Alumina Ceramic Gate Valve is a knife-type shut-off valve whose wear-facing parts—primarily the gate and seat/liners—are made from dense alumina (Al₂O₃) ceramic instead of metal. It is designed to isolate abrasive or corrosive slurries (e.g., limestone–gypsum in FGD, tailings in mining, kaolin in pulp & paper) where metallic trims erode or corrode quickly.

Alumina Ceramic Gate Valve Benefits

- Stable shut-off under solids — Lapped ceramic interfaces limit slurry under-seat washout.

- Predictable torque — Controlled flatness/roughness keeps opening force consistent as trim wears.

- Hybrid material stack — Alumina or ZTA sealing options to balance hardness vs. toughness.

- Clog-resistant gate path — Knife-type geometry for fibre/particulate-rich flows.

- Drop-in replacement — Face-to-face and flange standards matched to existing lines.

Properties of Alumina Ceramic Gate Valve

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Gate Valve Specifications

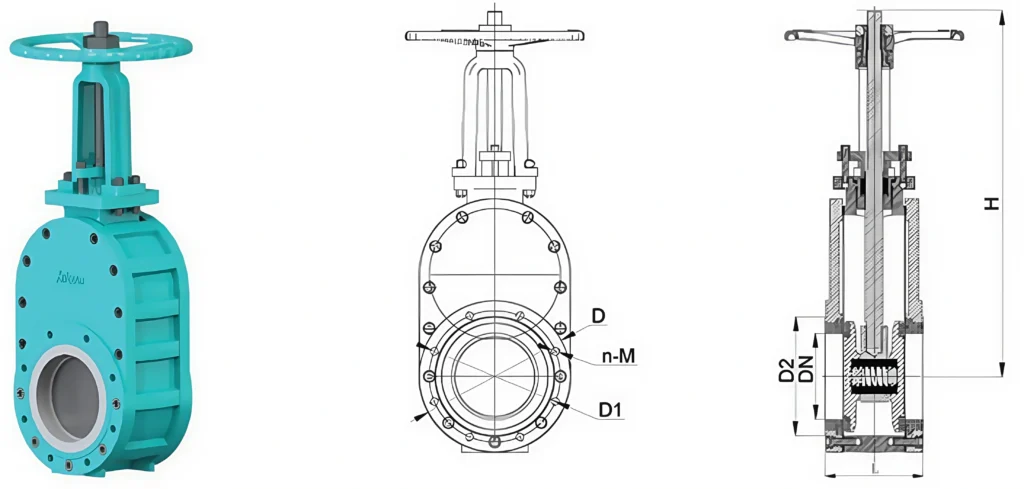

Type 1: Manual Ceramic Double Alumina Gate Valve

| Manual Ceramic Double Alumina Gate Valve | |||||||||

| Item NO. | inch | DN | L (mm) | D (mm) | D1 (mm) | D2 (mm) | n-M | H (mm) | Note |

| AT-CV2-S001 | 2" | 50 | 90 | 160 | 125 | 99 | 4-M16 | 380 | Size Range:DN50-DN250 Pressure Range:1.0MPa~1.6MPa Working Temperature:-220℃-180℃ Connection Type:Flanged, Wafer Operating Design:Manual,Pneumatic |

| AT-CV2-S002 | 2 1/2" | 65 | 125 | 185 | 145 | 118 | 4-M16 | 485 | |

| AT-CV2-S003 | 3" | 80 | 140 | 200 | 160 | 132 | 8-M16 | 490 | |

| AT-CV2-S004 | 4" | 100 | 170 | 220 | 180 | 156 | 8-M16 | 585 | |

| AT-CV2-S005 | 5" | 125 | 185 | 250 | 210 | 184 | 8-M16 | 630 | |

| AT-CV2-S006 | 6" | 150 | 200 | 280 | 240 | 211 | 8(12)-M20 | 750 | |

| AT-CV2-S007 | 8" | 200 | 220 | 340 | 295 | 266 | 8(12)-M20 | 830 | |

| AT-CV2-S008 | 10" | 250 | 220 | 395 | 350 | 320 | 12-M20 | 985 | |

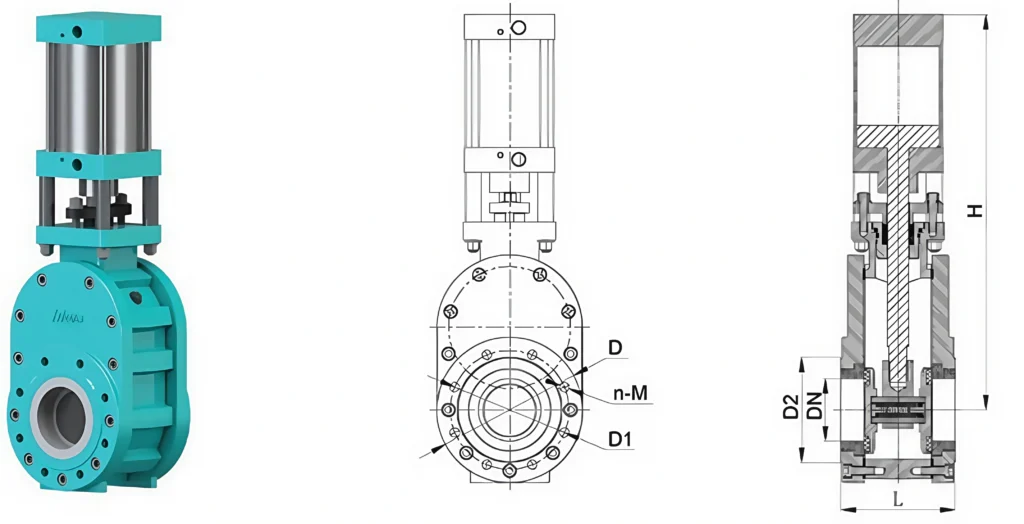

Type 2: Pneumatic Ceramic Double Alumina Gate Valve

| Pneumatic Ceramic Double Alumina Gate Valve | |||||||||

| Item NO. | inch | DN | L (mm) | D (mm) | D1 (mm) | D2 (mm) | n-M | H (mm) | Note |

| AT-CV2-Q009 | 2" | 50 | 90 | 160 | 125 | 99 | 4-M16 | 390 | Size Range:DN50-DN250 Pressure Range:1.0MPa~1.6MPa Working Temperature:-220℃-180℃ Connection Type:Flanged, Wafer Operating Design:Manual,Pneumatic |

| AT-CV2-Q010 | 2 1/2" | 65 | 125 | 185 | 145 | 118 | 4-M16 | 500 | |

| AT-CV2-Q011 | 3" | 80 | 140 | 200 | 160 | 132 | 8-M16 | 505 | |

| AT-CV2-Q012 | 4" | 100 | 170 | 220 | 180 | 156 | 8-M16 | 605 | |

| AT-CV2-Q013 | 5" | 125 | 185 | 250 | 210 | 184 | 8-M16 | 650 | |

| AT-CV2-Q014 | 6" | 150 | 200 | 280 | 240 | 211 | 8(12)-M20 | 770 | |

| AT-CV2-Q015 | 8" | 200 | 220 | 340 | 295 | 266 | 8(12)-M20 | 850 | |

| AT-CV2-Q016 | 10" | 250 | 220 | 395 | 350 | 320 | 12-M20 | 1050 | |

| AT-CV2-Q017 | 2" | 50 | 200 | 160 | 125 | 99 | 4-M16 | 390 | |

| AT-CV2-Q018 | 2 1/2" | 65 | 220 | 185 | 145 | 118 | 4-M16 | 500 | |

| AT-CV2-Q019 | 3" | 80 | 265 | 200 | 160 | 132 | 8-M16 | 505 | |

| AT-CV2-Q020 | 4" | 100 | 285 | 220 | 180 | 156 | 8-M16 | 605 | |

| AT-CV2-Q021 | 5" | 125 | 300 | 250 | 210 | 184 | 8-M16 | 650 | |

| AT-CV2-Q022 | 6" | 150 | 365 | 280 | 240 | 211 | 8(12)-M22 | 770 | |

| AT-CV2-Q023 | 8" | 200 | 400 | 340 | 295 | 266 | 8(12)-M22 | 850 | |

| AT-CV2-Q024 | 10" | 250 | 450 | 395 | 350 | 320 | 12-M22 | 1050 | |

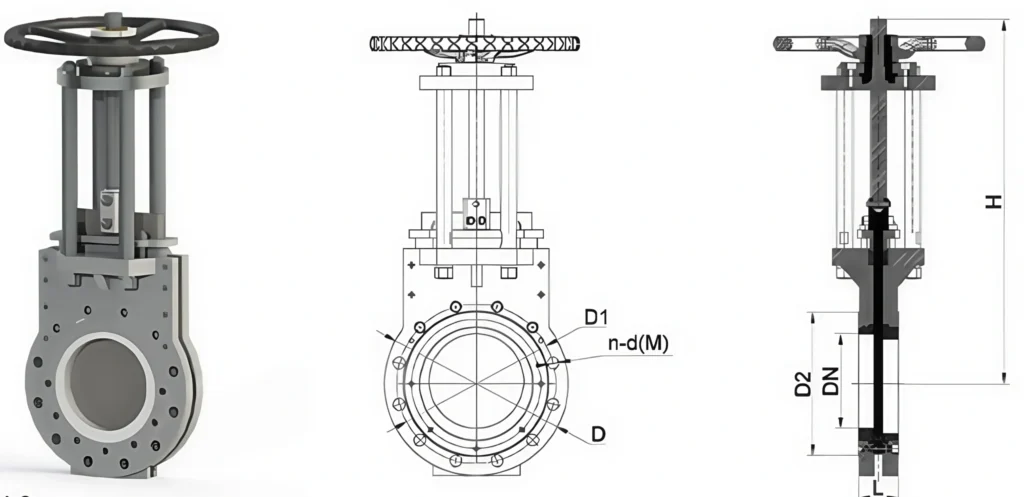

Type 3: Manual Ceramic Knife Alumina Gate Valve

| Manual Ceramic Knife Alumina Gate Valve | ||||||||

| Item NO. | DN | L (mm) | D (mm) | D1 (mm) | D2 (mm) | n-d(M) | H (mm) | Note |

| AT-CV1-S001 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 355 | Size Range:DN50-DN250 Pressure Range:1.0MPa~1.6MPa Working Temperature:-220℃-180℃ Connection Type:Flanged, Wafer Operating Design:Manual,Pneumatic |

| AT-CV1-S002 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 393 | |

| AT-CV1-S003 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 398 | |

| AT-CV1-S004 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 467 | |

| AT-CV1-S005 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 479 | |

| AT-CV1-S006 | 150 | 65 | 285 | 240 | 210 | 8-18(16) | 545 | |

| AT-CV1-S007 | 200 | 75 | 340 | 295 | 265 | 8-22(20) | 676 | |

| AT-CV1-S008 | 250 | 75 | 395 | 350 | 320 | 12-22(20) | 782 | |

| AT-CV1-S009 | 300 | 80 | 445 | 400 | 370 | 12-22(20) | 894 | |

| AT-CV1-S010 | 350 | 85 | 505 | 460 | 428 | 16-22(20) | 999 | |

| AT-CV1-S011 | 400 | 85 | 565 | 515 | 480 | 16-22(20) | 1266 | |

| AT-CV1-S012 | 450 | 95 | 615 | 565 | 530 | 20-26(22) | 1350 | |

| AT-CV1-S013 | 500 | 100 | 670 | 620 | 582 | 20-26(22) | 1415 | |

| AT-CV1-S014 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 355 | |

| AT-CV1-S015 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 393 | |

| AT-CV1-S016 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 398 | |

| AT-CV1-S017 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 467 | |

| AT-CV1-S018 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 479 | |

| AT-CV1-S019 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 545 | |

| AT-CV1-S020 | 200 | 75 | 340 | 295 | 265 | 12-22(20) | 676 | |

| AT-CV1-S021 | 250 | 75 | 405 | 355 | 320 | 12-26(22) | 782 | |

| AT-CV1-S022 | 300 | 80 | 460 | 410 | 370 | 12-26(22) | 894 | |

| AT-CV1-S023 | 350 | 85 | 520 | 470 | 428 | 12-26(22) | 999 | |

| AT-CV1-S024 | 400 | 85 | 580 | 525 | 480 | 16-30(27) | 1266 | |

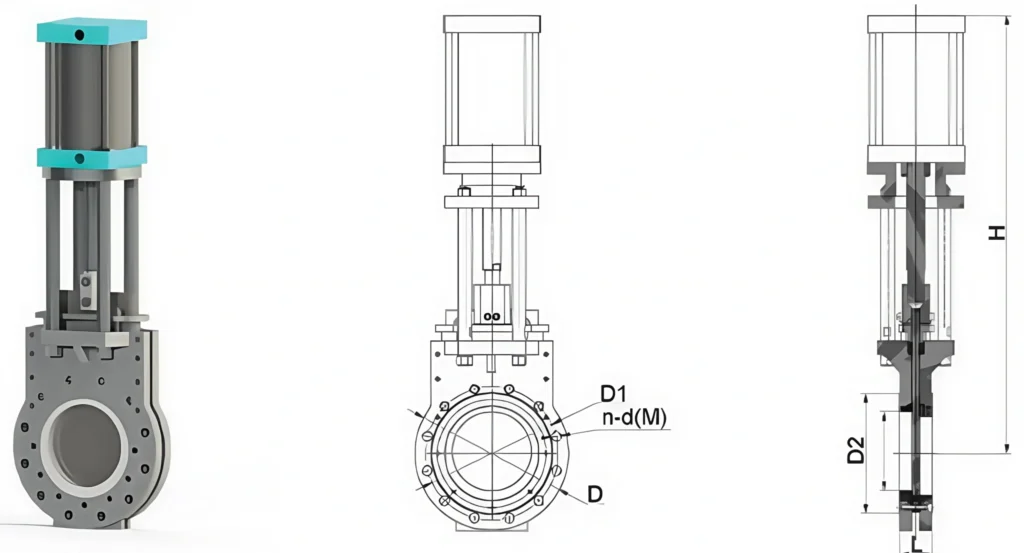

Type 4: Pneumatic Ceramic Knife Alumina Gate Valve

| Pneumatic Ceramic Knife Alumina Gate Valve | ||||||||

| Item NO. | DN | L (mm) | D (mm) | D1 (mm) | D2 (mm) | n-d(M) | H (mm) | Note |

| AT-CV1-Q001 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 463 | Size Range:DN50-DN250 Pressure Range:1.0MPa~1.6MPa Working Temperature:-220℃-180℃ Connection Type:Flanged, Wafer Operating Design:Manual,Pneumatic |

| AT-CV1-Q002 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 488 | |

| AT-CV1-Q003 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 523 | |

| AT-CV1-Q004 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 623 | |

| AT-CV1-Q005 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 673 | |

| AT-CV1-Q006 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 797 | |

| AT-CV1-Q007 | 200 | 75 | 340 | 295 | 265 | 8-22(20) | 976 | |

| AT-CV1-Q008 | 250 | 75 | 395 | 350 | 320 | 12-22(20) | 1175 | |

| AT-CV1-Q009 | 300 | 80 | 445 | 400 | 370 | 12-22(20) | 1349 | |

| AT-CV1-Q010 | 350 | 85 | 505 | 460 | 428 | 16-22(20) | 1508 | |

| AT-CV1-Q011 | 400 | 85 | 565 | 515 | 480 | 16-26(22) | 1668 | |

| AT-CV1-Q012 | 450 | 95 | 615 | 565 | 530 | 20-26(22) | 1870 | |

| AT-CV1-Q013 | 500 | 100 | 670 | 620 | 582 | 20-26(22) | 2075 | |

| AT-CV1-Q014 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 463 | |

| AT-CV1-Q015 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 488 | |

| AT-CV1-Q016 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 523 | |

| AT-CV1-Q017 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 623 | |

| AT-CV1-Q018 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 673 | |

| AT-CV1-Q019 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 797 | |

| AT-CV1-Q020 | 200 | 75 | 340 | 295 | 265 | 12-22(20) | 976 | |

| AT-CV1-Q021 | 250 | 75 | 405 | 355 | 320 | 12-26(22) | 1175 | |

| AT-CV1-Q022 | 300 | 80 | 460 | 410 | 370 | 12-26(22) | 1349 | |

| AT-CV1-Q023 | 350 | 85 | 520 | 470 | 428 | 16-26(22) | 1508 | |

| AT-CV1-Q024 | 400 | 85 | 580 | 525 | 480 | 16-30(27) | 1668 | |

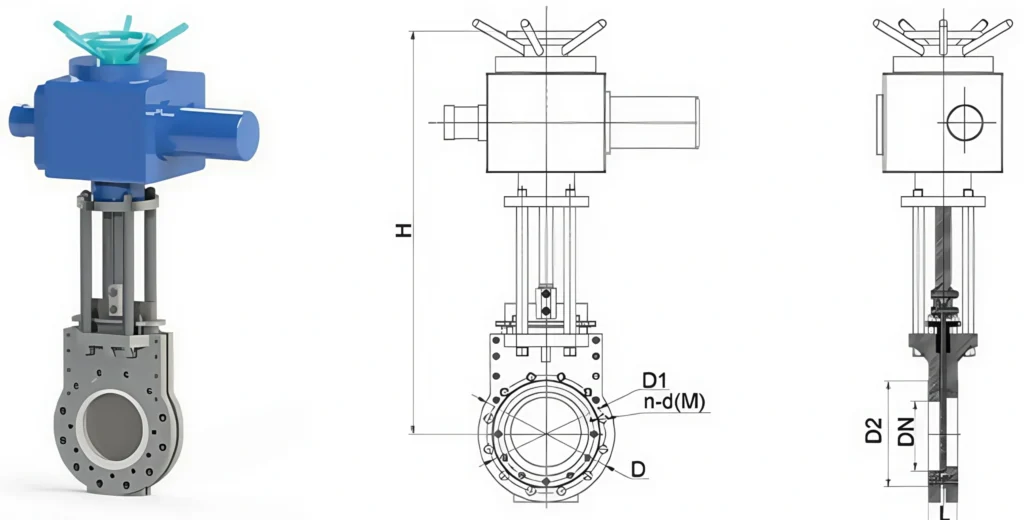

Type 5: Electric Ceramic Knife Alumina Gate Valve

| Electric Ceramic Knife Alumina Gate Valve | ||||||||

| Item NO. | DN | L (mm) | D (mm) | D1 (mm) | D2 (mm) | n-d(M) | H (mm) | Note |

| AT-CV1-D024 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 635 | Size Range:DN50-DN250 Pressure Range:1.0MPa~1.6MPa Working Temperature:-220℃-180℃ Connection Type:Flanged, Wafer Operating Design:Manual,Pneumatic |

| AT-CV1-D025 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 655 | |

| AT-CV1-D026 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 675 | |

| AT-CV1-D027 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 725 | |

| AT-CV1-D028 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 760 | |

| AT-CV1-D029 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 780 | |

| AT-CV1-D030 | 200 | 75 | 340 | 295 | 265 | 8-22(20) | 910 | |

| AT-CV1-D031 | 250 | 75 | 395 | 350 | 320 | 12-22(20) | 1115 | |

| AT-CV1-D032 | 300 | 80 | 445 | 400 | 370 | 12-22(20) | 1230 | |

| AT-CV1-D033 | 350 | 85 | 505 | 460 | 428 | 16-22(20) | 1320 | |

| AT-CV1-D034 | 400 | 85 | 565 | 515 | 480 | 16-26(22) | 1410 | |

| AT-CV1-D035 | 450 | 95 | 615 | 565 | 530 | 20-26(22) | 1550 | |

| AT-CV1-D036 | 500 | 100 | 670 | 620 | 582 | 20-26(22) | 1700 | |

| AT-CV1-D037 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 635 | |

| AT-CV1-D038 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 655 | |

| AT-CV1-D039 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 675 | |

| AT-CV1-D040 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 725 | |

| AT-CV1-D041 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 760 | |

| AT-CV1-D042 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 780 | |

| AT-CV1-D043 | 200 | 75 | 340 | 295 | 265 | 12-22(20) | 910 | |

| AT-CV1-D044 | 250 | 75 | 405 | 355 | 320 | 12-26(22) | 1115 | |

| AT-CV1-D045 | 300 | 80 | 460 | 410 | 370 | 12-26(22) | 1230 | |

| AT-CV1-D046 | 350 | 85 | 520 | 470 | 428 | 16-26(22) | 1320 | |

| AT-CV1-D047 | 400 | 85 | 580 | 525 | 480 | 16-30(27) | 1410 | |

Alumina Ceramic Gate Valve Packaging

- Each ceramic valve is packaged in PE foam