Ceramic Membrane Filters & Filtration Solutions for Water, Wastewater, and Industrial Separation

ADCERAX is a factory-direct source for ceramic membranes used in crossflow filtration systems. They help reduce performance drift in harsh feeds by supporting strong chemical cleaning and repeatable regeneration, so you can maintain stable solids control with fewer interruptions. Choose from standard options or custom configurations in Alumina (Al₂O₃), Zirconia (ZrO₂), and Silicon Carbide (SiC) based on your chemical exposure, abrasion level, and uptime goals.

☎️ Less fouling downtime, more controlled separation.

What is ceramic membrane?

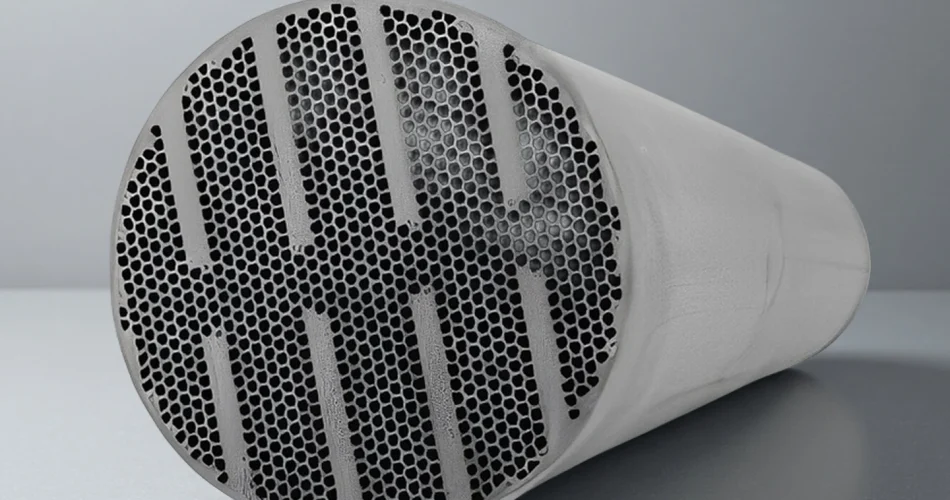

A ceramic membrane is a type of inorganic, porous filtration membrane used in ceramic membrane filtration and crossflow operation to remove suspended solids, emulsified oil, bacteria, and fine colloids from liquids.

It is typically built as a two-layer structure—a robust porous support with a finer separation layer—so it can handle abrasive or chemically aggressive feeds and recover performance through repeated cleaning.

🔍Why Choose Ceramic Membranes Over Other Filtration Options?

Ceramic membrane vs Polymeric membranes

Ceramic membranes: tolerate aggressive CIP cleaning and wider temperature/chemical stress without fast performance loss.

Ceramic membranes: stay more stable in abrasive, high-solids, or fast-fouling feeds where flux recovery matters.

Polymeric membranes: lower upfront cost for cleaner feeds, but tighter cleaning limits and faster fouling can increase changeouts.

Ceramic vs Metal filter tubes (sintered metal)

Ceramic membranes: provide more defined separation behavior for consistent filtration results than sintered metal tubes.

Ceramic membranes: are better when you need repeatable cut-off performance rather than “variable selectivity” typical of some metal media.

Sintered metal tubes: can still be attractive for coarse filtration, but ceramic membranes are preferred when separation precision matters.

Ceramic vs Disposable cartridges/media filters

Ceramic membranes: are stronger for continuous-duty, high-solids filtration where consumable replacement drives cost.

Ceramic membranes: support cleaning-based reuse, reducing ongoing consumable purchases and disposal workload.

Disposable cartridges/media: may still fit low-solids, low-risk duties, but ceramic membranes win when stability and reuse are priorities.

Ceramic Membrane Properties and Size

Ceramic membranes help maintain stable separation and predictable flux in abrasive, chemically aggressive, or fast-fouling feeds by enabling strong cleaning-based regeneration and repeatable recovery. Use the table below to compare membrane material options and select a configuration that fits your separation target, cleaning chemistry, and module integration needs.

⭐ Alumina Ceramic Membrane (Al₂O₃)

Alumina ceramic membranes deliver stable MF/UF separation with well-defined pores for suspended solids and colloids. They tolerate repeated CIP cleaning with reliable flux recovery, offering a cost-effective baseline for ceramic membrane filtration.

⭐ Zirconia Ceramic Membrane (ZrO₂)

Zirconia ceramic membranes deliver stable MF/UF separation with a tough, smooth layer that helps limit irreversible fouling. They tolerate repeated CIP cleaning with reliable recovery, ideal when surface integrity and consistent separation matter.

⭐ Silicon carbide ceramic membranes(SiC)

Silicon carbide ceramic membranes deliver stable MF/UF separation with high permeability for high-solids, abrasive feeds. They tolerate aggressive CIP cleaning with reliable recovery, ideal when uptime and durability matter.

| Material of support | α-Al2O3 |

| Material of membrane | ZrO₂ / TiO₂ /Sic/ α-Al₂O₃ |

| Pore size (mm) | 10 - 1200 |

| Length (mm) | 200 - 1200 |

| OD (mm) | 14.0 - 53.0 |

| ID (mm) | 3.3-8.0 |

| Number of Channels | 1..37 |

| Membrane element per element(M2) | 0.025 - 0.075 |

| Max. Operation Pressure(bar) | 10 |

| PH value | 0-14 |

| Flux (m³/h·bar) | 7150 - 2500 |

Ceramic Membrane Products & Types

Not all ceramic membrane filters behave the same in real feeds. To help you choose fast, we organize ceramic membrane products & types by material, structure, and MF/UF grade—so you can match your duty first, then move to sizing and a quote with fewer back-and-forth steps.

Alumina membrane tube

Cost-effective alumina ceramic membrane tube with consistent pore uniformity and repeatable batches for general water/wastewater filtration.

zirconia membrane tube

Tough zirconia ceramic membrane filter tube with a smoother separation layer to reduce irreversible fouling in fine clarification duty.

silicon carbide membrane tube

High-permeability silicon carbide ceramic filtration membrane tube for high-solids, abrasive feeds where throughput is the priority.

Tubular ceramic membrane

Tubular ceramic membranes deliver tight shutoff and smooth switching in abrasive or corrosive media, with wear-resistant sealing surfaces that slow leakage growth over long cycles.

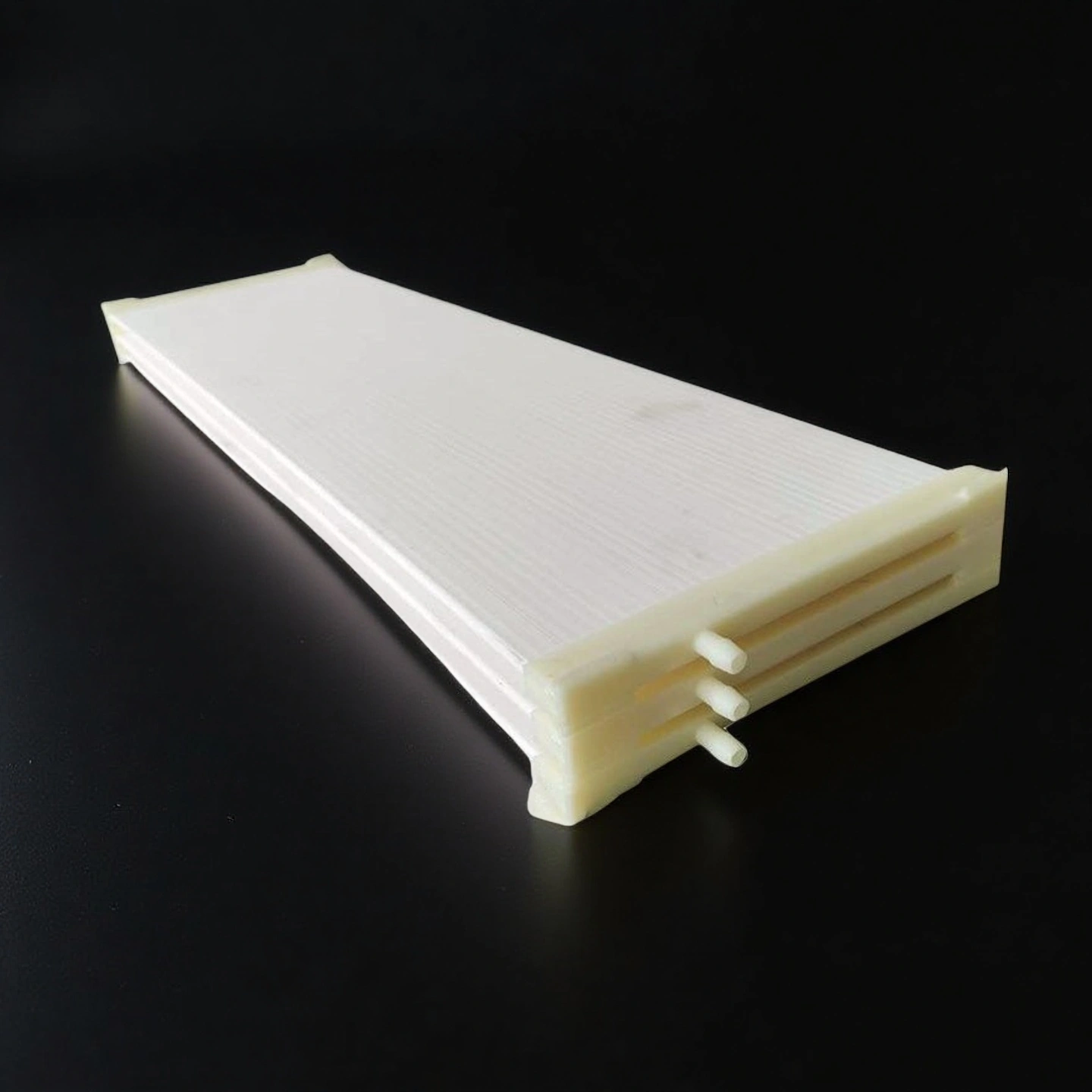

Flat sheet ceramic membrane

Ceramic flat sheet membrane offers a compact, low-torque design for larger lines, with protected sealing zones that reduce erosion and keep performance stable in particle-laden flow.

ceramic disc membrane

Ceramic disc membrane offers a compact ceramic membrane filter for slurry and solids-handling duty, with a protected flow path that resists scoring and sticking.

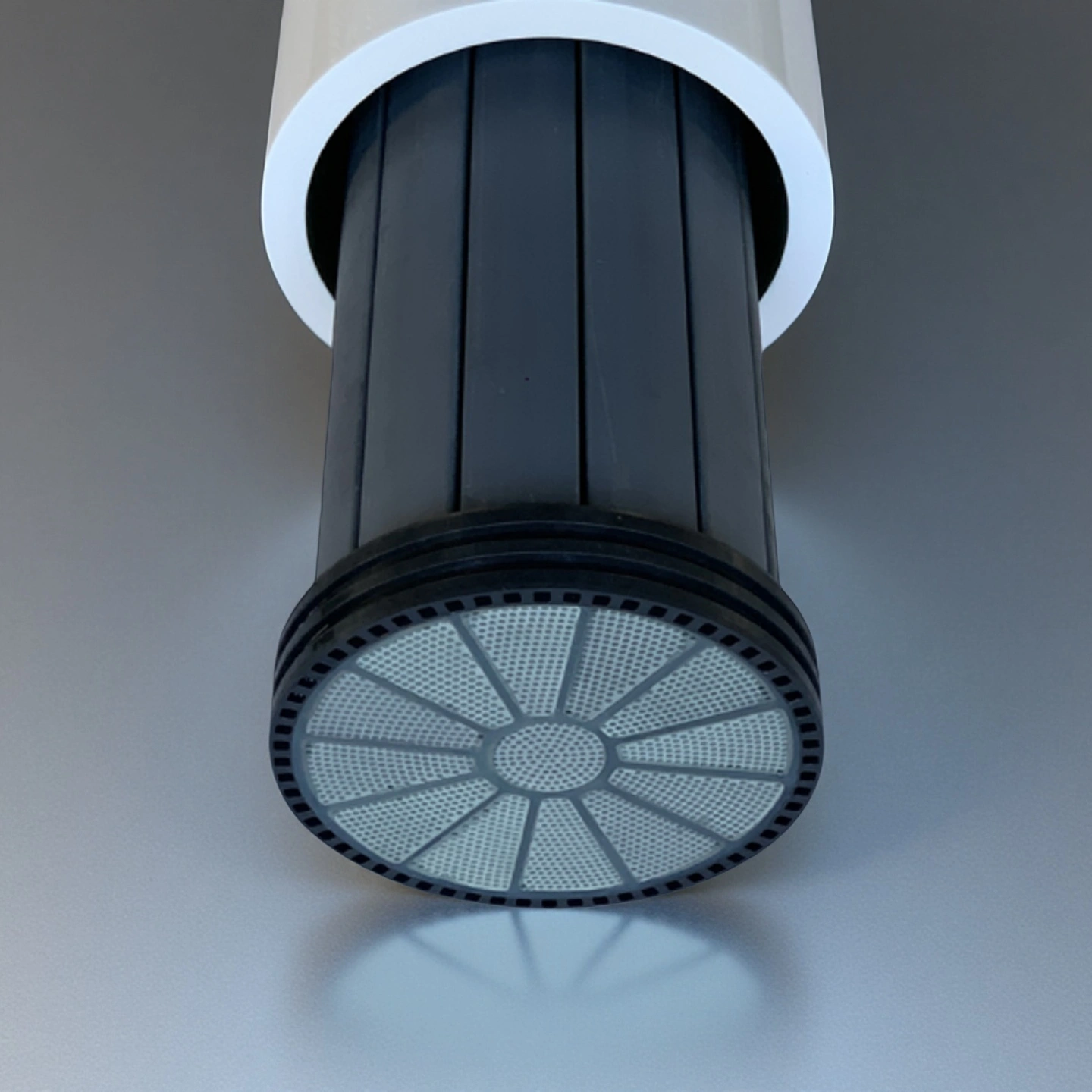

ceramic membrane module

Ceramic membrane module supports ceramic membrane filtration system builds, keeping performance stable at critical interfaces to reduce drift and unplanned stoppages.

Microfiltration ceramic membrane filter (MF)

Ceramic membrane microfiltration (MF) is best for suspended solids removal, turbidity control, bacteria reduction, and robust pretreatment duty.

Ultrafiltration ceramic membrane (UF)

Ceramic ultrafiltration membrane(UF) is best for removing finer colloids and emulsions where higher clarity and stable separation are required.

Cleaner filtration, fewer disruptions, more predictable output.

Ceramic membrane filtration delivers cleaner separation and more predictable output in harsh, fast-fouling feeds. Standard ceramic membranes enable quick replacement, while custom designs help reduce performance swings and unplanned downtime.

Ceramic Membrane Applications

Ceramic membranes are widely applied where water quality fluctuates, solids loading is high, or chemical cleaning is unavoidable. Below are the most common application scenarios where ceramic membrane filtration delivers clear operational value.

💧Water & Wastewater Treatment

✍🏻Why choose ceramic membranes

Operators use ceramic membranes when conventional media or polymer membranes fail under high turbidity, abrasive solids, or frequent CIP cleaning. Ceramic membranes provide stable separation and predictable recovery even when influent quality swings.

📍Typical use cases

Municipal wastewater polishing

• Industrial effluent clarification

• RO pretreatment and reuse water systems

🧩Case of ceramic membranes for wastewater treatment

A municipal reuse project (~45,000 m³/day) used ceramic membrane filtration as post-biological polishing, maintaining stable turbidity control during seasonal swings and reducing replacement frequency versus polymer membranes.

🏭Industrial Concentration & Process Filtration

✍🏻Why choose ceramic membranes

In industrial processes, ceramic membranes are selected for continuous-duty concentration where solids, oils, or by-products would rapidly foul disposable or polymer media.

📍Typical use cases

Process water concentration

• Chemical intermediate recovery

• High-COD stream reduction before evaporation

🧩Case of industrial ceramic membrane

A chemical processing facility used tubular ceramic membranes to concentrate process wastewater before thermal treatment. By reducing volume upstream, the plant lowered evaporator load by over 30%, while maintaining stable operation under abrasive conditions.

🛢️Oily Wastewater & Oil–Water Separation

✍🏻Why choose ceramic membrane filter

Ceramic membranes handle emulsified oil and surfactants better than traditional oil separators or cartridge filters, especially when oil concentration fluctuates.

📍Typical use cases

Machinery coolant wastewater

• Petrochemical and refinery effluent

• Produced water treatment

🧩Case of ceramic membrane filtration

An industrial equipment manufacturer treated oily wastewater with ceramic membrane filtration, achieving >98% oil removal while allowing aggressive alkaline cleaning to restore flux after oil spikes—something cartridge systems could not tolerate.

🔬Gas & Special Separation Applications

✍🏻Why choose ceramic membranes

Dense ceramic membranes are used in specialized separation and reaction systems where high temperature and chemical stability are required.

📍Typical use cases

Hydrogen or oxygen separation

• Reaction-assisted membrane processes

• High-temperature gas handling

🧩Case of ceramic membranes for gas separation

In a pilot hydrogen separation setup, dense ceramic membranes operated at elevated temperatures to selectively transport hydrogen while maintaining structural integrity under thermal cycling.

Customize Ceramic Membrane

ADCERAX custom ceramic membranes and ceramic membrane modules are made to your drawing or process specs, including pore size/MWCO target, channel structure, tube length/OD/ID, end-face design, and module interface details for reliable crossflow performance. Typical customization lead time is 2–9 weeks, depending on material choice, separation grade, tolerances, and complexity.

Customization Options

Define the separation duty first—MF or UF, target removal, feed chemistry, solids load, and temperature. Clear duty matching keeps flux stable and avoids over-cleaning, oversizing, or premature fouling.

Share your drawing or interface specs for key fit points—tube OD/ID/length, channel count, end-face design, and housing connections. Controlled fit reduces bypass risk and simplifies replacement.

Match the design to your feed behavior—abrasive solids, emulsified oil, gels, or biofouling. Options like crossflow velocity, backwash strategy, and CIP approach help limit fouling and keep recovery repeatable.

Choose the ceramic membrane material based on corrosion, abrasion, and cleaning intensity (Al₂O₃ / ZrO₂ / SiC). The right surface and pore structure improves cleanability and extends service life.

Customization Process

Send feed details, MF/UF goal, pore size or MWCO, pH/Temp. range, and cleaning method. Include drawing/interface, quantity, lead time, destination.

We confirm material (Al₂O₃ /ZrO₂ /SiC), pore grade, channel structure, tube OD/ID/length, end-face design, and housing/connection standard.

We produce ceramic membrane tubes/modules to spec and inspect key dimensions and separation grade by batch. Traceable marking and records are available.

Membranes are protected, labeled, and packed to prevent chipping and contamination, then shipped with complete export-ready documents.

Why Source Ceramic Membranes from ADCERAX?

ADCERAX supports export supply of ceramic membranes with controlled production and batch inspection for consistent pore grade and fit. Membranes are protected, labeled, and shipped with export-ready documents. Fast response to feed conditions and drawings confirms pore size/MWCO, interfaces, lead time.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Ceramic Membrane Manufacturers-ADCERAX

ADCERAX is one of the ceramic membrane suppliers with 20+ years of advanced ceramics experience, supplying ceramic membrane tubes and modules for crossflow filtration in abrasive, corrosive, and high-fouling duty.

We offer standard ceramic membranes for quick replacement and custom-to-spec builds to match pore size/MWCO, channel structure, and module interfaces. With documented inspection and protective packing, ADCERAX helps buyers keep separation performance stable and replacement cycles predictable.

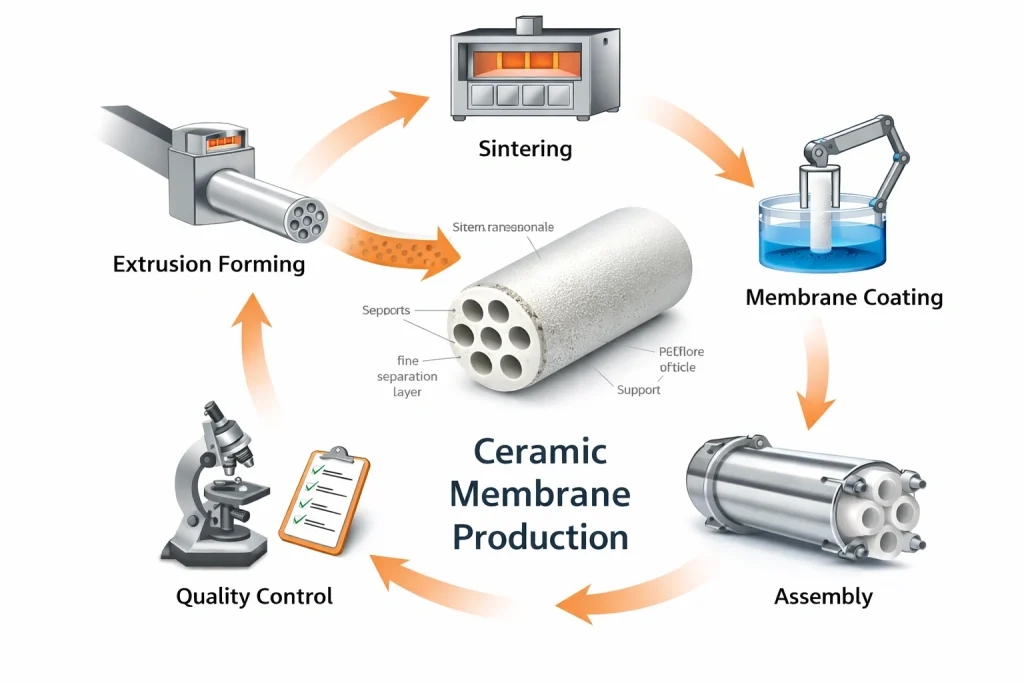

Ceramic Membrane Preparation Methods

Used to form tubular and multichannel ceramic supports by pushing ceramic paste through a die, followed by drying and sintering.

A ceramic slurry is cast as a thin “green tape,” dried, cut/stacked if needed, then laminated and sintered for flat supports.

Ceramic feedstock is injected into a mold for complex geometries, then debinded and sintered.

The porous support is dipped into a coating slurry/sol, then dried and fired to form a separation layer.

A controlled ceramic slurry is applied to build a filtration layer, then fired to lock in pore structure.

A ceramic slurry is poured into a porous mold; liquid is absorbed by the mold and a solid layer builds up, then demolded, dried, and sintered.

Includes uniaxial pressing and cold isostatic pressing (CIP) to form plates/discs/support bodies, followed by debinding and sintering.

The shaped green body is densified or stabilized by controlled firing; co-sintering can bond multilayers or structures in one firing cycle.

Gas-phase deposition forms thin layers inside pores or on surfaces; used for specific inorganic membrane types.

A sol is applied (often by dip/spin), gelled, dried, and heat-treated to form fine-pore layers.

FAQs About Ceramic Membrane

A Tubular Ceramic Membrane offers higher flux and fouling resistance compared to flat ceramic membranes, and its geometry makes backwashing and cleaning (CIP) easier for sustained performance.

Ceramic microfiltration tubes are commonly supplied in pore sizes from about 0.1 µm to 1.0 µm, with popular grades including 0.1, 0.2, 0.45, and 0.8 µm. The best choice depends on your particle size distribution, target clarity, and whether you need mainly turbidity control, bacteria reduction, or robust pretreatment.

Ceramic filter tubes are typically cleaned using backwashing, air scouring, and periodic chemical cleaning (CIP) matched to the foulants present. Alkaline, acidic, or oxidizing cleaners can be used within the recommended pH and temperature limits, followed by thorough rinsing. Routine monitoring of flux recovery after cleaning helps confirm proper maintenance and long-term performance.

Ceramic membranes work by crossflow (tangential) filtration: the feed flows along the membrane surface while pressure drives clean permeate through controlled pores. The sweeping flow helps limit cake buildup, and when fouling occurs, performance can be restored through backwash and CIP cleaning for repeatable recovery.

Ceramic membranes typically cost more upfront because they require high-temperature firing, precision pore control (pore size/MWCO), and durable inorganic materials (e.g., Al₂O₃, ZrO₂, SiC) with strict dimensional and batch inspection. Many buyers justify the price through longer service life, stronger cleaning tolerance, and fewer replacements in abrasive, corrosive, or fast-fouling duty.

Use ceramic membranes when you need reliable filtration in harsh duty—abrasive solids, aggressive chemistry, hot streams, or rapid fouling—where disposable media or polymer membranes struggle. Ceramic membrane filtration supports repeatable cleaning recovery, stable separation performance, and more predictable uptime over long operating cycles.

Service life depends on feed severity, operating pressure, cleaning frequency, and handling, but ceramic water membrane filters are typically chosen for multi-year operation because they tolerate repeated backwash and CIP cleaning with recoverable performance. The best indicator is not time alone—track flux decline rate and cleaning recovery; stable recovery usually signals the element is still within its usable life.

A ceramic membrane is made by forming a porous ceramic support (typically by extrusion or pressing), sintering it to create a strong, permeable structure, then applying a finer separation layer by coating or dip-coating. After a second controlled firing, the membrane achieves its target pore size or MWCO, followed by inspection and grading before assembly into elements or modules.

Ceramic membrane pricing is usually provided by quotation because it depends on membrane type (MF/UF), material, pore size or MWCO, dimensions, quantity, and whether standard or custom interfaces are required. To get an accurate ceramic membrane price, suppliers typically need your application details, operating conditions, and order volume rather than offering a fixed list price.

Yes. ADCERAX is China ceramic membrane manufacturers supplying industrial ceramic membrane elements for crossflow filtration, and we can support gas-separation ceramic membrane requests case-by-case. Please share your target gas, operating temperature/pressure, required selectivity, and module format so we can confirm feasibility and provide a quote.

ADCERAX is a factory-direct ceramic membrane producer and wholesaler in China, supplying standard and custom ceramic membrane tubes, elements, and modules with batch consistency and export-ready support. Buying direct from ADCERAX helps reduce intermediaries, control specifications, and secure better pricing for volume orders.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.