Advanced Boron Nitride (BN) Ceramic | High Thermal Conductivity & Insulation Solutions

ADCERAX is a professional boron nitride ceramic manufacturer in China, dedicated to producing machinable BN ceramics and custom-engineered components for high-temperature and vacuum applications. Our products offer stable performance where metal and oxide ceramics fail.

We supply both standard BN ceramic parts—such as tubes, plates, rings and nozzles —and custom BN components made to drawing for use in casting, furnace insulation, semiconductor processing, and precision equipment.

✈️ Boost your process reliability and extend equipment life with ADCERAX BN ceramic solutions.

- Factory-direct

- Engineering support

- Small-batch friendly

What is Ceramic Boron Nitride?

Is Boron Nitride a Ceramic?

Yes, Boron nitride ceramic (BN) is an advanced non-oxide ceramic composed of boron and nitrogen atoms.

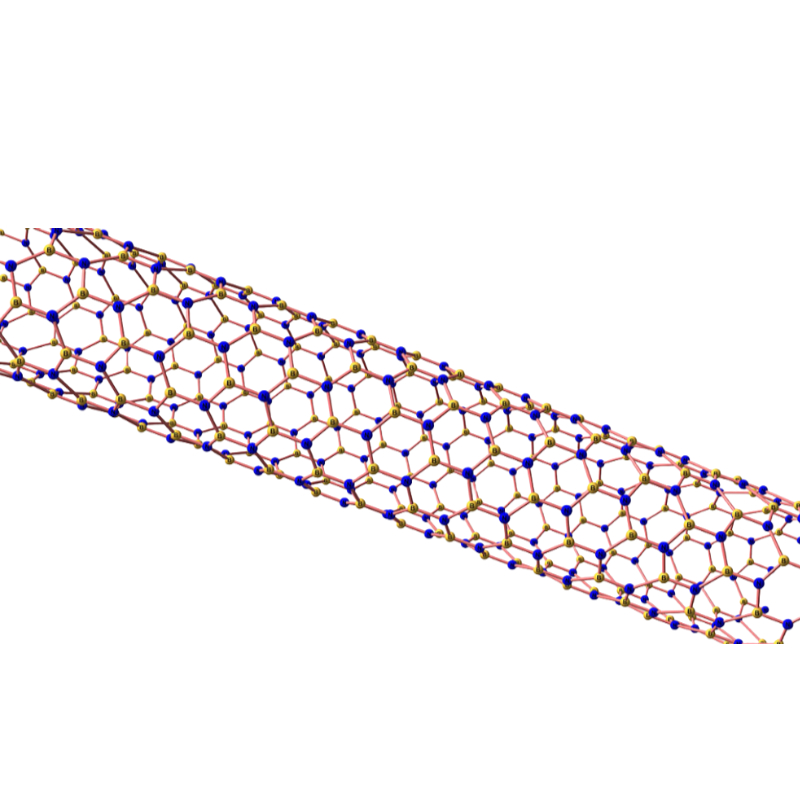

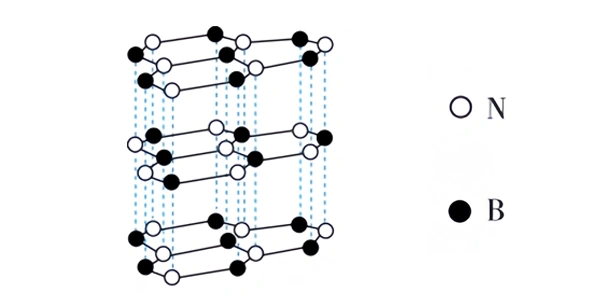

It exists in several structural forms — hexagonal (h-BN), cubic (c-BN), hot-pressed (HPBN), and pyrolytic (PBN) — each with distinct crystal arrangements and properties.

Together, these forms define the advanced ceramics boron nitride family widely used for high-temperature, non-wetting, and electrically insulating applications.

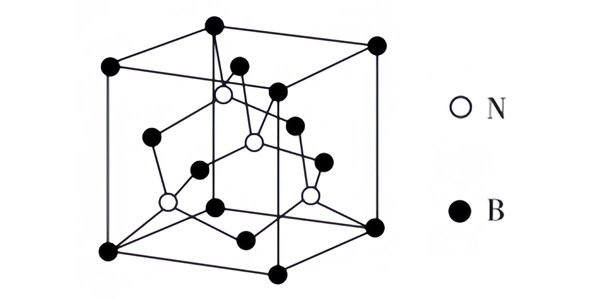

Boron Nitride Ceramic Crystal Structure

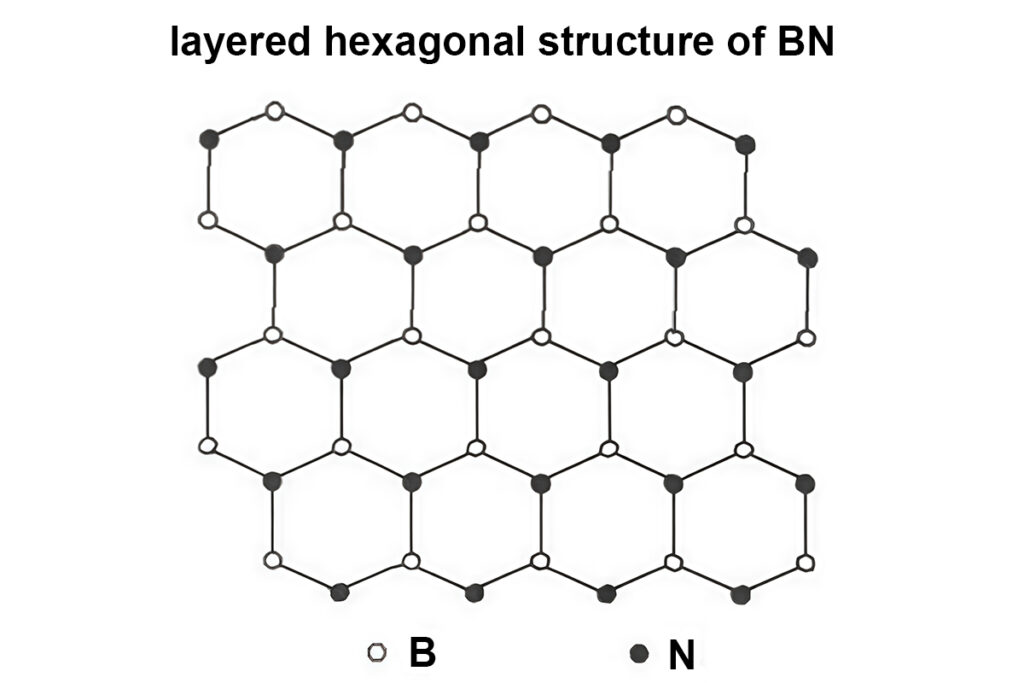

Hexagonal Boron Nitride (h-BN)

The hexagonal structure of boron and nitrogen atoms resembles graphite, forming layered sheets bonded by weak van der Waals forces. This gives h-BN its machinability, non-wetting behavior, and excellent electrical insulation at high temperatures.

Cubic Boron Nitride (c-BN)

Formed under high pressure and temperature, c-BN has a diamond-like cubic lattice with strong covalent bonds. It represents the superhard phase of boron nitride, providing extreme wear resistance and thermal conductivity.

BN Ceramic Processing Form

Hot-Pressed Boron Nitride (HPBN)

HPBN is produced by hot-pressing h-BN powder under controlled temperature and pressure to form a dense solid. The structure remains hexagonal but becomes smoother, stronger, and less porous—ideal for machining and assembly.

Pyrolytic Boron Nitride (PBN)

PBN is formed by chemical vapor deposition (CVD) of boron and nitrogen precursors, producing ultra-pure, layered material. Its atoms align directionally, giving strong in-plane thermal conductivity and through-thickness electrical insulation.

Relationship Among the Four Forms

| Form | Crystal Structure | Production Method | Key Features | Typical Use |

|---|---|---|---|---|

| h-BN | Hexagonal (sp² layered) | Sintered / pressed powder | Machinable, non-wetting, insulating | General BN parts, plates |

| HPBN | Densified h-BN | Hot pressing | Stronger, smoother, fine-grained | jigs, spacers |

| PBN | CVD-deposited layered | Chemical vapor deposition | Ultra-pure, anisotropic, high in-plane conductivity | Semiconductor, heaters, UHV |

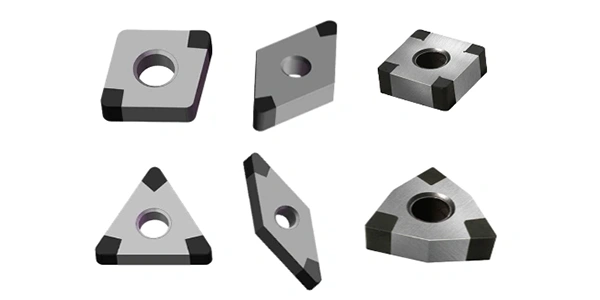

| c-BN | Cubic (sp³ lattice) | High pressure + temperature | Superhard, conductive, non-machinable | Abrasives, cutting tools |

✅Summary:

- h-BN is the base structure for ceramic components.

- HPBN is its densified, machinable engineering form.

- PBN is the vapor-deposited ultra-pure form used in high-tech industries.

- c-BN is a superhard phase, part of the BN family but outside the electrical-insulation ceramic category.

Boron Nitride Ceramic Properties

Boron nitride (BN) ceramics deliver exceptional thermal stability, chemical inertness, and electrical insulation. Their strong B–N bond provides high thermal conductivity, non-wetting behavior toward molten metals, and excellent machinability for high-temperature applications.

| Property | Unit | Pyrolytic Boron Nitride (PBN) | Hot-Pressed Boron Nitride (HPBN) | Description / Application Focus |

|---|---|---|---|---|

| Purity | % | 99.99 | 99.5 | High-purity BN ensures chemical stability and oxidation resistance under extreme temperatures. |

| Density | g/cm³ | 2.15–2.19 | 1.96–2.00 | Low density with high structural integrity; ideal for lightweight thermal and vacuum components. |

| Thermal Conductivity | W/m·K | 60 (A-direction) | 55 | Excellent heat transfer for high-temperature insulation and thermal management applications. |

| Dielectric Strength | kV/mm | 55 | 76 | Superior electrical insulation and high dielectric constant for electronic and vacuum environments. |

| Maximum Working Temperature | °C | 1000 (air) / 2300 (vacuum) | 900 (air) / 1850 (vacuum) | Maintains mechanical strength and stability in both oxidizing and vacuum atmospheres. |

| Bending Strength | MPa | 173 (A-direction) | 310 | Excellent mechanical reliability and resistance to cracking after repeated thermal cycling. |

| Thermal Expansion Coefficient | /°C | 6×10⁻⁷ | 1.8×10⁻⁶ | Low thermal expansion provides outstanding dimensional stability and thermal shock resistance. |

| Compressive Strength | MPa | 154 (A-direction) | 120 | High compressive strength supports long service life in demanding structural applications. |

Key values vary by BN grade (HPBN vs PBN) and working atmosphere; contact ADCERAX for grade selection.

⚙️ Physical Properties

- High Thermal Conductivity: Up to 60 W/m·K, enabling efficient heat transfer in furnaces and high-temperature assemblies.

- Thermal Stability: Remains structurally stable up to 2300 °C in vacuum, outperforming most oxide ceramics.

- Low Thermal Expansion: A coefficient of 6×10⁻⁷ /°C ensures excellent thermal shock resistance and dimensional stability.

🧪 Chemical Properties

- Chemical Inertness: Non-wetting to molten Al, Mg, Cu, and resistant to corrosion and reactive gases.

- Oxidation Resistance: Stable in air up to 1000 °C, maintaining purity and mechanical integrity.

- Clean & Non-Contaminating: BN does not react with graphite or refractories, ideal for high-purity environments.

🧱 Mechanical Properties

- Machinable Ceramic: Hot-pressed BN allows precise shaping (±0.05 mm) for custom parts like rings.

- High Strength: Bending strength up to 310 MPa ensures durability under cyclic thermal stress.

- Lightweight & Rigid:With density around 2 g/cm³, BN offers high stiffness-to-weight performance.

⚡ Electrical Properties

- Excellent Insulation: Dielectric strength up to 76 kV/mm with volume resistivity over 10¹⁴ Ω·cm.

- Low Dielectric Loss: Stable dielectric constant across wide temperature and frequency ranges.

- Dual Functionality:Combines thermal conductivity with electrical insulation, rare among ceramics.

China Boron Nitride Ceramics Products

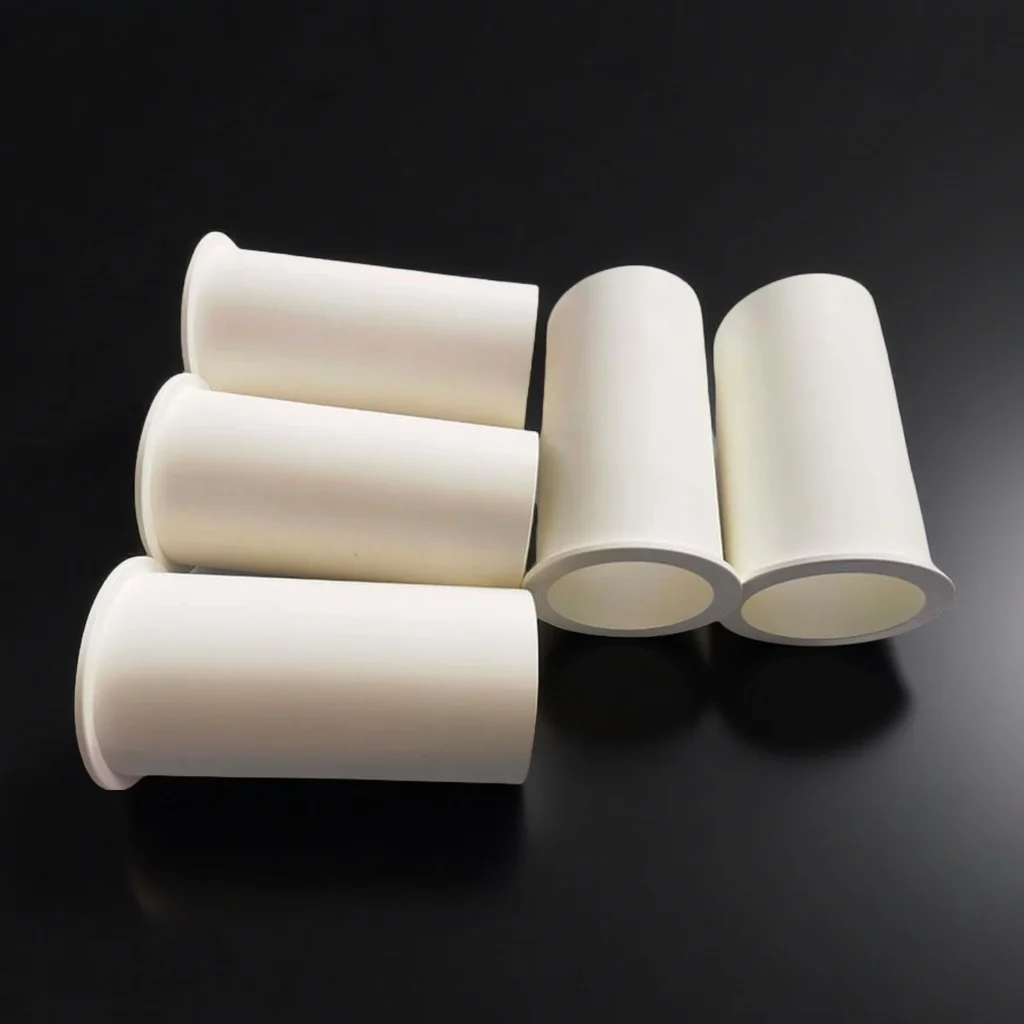

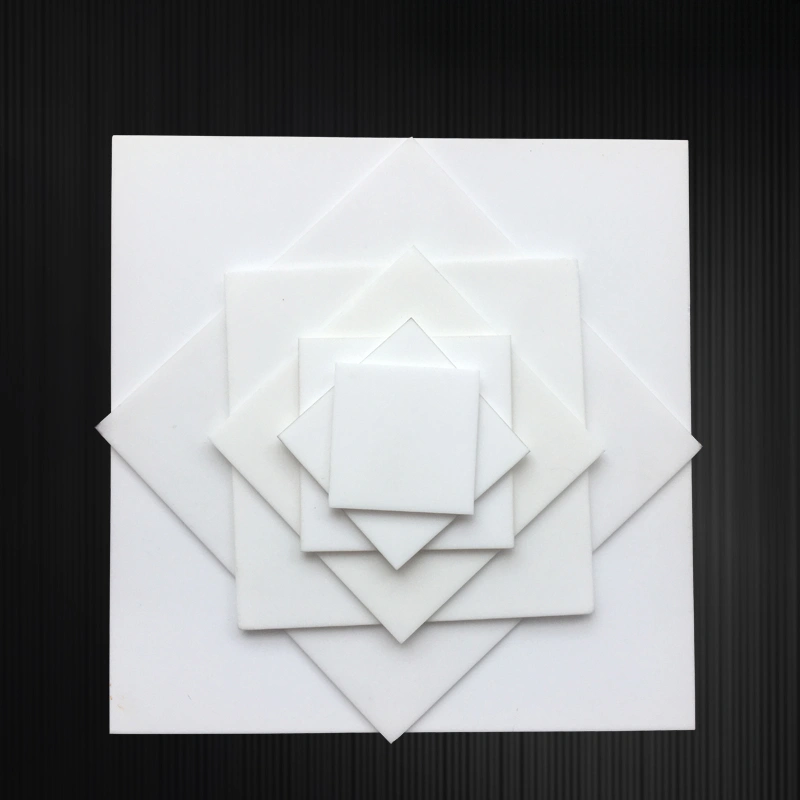

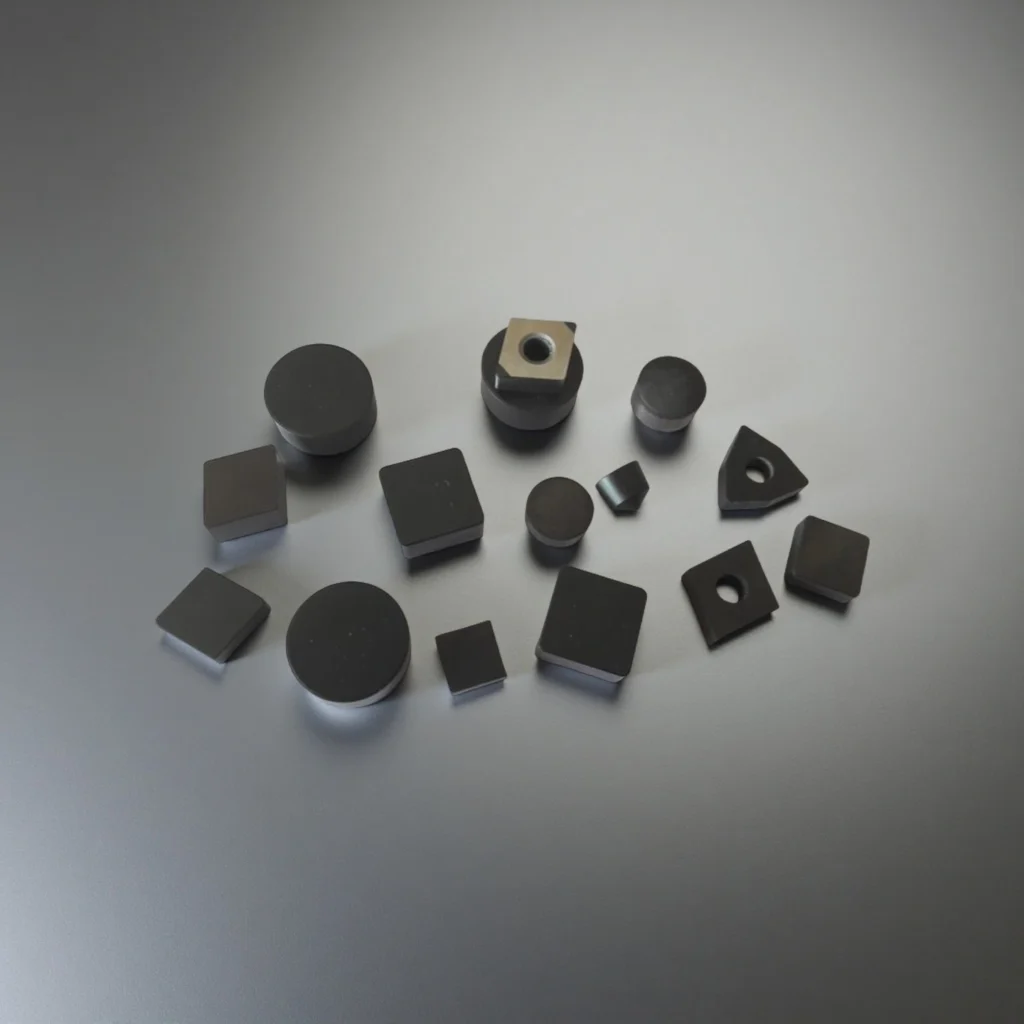

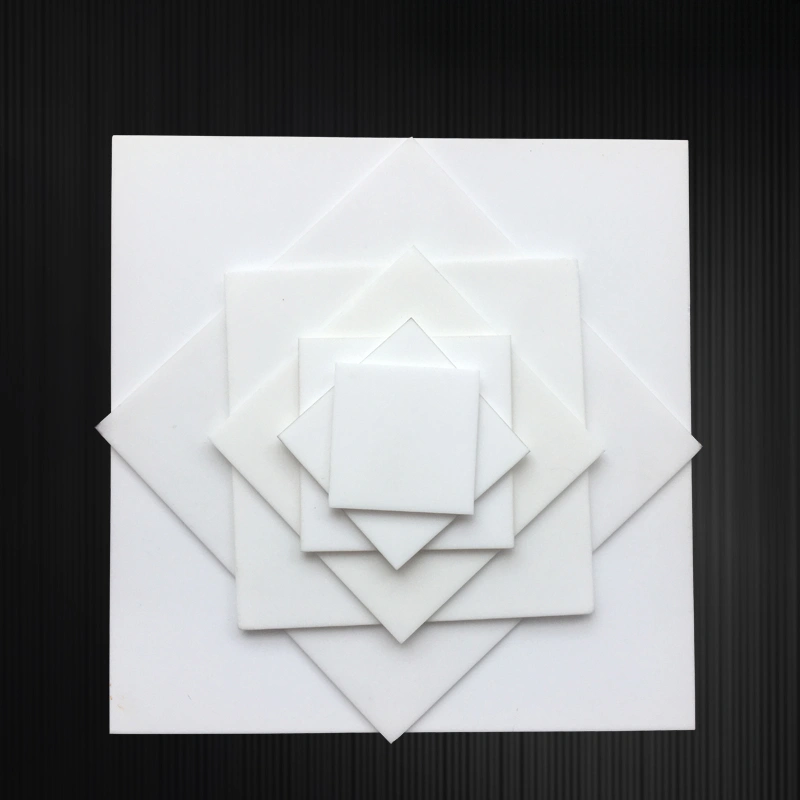

ADCERAX supplies a complete range of boron nitride (BN) ceramic products, including tubes, rods, rings, plates, washers, fibers, heaters, insulating columns, and nozzles. Below is our standard range of BN ceramic parts; all items can be modified in length, ID/OD, hole pattern, or stepped geometry according to your drawings.

BN ceramic tubes offer thermal conductivity and insulation, used in vacuum lines, semiconductor devices, and high-temperature sleeves.

BN ceramic rods feature machinability and thermal stability, serving as insulating pins, spacers, and supports in vacuum and heat-resistant assemblies.

Boron nitride ceramic rings offer non-wetting and stable dimensions, used for insulation and sealing in casting, metal processing, and furnace systems.

BN ceramic plates provide uniform heat transfer and chemical resistance, applied in furnace liners, shielding plates, and vacuum chamber insulation.

BN ceramic heaters deliver uniform heat and electrical insulation, used for precise temperature control in vacuum and semiconductor systems.

BN ceramic fibers provide strength and oxidation resistance, used in composites, thermal barriers, and electrical insulation.

BN insulating columns maintain dielectric strength and thermal stability, used as electrode supports and vacuum insulation structures.

BN ceramic nozzles resist wetting and erosion, used for molten metal flow, atomization, and plasma spraying at high temperatures.

Cubic BN ceramic cutting tools offer high hardness and wear resistance, ideal for precision cutting of hardened steels and superalloys.

BN ceramic tubes provide clean, non-wetting containers for melting and evaporation, used in vacuum coating, crystal growth, and analytical sampling.

Boron nitride plates act as machinable insulating barriers, used as heat shields, spacers, and substrates in vacuum systems and semiconductor tools.

Hexagonal boron nitride rings provides stable electrical insulation and heat management, used as spacers and seals in vacuum lines, semiconductor tools, and high-temperature assemblies.

💡 High Heat. High Precision. High Trust — That’s ADCERAX BN Ceramics.

From insulating tubes to custom heater parts, ADCERAX provides boron nitride (BN) ceramic solutions that combine strength, purity, and precision—engineered to keep your systems stable when everything else fails.

Boron Nitride (BN) Ceramic Applications

Boron Nitride (BN) ceramics are widely used in semiconductor processing, precision machinery, metallurgy, and laboratory equipment. They serve essential roles in components such as insulating rings, tubes, plates, and spacers supporting high-temperature operations, vacuum systems, and precision instruments across multiple industrial fields.

Vacuum & Thermal Processing Systems

Application: HPBN/PBN insulation plates, fixture supports, spacers, and electrical isolation parts for high-temperature and vacuum furnace systems.

Challenges: High-temperature systems often face insulation breakdown and contamination above 1000 °C, along with microcracking after repeated thermal cycles and long lead times for custom fixtures.

🧩 ADCERAX Solution:

- Dual-grade supply: HPBN for machinability and PBN for purity and anisotropic thermal control.

- CNC precision machining within ±0.05 mm, surface finish up to Ra 0.8–1.6 µm.

- Complete batch traceability with dielectric strength and cleanliness test reports.

- 🔹Case Example:

After replacing alumina insulators with HPBN spacers, thermal uniformity improved by 14% (from ±7 °C to ±6 °C), while electrical failure rates dropped from 2.1% to 0.3%.

Replacement cycles extended from 5 months to 9 months, saving USD 38,000 per year per line in downtime and maintenance.

Non-Ferrous Metal Casting & Continuous Casting

Application: BN flow-control rings, nozzles, sliding plates, liners, and non-wetting coatings for aluminum, magnesium, and copper alloy processing lines.

Challenges: Molten metal adhesion often leads to nozzle clogging and downtime, while erosion from high flow rates and temperature gradients shortens component life. Maintaining tight dimensional accuracy is also essential to ensure casting stability and process reliability.

🧩 ADCERAX Solution:

- Dense HPBN components with geometric optimization (chamfers, transitions) to minimize turbulence and adhesion.

- Non-wetting BN surfaces reduce cleaning time and enable fast changeover.

- Supply of ready-to-install component kits with lifecycle tracking.

- 🔹Case Example:

By switching to HPBN composite flow rings, nozzle clogging dropped 68%, and average downtime per shift decreased from 2.6 h to 0.9 h. Production capacity increased by 4.8%, cutting annual operating costs by USD 62,000 per extrusion line.

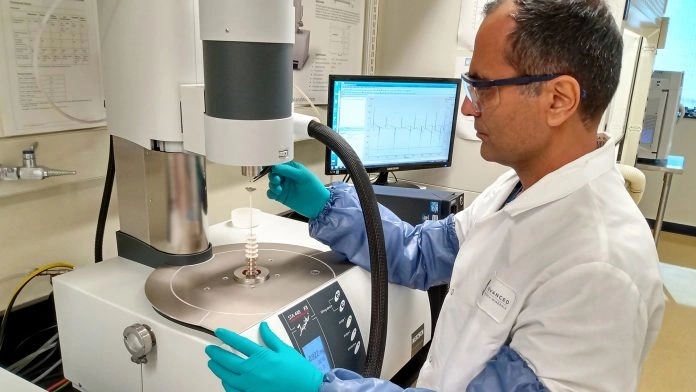

R&D and Analytical Equipment

Application: Machinable BN plates, rods, and tubes for TGA/DSC holders, thermal isolation fixtures, and sample supports in lab instruments.

Challenges: Labs face tight deadlines for small, high-precision parts, with contamination risks from oxide ceramics and surface wear after repeated use affecting consistency.

🧩 ADCERAX Solution:

- Fast prototyping within 7–12 days, flexible custom geometry.

- BN’s non-wetting and chemically inert nature minimizes contamination.

- Engineering consultation with purity selection between HPBN and PBN.

- 🔹Case Example:

Switching from alumina parts and supports to HPBN parts reduced sample residue by 70%, allowing 40+ reuse cycles (vs 18–22 previously).

Data repeatability (RSD) improved by 22%, and consumables cost dropped 31% annually.

Powder Metallurgy, Atomization & Thermal Spray

Application: BN nozzles, flow guides, insulation shields, and support components for gas atomization, plasma spray, and powder metallurgy processes.

Challenges: Plasma and particle processing environments cause strong abrasion and erosion, making it difficult to maintain flow stability and insulation under combined electromagnetic and thermal fields.

🧩 ADCERAX Solution:

- HPBN and BN-composite materials (BN+ZrO₂/Si₃N₄) for enhanced erosion and wear resistance.

- Precision machining ensures nozzle concentricity, roundness, and surface uniformity.

- Lifecycle assessment and design optimization for consistent powder quality.

- 🔹Case Example:

Using HPBN atomization nozzles (Ø2.2 mm) instead of SiC reduced D10–D90 particle width by 12% and improved yield by 8.5%. Nozzle lifetime doubled to 120 hours, cutting monthly consumable costs by 41%.

Custom Boron Nitride (BN) Ceramic Manufacturer

ADCERAX is a boron nitride (BN) ceramic factory in China, specializing in custom-made BN components produced to your drawings or samples. We support flexible geometries, tight tolerances, and stable batch quality with delivery typically within 3–9 weeks.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Trusted Boron Nitride Ceramics Supplier with Precision Manufacturing

ADCERAX specializes in boron nitride (BN) ceramics manufacturing, integrating isostatic pressing, hot pressing, precision machining, and custom forming. We provide tailor-made BN components with flexible dimensions and complex geometries to meet diverse industrial requirements.

BN Ceramics Processing Capacity

ADCERAX boron nitride (BN) ceramics are easily machinable—similar to graphite yet electrically insulating. They can be precisely shaped with standard carbide tools on conventional CNC machines.

🔷 Precision Forming & Machining: From pressing to CNC milling, complex BN parts are shaped with stable dimensional accuracy.

🔷 High-Accuracy Equipment: Multi-axis machines ensure ±0.05 mm precision and uniform surface finish across production.

🔷 Fast & Cost-Effective Manufacturing: Simplify processing, shorten lead times, and reduce machining costs without special diamond tools.

🔷 Surface Finishing & Coating: BN ceramics can be finely polished, coated, or impregnated to achieve specific surface roughness or oxidation resistance

BN Ceramics Manufacturing Strengths

Handling molten metals (like Aluminum, Zinc, Copper) and glasses presents significant challenges due to wetting, chemical reactions, and thermal stress. Our Boron Nitride Ceramic offers superior chemical inertness and non-wetting characteristics, leading to tangible benefits:

- Reduced Contamination: Prevents molten materials from sticking or reacting, ensuring the purity of your melt.

- Increased Component Lifespan: Resists erosion and chemical attack, reducing downtime for nozzle, or fixture replacement.

- Improved Process Yield: Facilitates smoother casting, pouring, and handling operations.

Ideal for nozzles, break rings, thermocouple sheaths, and fixtures in metal processing, casting, glass forming, and PVD coating environments.

Why Choose ADCERAX for Your Boron Nitride Ceramics Manufacturer?

Choosing the right boron nitride precision ceramics factory is crucial for the success of your industrial projects. ADCERAX stands out as a reliable and competitive partner.

Factory Direct & Competitive Pricing

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

Expert Engineering Support

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Flexible Customization

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Quality Control

Stringent quality measures from raw material inspection to final product testing.

24/7 Technical Support

24-hour response guarantee with dedicated support for global clientele.

500+ Satisfied Customers

Trusted by global customers for advanced ceramic materials and precision components.

Boron Nitride (BN) Ceramic Parts Quality & Certifications

FAQ

Hot-pressed BN ceramic withstands up to 1850 °C in vacuum and 900 °C in air, while pyrolytic BN (PBN) can reach 2300 °C in inert or vacuum atmospheres without decomposition.

The following shows the differences between hexagonal boron nitride (h-BN) and cubic boron nitride (c-BN):

| Property | Hexagonal Boron Nitride (h-BN) | Cubic Boron Nitride (c-BN) |

|---|---|---|

| Crystal Structure | Layered graphite-like structure | Diamond-like cubic structure |

| Thermal Conductivity | 30-60 W/mK (in-plane) 2-5 W/mK (cross-plane) | 200-400 W/mK (isotropic) |

| Hardness | 1-2 Mohs (machinable with steel tools) | 45-50 GPa (3rd hardest material) |

| Electrical Resistivity | > 1014 Ω-cm (natural insulator) | 103-106 Ω-cm (semiconductive) |

| Thermal Stability | Stable up to 2,000°C (inert atmosphere) | Degrades above 1,400°C in air |

| Primary Applications | • High-temperature furnace components • Electrical insulators • Thermal interface materials | • Cutting tools • Grinding wheels • Wear-resistant coatings |

| Typical Forms | Sintered ceramics, coatings, lubricant powders | Polycrystalline compacts, thin films |

| Processing Difficulty | Easily machinable (±0.02mm precision) | Requires laser/EDM machining |

Hexagonal Boron Nitride (h - BN) has a layered graphite - like structure, lower thermal conductivity, lower hardness, higher electrical resistivity, good thermal stability up to 2,000°C, is used for high - temperature furnace components, electrical insulators, and thermal interface materials, comes in sintered ceramics, coatings, lubricant powders and is easily machineable;

Cubic Boron Nitride (c - BN) has a diamond - like cubic structure, higher thermal conductivity, much higher hardness, lower electrical resistivity, degrades above 1,400°C in air, is used for cutting tools, grinding wheels, and wear - resistant coatings, exists as polycrystalline compacts and thin films, and requires laser/EDM machining.

Yes.Adcerax offers fully customized boron nitride (BN) ceramics to meet precise equipment requirements. The following is the information we need to produce samples more quickly:

- Application Equipment: ________ (semiconductor CVD furnace, aluminum melting furnace, laser, etc.)

- Core Function: ________ (thermal insulation/conductivity/lubrication/corrosion resistance,etc.)

- Maximum Temperature: ______°C / Operating Temperature: ______°C

- Key Dimensions: Length ______ mm × Width ______ mm × Thickness ______ mm

- Urgency Level: □ Standard (4-6 weeks) □ Expedited (2-3 weeks) □ Emergency (72 hours)

- Supporting Documents: □ CAD file □ Sketch □ None (requires our design support)

Processing Methods for Boron Nitride Ceramics:

1. Forming Techniques

Cold Isostatic Pressing (CIP):

Raw BN powder is compressed under 100-300 MPa pressure in flexible molds, ideal for complex geometries like crucibles. Achieves 50-60% green density.Injection Molding:

BN powder mixed with thermoplastic binders (15-20% vol.) enables mass production of small, intricate parts like insulators. Debinding occurs at 400-600°C.

2. Sintering Processes

Hot Pressing (HP):

Temperatures up to 2,000°C under 20-30 MPa pressure produce high-density (>95% TD) BN components. Standard for furnace fixtures.Spark Plasma Sintering (SPS):

Rapid sintering (minutes vs. hours) at 1,600-1,800°C minimizes grain growth, critical for nano-structured BN composites.

3. Machining & Finishing

CNC Milling:

Tungsten carbide tools cut as-sintered BN to ±0.05 mm tolerances. Coolant-free process prevents hydrolysis.Laser Cutting:

CO₂ lasers (10.6 μm wavelength) create slots/chamfers in thin BN plates (<3 mm) with <50 μm kerf width.

4. Surface Engineering

CVD Coating:

Deposits 50-200 μm pyrolytic BN layers on graphite substrates for enhanced oxidation resistance.Plasma Spraying:

Projects h-BN powder onto metal surfaces at 12,000°C plasma temps, forming wear-resistant thermal barriers.

When selecting a grade of boron nitride (BN) ceramic, it is essential to conduct a comprehensive evaluation based on the following key parameters in conjunction with the specific application scenario.

1. Core Selection Criteria:

| Parameter | Critical Factors | Application Scenarios |

|---|---|---|

| Operating Environment |

|

|

| Mechanical Loads |

|

|

| Thermal Cycling |

|

|

2.BN Grade Comparison Chart:

| Feature Focus | Recommended Grade(s) (Example) | Key Characteristics | Ideal Use Cases |

|---|---|---|---|

| High Purity / Inertness | BN-AX05 / BN-PCBN3000 | Binder-free, Max Temp >2000°C (Inert), Best Non-Wetting | Ultra-pure molten metals, Semiconductor, Vacuum systems, High-temp research |

| General Purpose / Workhorse | BN-HP / BN-PCBN4000 | Good balance of properties, improved moisture resistance (vs Grade A), Cost-effective | Furnace parts, Insulators, Jigs, Fixtures, General molten metal handling |

| Moisture Resistance | BN-M26 / BN-PCBN5000 | Silica binder, Excellent dielectric, resists humidity | Microwave components, Severe electrical applications, Humid environments |

| Wear Resistance | BN-ZSBN | BN + Zirconia + SiC composite, Harder, Stronger | Break rings, Nozzles in abrasive flows, High-wear molten metal contact points |

| Legacy / Standard | BN-Grade A | Original B₂O₃ binder, Good insulator, Hygroscopic | Replacement parts for older equipment, Specific legacy designs |

3.Avoid These Selection Pitfalls:

Myth 1: Prioritizing upfront cost alone

Myth 2: Ignoring CTE (Coefficient of Thermal Expansion) matching.

Our technical experts will help you select the appropriate grade according to your specific operating conditions and performance requirements.

The following is a comparison table of three types of BN ceramics,Alumina ceramics and SIC ceramics:

| Property | Boron Nitride (BN) Ceramic | Alumina (Al₂O₃) | Silicon Carbide (SiC) |

|---|---|---|---|

| Thermal Conductivity | 30-60 W/mK | 20-30 W/mK | 70-120 W/mK |

| Max Operating Temp | 2,000°C (inert), 1,800°C (oxidizing) | 1,600°C | 1,700°C |

| Thermal Shock Resistance | > 500 cycles (ΔT 1,200°C→25°C) | < 100 cycles | 150 cycles |

| Electrical Resistivity | > 10¹⁴ Ω·cm (intrinsic insulator) | 10¹⁰-10¹² Ω·cm | 10³-10⁵ Ω·cm (semiconductive) |

| Chemical Stability | Resists HF (except acids/alkalis) | Vulnerable to H₂SO₄ | Oxidizes above 1,300°C |

| Machinability | ±0.02mm (as-sintered) | Requires diamond tools (±0.1mm) | Requires EDM/Laser (±0.15mm) |

| Lubricity | 0.2-0.4 (self-lubricating) | 0.6-0.9 (requires lubricants) | 0.5-0.7 (abrasive) |

| Cost Efficiency | High initial cost 50-70% lifecycle savings | Low initial cost Frequent replacement | Moderate cost Brittle in thin sections |

| Typical Applications | Semiconductor wafer handling Vacuum furnace components EV battery insulation | Electrical insulators Medical implants Catalyst supports | Automotive brake systems Rocket nozzles High-temp bearings |

Boron nitride ceramic excels in thermal conductivity, thermal shock resistance, electrical insulation, chemical stability, and self - lubrication, suitable for high - end applications like semiconductor wafer handling despite high initial cost;

Alumina ceramic has moderate properties, is vulnerable to some chemicals, and is cost - effective for general electrical insulation and medical uses but needs frequent replacement;

Silicon carbide ceramic offers high thermal conductivity and good oxidation resistance but is semiconductive, costly in thin sections, and used in automotive and aerospace applications.

BN ceramic has a layered hexagonal structure with weak inter-layer bonding, allowing it to be cut, drilled, or milled easily using standard carbide tools while maintaining electrical insulation and chemical stability.

You can purchase boron nitride ceramics directly from ADCERAX, a China-based factory specializing in BN ceramic manufacturing and precision machining. The company supplies BN tubes, rods, plates, rings, crucibles, and nozzles, all customizable to drawings with tight tolerances. ADCERAX supports both small-batch prototypes and large-scale OEM production, ensuring reliable quality, fast response, and global delivery.

High thermal conductivity BN ceramics combine rapid heat dissipation with excellent electrical insulation, making them ideal for demanding environments such as thermal management systems, vacuum furnaces, and semiconductor tooling. Their stability at temperatures above 2000 °C ensures efficient energy transfer while preventing contamination, outperforming traditional oxide ceramics in both thermal shock resistance and dimensional precision.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours