Aluminum Silicate Fiber Solutions for Furnaces, Kilns and Boilers

ADCERAX is a Chinese manufacturer with more than 20 years of experience producing aluminum silicate ceramic fiber materials for high-temperature industrial insulation. Our factory supplies a complete range of aluminosilicate fiber products, including ceramic fiber boards, cut-to-size sheets, fiber papers, bulk wool, cloth, tapes, ropes and custom-formed shapes for furnace, kiln, boiler and process-heating applications. With integrated production and machining capabilities, we support both standard specifications and fully customized components based on drawings or samples.

🚀We ensure stable supply, consistent quality and fast export delivery, helping you avoid downtime, material variation and long lead times when sourcing aluminum silicate ceramic fiber products.

1260–1430°C

High-temperature rating for industrial furnaces and kilns

Faster installation and shorter maintenance downtime

What Is Aluminum Silicate Fiber?

Aluminum silicate fiber is a high-temperature insulation material made from a fused mixture of aluminum oxide (Al₂O₃) and silicon dioxide (SiO₂). With classification temperatures typically between 1260°C and 1430°C, it is produced through melting, fiberizing and needling processes to create lightweight, low-density fibers with strong thermal stability.

Key Features of Aluminum Silicate Fiber

The fiber retains structural stability and low thermal conductivity across this range, supporting reliable and efficient insulation for continuous and high-demand industrial furnace operations.

The fiber structure contains minimal mass, allowing furnace chambers and heated zones to heat up and cool down faster compared with dense refractories, improving cycle efficiency and reducing fuel use.

Compared with brick or castable linings, aluminum silicate fiber significantly lowers the overall lining weight, helping OEMs design lighter furnaces, supports, doors and movable kiln structures.

Its flexible fiber network absorbs rapid temperature fluctuations without cracking, making it suitable for frequent start-stop furnace operations and zones with uneven or rapidly shifting heating.

Blankets, boards and paper can be easily trimmed, curved or punched during installation, enabling precise fitting around burners, flanges, sight holes and irregular furnace geometries.

The material can be manufactured into blankets, rigid boards, paper, vacuum-formed blocks, modules, gaskets and custom shapes—offering furnace designers maximum layout flexibility.

Key Properties of Aluminum Silicate Ceramic Fiber

Aluminum silicate fiber maintains low thermal conductivity and stable structure within the 1260–1430°C range. Its lightweight fiber matrix offers strong thermal shock resistance and controlled shrinkage, ensuring reliable insulation performance in high-temperature furnace environments.

Aluminum Silicate Ceramic Fiber – Technical Specifications

| Parameter | Typical Value | Notes / Industrial Relevance |

|---|---|---|

| Material Composition | Al₂O₃–SiO₂ | Silicate-based refractory matrix |

| Working Temperature | 1000–1400°C | Depends on density & grade |

| Bulk Density | 200–400 kg/m³ | Lower density = better insulation |

| Thermal Conductivity | 0.08–0.22 W/m·K | Measured at 600–1000°C |

| Linear Shrinkage | ≤ 2% at 1000–1300°C | Ensures dimensional stability |

| Cold Crushing Strength | 0.6–1.2 MPa | Resistance to mechanical load |

| Thermal Shock Resistance | High | Suitable for rapid heating cycles |

| Water Absorption | Low | Supports clean installation |

| Available Thickness | 10–75 mm | Custom thickness on request |

| Available Forms | Boards, blocks, custom-machined shapes | Supports OEM engineering designs |

This chart displays the typical properties of aluminum silicate (Al₂SiO₅) ceramic fibre used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Why Choose Aluminum Silicate Fiber for High-Temperature Insulation?

Low thermal conductivity across the 1260–1430°C range helps reduce heat loss in furnace walls and hot zones, supporting energy-efficient operation during continuous industrial processes.

Engineered fiber composition maintains lining thickness and uniform insulation performance over long service cycles, reducing the risk of hot spots and premature lining degradation.

Aluminum silicate fiber integrates well with anchors, rigidizers, coatings and brick/castable backup layers, enabling flexible system design for both new furnace builds and retrofit upgrades.

Its low mass and easy-to-cut structure shorten installation time, reduce on-site labor intensity and allow faster turnaround during shutdowns or scheduled maintenance.

Aluminum Silicate Fiber Product Range from ADCERAX

ADCERAX provides a range of Al₂SiO₅ ceramic products, including ceramic fiber, pouring cups, filter boxes, and customized insulation components for high-temperature casting and furnace applications. Standard formats and fully custom shapes are available according to drawings or project requirements.

Aluminum silicate fiber blankets are used in furnace linings, heat-treatment units, and thermal-control systems to keep stable insulation, reduce heat loss, and support uniform temperatures in high-temperature.

- Helps maintain stable insulation behavior under long-term heating cycles

- Provides lightweight, flexible coverage for furnace and heater systems

- Offers adjustable thickness and density options to match project design needs

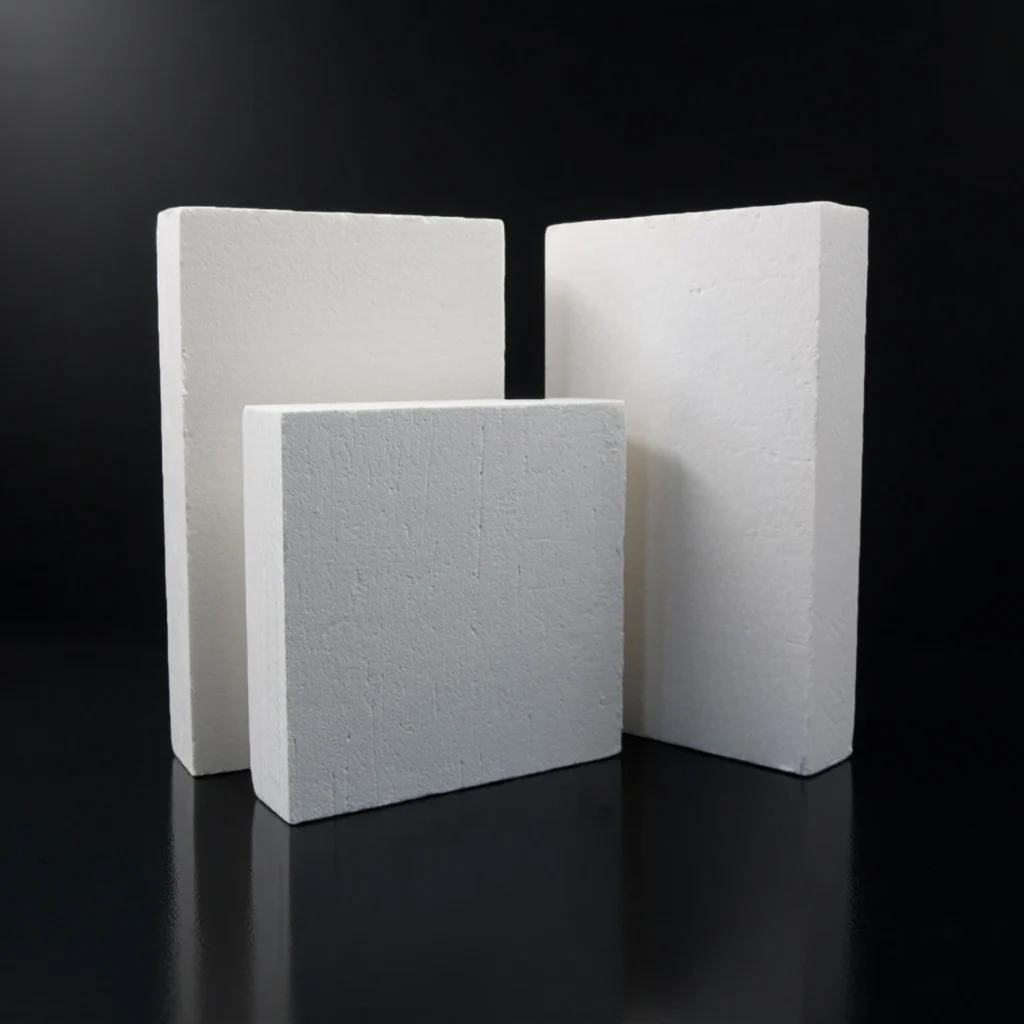

Aluminum silicate ceramic fiber is used for furnace and kiln insulation, molten-metal processing parts, casting filtration, and lightweight thermal components in high-temperature industrial equipment.

- Supports complex insulation geometries with stable formability

- Lightweight and easy to install in high-temperature systems

- Flexible in thickness and dimensions for project-specific engineering

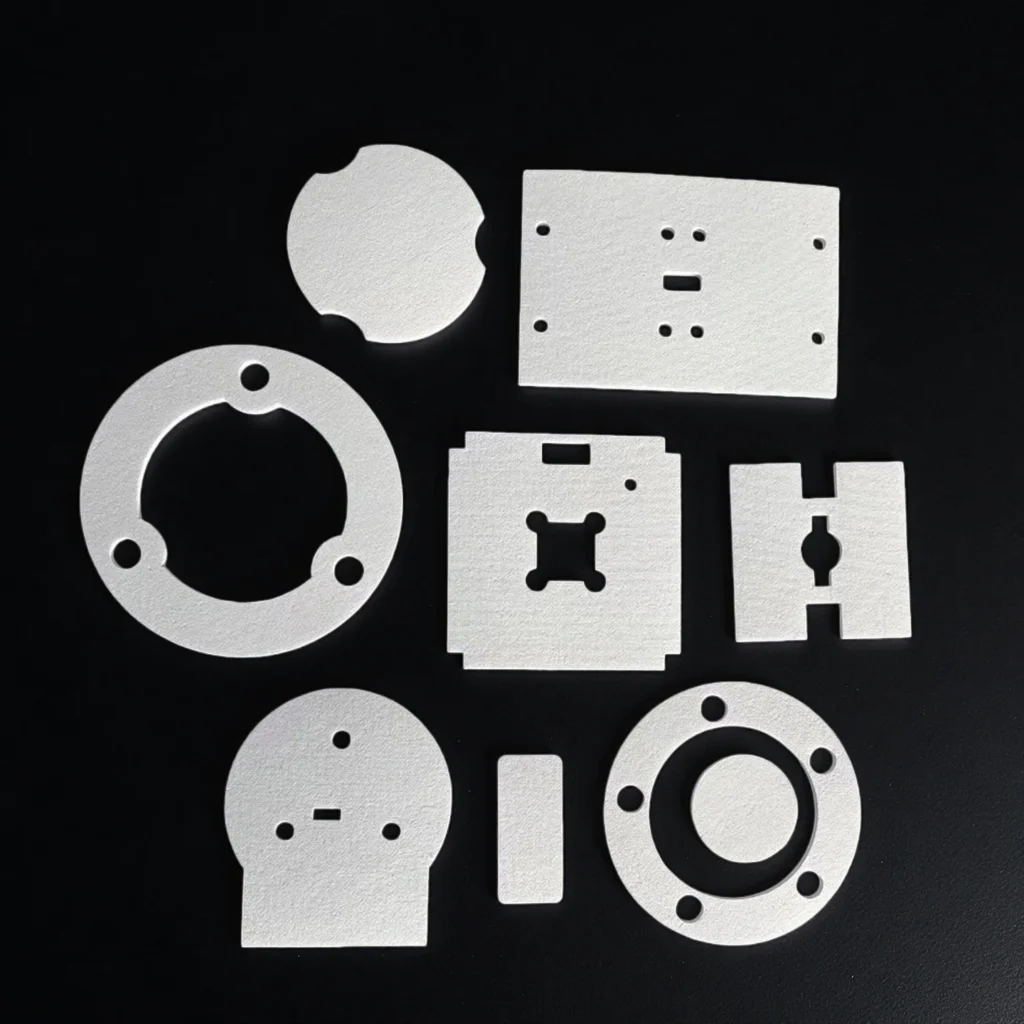

Aluminum silicate fiber gaskets are used in aluminum casting systems to seal molten-metal flow paths, improve filling stability, and reduce turbulence that may lead to inclusions, or surface defects in high-temperature casting.

- Maintains a stable thermal barrier for consistent metal flow during filling

- Provides reliable sealing and positioning within gating assemblies

- Customizable thickness, density, and profiles to match specific casting tools

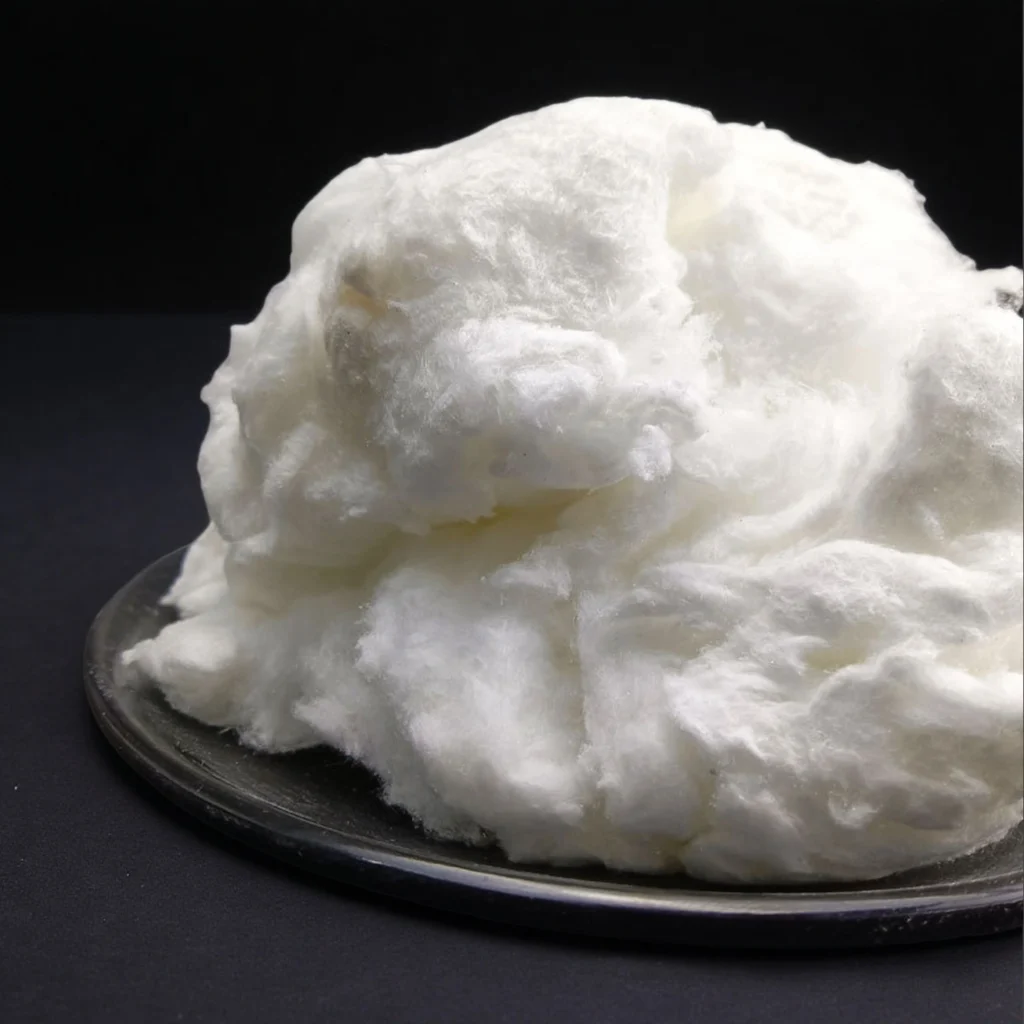

Aluminum silicate fiber cotton is used in furnace linings, heating units, casting systems, and high-temperature insulation zones to stabilize heat flow, reduce thermal loss, and support consistent temperature.

- Enhances thermal insulation stability for more uniform system heating

- Supports stable positioning within gating systems for repeatable production

- Customizable shapes and inlet/outlet dimensions to match specific mold designs

Aluminum silicate fiber paper is used in casting systems to control molten metal flow, improve filling stability, and limit turbulence that can create inclusions or other casting surface defects.

- Maintains smooth, controlled metal flow to improve casting consistency

- Lightweight, flexible fiber structure simplifies installation

- Customizable density and thickness to fit specific thermal designs

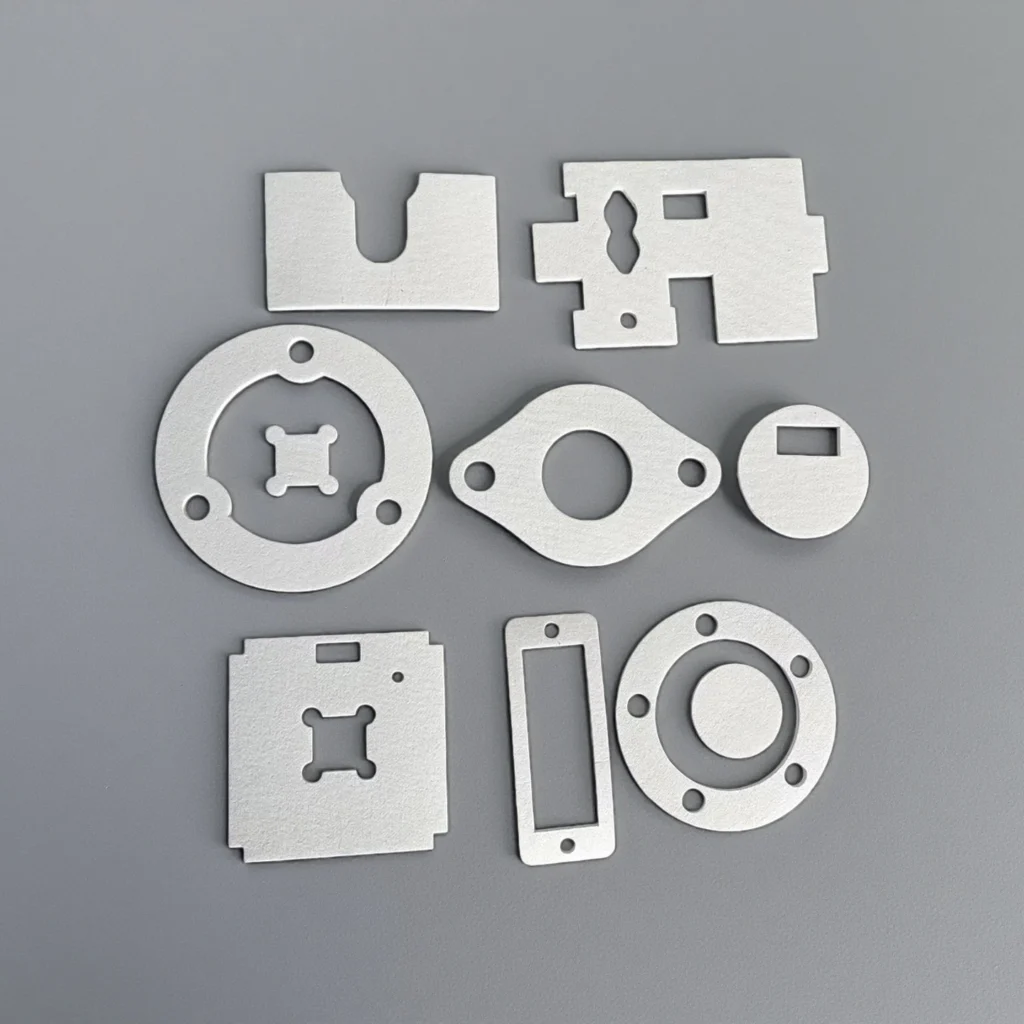

Aluminum silicate fiber felt is used in aluminum casting systems to guide molten metal, support stable flow during filling, and reduce turbulence that may cause inclusions or casting defects.

- Maintains smooth, controlled metal flow to improve casting consistency

- Supports stable positioning within gating systems for repeatable production

- Customizable shapes and inlet/outlet dimensions to match specific mold designs

Aluminum silicate fiber ropes are used in furnace doors, expansion joints, pump seals, and high-temperature insulation zones to contain heat, limit leakage, and support stable sealing performance.

- Withstands repeated thermal cycling for reliable sealing

- Flexible fiber structure adapts to uneven surfaces

- Cuttable and formable for project-specific installation

Aluminum silicate fiber modules are used in furnace linings and thermal systems to maintain insulation stability, reduce heat loss, and support uniform heating in continuous high-temperature processes.

- Ensures stable insulation performance for steady furnace operation

- Supports repeatable installation with modular block geometry

- Customizable densities and dimensions for different system layouts

Aluminum silicate fiber shaped parts are used in high-temperature insulation parts, sealing interfaces, and thermal-control sections to support stable heating, reduce energy loss, and maintain system reliability.

- Ensures smoother, controlled metal flow for improved casting uniformity

- Maintains accurate placement for repeatable casting cycles

- Offers customizable contours and interfaces to match mold layouts

🔥 For furnaces, kilns and heating systems—get aluminum silicate fiber you can rely on.

ADCERAX supplies aluminum silicate fiber engineered for consistent insulation at elevated temperatures, providing reliable thermal control and stable density across demanding furnace conditions. Suitable for kilns, heaters and casting lines, our fiber products support uniform operation and long-term dimensional stability. Share your drawings or requirements, and our team will respond quickly with technical guidance and a clear quotation.

Where Aluminum Silicate Ceramic Fiber Is Used?

Aluminium silicate ceramic fibre is used in high-temperature insulation systems, furnace linings, kiln walls, molten-metal handling equipment, petrochemical heating units, thermal-processing chambers, expansion-joint insulation, and fire-protection assemblies across industrial, metallurgical, and energy-processing sectors.

Industrial Furnaces & Kilns

- Wall/roof backup insulation

- Furnace door seals

- Burner block surrounding insulation

- Sight-hole gaskets and expansion joints

- Kiln car decks and door linings

🧩 Industry Pain Points:

- Unstable insulation thickness

- Shrinkage causing heat leakage

- Slow delivery is impacting shutdown schedules

🔹ADCERAX Solutions:

- Precise density & thickness control for stable insulation

- Low-shrinkage formulations for long-term dimensional stability

- 24-hour stock supply + 2–4 week custom manufacturing cycles

- Engineering support for module layouts and cut-to-fit parts

Metal Casting & Non-Ferrous Processing

- Launder and trough insulation

- Casting line covers & lid insulation

- Filter box and distribution runner insulation

- Furnace access port gaskets

- Molten metal ladle insulation layers

🧩 Industry Pain Points:

- Temperature loss in aluminum transfer lines

- Thermal shock when opening furnace doors

- Need for smooth fiber surfaces to avoid contamination

🔹ADCERAX Solutions:

- Clean, controlled fiber surfaces with low shot content

- Custom-cut boards/papers for precise fit in launders and filter boxes

- Lightweight insulation improving thermal retention

- Reliable batch stability for consistent molten metal handling

Petrochemical Heaters & Refinery Furnaces

- Radiant wall backup insulation

- Flue gas duct insulation

- Expansion joint packing

- Burner tile peripheral insulation

- Access door insulation panels

🧩 Industry Pain Points:

- Rising energy loss due to refractory degradation

- High-temperature shrinkage leading to uneven heating

- Strict turnaround schedules requiring reliable supply

🔹ADCERAX Solutions:

- High-grade 1430°C fiber with proven low thermal conductivity

- Controlled shrinkage for radiant and convection sections

- On-time export delivery optimized for overhaul windows

- Engineering review to match heater lining design

Power Generation & Boiler Insulation

- Boiler walls and roof insulation

- Ducting and exhaust paths

- Turbine enclosure insulation

- Fireproof barriers and protection panels

🧩 Industry Pain Points:

- Structural load from heavy refractory

- Vibration + thermal cycling damage

- High downtime cost during outages

🔹ADCERAX Solutions:

- Lightweight fiber blankets reducing load and improving efficiency

- Dense fiber boards for vibration-resistant insulation areas

- Fast manufacturing for urgent shutdown requirements

- Cut-to-size insulation panels for quick replacement

Custom Aluminum Silicate Fiber Supplier

We specialize in custom aluminum silicate fiber solutions based on customer drawings, samples, or insulation specifications. Tailored thicknesses, densities, cut shapes, and punched or profiled features can be produced for furnace linings, kiln interiors, casting-line insulation, and high-temperature heating systems. Custom aluminum silicate fiber parts usually require 3–9weeks, depending on shape complexity and processing requirements.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – aluminum silicate (Al₂SiO₅) Fiber manufacturer

ADCERAX is a China-based aluminum silicate fiber factory focused on stable material quality, reliable thermal performance, and efficient customization. With factory-direct supply, flexible engineering support, and fast response to drawings or specifications, we help global industrial buyers reduce project cost and secure consistent high-temperature insulation.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX provides integrated manufacturing for aluminum silicate fiber products, covering fiber-forming, needling, shaping, precision cutting, and thermal processing. We supply high-temperature insulation materials for furnaces, kilns, casting lines, and industrial heating equipment. Both prototype and large-batch orders are supported with stable quality and reliable export delivery.

-

Precision Cutting & Dimensional Consistency:

Aluminum silicate fiber blankets, boards, papers and custom-cut shapes are processed to maintain accurate thickness, clean edges, and consistent density. Controlled shrinkage and smooth fiber surfaces ensure proper fitment and stable insulation performance in high-temperature furnace zones. -

Batch Stability & Performance Control:

Each batch is checked for fiber uniformity, density accuracy, thermal stability and shrinkage behavior. The optimized fiber structure supports low thermal conductivity, strong thermal shock resistance and predictable insulation performance under continuous or cyclic heating. -

Customization & Engineering Support:

We offer drawing-based customization for thickness ranges, densities, cut patterns, slots, cavities, and shaped insulation parts. Our engineering support ensures compatibility with furnace linings, casting-line insulation, heat-flow requirements, and refurbishment projects across high-temperature industrial systems.

ADCERAX specializes in producing aluminum silicate ceramic components using controlled fiber-forming, thermal processing, precision cutting, and strict dimensional inspection. Our aluminum silicate materials deliver stable high-temperature insulation, low thermal conductivity, strong thermal shock resistance, and reliable structural integrity for furnaces, kilns, casting systems, and industrial heating equipment.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Performance Consistency | Aluminum silicate fiber is produced with controlled density and uniform fiber distribution, ensuring stable insulation performance, low thermal conductivity and predictable thermal shrinkage. | ||

| High-Temperature Precision Cutting & Shaping | CNC and die-cutting deliver clean edges, accurate thickness and consistent profiles for boards, papers and custom fiber shapes, with typical tolerances of ±0.20–0.50 mm. | ||

| Advanced Processing Capability | We support layering, lamination, contour cutting and cavity shaping, enabling aluminum silicate fiber to be formed into insulation panels, gaskets and complex thermal components. | ||

| Dimensional Stability Under Heat Load | Thermal stabilization and controlled forming reduce shrinkage and warpage, maintaining reliable dimensions during long-term furnace or kiln operation. | ||

| Strict Thermal & Structural Quality Control | Each batch is inspected for density uniformity, bonding strength and shrinkage rate, ensuring repeatable performance and strong thermal shock resistance. | ||

FAQs About Al₂SiO₅ Ceramic Fiber

Its low thermal conductivity minimizes heat loss through furnace walls, allowing faster heat-up and lower firing energy. Plants typically report 5–12% energy reduction when switching from brick linings to fiber-based systems.

Yes. The fiber network tolerates rapid temperature changes without cracking, making it suitable for start-stop furnaces, forging lines, batch kilns and lift-door heat-treatment equipment.

All fiber products produce some airborne dust during cutting. ADCERAX supplies:

• Pre-compressed low-dust boards

• Rigidized surfaces

• Vacuum-formed shapes with enhanced structural strength

These lower dust generation during installation and maintenance.

Modules cut installation time by 30–50% versus brick systems. They preserve lining thickness, reduce joints, and maintain uniformity. ADCERAX offers pre-folded and pre-compressed modules compatible with standard anchor systems.

Aluminum silicate fiber is stable in neutral, oxidizing and reducing conditions.

ADCERAX reviews your fuel type, flue gas composition, and burner arrangement to ensure compatibility and avoid fiber surface crystallization.

Yes—when the furnace requires lightweight construction, faster heat-up, and improved thermal efficiency. However, bricks may still be needed in areas with high mechanical abrasion. ADCERAX can design hybrid fiber–brick linings.

Look for:

• Hot spots on shell surfaces

• Significant shrinkage at joints

• Fiber powdering or delamination

• Reduced heat-up speed

ADCERAX can evaluate your lining condition from photos or drawings.

We usually need your required temperature rating (1260°C / 1360°C / 1430°C), density, thickness, dimensions, and whether you need blankets, boards, paper or custom-cut parts. Drawings or photos help us prepare a precise quotation quickly.

Yes. We provide CNC-cut, die-cut, punched, slotted and contoured aluminum silicate fiber shapes. Simply send your drawing, and we will match thickness, density and tolerances.

Yes. It works with most refractory anchors, rigidizers and ceramic coatings, allowing you to build multi-layer composite insulation systems.

Yes. We offer flexible pilot sampling, including 1–10 piece trial runs, precision-cut prototypes, and small-batch evaluations. This helps you verify fit, insulation performance, and installation tolerance before moving to volume production. Send your drawing or target dimensions, and our team will prepare a fast sample plan and lead time.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours