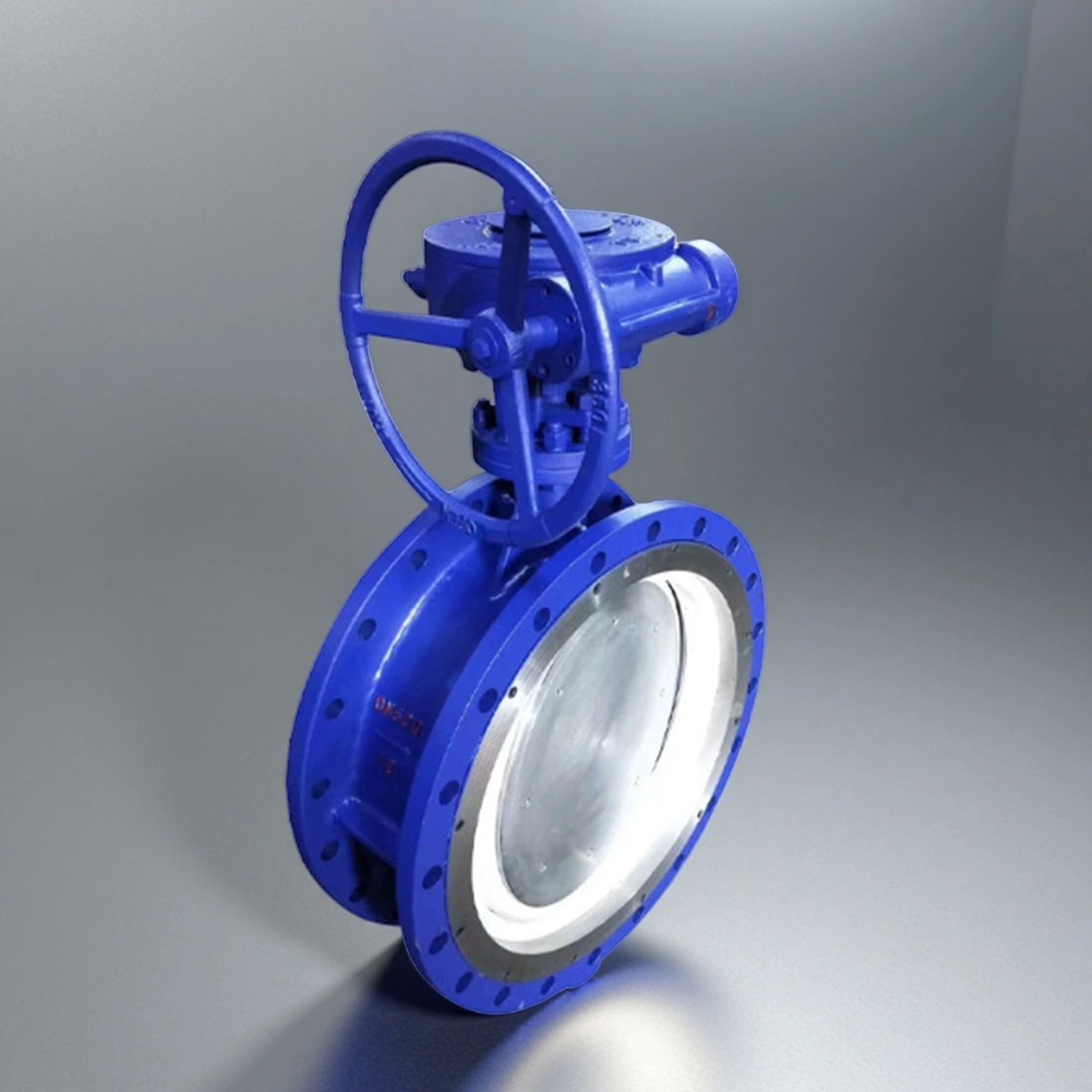

The alumina ceramic butterfly valve is a quarter-turn flow control device designed to handle abrasive, corrosive, or high-temperature media that quickly damage conventional metal or polymer-lined valves. It replaces key wetted components—such as the disc, seat, and sometimes the liner—with high-purity alumina (Al₂O₃) ceramics.

Alumina Ceramic Butterfly Valve Benefits

- Erosion-stable sealing: polished ceramic seat/disc maintains geometry under slurry impact, stabilizing torque and shut-off.

- Chemical durability: alumina internals resist acids/alkalis, where metal trims pit or passivate poorly.

- Thermal readiness: design envelopes, high-temperature seals and packing selections for hot gas/steam service.

- Tight shut-off repeatability: ground ceramic interfaces enhance sealing consistency across cycles.

- Retrofit-friendly: wafer/lug bodies and ISO top-works simplify actuator swaps and line replacements.

Alumina Butterfly Valve Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

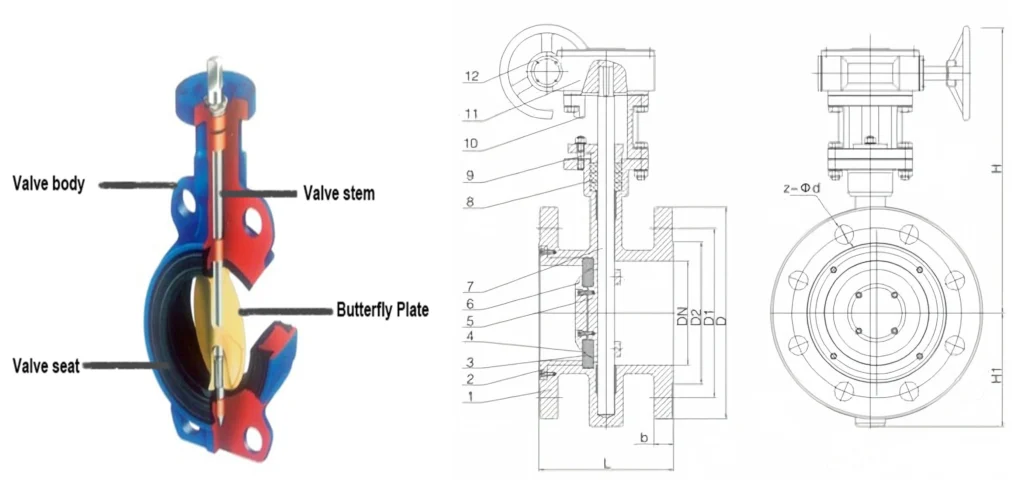

Alumina Ceramic Butterfly Valve Specifications

| Alumina Ceramic Butterfly Valve | |||||||||

| Item | DN | PN(MPa) | L | D | D1 | D2 | H | H1 | z-d |

| AT-CVD-001 | 50 | 1.0 | 108 | 140 | 125 | 100 | 254 | 85 | 4-∅18 |

| AT-CVD-002 | 65 | 112 | 160 | 145 | 120 | 278 | 95 | 4-∅18 | |

| AT-CVD-003 | 80 | 114 | 185 | 160 | 135 | 312 | 106 | 4-∅18 | |

| AT-CVD-004 | 100 | 127 | 205 | 180 | 155 | 330 | 114 | 8-∅18 | |

| AT-CVD-005 | 125 | 140 | 235 | 210 | 185 | 365 | 130 | 8-∅18 | |

| AT-CVD-006 | 150 | 140 | 260 | 240 | 210 | 404 | 148 | 8-∅23 | |

| AT-CVD-007 | 200 | 152 | 315 | 295 | 265 | 496 | 176 | 8-∅23 | |

| AT-CVD-008 | 250 | 165 | 370 | 350 | 320 | 538 | 210 | 8-∅23 | |

| AT-CVD-009 | 300 | 178 | 435 | 400 | 368 | 632 | 238 | 8-∅23 | |

Alumina Ceramic Butterfly Valve Packaging

- foam-inset inner box for protection→ reinforced export carton → strapped pallet.