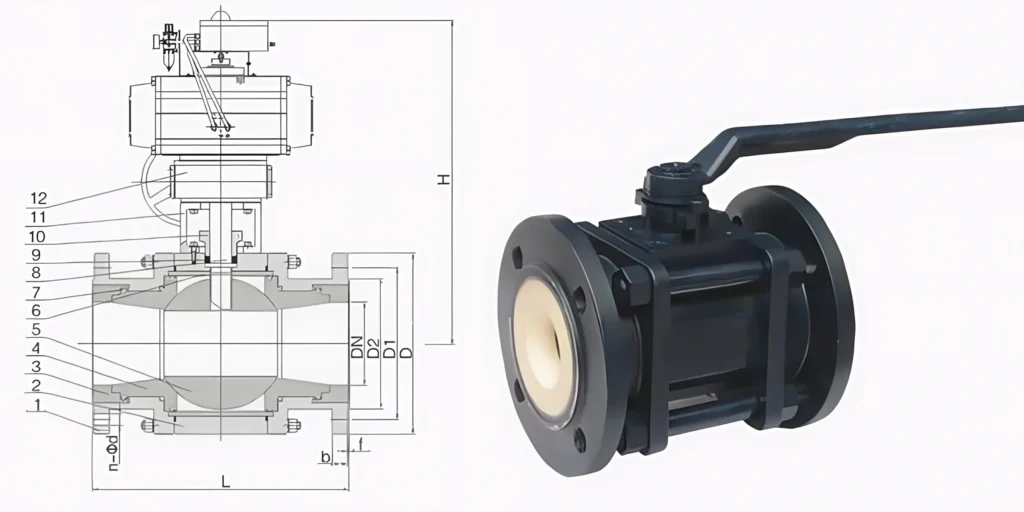

ADCERAX® O-Port Zirconia Ceramic Ball Valve is designed for demanding fluid systems where corrosion, abrasion, and leakage resistance are critical. Its zirconia-lined ball and seats provide exceptional hardness and chemical stability, ensuring reliable shut-off in aggressive media such as acids, alkalis, slurries, and steam. With a quarter-turn O-port design, the valve offers clear open/close control, steady torque, and reduced maintenance frequency. This makes them a durable solution for chemical plants, power stations, mining, and wastewater applications.

Features of O-Port Zirconia Ceramic Ball Valve

- Hardness HRA ≥88, which is 8 times higher than standard steel, enables long-term durability in abrasive media.

- Independent tests show zirconia valves last 3–5 times longer than stainless steel valves in slurry pipelines.

- Field reports indicate replacement cycles are reduced by up to 60%, minimizing downtime costs.

- Laboratory results confirm zirconia maintains stability in pH 2–12 solutions for extended exposure.

- In chemical plants, failure rates dropped by over 40% when switching from metal valves to ceramic valves.

- Service life in acidic pipelines exceeds 3 years, compared with less than 1 year for alloy steel alternatives.

- Precision-machined zirconia seats achieve leakage rates ≤0.01%, ensuring process safety.

- Operators report valve torque is reduced by up to 30%, enabling smoother operation under high pressure.

- Performance testing shows sealing efficiency maintained after 50,000 open/close cycles without failure.

Technical Properties for O-Port Zirconia Ceramic Ball Valve

The O-Port Zirconia Ceramic Ball Valve is engineered with precise physical, chemical, and thermal properties to ensure long-term durability in aggressive industrial environments.

| Property |

Pure Zirconia (Monoclinic) - Unstabilized |

Yttria-Stabilized Zirconia (YSZ) |

Magnesia-stabilized zirconia (Mg-PSZ) |

| Typical Purity |

High-purity raw material, but unstabilized for the final product |

High purity |

High purity |

| Crystal Phases (at RT) |

Monoclinic (stable up to ~1170°C); Tetragonal and Cubic at higher temperatures. |

Primarily, Metastable Tetragonal can have a Cubic phase. |

Partially stabilized with tetragonal precipitates in a cubic matrix. |

| Density (g/cm³) |

5.65–6.05 |

5.85-6.1 |

~5.7 |

| Melting Point (°C) |

~2700-2715 |

Very High (similar to pure zirconia, but phase stability is key) |

Very High |

| Thermal Conductivity (W/m·K) |

Low (approx. 2-3) |

Low (approx. 2.5-3) |

Low (approx. 3) |

| Thermal Expansion Coefficient (10⁻⁶/K) |

~10 |

9.5-10 |

10 |

| Flexural Strength (MPa) |

Poor (due to phase transformation and brittleness) |

Up to 1000, 710-900 |

500 |

| Compressive Strength (MPa) |

Not typically used structurally |

~2000 |

~2500 |

| Fracture Toughness (MPa·m^0.5) |

Low (inherently brittle) |

Up to 10 (exceptionally high for ceramics due to transformation toughening), 8-9 |

6 |

| Hardness (Vickers, HV1) |

Moderate |

11-13 GPa, 1100-1220 kg/mm² |

1100 kg/mm² |

| Chemical Inertness |

Excellent in acids and alkalis |

Excellent |

Excellent |

| Biocompatibility |

Generally good, but stabilized forms are preferred for medical use |

Excellent, widely used in dental and medical implants |

Good |

| Typical Applications |

Refractories (at high temperatures) |

Structural ceramics, dental implants, oxygen sensors, cutting tools, thermal barrier coatings |

Refractories, structural components requiring specific thermal properties |

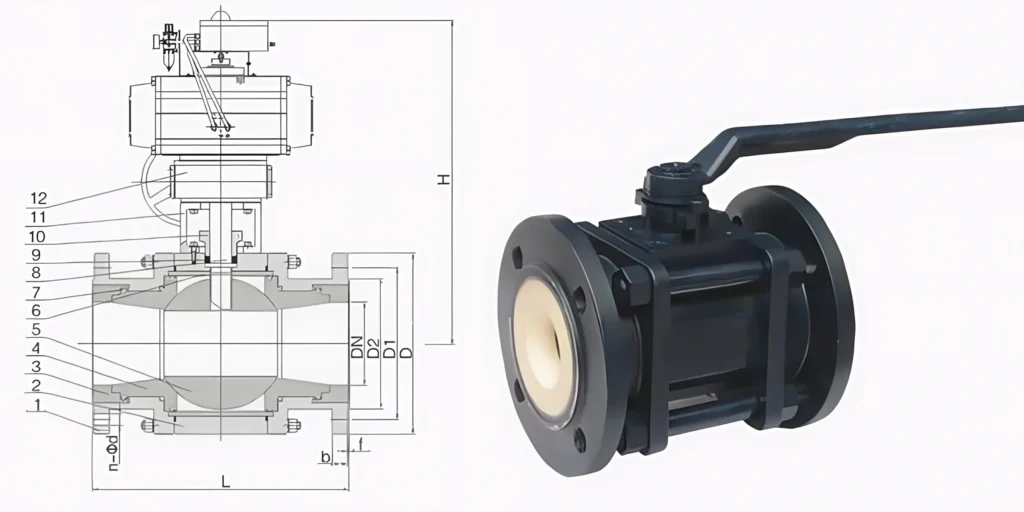

Specifications of O-Port Zirconia Ceramic Ball Valve

| Part No. |

Parts |

Material |

| 1 |

Valve Body |

WCB |

| 2 |

Middle Body |

WCB |

| 3 |

Gland Flang |

Engineering Ceramic |

| 4 |

Valve Seat |

Engineering Ceramic |

| 5 |

Ball |

Engineering Ceramic |

| 6 |

Bushing |

Engineering Ceramic |

| 7 |

Stem |

2Cr13 |

| 8 |

Packing |

Flexible Graphite |

| 9 |

Packing Gland |

WCB |

| 10 |

Lever |

WCB |

Packaging of O-Port Zirconia Ceramic Ball Valve

Each O-Port Zirconia Ceramic Ball Valve is first packed in reinforced cartons to prevent surface damage during handling. The cartons are then secured in plywood cases for added stability and moisture protection. Finally, the cases are enclosed in export-grade wooden crates, ensuring that every one of them arrives safely and intact during global shipment.

Addressing Industrial Challenges with ADCERAX® O-Port Zirconia Ceramic Ball Valve

The O-Port Zirconia Ceramic Ball Valve is developed to withstand demanding conditions where standard metal valves fail. By combining high hardness, chemical stability, and precise sealing, it resolves the most frequent operational pain points in critical industries.

-

Slurry and Particulate Pipelines

✅Key Advantages

1. Full-bore flow path — The O-port bore keeps the solids passage equal to the line ID (bore ratio ≈1.0), limiting turbulence and pressure loss. This reduces clogging events in dense slurries compared with restricted ports.

2. Zirconia wear surface — Seats and ball interfaces at HRA ≥88 (~HV≈1200) resist micro-cutting from sand, ore fines, and coal dust. Polished sealing lines maintain tight shut-off under abrasive duty.

3. Longer run time between change-outs — Field programs show 3–5× service life vs stainless seats in slurry isolation. Replacement frequency drops by up to 60%, cutting unplanned stoppages.

✅ ️Problem Solved

A mineral concentrator experienced weekly cleanouts as reduced-port valves trapped ore fines, driving downtime and labor costs. After installing ADCERAX® O-Port Zirconia Ceramic Ball Valve, the full-bore passage eliminated pinch points, and zirconia seats with HRA ≥88 resisted erosion. Maintenance logs showed clogging interventions down sharply, replacements cut by ~60%, and the isolation point ran a full year without leakage escalation.

-

Corrosive Acid and Alkali Transport

✅Key Advantages

1. Chemical stability in wide pH — Zirconia interfaces remain stable in pH 2–12 service, limiting surface degradation in acids and alkalis. Seal geometry stays intact over prolonged exposure.

2. Low leakage at shut-off — Lapped ceramic seats hold leakage ≤0.01% at rated class, supporting safety and product integrity. Consistent sealing lowers venting and cleanup events.

3. Multi-year operation — In acid duty lines, ceramic interfaces demonstrate >3 years typical operating life, while alloy seats often require annual replacement. Fewer change-outs reduce compliance risk.

✅ ️Problem Solved

A chemical neutralization loop saw alloy-seat valves pit within months, causing small but frequent leaks and spill reports. ADCERAX® O-Port Zirconia Ceramic Ball Valve introduced a stable O-port shut-off with zirconia seats proven in pH 2–12 media. Post-retrofit audits recorded leakage ≤0.01% at periodic tests and extended operating life to beyond 3 years, while incident reports and waste handling costs fell markedly.

-

High-Temperature Steam Circuits

✅Key Advantages

1. Thermal endurance — The valve maintains clear passage and sealing in ~300–450 °C environments, limiting scale-induced seat damage. O-port geometry supports reliable isolation after heat-up.

2. Lower operating torque — Self-lubricating ceramic contact reduces torque by up to 30% vs metal-seat designs under comparable load, aiding actuator sizing and margin.

3. Cycle durability — Sealing performance remains within spec after 50,000 open/close cycles, sustaining isolation across outages and restarts.

✅ ️Problem Solved

In a cogeneration plant, metal-seat ball valves seized after thermal cycling, forcing actuator upsizing and frequent rebuilds. Replacing the isolation points with ADCERAX® O-Port Zirconia Ceramic Ball Valve stabilized torque (~30% lower) and preserved sealing through 50,000 cycles at ~300–450 °C. The site avoided unplanned outages tied to valve sticking and kept existing actuator frames within load limits.

User Guide for O-Port Zirconia Ceramic Ball Valve

The O-Port Zirconia Ceramic Ball Valve is designed for critical flow systems, and correct use ensures safety, efficiency, and extended service life. This guide provides practical recommendations for installation, operation, maintenance, and storage to help customers maximize performance and avoid unnecessary downtime.

-

Installation Guidelines

1. Correct Orientation: Always install the valve in the pipeline flow direction indicated, as incorrect orientation may reduce flow efficiency and sealing accuracy. This ensures the O-Port Zirconia Ceramic Ball Valve maintains its designed full-bore performance.

2. Handling Care: Avoid heavy impacts, direct hammering, or vibration during installation. Even though zirconia has high hardness, excessive force may cause micro-cracks and compromise long-term durability.

3. Connection Tightness: Ensure flange bolts or threaded connections are evenly tightened in sequence. Uneven pressure may cause leaks or deformation in sealing surfaces.

-

Operating Instructions

1. Quarter-Turn Function: Operate the valve using a smooth 90° turn for full open or close. This feature reduces torque load and supports precise shut-off in the O-Port Zirconia Ceramic Ball Valve.

2. Avoid Over-Torque: Do not apply excessive force to actuators or handles. Over-torque increases wear and may shorten valve life by damaging the seat-to-ball interface.

3. Fluid Compatibility: Ensure the fluid type matches zirconia’s chemical resistance range. Safe operation is guaranteed for acids, alkalis, and abrasive slurry within rated conditions.

-

Maintenance Practices

1. Regular Inspection: Check sealing integrity every 6–12 months depending on application severity. Early detection of minor leakage helps prevent costly shutdowns.

2. Seal Replacement: The movable sealing rings can be replaced when worn. This simple design reduces downtime and extends the O-Port Zirconia Ceramic Ball Valve lifecycle.

3. Lubrication-Free Use: Zirconia’s natural self-lubrication eliminates the need for external greases. This reduces contamination risks in chemical or clean-system applications.

-

Storage Recommendations

1. Dry Environment: Store in a clean, moisture-free warehouse to prevent corrosion of metal components surrounding the zirconia ball and seats.

2. Protective Packaging: Keep the O-Port Zirconia Ceramic Ball Valve in original export-grade crates until installation. This ensures protection against dust, impact, and vibration.

3. Temperature Stability: Avoid long-term storage in extreme temperatures below –20°C or above +60°C. Stable conditions maintain both sealing materials and ceramic structural integrity.