a thin grit film on the sleeve ID. As a result, early-life wear accelerates and the next shutdown is blamed on alignment rather than contamination.

Particle Erosion in Grinding and Dispersion Systems

Erosion occurs when particles repeatedly impact Alumina Ceramic Parts at speed. For instance, classifier wheels, agitator discs, and dispersion rotors can face slurry line velocities in the 2–15 m/s range, which is sufficient to initiate chipping at edges if entry geometry is too sharp.

In abrasive slurries, particle size above 20–50 μm typically increases cutting and micro-chipping probability, especially at high solids loading. Notably, impact angle matters: shallow angles promote cutting grooves, while higher angles promote brittle chipping at exposed corners. In one rotor retrofit I reviewed, increasing the leading-edge radius from 0.2 mm to 0.8 mm reduced edge spall frequency by over 60% after 500 operating hours, even though material grade stayed constant.

Afterwards, the operational benefit was not only longer life but also more stable dispersion quality, because fewer ceramic fragments entered the product stream.

Thermal Mechanical Fatigue Under Cyclic Load

Cyclic load fatigue in Alumina Ceramic Parts is often triggered by start-stop operation and localized heating at contact zones. Consequently, microcracks initiate at stress concentrators and propagate incrementally rather than causing immediate breakage.

In rotating assemblies, speed ramps can impose repeating stress cycles above 10⁶ cycles per month in continuous manufacturing. If frictional heating drives local temperature swings of 20–60 °C per cycle, thermal mismatch between ceramic and metal fixtures can elevate tensile stress at interfaces. In practice, parts with abrupt section transitions frequently show early crack initiation within the first 200–800 hours, whereas the same alumina grade with smoother transitions often extends service life to 1500–3000 hours under comparable duty.

Earlier in commissioning, engineers sometimes focus on maximum RPM only. However, fatigue is usually governed by the number of ramps, stops, and load reversals, so operational history must be treated as a primary input during selection.

Wear Mode Indicators for Alumina Ceramic Parts

| Wear Mode | Typical Trigger | Practical Indicator | Common Geometric Sensitivity |

|---|---|---|---|

| Sliding abrasion | Continuous contact load | Polished track, stable friction | Surface roughness zoning |

| Three-body abrasion | Trapped fines at interface | Matte groove patterns | Clearances and seal design |

| Particle erosion | High-velocity slurry impact | Edge chipping, pitted surfaces | Leading-edge radius |

| Thermal fatigue | Repeated ramps and hotspots | Microcrack networks | Section transitions and corners |

Once wear mechanisms are understood, engineers naturally compare material options for dynamic interfaces. Therefore, this section explains why Alumina Ceramic Parts increasingly replace metallic components in rotating, grinding, and dispersing zones where wear stability matters more than ductility.

Why Alumina Ceramic Parts Replace Metals in Dynamic Wear Zones

Metal components rarely fail abruptly in dynamic systems; instead, they deform, smear, and contaminate processes over time. Consequently, Alumina Ceramic Parts are adopted where predictable wear and chemical neutrality outweigh the toughness advantages of metals. Moreover, alumina maintains its mechanical identity under conditions that progressively degrade steel or alloy counterparts.

Hardness Stability Versus Metal Work Hardening

Alumina Ceramic Parts exhibit intrinsic hardness stability, whereas metals evolve during service. Specifically, alumina hardness remains within HV 1500–1900 across its operating life, independent of sliding history.

In contrast, carbon and alloy steels initially harden through plastic deformation, then soften locally as microstructural damage accumulates. In rotating sleeves and thrust rings, I have observed steel components lose dimensional fidelity after 300–600 hours, even when nominal hardness remains high. Alumina sleeves under the same load often retain roundness within ±2–4 μm after 2000+ hours, because no work hardening or smearing occurs.

As a result, alumina-based interfaces deliver wear rate linearity, which simplifies maintenance planning and reduces unexpected clearance growth.

Chemical Inertness and Media Purity Control

Chemical interaction is a hidden failure driver in dynamic equipment. Alumina Ceramic Parts are chemically inert across most aqueous, acidic, and alkaline environments encountered in grinding and dispersion systems.

Metals, however, release ions under sliding contact, especially in the presence of moisture or reactive additives. In pigment dispersion lines, iron contamination above 5–10 ppm has repeatedly correlated with color shift and downstream filtration issues. By contrast, high-purity alumina components typically maintain impurity release below 1 ppm, even after extended slurry exposure.

In one production trial, replacing stainless agitator wear plates with alumina reduced detectable metallic residues by over 80% within the first 100 operating hours, restoring batch consistency without altering process chemistry.

Electrical and Magnetic Neutrality in Motion Systems

Dynamic systems often operate near sensors, drives, or electromagnetic controls. Alumina Ceramic Parts provide electrical insulation (>10¹⁴ Ω·cm) and complete magnetic neutrality, eliminating interference risks inherent to metals.

In high-speed classification equipment, metallic wear debris can accumulate on magnetic sensors, gradually skewing feedback signals. Alumina wear particles, when present, remain electrically inert and nonmagnetic, preventing signal drift. Field data from motion-controlled mixers show that sensor recalibration intervals can extend from 6 months to over 18 months once ceramic wear interfaces replace metallic ones.

Accordingly, alumina contributes not only to mechanical durability but also to signal integrity and control stability in complex motion systems.

Material Behavior Comparison in Dynamic Wear Zones

| Property | Alumina Ceramic Parts | Hardened Steel Components | Practical Impact |

|---|---|---|---|

| Hardness (HV) | 1500–1900 | 600–800 | Lower wear rate |

| Wear behavior | Linear, predictable | Progressive deformation | Stable clearances |

| Chemical reactivity | Inert | Ion release possible | Reduced contamination |

| Magnetic response | None | Present | Sensor stability |

| Electrical resistivity (Ω·cm) | >10¹⁴ | <10⁻⁵ | Electrical isolation |

After material justification, engineers require concrete component references to align drawings, interfaces, and operating conditions. Therefore, this section maps Alumina Ceramic Parts to the dynamic geometries most frequently specified in rotating, grinding, dispersing, and motion-driven equipment.

Typical Dynamic Alumina Ceramic Parts and Functional Geometry

Dynamic Alumina Ceramic Parts are rarely generic shapes; instead, they are geometry-driven wear elements designed to manage contact mechanics, flow paths, and rotational stability. Accordingly, understanding how geometry governs stress distribution and wear progression is essential before tightening tolerances or scaling production.

Rotating Components

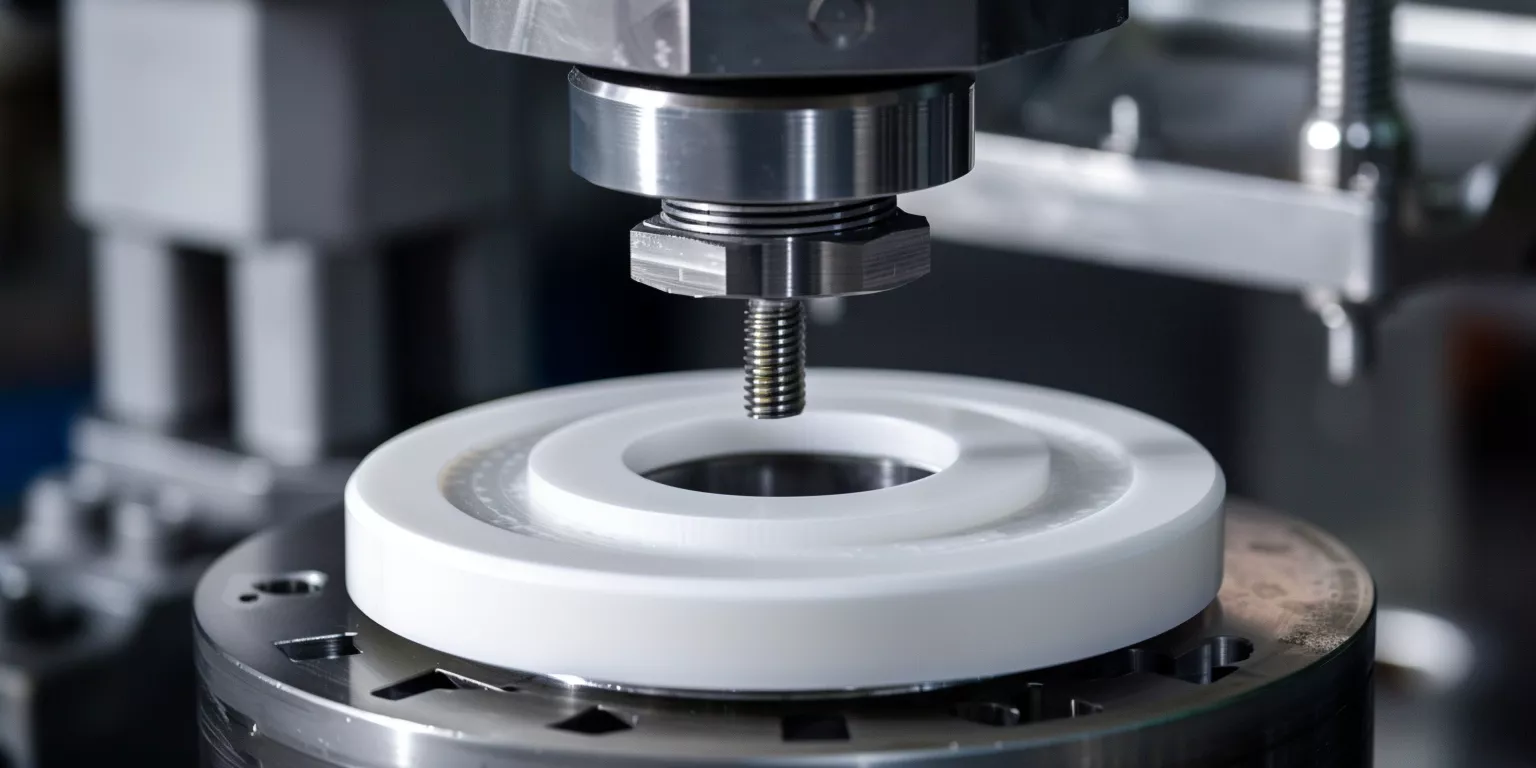

Rotating Alumina Ceramic Parts typically include agitator discs, classifier wheels, and dispersion rotors. These components experience combined centrifugal stress and surface interaction with particles or fluids, which elevates sensitivity to imbalance and edge design.

In practical installations, rotational speeds commonly range from 300 to 6000 rpm, depending on diameter and process intensity. At these speeds, even 5–10 μm of eccentricity can amplify vibration and accelerate bearing wear. I have encountered classifier wheels that met dimensional drawings but failed prematurely because mass distribution was not symmetric after machining. Once dynamic balance was improved to G2.5–G6.3, service life increased by 40–70% without altering material grade.

Therefore, rotating alumina components demand geometry that prioritizes concentricity, smooth transitions, and controlled mass distribution over aggressive weight reduction.

Wear Interface Components

Wear interface Alumina Ceramic Parts include shaft sleeves, rings, washers, and bearing elements. These parts operate under continuous sliding or mixed rolling-sliding conditions, where contact pressure and surface finish dominate performance.

Typical contact pressures range between 2–15 MPa in industrial mixers and rotary feeders. Under such loads, surface roughness above Ra 0.8 μm often initiates micro-chipping at asperity peaks. In contrast, finishes maintained near Ra 0.2–0.4 μm show significantly lower debris generation. In one shaft-sleeve retrofit, improving finish quality reduced measured wear debris mass by approximately 55% after 1000 hours of operation.

Consequently, wear interface geometry must be treated as a tribological system rather than a simple dimensional constraint.

Fluid and Particle Interaction Components

Fluid- and particle-facing Alumina Ceramic Parts include nozzles, liners, and contact plates exposed to high-velocity flow or abrasive suspensions. These geometries face erosion dominated by impact angle, velocity, and particle hardness.

Process data from slurry transport systems indicate that erosion rates increase sharply once flow velocity exceeds 8–12 m/s, particularly when particle sizes exceed 30 μm. Sharp leading edges act as stress concentrators and erosion initiators. By increasing inlet chamfer angles or adding edge radii of 0.5–1.0 mm, erosion depth per 1000 hours can be reduced by 30–60%, depending on media hardness.

As a result, geometry optimization frequently yields greater lifetime gains than material substitution alone in fluid-contact applications.

Functional Geometry Summary for Dynamic Alumina Ceramic Parts

| Component Type | Dominant Load | Critical Geometry Parameter | Typical Sensitivity |

|---|---|---|---|

| Agitator disc | Centrifugal + abrasion | Concentricity (μm) | Vibration growth |

| Classifier wheel | Particle erosion | Edge radius (mm) | Chipping frequency |

| Shaft sleeve | Sliding contact | Surface roughness (Ra μm) | Wear debris rate |

| Washer / ring | Axial load | Flatness (μm) | Uneven contact |

| Nozzle / liner | Flow impact | Inlet angle (°) | Erosion depth |

Even when drawings are met, dynamic ceramic components may still fail prematurely. Therefore, this section explains how geometry-driven stress amplification undermines Alumina Ceramic Parts in motion-intensive environments, despite material compliance.

Geometry Driven Failure Risks in Dynamic Alumina Ceramic Parts

Geometry governs how forces concentrate, dissipate, and repeat during motion. Consequently, Alumina Ceramic Parts that appear dimensionally correct can accumulate damage rapidly if geometric transitions ignore ceramic stress behavior. Moreover, failure often initiates locally and propagates invisibly until catastrophic chipping or fracture occurs.

Stress Concentration from Sharp Transitions

Sharp corners and abrupt section changes generate tensile stress peaks in ceramics. Specifically, alumina exhibits low fracture strain, so even minor stress concentration factors above 2.0–2.5 can initiate microcracks under cyclic load.

In rotating wear rings and sleeves, corner radii below 0.2 mm frequently act as crack starters. During one retrofit review, increasing internal fillet radii from 0.15 mm to 0.6 mm reduced early cracking incidents by approximately 65% within the first 500 hours. Notably, this improvement occurred without altering external dimensions or tolerance bands.

Thus, stress-managed geometry often delivers greater reliability gains than material upgrades alone.

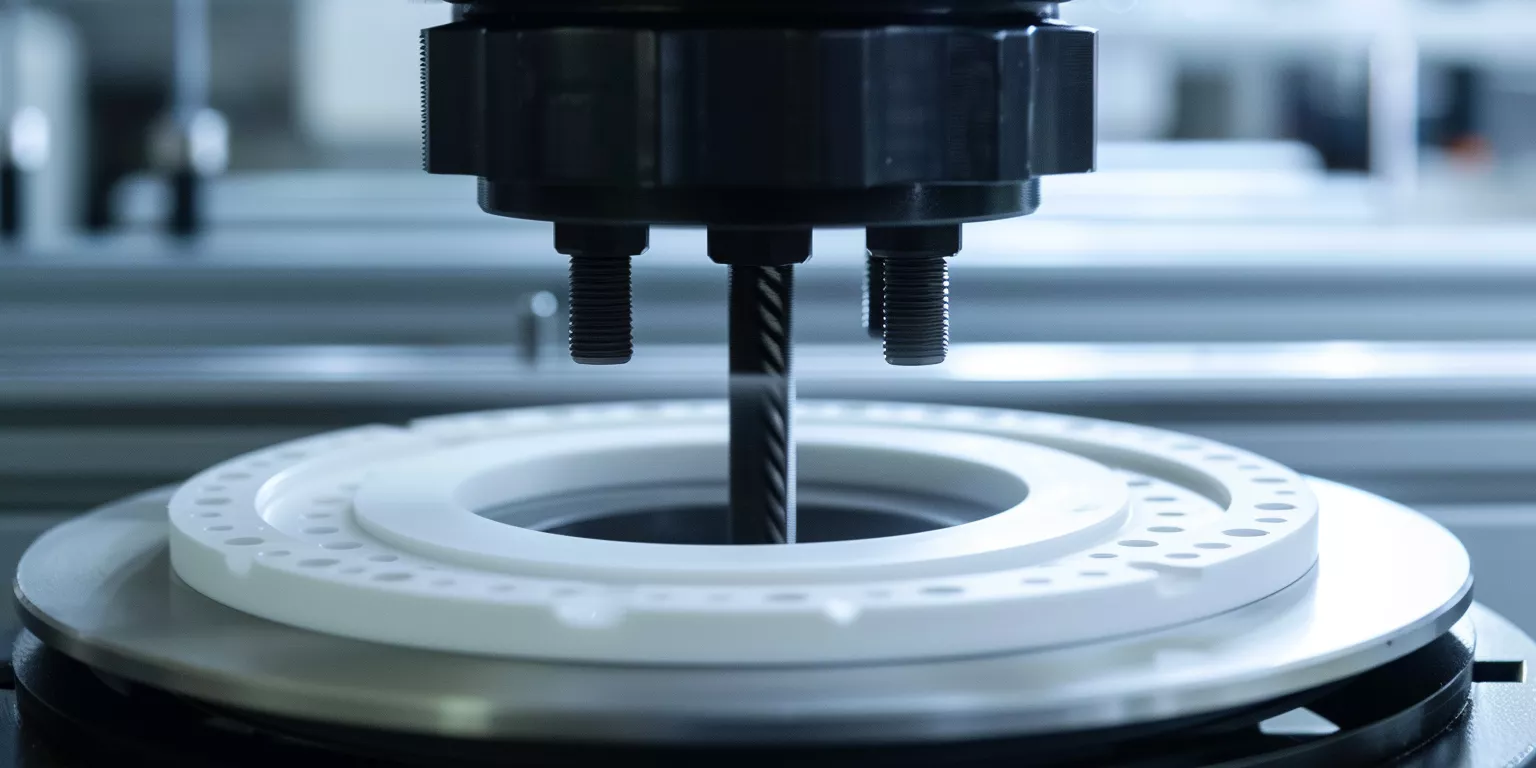

Dynamic Imbalance in Rotating Ceramic Parts

Rotational imbalance introduces alternating tensile and compressive stress that ceramics tolerate poorly. Even small mass offsets become critical at speed. For example, a 10 μm eccentricity at 3000 rpm can generate cyclic loads sufficient to exceed local tensile limits near mounting interfaces.

In practice, alumina rotors balanced only statically often show edge chipping after 200–400 hours. However, once dynamic balance levels of G2.5–G6.3 are achieved, operational vibration amplitude typically drops by 40–60%, extending service life significantly. I have seen dispersion rotors exceed 1500 hours without chipping after balance correction alone.

Accordingly, dynamic balance must be treated as a structural requirement rather than an optional refinement.

Surface Zoning for Controlled Wear

Uniform surface finish across an entire part is not always optimal. In Alumina Ceramic Parts, different zones serve different functions and should wear at controlled rates.

For instance, functional sliding faces benefit from finishes near Ra 0.2–0.4 μm, whereas non-contact faces can remain rougher without penalty. In classifier wheels, polishing only particle-impact zones while leaving structural areas unpolished reduced processing time by 20% while maintaining erosion resistance. Furthermore, localized surface zoning limits unintended load transfer during wear progression.

As a result, zoning strategies convert random wear into predictable, gradual material loss.

Geometry Risk Indicators in Dynamic Alumina Ceramic Parts

| Risk Factor | Typical Threshold | Failure Mode | Mitigation Strategy |

|---|---|---|---|

| Corner radius | <0.2 mm | Crack initiation | Radius ≥0.5 mm |

| Eccentricity | >5–10 μm | Vibration fatigue | Dynamic balancing |

| Surface roughness | >0.8 μm | Accelerated wear | Controlled polishing |

| Section transition | Abrupt | Stress concentration | Tapered geometry |

After geometric risks are understood, attention naturally shifts toward manufacturing realities. Therefore, this section clarifies how machining and process constraints shape the achievable performance of Alumina Ceramic Parts used in dynamic wear environments.

Machining and Manufacturing Constraints of Dynamic Alumina Parts

Dynamic Alumina Ceramic Parts demand more than nominal dimensional accuracy; they require microstructural uniformity and process stability across batches. Consequently, manufacturing constraints often define real performance limits long before design intent is reached. Moreover, understanding these constraints early prevents over-specification that raises cost without extending service life.

Sintering Density and Microstructural Uniformity

Sintering density directly influences wear resistance and fracture tolerance in Alumina Ceramic Parts. In dynamic applications, relative density below 99.2% often correlates with accelerated grain pull-out under sliding or erosive contact.

Field evaluations show that components sintered to ≥99.5% relative density typically exhibit 20–35% lower volumetric wear rates than lower-density counterparts under identical slurry conditions. In one grinding system upgrade, replacing mixed-density batches with uniform high-density alumina reduced unexpected edge chipping within the first 300 hours. Consequently, density consistency across batches matters as much as the absolute density value.

Therefore, sintering control windows must be treated as functional parameters rather than internal process details.

Precision Machining Limits for Rotating Geometry

Machining alumina to tight tolerances introduces residual stresses if material removal is uneven. Typically, roundness and concentricity within ±3–6 μm are achievable for diameters below 200 mm, provided tool paths are symmetric and heat input is controlled.

However, pushing tolerances below ±2 μm without functional justification often increases scrap rates without improving dynamic stability. I have observed cases where reducing tolerance from ±5 μm to ±2 μm increased machining-induced microcracking incidents by over 40%, while vibration behavior remained unchanged during operation.

Thus, machining limits must align with dynamic performance needs rather than theoretical capability.

Batch Consistency and Statistical Control

Dynamic systems amplify small dimensional variations over time. Therefore, batch-to-batch consistency is critical for Alumina Ceramic Parts used as wear or rotating elements.

Statistical process control data from series production indicate that maintaining Cpk ≥1.67 on key dimensions typically keeps vibration drift within ±10% across installations. When Cpk falls below 1.33, early-life variation often triggers uneven wear patterns within the first 200–400 hours. In maintenance audits, these variations are frequently misattributed to alignment errors rather than component variability.

Accordingly, SPC discipline transforms ceramic components from “fragile parts” into predictable mechanical elements.

Manufacturing Capability Summary for Dynamic Alumina Ceramic Parts

| Manufacturing Aspect | Typical Capability Range | Operational Impact |

|---|---|---|

| Relative density (%) | ≥99.5 | Lower wear rate |

| Concentricity (μm) | ±3–6 | Vibration control |

| Surface roughness (Ra μm) | 0.2–0.6 | Stable sliding |

| Dimensional Cpk | ≥1.67 | Batch consistency |

| Scrap risk increase | <2 μm tolerance | Residual stress |

Once manufacturing capability is confirmed, operational teams must plan how long Alumina Ceramic Parts will perform before intervention is required. Therefore, this section addresses lifetime prediction and replacement planning for dynamic wear environments without relying on reactive maintenance.

Lifetime Prediction and Replacement Planning

Predicting service life for Alumina Ceramic Parts in dynamic systems depends on measurable wear progression rather than nominal material limits. Consequently, lifetime estimation should be approached as a controlled engineering activity rather than an after-the-fact observation.

-

Wear rate modeling based on operating velocity and media hardness

In rotating and dispersing systems, wear rate often scales linearly with surface speed once steady-state contact is established. For alumina components operating between 2–10 m/s, volumetric wear typically remains stable when particle hardness does not exceed HV 1200–1500. Above this threshold, erosion-dominated wear accelerates sharply, reducing predictable service life windows. -

Inspection intervals and early failure indicators

Visual inspection every 300–600 operating hours commonly reveals early indicators such as edge whitening, localized roughening, or fine radial marks. These signs usually precede measurable dimensional drift by 200–400 hours, allowing planned replacement rather than emergency shutdowns. -

Spare strategy for high-downtime systems

Systems with restart penalties benefit from staged spare planning. Maintaining one fully finished spare and one semi-finished blank typically reduces response time by 40–60%, particularly for custom rotating Alumina Ceramic Parts.

Following this planning framework, maintenance shifts from reactive replacement to scheduled intervention, stabilizing uptime and reducing secondary damage to mating components.

However, lifetime planning often triggers a broader material comparison. Therefore, this section clarifies where Alumina Ceramic Parts remain the most appropriate choice in dynamic wear environments, and where alternative ceramics may offer advantages under specific constraints.

Alumina Versus Alternative Ceramics in Dynamic Applications

Material substitution is frequently proposed when wear issues arise. Nevertheless, changing ceramics without revisiting wear mode and geometry often shifts failure rather than eliminating it. Consequently, alumina should be evaluated relative to alternatives based on operating physics rather than reputation alone.

-

Alumina versus zirconia in abrasive media

Zirconia offers higher fracture toughness, typically 7–10 MPa·m¹ᐟ², compared with alumina at 3–5 MPa·m¹ᐟ². However, alumina hardness above HV 1500 often delivers lower abrasive wear rates in particle-rich slurries. In long-duration grinding, zirconia components sometimes show higher mass loss despite surviving impact events better. -

Alumina versus silicon carbide in chemical wear

Silicon carbide provides superior chemical resistance in extreme acidic or alkaline conditions. Yet, its higher stiffness and lower fracture strain can amplify chipping under mixed mechanical and erosive loads. Alumina Ceramic Parts, operating within pH 3–11, often achieve longer stable service without sudden fracture. -

Cost stability versus performance envelope

Alumina maintains consistent performance across a wide duty range with fewer process sensitivities. Alternative ceramics may outperform alumina at specific extremes, but they also introduce narrower operating windows that increase selection risk.

Accordingly, alumina remains the default dynamic wear material when predictable behavior, manufacturability, and broad chemical compatibility outweigh marginal gains in toughness or corrosion resistance.

Moreover, once material and wear behavior are aligned, successful deployment depends on how Alumina Ceramic Parts integrate with surrounding mechanical systems. Therefore, this section examines interface design with bearings, drives, and process equipment where dynamic interaction governs long-term stability.

Integration with Bearings Drives and Process Equipment

Dynamic Alumina Ceramic Parts never operate in isolation. Instead, their performance emerges from interaction with shafts, bearings, seals, and drive controls. Consequently, integration errors frequently negate material advantages, even when individual components meet specification.

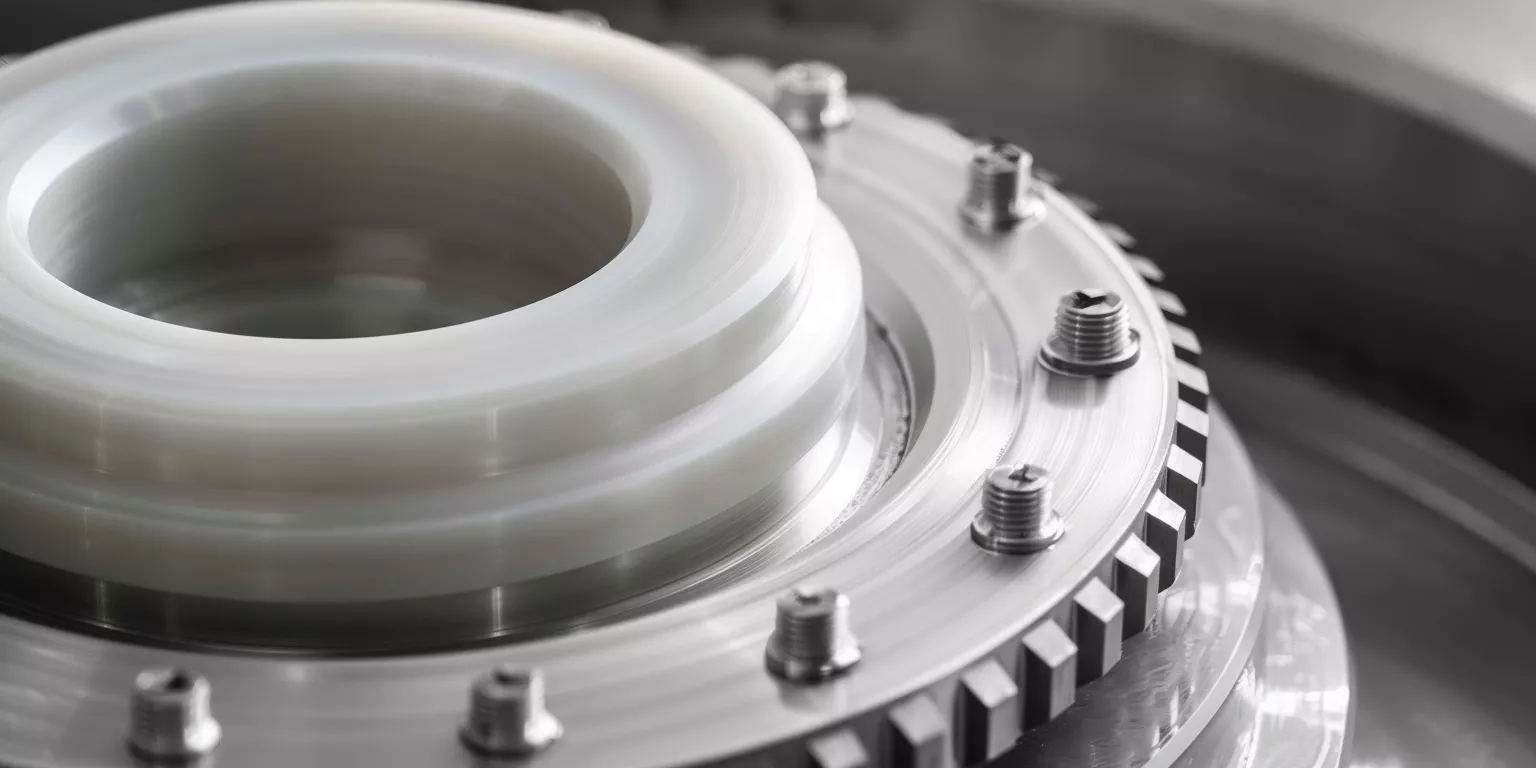

Shaft Fit and Assembly Interfaces

Fit strategy determines how load transfers into Alumina Ceramic Parts during rotation. Typically, interference or transition fits must remain within controlled limits to avoid tensile hoop stress. For alumina sleeves and hubs, interference above 0.02–0.04% of diameter often increases fracture risk during thermal excursions.

In practical assembly, engineers often adopt H7/g6 or H7/f7 style fits for ceramic-to-metal interfaces. I have seen installations where reducing nominal interference by 10–15 μm eliminated recurring sleeve cracks without affecting torque transmission. Moreover, uniform contact length along the shaft minimizes local stress peaks, which is especially critical during startup torque spikes.

Accordingly, ceramic fit design should prioritize stress moderation over traditional metal press-fit logic.

Compatibility with Seals and Lubrication

Sealing and lubrication conditions strongly influence wear evolution. Alumina Ceramic Parts tolerate dry running better than metals; however, mixed lubrication regimes still benefit from controlled surface finish.

In rotating assemblies with elastomer seals, surface roughness around Ra 0.3–0.5 μm typically balances sealing effectiveness and wear suppression. Excessively smooth finishes below Ra 0.1 μm may reduce lubricant retention, while rougher surfaces accelerate seal abrasion. In one mixer retrofit, adjusting sleeve finish from Ra 0.7 μm to 0.4 μm extended seal life by approximately 45% over 1200 operating hours.

Thus, lubrication strategy must be co-designed with ceramic surface characteristics rather than applied afterward.

Interaction with Drive Systems

Drive systems impose transient loads that ceramics experience differently from metals. Rapid acceleration, deceleration, and torque ripple introduce cyclic stress even when average speed is moderate.

Data from variable-frequency drive applications show that torque oscillations above ±10% of nominal can elevate microcrack growth rates in ceramic hubs. By contrast, smoothing acceleration ramps over 1.5–3 seconds often reduces stress amplitude enough to double ceramic service life. In one classifier system, modifying drive parameters alone extended alumina rotor life from 700 to over 1600 hours.

Therefore, electrical drive tuning is a legitimate durability control for dynamic Alumina Ceramic Parts.

Integration Considerations for Dynamic Alumina Ceramic Parts

| Interface Element | Key Parameter | Typical Range | Reliability Effect |

|---|---|---|---|

| Shaft fit | Interference (μm) | 10–40 | Stress moderation |

| Seal contact | Surface roughness (Ra μm) | 0.3–0.5 | Seal longevity |

| Drive ramp time | Acceleration (s) | 1.5–3.0 | Fatigue reduction |

| Torque ripple | Peak variation (%) | <10 | Crack suppression |

Additionally, after integration parameters are established, verification becomes the final safeguard against premature failure. Therefore, this section details how quality verification converts Alumina Ceramic Parts from nominally compliant components into reliable dynamic wear elements.

Quality Verification for Dynamic Alumina Ceramic Parts

Quality verification for dynamic applications must extend beyond dimensional pass–fail checks. Consequently, inspection strategies should confirm that Alumina Ceramic Parts will behave predictably under rotation, abrasion, and cyclic load. Moreover, verification data often reveals latent risks that drawings alone cannot capture.

Dimensional Verification for Rotating Accuracy

Dimensional accuracy in dynamic parts is meaningful only when measured relative to functional datums. For rotating Alumina Ceramic Parts, concentricity, roundness, and axial runout are more critical than isolated diameter values.

In practice, high-speed rotors and sleeves typically require concentricity within ±3–6 μm to maintain vibration stability. During incoming inspection audits, I have observed components passing diameter tolerance yet failing in service because datum selection during measurement did not reflect the actual mounting condition. Once inspection protocols were revised to mirror assembly orientation, vibration-related failures dropped by over 50% within the first production cycle.

Accordingly, verification must replicate real assembly constraints rather than abstract measurement setups.

Surface and Edge Integrity Inspection

Surface and edge defects often initiate failure long before bulk material limits are reached. Alumina Ceramic Parts are particularly sensitive to micro-chipping and grinding-induced tensile stress near edges.

Typical inspection thresholds include rejecting edge chips larger than 50–80 μm in high-speed applications, as these defects can grow under cyclic load. In erosion-prone components, surface waviness above 5–8 μm peak-to-valley has been linked to uneven flow impact and accelerated material loss. In one dispersion system, tightening edge integrity criteria alone extended rotor life by approximately 35% without modifying geometry or material grade.

Thus, surface and edge inspection directly translate into service-life gains.

Material Traceability and Batch Records

Traceability closes the loop between manufacturing and field performance. For dynamic Alumina Ceramic Parts, batch-level records linking density, grain size, and sintering conditions enable rapid root-cause analysis when anomalies arise.

Facilities maintaining full traceability have demonstrated 30–40% shorter downtime during failure investigations, because suspect batches can be isolated quickly. In contrast, mixed-batch inventories often force blanket replacement strategies. From a reliability standpoint, traceability transforms ceramics from “consumables” into engineered system elements with documented behavior histories.

Therefore, batch records are not administrative overhead but operational risk controls.

Quality Verification Summary for Dynamic Alumina Ceramic Parts

| Verification Aspect | Typical Threshold | Failure Risk Addressed |

|---|---|---|

| Concentricity (μm) | ±3–6 | Vibration fatigue |

| Edge defect size (μm) | <50–80 | Crack initiation |

| Surface waviness (μm) | <5–8 | Uneven erosion |

| Batch traceability | Full lot linkage | Root-cause isolation |

Subsequently, after verification requirements are clarified, engineers and buyers must condense technical complexity into a repeatable decision path. Therefore, this section consolidates prior analysis into a practical selection logic for Alumina Ceramic Parts used in dynamic wear environments.

Practical Selection Logic for Dynamic Wear Components

Selecting Alumina Ceramic Parts for rotating, grinding, and dispersing systems is most effective when decisions follow wear physics rather than catalog hierarchies. Consequently, the selection process should begin with operating interaction and only then narrow toward material grade and tolerance.

-

Start from dominant wear mode rather than rotational speed alone

Sliding abrasion, particle erosion, and thermal fatigue impose fundamentally different stresses on Alumina Ceramic Parts. For example, systems operating below 2000 rpm may still experience severe erosion if slurry velocity exceeds 8 m/s, whereas higher-speed dry systems may remain stable with proper surface control. -

Balance hardness with fracture risk under cyclic load

While alumina hardness above HV 1600 suppresses abrasive wear, excessive geometric constraint can elevate tensile stress during startup and shutdown. In practice, modest hardness combined with smoother transitions often outperforms ultra-hard grades in long-duration service. -

Design geometry before tightening tolerances

Concentricity, fillet radii, and surface zoning usually govern lifetime more strongly than pushing diameter tolerances below ±3 μm. Over-tightening tolerances without addressing stress concentration frequently increases scrap without improving reliability.

Following this logic, Alumina Ceramic Parts become predictable wear stabilizers rather than experimental consumables, allowing procurement and engineering teams to converge on decisions with fewer trial iterations.

Moreover, once selection logic is established, execution quality becomes the decisive factor separating stable operation from recurring adjustment. Therefore, this section explains how ADCERAX supports dynamic wear applications through application-oriented customization rather than catalog substitution.

ADCERAX Custom Alumina Ceramic Parts for Dynamic Wear Systems

Dynamic wear components demand coordination between design intent, manufacturability, and operational reality. Consequently, ADCERAX approaches Alumina Ceramic Parts as engineered subsystems rather than isolated items. Moreover, customization is guided by wear physics, assembly constraints, and lifecycle targets to reduce iteration cycles.

Application Oriented Engineering Review

ADCERAX begins with a structured engineering review that evaluates drawings against real operating conditions. Specifically, shaft speed, media hardness, particle size, and duty cycle are mapped to stress distribution and wear mode before tooling decisions are finalized.

In practice, this review frequently identifies non-obvious risks such as excessive interference, sharp internal transitions, or unbalanced mass distribution. During one dispersion rotor project, adjusting edge radii from 0.3 mm to 0.7 mm and relaxing a non-critical tolerance by 8 μm reduced early chipping incidents by over 50% during the first 600 operating hours. Consequently, drawing optimization often delivers reliability gains without increasing component cost.

Therefore, engineering review serves as a risk filter rather than a cosmetic design step.

One Stop Manufacturing and Verification

ADCERAX integrates forming, sintering, precision machining, and verification within a single workflow. This integration allows Alumina Ceramic Parts to maintain consistent microstructure and dimensional alignment across batches.

Typical production capability includes relative density ≥ 99.5%, concentricity within ±3–6 μm, and controlled surface finishes between Ra 0.2–0.6 μm, depending on application needs. In series production, statistical controls maintain Cpk ≥1.67 on functional dimensions, limiting vibration variation across installations. In one multi-site deployment, this consistency reduced on-site fitting adjustments by approximately 40%.

As a result, integrated manufacturing converts customization from a risk factor into a stability advantage.

Support for Trial Runs and Scale Up

Dynamic wear systems rarely reach optimal performance on the first iteration. Accordingly, ADCERAX supports staged validation from prototype to volume supply.

Prototype batches are typically evaluated over 300–800 operating hours, generating wear and vibration feedback before scale-up. Based on these results, geometry or surface adjustments are incorporated into the production version. Customers transitioning from pilot to series production have reduced post-installation modification cycles by over 60%, because lessons from early trials are embedded upstream.

Thus, trial-supported scaling ensures Alumina Ceramic Parts evolve with the system rather than reacting to failures.

ADCERAX Customization Capability Summary

| Capability Area | Typical Range | Operational Benefit |

|---|---|---|

| Density control (%) | ≥99.5 | Wear stability |

| Concentricity (μm) | ±3–6 | Vibration reduction |

| Surface finish (Ra μm) | 0.2–0.6 | Controlled wear |

| Prototype validation (h) | 300–800 | Risk reduction |

| Dimensional Cpk | ≥1.67 | Batch consistency |

Finally, after customization pathways are clarified, decision-makers require a concise synthesis to align engineering, procurement, and maintenance priorities. Therefore, this section consolidates dynamic wear selection principles into a unified operational perspective.

Practical Selection Summary for Dynamic Applications

Dynamic wear systems reward predictability more than extreme material performance. Consequently, Alumina Ceramic Parts succeed when specified as stabilizing elements within a broader mechanical ecosystem rather than as isolated wear items.

-

Alumina Ceramic Parts as wear stabilizers

In rotating and dispersing equipment, alumina converts uncontrolled abrasion into gradual, measurable material loss. When wear rates remain below 10⁻⁵ mm³/N·m, maintenance planning becomes proactive rather than reactive. -

Predictability over extreme toughness

Although tougher ceramics may survive isolated impacts, alumina often delivers longer uninterrupted service under steady abrasion and erosion. In long-duty cycles exceeding 1500 hours, stable wear behavior typically outweighs marginal gains in fracture toughness. -

System-level thinking reduces downtime

Geometry, balance, fit, and drive control frequently extend alumina service life by 30–70% without material substitution. Accordingly, system integration decisions should precede grade escalation.

By applying these principles, Alumina Ceramic Parts function as reliability anchors that simplify lifecycle management in dynamic wear environments.

Conclusion

Alumina Ceramic Parts enable dynamic systems to operate with controlled wear, stable geometry, and reduced contamination, transforming unpredictable degradation into manageable service behavior.

ADCERAX provides custom Alumina Ceramic Parts for rotating, grinding, and dispersing equipment based on drawings, operating data, and lifecycle objectives. Engineering consultation is available to support prototypes through series production.

FAQ

How fast can Alumina Ceramic Parts operate in rotating systems?

Properly balanced alumina components routinely operate between 300 and 6000 rpm, depending on diameter and load distribution.

Are Alumina Ceramic Parts suitable for abrasive slurries?

Yes. In particle-rich media below HV 1500, alumina typically maintains linear wear behavior with low contamination risk.

Can alumina replace metal parts without redesign?

Direct substitution is rarely optimal. Fit, edge geometry, and surface zoning usually require adjustment to avoid stress concentration.

Is small-batch customization feasible for dynamic wear parts?

Yes. Prototypes validated over 300–800 hours commonly transition to stable series production with minimal redesign.

References: