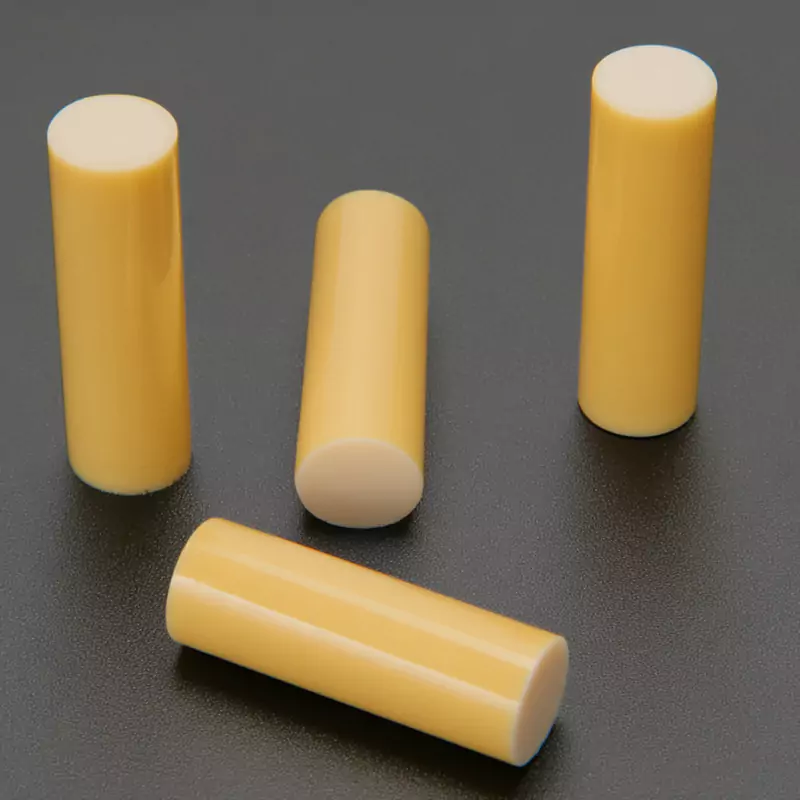

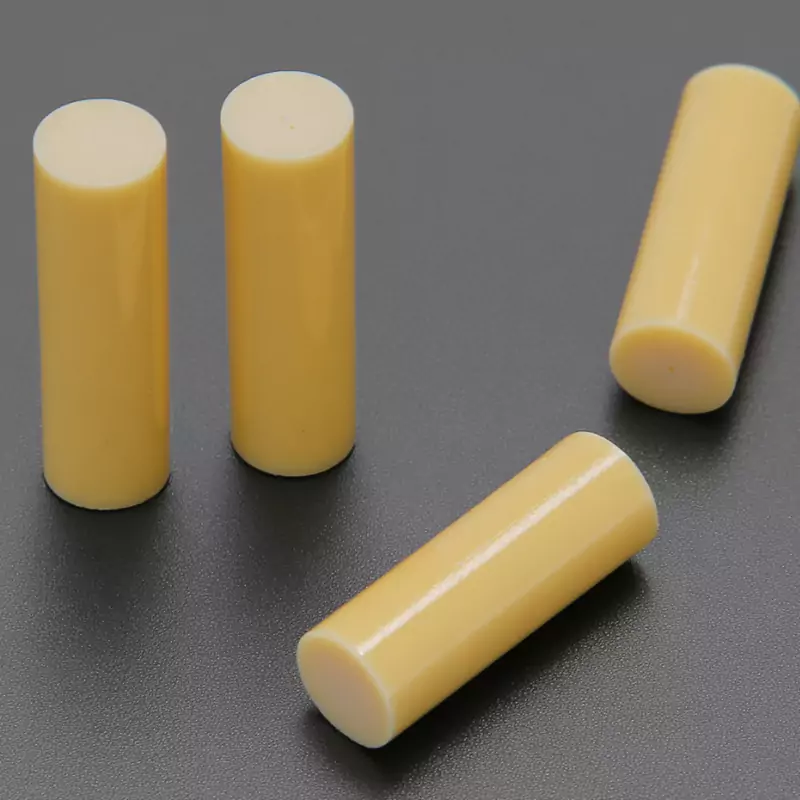

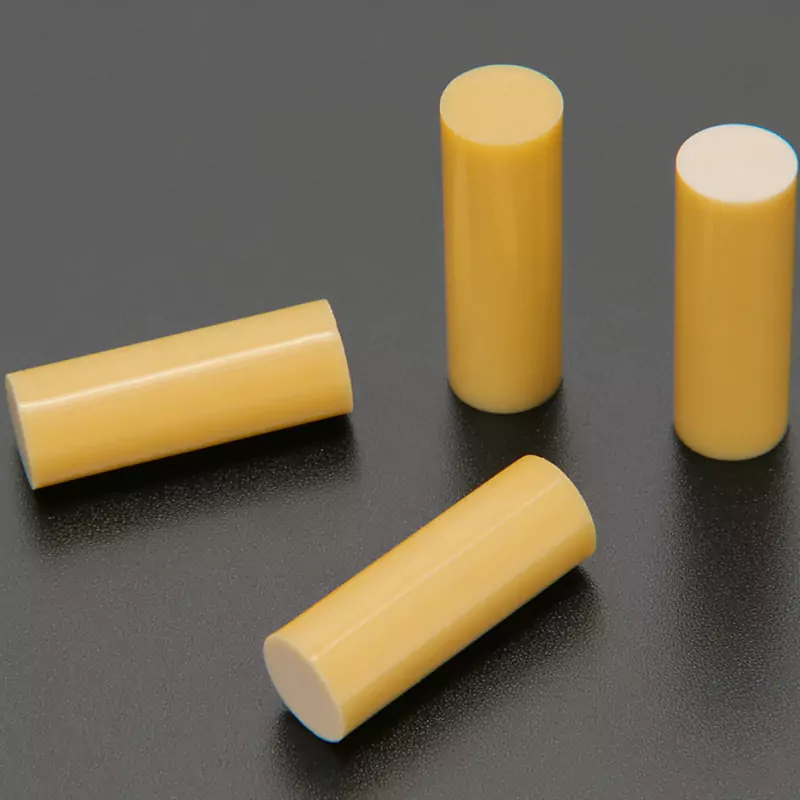

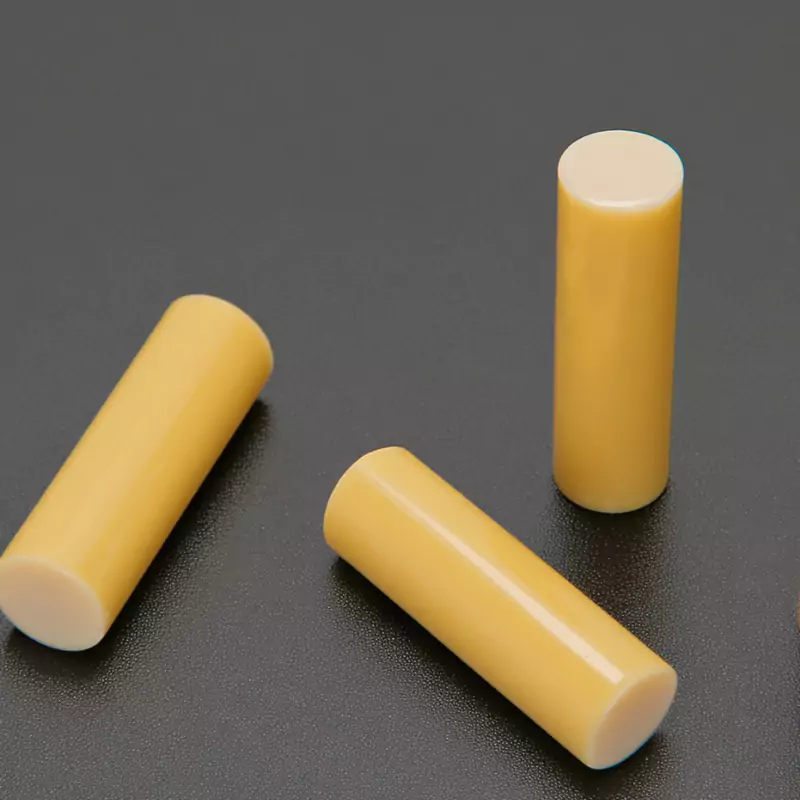

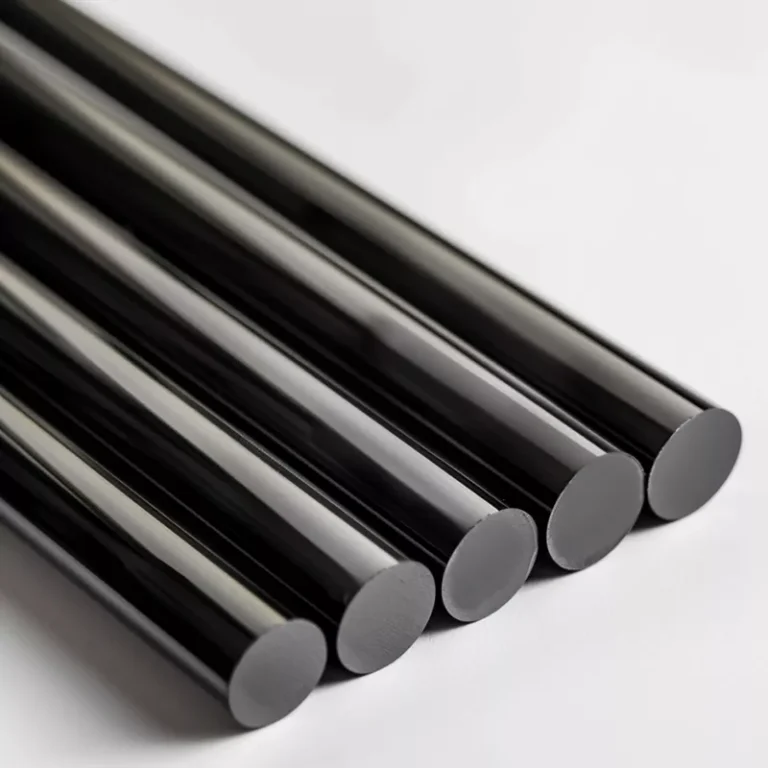

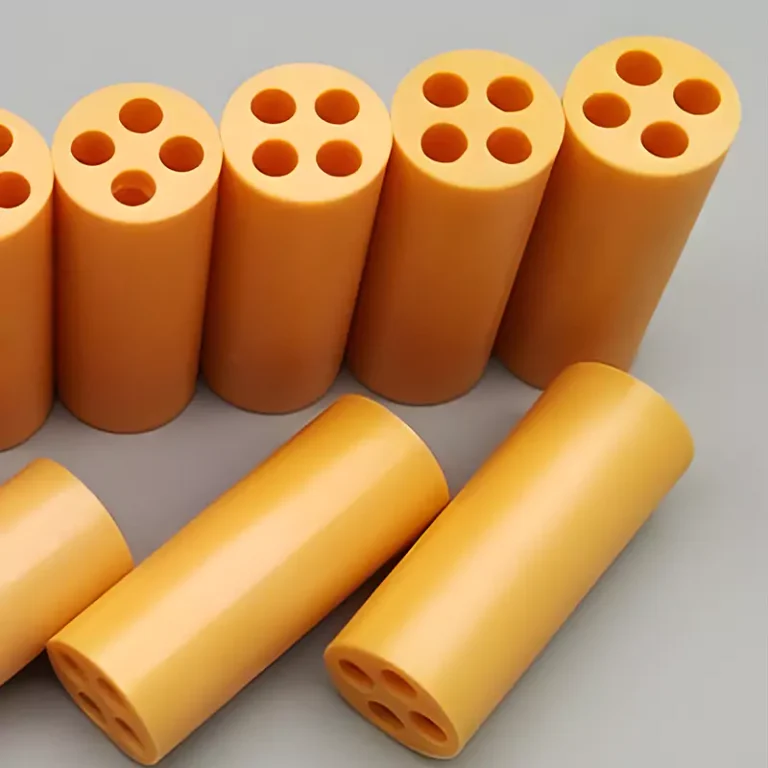

ADCERAX® Magnesia Stabilized Zirconia Rod is engineered for industries that demand reliable performance under extreme operating conditions. It delivers a combination of high strength, fracture toughness, and resistance to both thermal shock and chemical attack. This material ensures stability in applications such as chemical processing, metallurgical furnaces, and heavy machinery components. ADCERAX® supplies standard stock and customized MSZ Rod to meet diverse industrial needs with consistent quality and dependable delivery.

Features of Magnesia Stabilized Zirconia Rod

- Typical flexural strength of >800 MPa supports heavy industrial loads. This strength reduces component breakage and extends operational uptime.

- Fracture toughness values in the 6–12 MPa·m^0.5 range deliver reliability under mechanical shock. This prevents costly unplanned shutdowns in machinery lines.

- Hardness near 1200 HV resists wear during continuous friction. This makes the Magnesia Stabilized Zirconia Rod suitable for long-cycle equipment use.

- Stable at service temperatures between 1000–2000 °C, depending on grade. This allows safe operation in furnaces and high-temperature reactors.

- Thermal expansion coefficient of ≈10 × 10⁻⁶ /K provides dimensional reliability. It prevents misalignment during repeated heating and cooling cycles.

- Maintains integrity after rapid heating and cooling tests exceeding 100 cycles. This proves excellent thermal shock resistance for industrial applications.

Properties for Magnesia Stabilized Zirconia Rod

The Magnesia Stabilized Zirconia Rod delivers proven performance across physical, thermal, and mechanical dimensions. This section provides key technical parameters together with the material’s dimensional specification table, ensuring engineers can evaluate suitability for industrial applications.

| Property |

Specification |

| Density |

5.70–5.72 g/cm³ |

| Flexural Strength (MOR) |

>800 MPa |

| Fracture Toughness (K_IC) |

6–12 MPa·m^0.5 |

| Vickers Hardness (HV10) |

≈1200 HV |

| Thermal Expansion (20–1000 °C) |

≈10 × 10⁻⁶ /K |

| Maximum Service Temperature |

1000–2000 °C (application dependent) |

| Chemical Resistance |

Stable in acids/alkalis; inert to molten salts at >1000 °C |

| Electrical Insulation |

Volume resistivity >10¹² Ω·cm at room temperature |

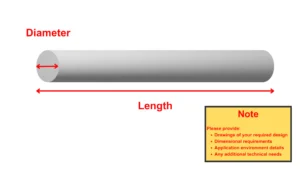

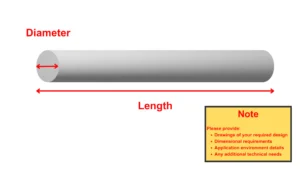

Dimension for Magnesia Stabilized Zirconia Rod

|

Magnesia-Stabilized Zirconia Rods |

|

Item No. |

Outer Diameter(mm) |

Length (mm) |

|

AT-MGO-B001 |

5 |

10-400 |

|

AT-MGO-B002 |

10 |

10-400 |

|

AT-MGO-B003 |

15 |

10-400 |

|

AT-MGO-B004 |

17 |

10-400 |

|

AT-MGO-B005 |

20 |

10-400 |

|

AT-MGO-B006 |

25 |

10-400 |

|

AT-MGO-B007 |

30 |

10-400 |

|

AT-MGO-B008 |

50.8 |

304 |

Packaging of Magnesia Stabilized Zirconia Rod

Each Magnesia Stabilized Zirconia Rod is securely packed with foam-lined boxes to prevent vibration and surface damage. Strong wooden crates are used to protect the MSZ Rod during long-distance transportation. Bulk shipments are reinforced with strapping to ensure the MSZ Ceramic Rod arrives safely at the customer’s facility.

Addressing Critical Industrial Demands with ADCERAX® Magnesia Stabilized Zirconia Rod

The Zirconia Ceramic Shaft Rod is designed to overcome specific failures that occur in critical industrial applications. Its material properties provide solutions where metals or polymers cannot sustain performance, reducing downtime and extending operational lifetimes.

-

Continuous Casting Rollers in Steelmaking

✅Key Advantages

1. Molten-slag corrosion resistance — MgO-stabilized ZrO₂ shows low reactivity with CaO–SiO₂–Al₂O₃ slags at ≥1400 °C; hardness ≈1200 HV limits abrasive wear. This protects roller surfaces during continuous contact with molten steel and slag streams.

2. Thermal-shock endurance to casting cycles — K_IC 6–12 MPa·m^0.5 and MOR ≥800 MPa absorb start/stop thermal gradients. CTE ≈10×10⁻⁶/K reduces crack initiation under secondary-cooling water sprays.

3. High-temperature strength retention — Strength remains robust through 100+ rapid heat–cool cycles in 1450–1500 °C exposure zones. Dimensional stability supports smoother strand guidance between maintenance intervals.

✅ ️Problem Solved

A slab caster reported roller shell wear and corrosion causing unplanned stoppages every 1–2 weeks at ~1500 °C. After switching to ADCERAX® Magnesia Stabilized Zirconia Rod cores, trials completed 100+ thermal cycles without spalling, and slag attack visibly decreased. With MOR ≥800 MPa and hardness ≈1200 HV, service life extended beyond the prior interval, cutting strand interruptions and stabilizing throughput under identical casting speeds and spray patterns.

-

Kiln Furniture and Structural Supports

✅Key Advantages

1. Low-expansion geometry control — CTE ≈10×10⁻⁶/K mitigates warping across fast-fire ramps. Flatness and straightness hold through 1200–1400 °C schedules with rapid cool-down.

2. Cycle durability under load — MOR ≥800 MPa and K_IC 6–12 MPa·m^0.5 resist bending and crack growth. Structural integrity persists over 100+ quick heat–quench cycles with stacked loads.

3. Atmosphere and glaze inertness — Chemically stable to common kiln vapors and condensates; hardness ≈1200 HV limits abrasion from setters and carriers. Surfaces remain clean, reducing defect transfer.

✅ ️Problem Solved

A tile line experiencing support rod cracking after <40 cycles replaced fixtures with ADCERAX® Magnesia Stabilized Zirconia Rod. Under identical load and ramp rates to 1250–1280 °C, rods ran 100+ cycles without visible cracks or measurable sag. The combination of CTE control and high K_IC reduced thermal-fatigue damage, cutting fixture changeovers and scrap linked to warped supports.

-

Insulating Rods in High-Voltage Electrical Equipment

✅Key Advantages

1. High volume resistivity — Volume resistivity >10¹² Ω·cm at 25 °C provides robust insulation margins. Non-magnetic ZrO₂–MgO composition avoids EM interference in energized assemblies.

2. Thermal endurance under electrical load — Maximum service temperature 1000–2000 °C (grade dependent) prevents heat-induced degradation. CTE ≈10×10⁻⁶/K supports stable alignment near hot bus bars.

3. Environmental stability — Chemically inert to moisture and industrial contaminants; surfaces retain insulating character after 100+ heat cycles. Hardness ≈1200 HV resists mechanical scuffing during maintenance.

✅ ️Problem Solved

A MV switchgear OEM logged recurrent tracking and arc marks on legacy insulators after thermal soaks. With ADCERAX® Magnesia Stabilized Zirconia Rod installed, assemblies maintained volume resistivity >10¹² Ω·cm at room temperature following a 96 h elevated-temperature conditioning. Over the subsequent test window, no leakage-current alarms or maintenance-related replacements were recorded, while operating temperature profiles and load currents remained unchanged.

User Guide for Magnesia Stabilized Zirconia Rod

The Magnesia Stabilized Zirconia Rod provides reliable performance across harsh operating environments, but proper handling and application practices are essential to maximize its service life. This guide outlines key recommendations for storage, installation, operation, and maintenance, ensuring customers achieve stable results and minimize replacement costs.

-

Storage and Handling

1. Controlled Environment — Store rods in dry, temperature-controlled areas to prevent surface moisture absorption. Prolonged humidity exposure may reduce insulation reliability over time.

2. Safe Handling — Avoid sudden impacts or accidental drops during transport or setup. Mechanical shocks can cause microcracks that shorten service life.

3. Protective Packaging — Use cushioned crates or foam-lined boxes during shipping. This minimizes vibration damage and keeps surfaces free from contamination.

-

Installation Guidelines

1. Proper Alignment — Ensure rods are aligned with system fixtures during assembly. Misalignment increases stress points and can lead to premature fracture.

2. Support Compatibility — Pair rods with materials having similar thermal expansion coefficients. This prevents joint stress when operating under temperature variations.

3. Gradual Tightening — Apply fastening pressure evenly across all contact points. Excessive localized force may induce structural flaws or distortion.

-

Operational Recommendations

1. Controlled Heating — Warm up systems gradually rather than applying direct high-temperature exposure. This reduces thermal shock and prolongs rod durability.

2. Load Monitoring — Do not exceed recommended load capacities during mechanical operation. Overloading increases wear and raises fracture risk under repeated cycles.

3. Chemical Exposure — Limit unnecessary contact with aggressive acids outside designed operating parameters. This ensures consistent corrosion resistance and material longevity.

-

Maintenance and Inspection

1. Routine Checks — Inspect rods periodically for surface wear, microcracks, or discoloration. Early detection helps prevent unexpected failures in production lines.

2. Cleaning Practices — Use non-abrasive cleaning tools and neutral solutions. Harsh abrasives may erode the surface and compromise performance.

3. Replacement Scheduling — Establish service-life tracking based on application cycles. Planned replacement reduces downtime and improves overall system reliability.