ADCERAX® MSZ Ceramic Ball Valve is designed with magnesia-stabilized zirconia to deliver high strength, chemical resistance, and long service life in demanding process industries. It provides reliable flow control in corrosive, abrasive, and high-temperature environments where conventional metal or lined valves fail. The material stability ensures consistent sealing under thermal shock, while the smooth ceramic surface reduces maintenance and minimizes downtime. This makes it a trusted choice for chemical plants, mining slurry transport, power generation, water treatment, and pharmaceutical systems.

Features of MSZ Ceramic Ball Valve

- Flexural strength >500 MPa enables the MSZ Ceramic Ball Valve to withstand high pressure cycles without cracking. Its compressive strength of 2,500 MPa guarantees reliable sealing even under extreme load.

- With fracture toughness 6–7 MPa·m½, the material resists crack propagation, extending service intervals. Combined with an elastic modulus of 250 GPa, it ensures dimensional stability under stress.

- Hardness ~1,100 HV0.5 provides superior wear resistance compared to steel valves, reducing particle erosion in slurry lines.

- Thermal expansion coefficient 10×10⁻⁶/K ensures stable sealing against metal housings, lowering risk of leakage during temperature fluctuations.

- With a thermal shock tolerance of 450 ∆T°C, the valve survives rapid quenching cycles where polymers or metals fail.

- Volume resistivity >10¹⁴ Ω·cm at 20 °C keeps MSZ Ceramic Ball Valve electrically insulating, useful in processes where electrochemical corrosion is a concern.

- In 60% nitric acid at 90 °C, weight loss is only 0.1 mg/cm²/day, showing high resistance in acidic media.

- Even in 95% sulfuric acid at 95 °C, weight loss remains 0.34 mg/cm²/day, proving strong durability in concentrated acids for chemical industries.

Technical Properties for MSZ Ceramic Ball Valve

The ZrO2 Dispensing Valve combines advanced material properties with industrial durability to support precision dispensing.

| Property |

Specification |

| Density |

5.7 g/cm³ |

| Hardness (Vickers) |

1,100 HV0.5 |

| Flexural Strength |

500 MPa |

| Compressive strength |

2,500 MPa |

| Elastic modulus |

250 GPa |

| Fracture toughness |

6–7 MPa·m½ |

| Weibull modulus |

12 M |

| Thermal shock resistance |

450 ∆T°C |

| Max service temperature |

2,100 °C |

| Nitric acid 60% at 90 °C |

0.1 mg/cm²/day |

| Sulfuric acid 95% at 95 °C |

0.34 mg/cm²/day |

| Sodium hydroxide 30% at 80 °C |

0.95 mg/cm²/day |

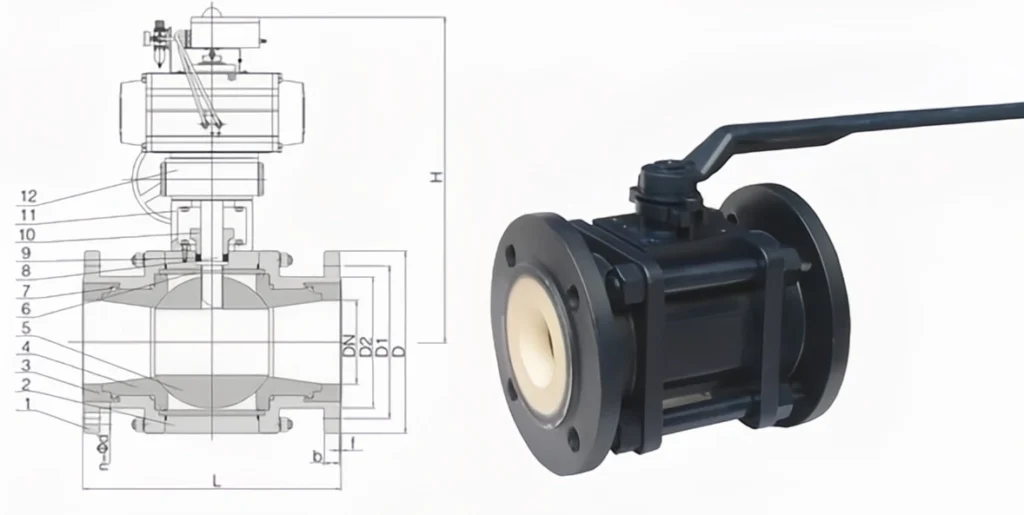

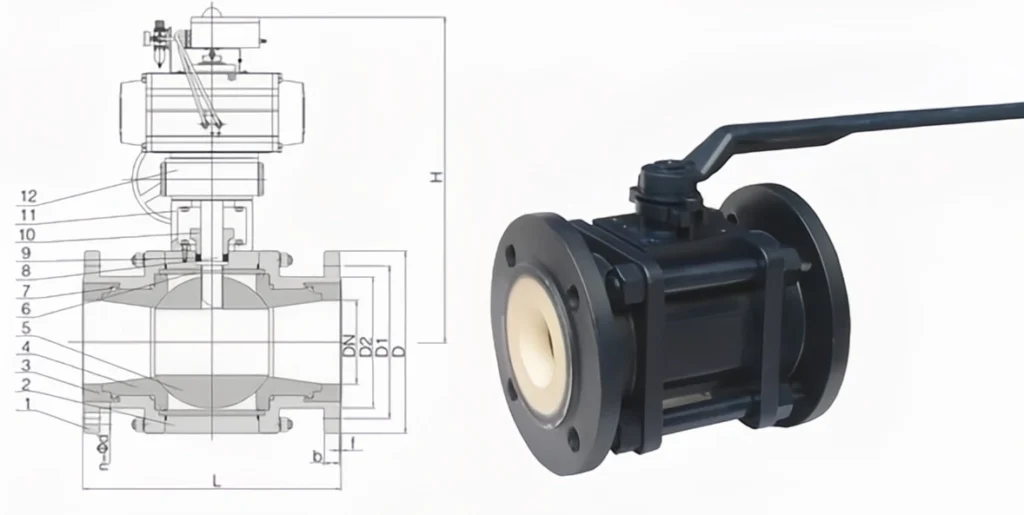

Specifications of MSZ Ceramic Ball Valve

|

O shaped Magnesia Stabilized Zirconia Ceramic Valve |

|

Item No. |

Nominal Diameter |

PH (Mpa) |

D |

D1 |

D2 |

C |

H |

n-d |

|

AT-MGO-QF1001 |

DN32 |

1.6 |

165 |

135 |

75 |

18 |

235 |

4-∅18 |

|

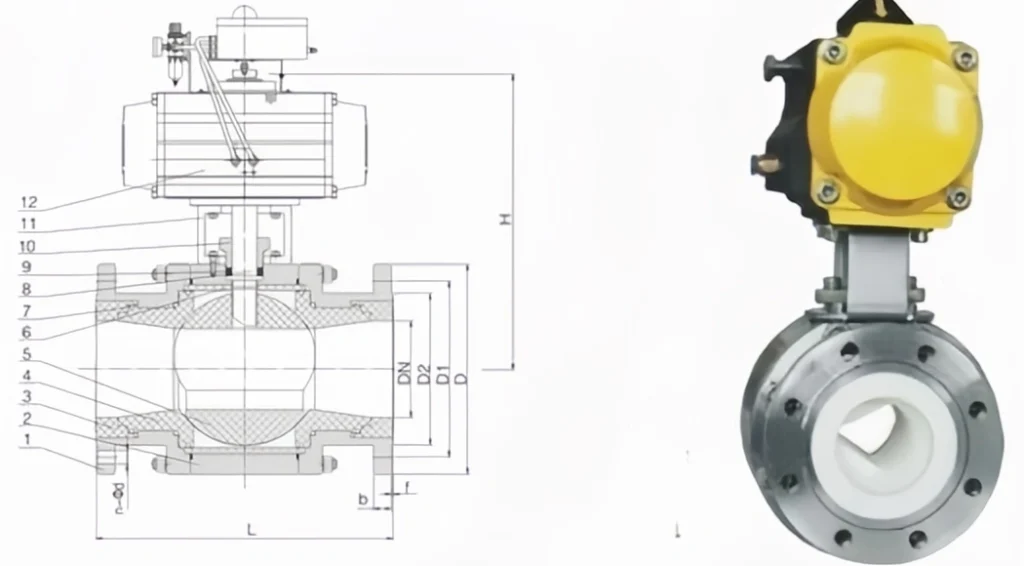

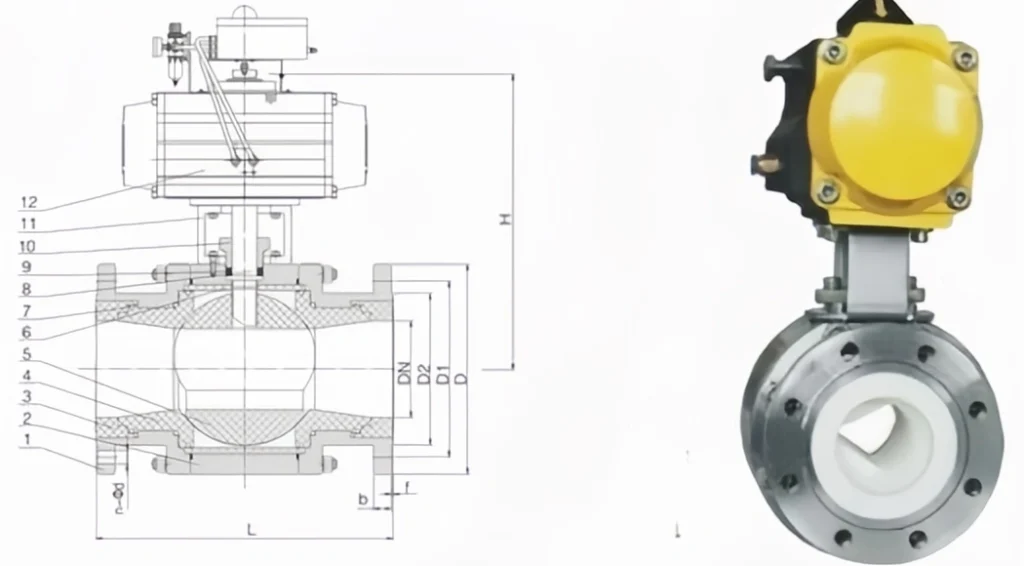

V Shaped Magnesia Stabilized Zirconia Ceramic Valve |

|

Item No. |

Nominal Diameter |

Size (NPS) |

H |

L |

D |

D1 |

D2 |

n-d |

b |

f |

|

AT-MGO-QF2001 |

DN32 |

1-1/4" |

220 |

140 |

115 |

88.9 |

63.5 |

4-M12 |

16.3 |

2 |

Packaging of MSZ Ceramic Ball Valve

Each MSZ Ceramic Ball Valve is first packed in reinforced cartons and then secured inside wooden cases for safe transit. The layered protection ensures that the units remain intact against shock, vibration, and moisture during international shipping. All crates are export-compliant, guaranteeing reliable delivery of them to global industrial customers.

Addressing Industrial Challenges with ADCERAX® MSZ Ceramic Ball Valve

The ZrO2 Piezoelectric Injector Pin addresses precise dispensing needs in advanced manufacturing sectors where adhesives, pastes, and coatings must be applied with consistent accuracy. Its engineered ceramic properties directly solve pain points in demanding application environments.

-

Petrochemical Acid Chlorination Units

✅Key Advantages

1. Halide-acid corrosion inertia — 0.1 mg/cm²/day weight loss in 60% HNO₃ @ 90 °C and 0.34 mg/cm²/day in 95% H₂SO₄ @ 95 °C indicate strong acid resistance; >10¹⁴ Ω·cm volume resistivity suppresses pitting currents in chloride-rich streams.

2. Seal integrity under load — 2,500 MPa compressive strength and 500 MPa flexural strength keep the trim stable at high differential pressures; 6–7 MPa·m½ toughness limits crack growth at seats.

3. Thermal upset tolerance — 450 ∆T °C thermal-shock capacity and 10×10⁻⁶/K CTE maintain seat alignment during hot restarts, reducing leak paths.

✅ ️Problem Solved

Alloy-lined valves in an acid chlorination loop showed pitting and leakage within weeks, forcing emergency stops. ADCERAX® MSZ Ceramic Ball Valve replaced the trim with Mg-PSZ exhibiting 2,500 MPa compressive strength and acid loss ≤0.34 mg/cm²/day in strong acids. During high-chloride batches and rapid heat-up/flush cycles, thermal shocks near commissioning transients were absorbed by the 450 ∆T °C tolerance. Leak checks remained within control-valve tightness targets (Class VI regime) across the initial inspection window, avoiding unplanned shutdown exposure.

-

Pharmaceutical CIP/SIP Systems

✅Key Advantages

1. Steam-cycle stability — 450 ∆T °C thermal-shock resistance and 10×10⁻⁶/K CTE keep sealing consistent through SIP steam at 121–134 °C; material capability to 2,100 °C provides wide safety margin.

2. Caustic/acid cleaning resistance — NaOH testing shows 0.95 mg/cm²/day weight loss at 30% @ 80 °C; acid data of 0.1 mg/cm²/day in 60% HNO₃ @ 90 °C support durability across CIP chemistries.

3. Ion-free flow path — Ceramic trim with >10¹⁴ Ω·cm resistivity and 1,100 HV hardness avoids metal ion leaching and wear debris during repeated sterilization cycles.

✅ ️Problem Solved

Stainless valves on a vial-filling line faced SIP/CIP alternation, with ion leaching concerns and rising leak rates after several cycles. ADCERAX® MSZ Ceramic Ball Valve introduced an inert Mg-PSZ ball/seat; caustic exposure tolerance (0.95 mg/cm²/day at 30% NaOH, 80 °C) and thermal-shock capacity (450 ∆T °C) matched the cleaning profile. Post-retrofit, steam-cycle transitions preserved seat contact without measurable drift, and swab tests showed no metallic contamination signals. The line maintained Class-target sealing through qualification and routine production.ctivity targets.

-

Food Processing High-Temperature Pipelines

✅Key Advantages

1. Heat-sterilization endurance — 450 ∆T °C thermal-shock rating withstands rapid hot-rinse/steam to ambient swings; 3 W/m·K thermal conductivity moderates heat flux through the trim.

2. Non-reactive contact surface — Acid loss 0.1 mg/cm²/day (60% HNO₃ @ 90 °C) and alkali loss 0.95 mg/cm²/day (30% NaOH @ 80 °C) indicate low reactivity to detergents and sanitizers.

3. Wear and fouling resistance — 1,100 HV hardness limits micro-abrasion from particulates; 6–7 MPa·m½ toughness reduces chip initiation at frequent actuations.

✅ ️Problem Solved

A hot-fill sauce line ran daily heat sterilization and acidic detergent cycles; metal valves developed scaling and sealing defects, causing batch holds. ADCERAX® MSZ Ceramic Ball Valve delivered a chemically inert trim with documented acid/alkali loss (≤0.95 mg/cm²/day) and 1,100 HV surface hardness. Repeated thermal swings were accommodated by 450 ∆T °C capability, keeping the seat interface stable. The upgrade sustained hygienic sealing across production shifts while minimizing clean-in-place downtime.

User Guide for MSZ Ceramic Ball Valve

The MSZ Ceramic Ball Valve is designed for demanding industrial environments, and its proper use ensures long service life and reliable performance. This guide provides practical advice from installation to routine checks, helping engineers and maintenance teams avoid unnecessary downtime. By following these instructions, customers can fully benefit from the unique durability and stability of the them.

-

Installation Precautions

1. Always verify fluid parameters such as temperature, pressure, and chemical composition before installation. Proper selection ensures the valve’s 500 MPa flexural strength and 2,500 MPa compressive strength are fully utilized.

2. Ensure correct flow direction alignment and use stable supports during fitting. Incorrect positioning may reduce the effectiveness of the 450 ∆T °C thermal shock resistance.

3. Prevent sudden impacts or vibration during assembly. Excessive force may compromise sealing integrity even though the valve material has 6–7 MPa·m½ fracture toughness.

-

Operational Guidance

1. Operate the valve gradually under pressure to maintain stable sealing and reduce internal stress cycles. Sudden changes can challenge the 10×10⁻⁶/K thermal expansion coefficient.

2. Regularly monitor for flow stability in corrosive or slurry environments. Consistent readings confirm the performance of its 1,100 HV hardness and anti-abrasion qualities.

3. Use suitable actuators or manual operation torque settings. Overloading may accelerate wear despite the valve’s 2,100 °C maximum service temperature capacity.

-

Maintenance and Inspection

1. Inspect sealing surfaces during scheduled shutdowns. Minimal wear rates (≤0.34 mg/cm²/day in sulfuric acid) should be confirmed under aggressive chemical service.

2. Replace gaskets or packing if any leakage is detected. Even with >10¹⁴ Ω·cm volume resistivity, sealing elements must be maintained for system safety.

3. Record service cycles and valve actuation frequency. This helps predict replacement intervals and leverage the Weibull modulus 12 M reliability data.

-

Storage and Handling

1. Store valves in a dry, vibration-free area with protective packaging to preserve factory condition. Packaging includes reinforced cartons and wooden crates for global transport.

2. Avoid contact with acidic vapors or abrasive dusts during storage. Even though corrosion resistance is strong, contamination may affect long-term performance.

3. Keep valves in upright positions on pallets or racks. This prevents stress on flanges and maintains structural integrity ensured by the 250 GPa elastic modulus.