Aluminum Titanate Ceramic (Al₂TiO₅) for Molten Aluminum Casting

As an aluminum titanate ceramic (Al₂TiO₅) manufacturer with over 20 years of production and engineering experience, ADCERAX provide a complete range of components for molten aluminum systems. Our product line includes sprue bushes, insulating sleeves, riser tubes, stalk tubes, pouring cups, casting spouts, insulating rings, and other Al₂TiO₅ ceramic parts used throughout LPDC and non-ferrous casting operations.

We offer both standard sizes and fully customized designs, producing parts according to your drawings, samples, or specific equipment requirements. Whether you need small trial quantities or long-term volume supply, our team supports you with engineering guidance, controlled material quality, precise machining, and reliable lead times.

ADCERAX will provide aluminum titanate ceramic components that help your casting line run more stable, cleaner, and with fewer interruptions.

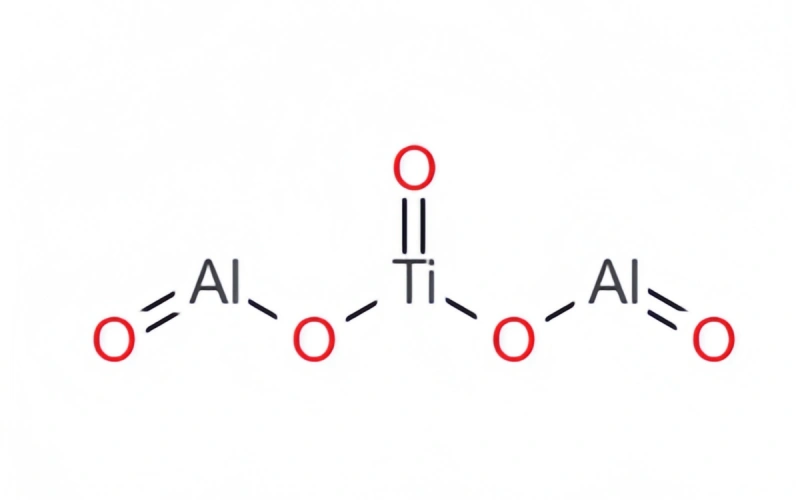

What Is Aluminum Titanate Ceramic?

Aluminum titanate ceramic (Al₂TiO₅) is a specialized oxide ceramic known for its very low thermal expansion, strong thermal shock resistance, and non-wetting behavior to molten aluminum. It is produced by reacting alumina and titania at high temperatures to form a stable micro-porous structure that remains dimensionally consistent under rapid heating and cooling.

Aluminum Titanate Ceramic (Al₂TiO₅) Advantages

The durable microstructure of Al₂TiO₅ allows components such as riser tubes, stalk tubes and sprue bushes to remain operational for longer intervals. This reduces replacement frequency, lowers total consumable cost and helps maintain stable casting performance across extended production cycles.

Aluminum titanate ceramic supports smoother aluminum transfer in LPDC and gravity casting systems, helping minimize turbulence, oxide entrapment and filling inconsistencies. The result is fewer defects, more stable melt flow behavior and improved casting consistency across repeated cycles.

Its predictable dimensional behavior and compatibility with molten-aluminum hardware lessen mechanical load on mounting interfaces, seals and refractory transitions. This helps prevent premature wear on surrounding equipment, contributing to lower maintenance requirements and better long-term system reliability.

The lightweight structure and consistent geometry of Al₂TiO₅ parts make them easier to handle, align and install. This shortens changeover time during scheduled maintenance and accelerates production restarts, supporting higher overall equipment efficiency.

Aluminum Titanate Ceramic Properties

Aluminum titanate ceramic (Al₂TiO₅) provides exceptionally low thermal expansion, strong thermal shock resistance and non-wetting behavior to molten aluminum, delivering stable performance and dimensional reliability in casting environments.

Aluminum Titanate Ceramic (Al₂TiO₅)– Technical Sheet

| Parameter | Typical Value | Description |

|---|---|---|

| 1. Coefficient of Thermal Expansion (CTE) | 0.5–1.5 ×10⁻⁶ /K | Extremely low expansion that maintains dimensional stability under molten aluminum temperatures. |

| 2. Thermal Shock Resistance | Very high | Withstands rapid temperature fluctuations without cracking during casting cycles. |

| 3. Density | 2.8–3.0 g/cm³ | Medium-density ceramic structure suitable for molten aluminum system components. |

| 4. Thermal Conductivity | 1.5–3.0 W/m·K | Helps reduce heat loss along riser tubes, spouts and transfer components. |

| 5. Maximum Service Temperature | 900–1100°C | Suitable for typical molten-aluminum environments and transfer systems. |

| 6. Flexural Strength (MOR) | 10–25 MPa | Provides sufficient strength for handling, installation and operational load. |

| 7. Elastic Modulus | 20–40 GPa | Lower stiffness contributes to excellent thermal shock tolerance. |

| 8. Porosity | 12–25% | Supports insulation and limits internal thermal stress accumulation. |

| 9. Chemical Compatibility | Non-wetting to molten aluminum | Prevents adhesion, oxide buildup and contamination in casting processes. |

| 10. Dimensional Stability | Stable through long cycles | Maintains geometry during prolonged molten-aluminum exposure and thermal cycling. |

This chart displays the typical properties of aluminium titanate (Al₂TiO₅) ceramic materials used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Key Features of Aluminum Titanate Ceramic

The Al₂TiO₅ microstructure tolerates rapid temperature swings between ambient and molten aluminum without cracking. This makes the material suitable for frequent start–stop cycles in low pressure die casting, dosing furnaces and launder systems.

Molten aluminum does not readily wet aluminum titanate surfaces, which reduces metal build-up, oxide adhesion and contamination in the flow path. Cleaner internal surfaces support smoother metal transfer and more stable filling behavior.

Under continuous molten-aluminum exposure, aluminum titanate maintains its geometry and structural integrity over long service periods. Stable dimensions reduce the risk of leakage, misalignment and premature failure at critical interfaces.

Compared with many dense refractories, aluminum titanate ceramic has relatively low thermal conductivity. This helps limit heat loss along riser tubes, spouts and other transfer components, improving thermal efficiency and temperature control in casting operations.

Aluminum titanate ceramic exhibits a very low coefficient of thermal expansion, so dimensional change under operating temperatures is minimal. This helps riser tubes, stalk tubes and sprue bushes stay aligned with dies, seals and furnace nozzles during repeated heating and cooling.

Aluminum titanate ceramic can be engineered into riser tubes, stalk tubes, sprue bushes, pouring cups, spouts, rings and other custom shapes. This flexibility allows foundry and LPDC engineers to match component design precisely to furnace layouts and casting equipment.

Aluminum Titanate Ceramic (Al2TiO5) components

ADCERAX supplies a full range of aluminium titanate ceramic parts, including riser tubes, sprue bushings, pouring ladles, stalk tubes, casting spouts and custom Al₂TiO₅ components for molten-aluminum casting systems. Both standard sizes and fully customized shapes are available according to drawings or project requirements.

Aluminum titanate sprue bushings are used in LPDC gating systems, molten-aluminum feed points, casting interfaces, and transfer zones to maintain clean flow, reduce oxide adhesion, and support stable metal delivery during casting cycles.

- Helps improve metal-flow stability at casting entry points

- Provides a lightweight structure for easier handling and setup

- Offers tailored dimensions and shapes to match equipment design

Aluminum titanate riser tubes are used in low-pressure die casting, molten-aluminum transfer systems, furnace connection points, and metal-flow control zones where stable performance and clean aluminum delivery are required.

- Provides reliable metal-flow stability with low deformation

- Lightweight ceramic body for easier installation and handling

- Offers tailored dimensions and configurations for LPDC equipment

Aluminium titanate pouring ladles are used in molten-aluminum transfer, sampling operations, pouring stations, and feed zones to support clean metal handling, reduce oxide pickup, and maintain controlled flow during casting processes.

- Ensures consistent metal-transfer behavior with reduced adhesion

- Supports repeatable handling with a lightweight ceramic structure

- Offers custom shapes and capacities to fit different casting layouts

🔥 Improve casting stability and reduce maintenance—upgrade to aluminum titanate ceramic.

Our Al₂TiO₅ parts are designed to keep your molten-aluminum system running smoothly. With excellent thermal behavior and non-wetting properties, they help prevent buildup, ensure consistent filling and lower total operating cost. 👉Tell us what you need, and we’ll tailor the right aluminum titanate solution for your process.

Applications of Aluminum Titanate Ceramic (Al₂TiO₅)

Aluminum titanate ceramic is applied in molten-aluminum processing, casting operations, melt-delivery systems, high-temperature transfer zones and thermal-cycling environments across metal casting, non-ferrous metallurgy, thermal-engineering systems and automated casting equipment.

Aluminum Casting & Foundry Industry

Aluminum titanate ceramics are extensively used in molten aluminium handling because of their non-wetting behaviour, low thermal expansion, and excellent thermal-shock resistance.

- LPDC riser tubes/stalk tubes

- Sprue bushings & insulating sleeves

- Pouring cups/ladles

- Casting spouts, flow-control rings

- Gravity-casting feed interfaces

🔹Customer Value:

- Stable melt flow, fewer blockages, lower downtime, extended component service life.

Aluminum Smelting, Refining & Melt Treatment

In upstream aluminum processing, Al₂TiO₅ provides high stability against molten aluminum corrosion and temperature cycling.

- Molten aluminum transfer tubes

- Filter box bushings & adaptor rings

- Trough inserts and thermal barriers

- Degassing system components (non-wetting interfaces)

🔹Customer Value:

- Cleaner melt, reduced dross buildup, longer operational cycles, improved thermal efficiency.

High-Temperature Furnace & Industrial Heating Equipment

Aluminum titanate Al2TiO5 ceramic is used where rapid heating–cooling cycles and mechanical isolation are required.

- Furnace riser sleeves and thermal isolators

- Kiln support rings

- High-temperature spacers & positioning ceramics

- Heat-shock-resistant inserts for start–stop furnaces

🔹Customer Value:

- Maintains dimensional stability, avoids cracking under cycling, reduces maintenance frequency.

OEM Casting Machinery & Automation Engineering

Machine builders and automation integrators use Al₂TiO₅ ceramics for precision interfaces and stable long-term operation.

- LPDC machine consumable sets

- Custom ceramic interfaces for robotic casting lines

- Precision-matched ceramic bushings / guiding rings

- Anti-wetting ceramic components for automated pour systems

🔹Customer Value:

- Reduced machine downtime, consistent repeatability, improved reliability for high-throughput casting cells.

Custom Aluminum Titanate Ceramic Supplier

We specialize in custom aluminum titanate ceramic parts based on customer drawings, samples, or molten-aluminum system requirements. Tailored dimensions, wall thicknesses, stepped profiles, flanges, and shaped geometries can be produced for LPDC riser tubes, sprue bushings, pouring ladles, stalk tubes, and casting-line components. Custom aluminum titanate parts typically require 3–9 weeks, depending on design complexity and machining needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Aluminum Titanate Ceramic Manufacturer in China

ADCERAX is a China-based aluminum titanate ceramic manufacturer delivering consistent quality, stable lead times and responsive technical support—built to improve casting quality and reduce downtime. Our factory-direct model helps industrial buyers lower procurement cost, reduce supply risk and maintain reliable performance in demanding casting environments.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

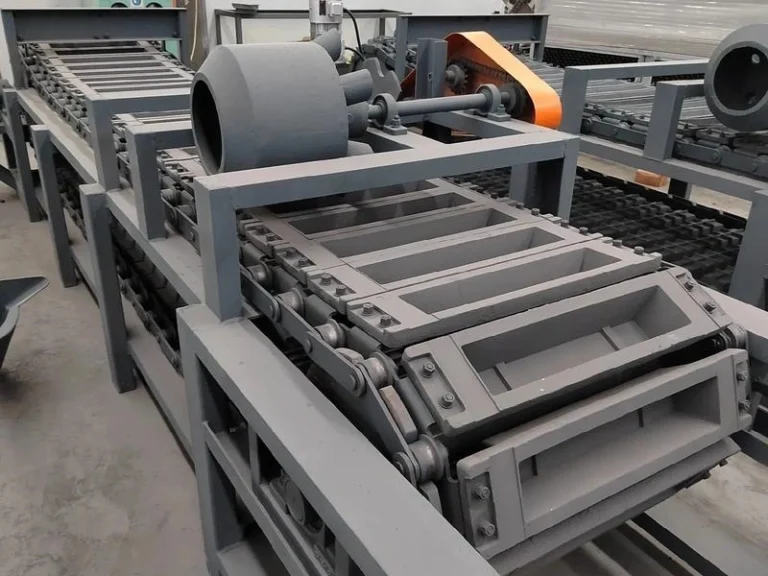

ADCERAX provides integrated manufacturing for aluminum titanate (Al₂TiO₅) ceramic parts used in molten-aluminum casting and LPDC systems. Our capabilities cover material formulation, precision machining, shaping, joining, and high-temperature ceramic processing. Both prototype and volume-batch orders are supported with stable quality and dependable export delivery.

-

Precision Machining & Dimensional Consistency:

Aluminum titanate riser tubes, sprue bushings, stalk tubes, and shaped components are processed to achieve accurate bore sizes, stable wall thickness, clean sealing surfaces and consistent geometry. Controlled shrinkage and smooth ceramic surfaces ensure proper fitment and clean metal flow in LPDC and gravity-casting zones. -

Batch Stability & Performance Control:

Each batch is checked for phase composition, density accuracy, thermal behavior and dimensional stability. Optimized Al₂TiO₅ microstructure supports low thermal expansion, strong thermal-shock performance and predictable service life under continuous molten-aluminum contact. -

Customization & Engineering Support:

We offer drawing-based customization for complex geometries, stepped profiles, flanges, transition zones, and connection interfaces. Our engineering team ensures compatibility with LPDC machines, casting-line layouts, molten-aluminum handling systems and refurbishment projects requiring stable performance under thermal cycling.

ADCERAX produces aluminum titanate ceramics with controlled formulation, precision machining and strict dimensional stability. Our Al₂TiO₅ components deliver low thermal expansion, strong thermal-shock resistance and excellent molten-aluminum non-wetting performance—ensuring reliable operation in LPDC systems, casting lines and high-temperature transfer equipment.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Performance Consistency | Aluminum titanate ceramics are produced with controlled phase composition and density uniformity, ensuring low thermal expansion, excellent thermal-shock resistance, and stable behavior in molten-aluminum environments. | ||

| High-Temperature Precision Machining & Shaping | CNC machining, turning and profiling deliver clean surfaces, accurate bores and stable wall thickness for riser tubes, sprue bushings and complex shapes. Typical tolerances: ±0.05–0.20 mm depending on geometry. | ||

| Advanced Processing Capability | Supports stepped profiles, flanges, transition zones, sealing interfaces and deep cavities required for LPDC and gravity-casting systems. Complex shapes can be produced to match equipment requirements. | ||

| Dimensional Stability Under Molten-Aluminum Contact | Optimized Al₂TiO₅ microstructure minimizes thermal growth, cracking and deformation during repeated heating cycles, maintaining reliable sealing and metal-flow stability throughout service life. | ||

| Strict Thermal & Structural Quality Control | Each batch is inspected for density accuracy, thermal expansion rate, shrinkage behavior and wetting resistance. Ensures predictable performance, reduced downtime and improved casting consistency. | ||

FAQs About Aluminum Titanate Al2TiO5 Ceramic

Aluminum titanate ceramic offers extremely low thermal expansion, excellent thermal-shock resistance and strong non-wetting behavior with molten aluminum, making it reliable for LPDC riser tubes, sprue bushings and transfer components.

No. Aluminum titanate ceramics exhibit very low wettability and chemical reactivity, minimizing inclusion formation and ensuring cleaner metal flow compared with traditional refractories.

Machined aluminum titanate components generally meet ±0.05–0.20 mm tolerances, depending on bore depth, wall thickness and shape complexity. Critical sealing surfaces can be processed to tighter specifications.

Yes. Aluminum titanate parts—including riser tubes, stalk tubes, pouring cups and sprue bushings—can be manufactured according to drawings, CAD files or samples, including stepped geometries, flanges, transitions and special interfaces.

Aluminum titanate ceramic combines low thermal expansion, excellent thermal-shock resistance, and strong non-wetting performance, making it an ideal and cost-efficient choice for LPDC and molten-aluminum casting.

Silicon nitride provides higher mechanical strength but at a much higher cost, while fused silica is economical but lacks dimensional stability and durability under thermal cycling.

| Performance Factor | Aluminum Titanate Ceramic (Al₂TiO₅) | Silicon Nitride (Si₃N₄) | Fused Silica |

|---|---|---|---|

| Thermal Expansion | Very low, ideal for dimensional stability in LPDC systems | Low to medium | High (most unstable under thermal cycling) |

| Thermal-Shock Resistance | Excellent, designed for rapid heating–cooling cycles | Very good | Moderate to poor under fast temperature changes |

| Wettability with Molten Aluminum | Non-wetting, prevents buildup and clogging | Generally good but varies by grade | Readily wetted; often requires coatings |

| Chemical Stability | Stable in molten aluminum; minimal reaction | Very stable; excellent corrosion resistance | More reactive; can degrade faster |

| Mechanical Strength | Moderate; not ideal for heavy mechanical load | High strength, suitable for structural components | Low–medium strength |

| Cost Efficiency | Highly cost-effective for LPDC and gravity casting | High cost | Low cost but shorter lifespan |

| Typical Applications | Riser tubes, sprue bushings, stalk tubes, pouring cups | Degassing rotors, break rings, pump parts | Basic furnace linings, insulation areas |

Yes. Aluminum titanate (Al₂TiO₅) is specifically valued for its exceptional thermal-shock resistance. Its unique crystal structure and extremely low thermal expansion allow it to tolerate sudden heating and cooling without cracking. This makes it well-suited for:

intermittent casting cycles

start-stop LPDC/HPDC operations

repeated immersion and withdrawal from molten aluminum

In demanding casting environments where temperature swings are unavoidable, aluminum titanate maintains structural stability far better than fused silica or standard refractories.

Aluminum titanate ceramics can tolerate moderate mechanical vibration during normal casting operation because of their low elastic modulus and inherent thermal-stress damping behavior. However, they are not designed for high-impact loads, strong mechanical shocks or continuous side loading.

To maximize service life of riser tubes, sprue bushings and pouring components:

ensure proper axial alignment and avoid lateral forces

use support fixtures or seals that prevent rigid clamping

minimize impact during installation and removal

With correct mounting and controlled loading conditions, aluminum titanate components deliver stable performance and long service life in LPDC and molten-aluminum handling systems.

Common factors include thermal shock beyond design limits, incorrect mounting, mechanical overload, metal infiltration from improper alloy cleanliness or temperature spikes.

No. Once cracked, aluminum titanate parts cannot be structurally repaired. Replacement ensures process stability and casting quality.

High-quality producers control density, porosity, phase composition and shrinkage rate, ensuring predictable expansion behavior, improved lifetime and minimal dimensional variation between batches.

Provide drawings, key dimensions, tolerances, thermal conditions, alloy temperature and expected cycle load. This allows accurate pricing and selection of the proper aluminum titanate ceramic grade.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours