Figure 1: Adcerax engineers high-performance Zirconia solutions for extreme environments.

Zirconia ceramic (ZrO₂) is widely regarded as one of the most advanced structural ceramic materials in modern engineering. Known for its combination of fracture toughness, high bending strength, chemical stability, and versatile manufacturing capabilities, Zirconia is increasingly displacing traditional metals in high-performance applications—from deep-sea valves to semiconductor automation components.

At Adcerax, we see Zirconia repeatedly outperform conventional materials where mechanical wear, corrosion, and thermal stress cause failure. Whether you are an engineer specifying materials for precision components or a product designer optimizing durability, this guide provides a technical, design-ready understanding of Zirconia ceramics.

1. What Makes Zirconia Exceptional? The Science of Transformation Toughening

Ceramics historically suffer from brittleness: they crack easily under tensile stress because they lack the plastic deformation mechanisms familiar in metals. Zirconia achieves its superior performance through a mechanism known as phase transformation toughening.

Polymorphism of Zirconia

Figure 2: The "self-healing" mechanism where crystal expansion stops cracks from propagating.

Zirconia exhibits three principal crystal structures depending on temperature:

-

Monoclinic – stable at room temperature

-

Tetragonal – stable at intermediate temperatures

-

Cubic – stable at very high temperatures

In pure zirconia, cooling from high temperatures would naturally yield a brittle monoclinic phase. However, by using stabilizers such as Yttria (Y₂O₃), we allow the strong tetragonal phase to exist at room temperature. In addition to stress-induced phase transformation, the fine grain size and high density of zirconia ceramics contribute to their exceptional mechanical behavior. Fine grains reduce the available space for cracks to initiate and propagate, further enhancing strength and toughness. Zirconia’s transformation toughening is widely regarded as one of the most significant advances in structural ceramic engineering.

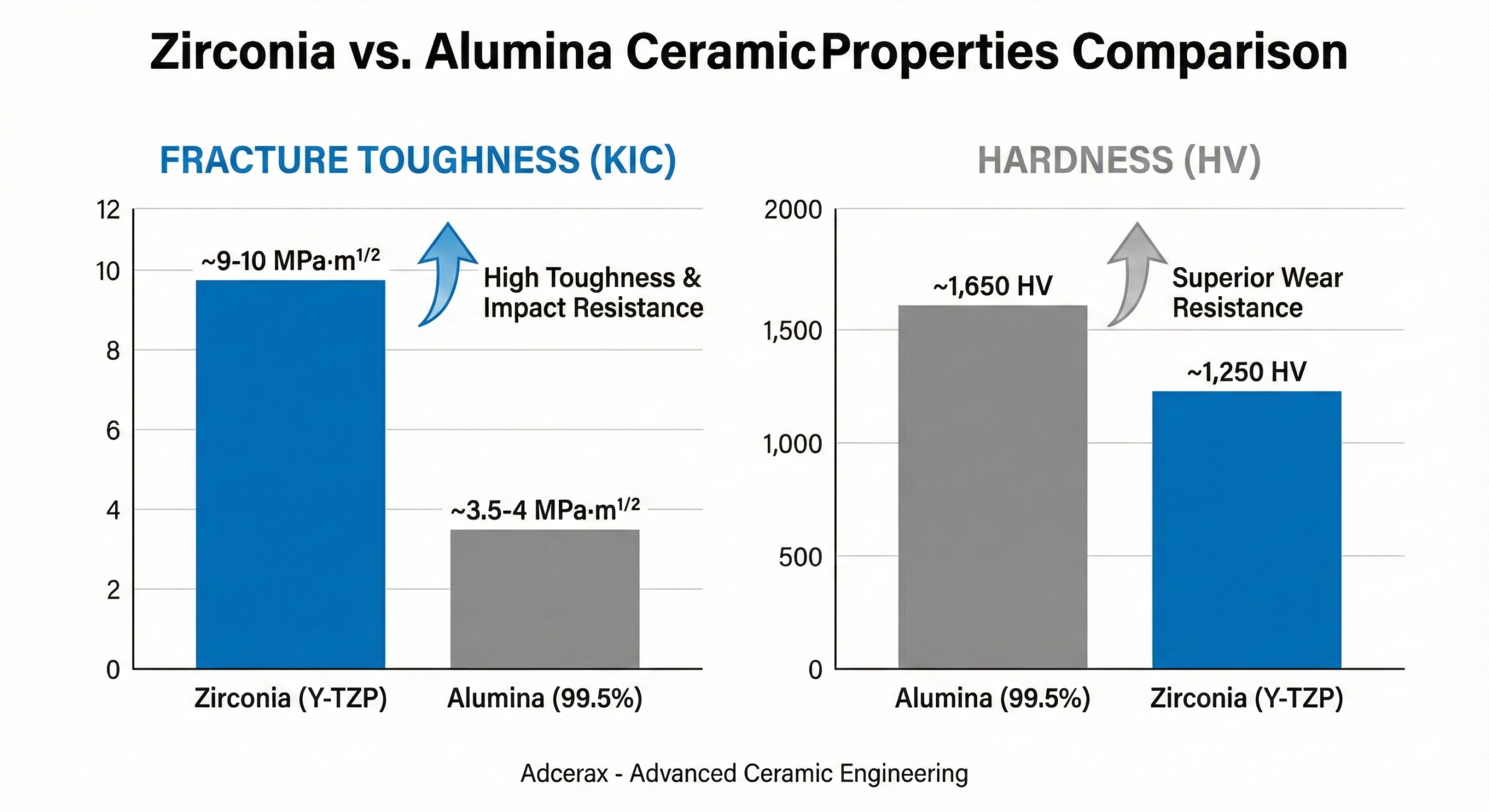

2. Zirconia vs. Alumina vs. Steel Material Comparison

Below is a performance comparison of Zirconia (Y-TZP) against Alumina (Al₂O₃) and Stainless Steel (316L):

| Property | Zirconia (Y-TZP) | Alumina (99.5%) | Stainless Steel (316L) |

|---|---|---|---|

| Primary Advantage | Toughness & Impact | Hardness & High Temp | Ductility & Cost |

| Fracture Toughness (KIC) | ~8–10 MPa·m¹/² | ~3.5–4 MPa·m¹/² | Very High |

| Hardness (HV) | ~1,250 | ~1,650 | ~200 |

| Thermal Expansion (10⁻⁶/°C) | ~10.5 | ~8.0 | ~16.0 |

| Max Working Temp (Air) | ~1,000°C | ~1,600°C | ~800°C |

Figure 3: While Alumina is harder, Zirconia offers significantly higher fracture toughness.

This comparison shows that while alumina may have slightly higher hardness, Zirconia’s superior toughness and steel-like thermal expansion make it an excellent structural ceramic choice. Zirconia also exhibits low thermal conductivity (typically 2–3 W/m·K), making it an excellent thermal insulator compared to metals, while still maintaining high strength at elevated temperatures. Its thermal expansion coefficient (~10–11 ×10⁻⁶/°C) closely matches that of some steels, which is beneficial when designing hybrid metal-ceramic assemblies where mismatched thermal expansion can cause cracking during thermal cycling.

3. Types of Zirconia Ceramics: Beyond “Just White”

Zirconia ceramics come in multiple engineered grades, each tailored for specific application needs:

Y-TZP (Yttria-Stabilized Tetragonal Zirconia Polycrystal)

-

Most common advanced Zirconia grade

-

Exceptional bending strength and fracture toughness

-

Suitable for structural and precision wear parts requiring durability

Mg-PSZ (Magnesia-Stabilized Zirconia)

-

Stabilized with magnesia

-

Offers improved thermal shock resistance

-

Often applied in high-temperature valves and industrial hardware

ESD Zirconia (Often Black)

-

Engineered to be semi-conductive (Electro-Static Dissipative)

-

Essential for preventing static buildup in semiconductor handling equipment.

ZTA (Zirconia-Toughened Alumina)

-

A composite that combines alumina’s hardness with zirconia’s toughness

-

Used in wear-resistant parts such as bearings, seals, and cutting tools

-

A cost-effective solution for large wear liners.

By selecting the correct grade, engineers can optimize a component for strength, wear resistance, or specific electrical/thermal properties.

4. Manufacturing Zirconia Parts: Processes and Best Practices

Producing Zirconia components with consistent quality requires careful control at each stage of manufacturing. The general workflow includes:

Powder Preparation and Stabilization

High-purity ZrO₂ powder is mixed with stabilizers and binders. Powder chemistry and particle size directly influence sintered density and mechanical performance.

Forming Methods

CIP (Cold Isostatic Pressing)

-

Powder placed in a flexible mold

-

High-pressure fluid applied isotropically

-

Ideal for large rods, plates, and prototypes

CIM (Ceramic Injection Molding)

-

Uses binder-loaded feedstock similar to plastic injection molding

-

Best for complex shapes and high volumes (e.g., >5,000 parts)

Sintering

Green bodies are fired at high temperatures (typically 1,400–1,600°C) to densify the material and eliminate porosity.

Post-Processing (Diamond Machining)

Figure 4: Precision diamond grinding is required to achieve micron-level tolerances.

Because Zirconia is exceptionally hard (often above 1,000 HV), final machining requires diamond grinding and precision tooling. This stage is critical for achieving tight tolerances and surface finishes.

Each manufacturing process carries trade-offs in cost, tolerances, and throughput. Understanding these helps engineers effectively specify both design and production parameters.

5. Comprehensive Product Portfolio for Standard and Custom Zirconia Solutions

At Adcerax, our dedication to the advanced ceramics industry drives us to constantly explore new applications and expand our product capabilities. We don't just manufacture ceramic material, we engineer solutions that span the entire industrial spectrum.

Whether you need standard stock for R&D or fully assembled industrial units, explore our full range of Zirconia Ceramic Products to find the exact fit for your project.

Fluid Handling & Industrial Assemblies

Moving aggressive fluids where metals fail. Adcerax goes beyond basic shapes to provide complex, finished assemblies.

-

Zirconia Pumps & Valves: We manufacture complete Zirconia Valve components and Zirconia Pump liners. These are critical for petrochemical and battery slurry industries where corrosion and abrasion would destroy stainless steel in days.

-

Zirconia Rods: High-precision CIP rods used as the core for durable pump plungers and drive shafts.

Precision Metrology & Instrumentation

Where accuracy meets permanence. Because Zirconia is dimensionally stable and harder than steel, it is the superior choice for high-precision measurement tools.

-

ZrO2 Gauges: Our ceramic Gauge Blocks resist thermal expansion and never rust, ensuring your calibration standards remain accurate year after year.

-

ZrO2 Balls: Used in check valves and precision bearings. Their perfect sphericity and extreme hardness ensure a tight seal and smooth rotation under load.

High-Temperature & Lab Essentials

Purity for extreme heat.

-

ZrO2 Crucibles: Chemically inert vessels for melting platinum and superalloys without contamination.

-

Zirconia Tubes: Used as protection sheaths for thermocouples and heating elements, offering superior thermal shock resistance compared to alumina.

Wear Protection & Custom Engineering

Solving the toughest wear challenges.

-

ZrO2 Plates: Used as substrates or wear-resistant lining plates in chutes and hoppers to prevent erosion.

-

Custom Zirconia Parts: From complex textile guides to semiconductor end-effectors, we machine custom geometries to your exact CAD specifications.

Explore More: We are constantly adding new specifications and solutions to our catalog. [👉 View All Adcerax Zirconia Products]

6. Design Guidelines for Zirconia Components

When designing Zirconia parts, engineer-centered guidelines help enhance reliability and manufacturability.

Avoid Sharp Internal Corners

Ceramics are sensitive to stress concentrations. Always use radii (e.g., R ≥ 0.2 mm) to reduce stress raisers under load.

Control Wall Thickness

-

For CIM: Uniform wall thickness (recommended 1–5 mm) prevents warpage during sintering

-

For CIP: Thicker sections are acceptable but avoid abrupt thickness changes

Tolerance Considerations

-

As-fired parts: ±2%

-

After precision grinding: As tight as ±0.005 mm can be achieved with diamond tooling

These design practices help minimize defects and ensure high performance in final parts.

7. Surface Finishes, Performance & Cost Drivers

Surface finish dramatically affects performance, especially in wear applications.

Surface Options

-

As-Fired (Ra 1.6) – Matte, cost-effective

-

Fine Ground (Ra 0.4–0.8) – Standard finish for structural parts

-

Mirror Polished (Ra < 0.1) – Essential for pump plungers and sealing surfaces

Cost Drivers

-

Raw Material Premium – High-purity Zirconia powder costs more than alumina

-

Machining Time – Diamond tooling and slow feed rates increase processing time

-

Quality Control – Precision inspection ensures performance but adds cost

Understanding these drivers allows engineers to balance performance requirements with budget constraints.

8. Diverse Industry Applications of Zirconia Ceramics

The unique combination of extreme fracture toughness and chemical inertness makes Zirconia the material of choice where metals fail, and plastics melt. Below are the primary sectors where Adcerax components deliver critical performance upgrades.

Industrial Fluid Control and Metering Systems

In the chemical and oil & gas industries, equipment often faces a dual threat: aggressive corrosion and abrasive slurries. Stainless steel plungers often degrade within weeks.

-

The Zirconia Solution: Our ceramic plungers and valve seats are virtually immune to chemical attack and resist cavitation damage.

-

Key Parts: Metering pump plungers, ball valve seats, and mechanical seal faces.

Semiconductor Manufacturing and Automation

Modern chip manufacturing requires environments that are absolutely free of particulate contamination and static electricity.

-

The Zirconia Solution: Adcerax offers ESD (Electro-Static Dissipative) Zirconia grades. These components prevent static discharge events that could destroy sensitive wafers, while the high hardness ensures no microscopic particles are shed during operation.

-

Key Parts: Wafer handling end-effectors, vacuum chucks, and precision positioning pins.

Medical Implants and Surgical Devices

Zirconia is compliant with ISO 13356 standards, meaning it is biologically inert and does not trigger immune responses.

-

The Zirconia Solution: Beyond its biological safety, Zirconia is non-magnetic, making it safe for MRI environments (unlike metal implants). Its white color also offers superior aesthetics for dental applications.

-

Key Parts: Dental roots and crowns, hip joint heads, and minimally invasive surgical instrument tips.

Advanced Energy and Oxygen Sensing

Unlike other structural ceramics, Zirconia has a unique property: it conducts oxygen ions at high temperatures (>600°C).

-

The Zirconia Solution: This ionic conductivity allows Zirconia to act as a solid electrolyte. It is the core functional material in sensors that monitor combustion efficiency in engines and furnaces.

-

Key Parts: Oxygen (Lambda) sensors, Solid Oxide Fuel Cell (SOFC) electrolytes, and heater protection tubes.

Aerospace and Extreme Environments

Aerospace engineers require materials that can withstand rapid temperature changes and protect internal systems from heat.

-

The Zirconia Solution: With low thermal conductivity and a high melting point, Zirconia acts as an effective thermal barrier. Its thermal expansion coefficient is also close to steel, allowing it to be brazed into metal assemblies without cracking during flight.

-

Key Parts: Thermal barrier coatings (TBC), jet engine turbine components, and high-pressure insulators.

9. Sourcing Strategy: A Buyer's Guide to Zirconia Ceramics

Sourcing advanced ceramics is not like buying standard metals; the difference between a high-performance component and a catastrophic failure often lies in the invisible microstructure. To ensure you are getting reliable quality, here is a procurement checklist based on industry best practices.

What to Ask Your Supplier When Purchasing Zirconia?

Quality Assurance and Testing Standards

When sourcing zirconia ceramics, buyers should request material test reports that include density, flexural strength, fracture toughness, and grain size. This ensures batch-to-batch consistency and verifies that parts meet specified mechanical requirements.

Price vs Performance

Zirconia ceramics may appear more expensive upfront compared to alumina or metals, but lifetime cost savings due to reduced wear, corrosion and maintenance often justify the investment. Look for suppliers that provide transparent pricing tied to mechanical property data rather than vague quality descriptions.

Supplier Transparency and Certifications

A reputable supplier should disclose manufacturing standards, testing protocols, and any quality certification (e.g., ISO 13356 for medical grade zirconia). Providing clear traceability supports qualification in regulated industries.

Low Temperature Degradation (LTD) Awareness

Zirconia can be susceptible to low-temperature degradation (LTD), where moisture can induce spontaneous tetragonal-to-monoclinic transformation over time causing surface microcracking. Buyers should understand stabilizer content (such as CeO₂ or higher Y₂O₃) and testing data on LTD resistance to ensure long-term performance.

Lead Times and Supply Chain Risks

Raw material supply and sintering capacity can affect delivery times. Vertical-integration or multi-year offtake agreements with zircon suppliers help secure inventory and maintain steady lead times.

Custom vs Standard Parts

Assess whether you require standard catalog parts or fully custom geometries. Custom designs necessitate early engagement with suppliers to confirm manufacturability and tolerance capabilities.

The Hidden Risk: Why "Cheap" Zirconia Fails

While budget is a priority, buyers must be cautious of generic "low-cost" options. As mentioned regarding Low Temperature Degradation (LTD), moisture can induce spontaneous microcracking over time. Inexpensive ceramics often utilize impure powders or expedited sintering cycles, which drastically accelerates this degradation.

Buyers should understand that the initial savings on a "cheap" part are often quickly erased by the astronomical cost of machine downtime and replacement. Therefore, verifying stabilizer content (such as higher Y₂O₃ levels) and requesting LTD resistance data is crucial for long-term performance.

The Adcerax Advantage: Direct Manufacturing

You don't have to choose between budget and quality. Adcerax operates as a factory-direct manufacturer, not a trading company. By controlling the entire production chain in-house, from CIP/CIM molding to precision diamond grinding, we eliminate middleman markups. This vertical integration allows us to deliver aerospace-grade Zirconia components at a price point that makes sense for your bottom line, ensuring you get both transparency and value.

10. Frequently Asked Questions about Zirconia Ceramics

Q1: Is Zirconia ceramic electrically conductive?

Standard Zirconia is an electrical insulator at room temperature. Specialty ESD grades provide controlled conductivity for static-sensitive environments. At elevated temperatures (>600°C), zirconia becomes an oxygen ion conductor, which is why it serves as a solid electrolyte in oxygen sensors and solid oxide fuel cells (SOFCs).

Q2: Can Zirconia rust or corrode?

Zirconia is chemically inert and resists oxidation, corrosion, and rust in most environments. Only highly aggressive chemicals (e.g., concentrated HF) may attack it over time.

Q3: What are typical size limits for manufactured parts?

With modern CIP equipment, parts up to several hundred millimeters up to 400mm length and 200mm diameter for CIP rods can be produced; custom solutions can extend beyond these dimensions with special tooling.

11. Conclusion

Zirconia ceramic has undeniably evolved from a niche material into a cornerstone of modern engineering. Its unique ability to combine the toughness of steel with the chemical inertness of ceramic makes it the ultimate solution for applications where traditional metals fail due to wear, corrosion, or heat.

However, the material is only as good as the manufacturing process behind it. As we have explored in this guide, achieving properties like "Transformation Toughening" and "Micron-level Precision" requires strict control over powder quality, sintering curves, and diamond machining.

This is where Adcerax steps in. We don't just sell ceramics; we bridge the gap between advanced material science and practical industrial application. Whether you need standard Zirconia Rods & Tubes for immediate use, or complex custom-engineered components for a specific challenge, Adcerax ensures that every part we ship meets the rigorous standards of aerospace and medical industries.

Ready to replace metal with a material that lasts? Don't let material failure hold your innovation back. Contact the Adcerax Engineering Team today for a manufacturability analysis, or explore our Full Zirconia Product Catalog to find your zirconia solution.