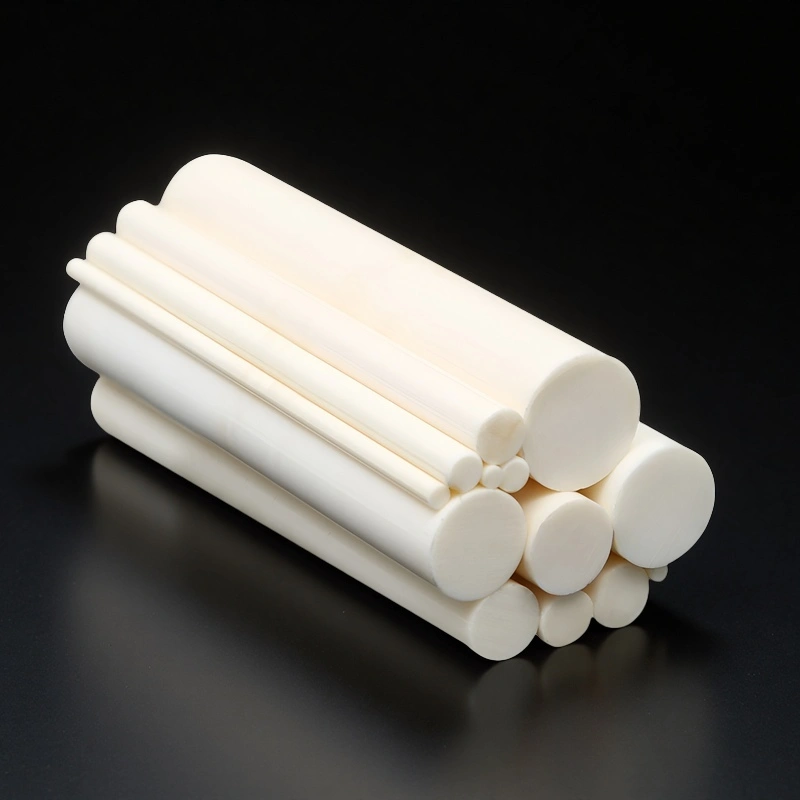

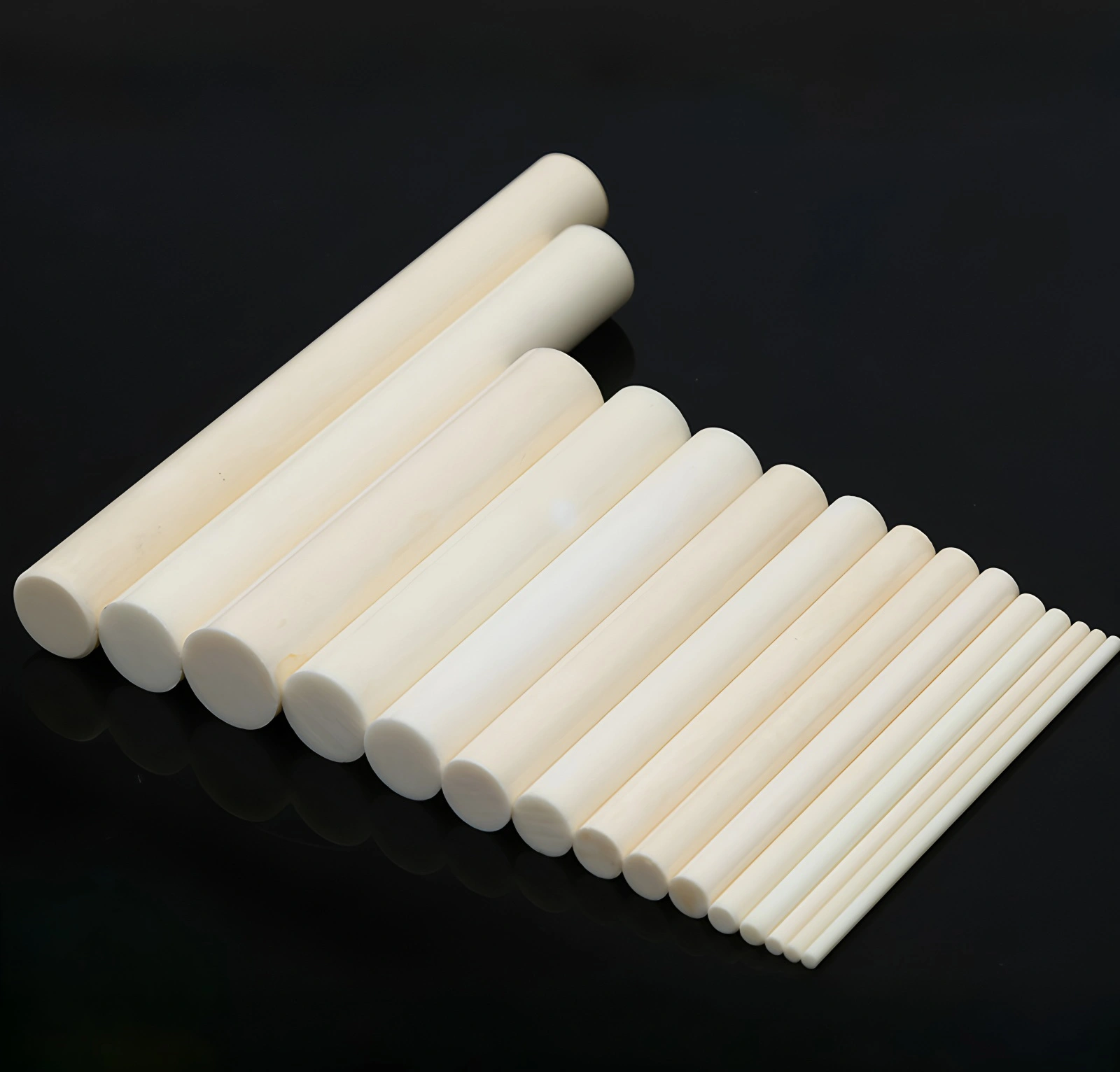

Alumina ceramic solid rods are solid bars made from high-purity aluminum oxide. They are widely used as insulating and support components in industrial and laboratory equipment because of their excellent heat resistance, electrical insulation, and strength.

Advantages of Alumina Ceramic Solid Rods

- High temperature stability reduces warping risk during rapid thermal cycling

- Smooth surface minimizes contamination and particle release

- Precise machining allows direct replacement in mechanical systems

- Corrosion resistance supports use in acid/alkaline atmospheres

- Long service life lowers annual maintenance costs

Alumina Ceramic Solid Rods Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

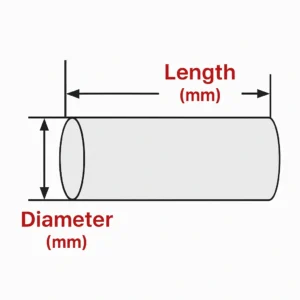

Specifications of Alumina Ceramic Solid Rods

| Item No. | Diameter (mm) | Length(mm) |

| TE-AT-30001 | 0.5 | ≤3000 |

| TE-AT-30002 | 1.2 | ≤3000 |

| TE-AT-30003 | 1.3 | ≤3000 |

| TE-AT-30004 | 1.4 | ≤3000 |

| TE-AT-30005 | 1.5 | ≤3000 |

| TE-AT-30006 | 1.6 | ≤3000 |

| TE-AT-30007 | 2.2 | ≤3000 |

| TE-AT-30008 | 2.4 | ≤3000 |

| TE-AT-30009 | 3.5 | ≤3000 |

| TE-AT-30010 | 3.8 | ≤3000 |

| TE-AT-30011 | 4.5 | ≤3000 |

| TE-AT-30012 | 5.5 | ≤3000 |

| TE-AT-30013 | 6.3 | ≤3000 |

| TE-AT-30014 | 6.5 | ≤3000 |

| TE-AT-30015 | 6.8 | ≤3000 |

| TE-AT-30016 | 8.3 | ≤3000 |

| TE-AT-30017 | 8.5 | ≤3000 |

| TE-AT-30018 | 9.5 | ≤3000 |

| TE-AT-30019 | 10.5 | ≤3000 |

| TE-AT-30020 | 11 | ≤3000 |

| TE-AT-30021 | 11.5 | ≤3000 |

| TE-AT-30022 | 12.5 | ≤3000 |

| TE-AT-30023 | 13 | ≤3000 |

| TE-AT-30024 | 13.5 | ≤3000 |

| TE-AT-30025 | 14 | ≤3000 |

| TE-AT-30026 | 16 | ≤3000 |

| TE-AT-30027 | 16.5 | ≤3000 |

| TE-AT-30028 | 17 | ≤3000 |

| TE-AT-30029 | 19 | ≤3000 |

| TE-AT-30030 | 21 | ≤3000 |

| TE-AT-30031 | 22 | ≤3000 |

| TE-AT-30032 | 23 | ≤3000 |

| TE-AT-30033 | 24 | ≤3000 |

| TE-AT-30034 | 24.5 | ≤3000 |

| TE-AT-30035 | 42 | ≤3000 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

Alumina Ceramic Solid Rod Packing:

Sealed plastic bags, protective foam, export-grade cartons.