Silicon Nitride Cutting Tools are machining tools whose working edges are made from sintered silicon nitride (Si₃N₄) ceramics. They are engineered for high-speed, dry or MQL cutting where hot hardness, thermal‐shock resistance, and chemical stability are critical.

Silicon Nitride Cutting Tools Benefits

-

High surface-speed capability: Stable performance in cast iron cutting between 600–1200 m/min, even under dry machining conditions. The material’s inherent hot hardness and thermal stability enable consistent surface finish and extended tool life in high-speed continuous or interrupted operations.

-

Low adhesion to iron phases: The chemical inertness of Si₃N₄ minimizes diffusion and adhesion to ferrous alloys, effectively reducing built-up edge and crater wear. This ensures smoother chip evacuation, lower friction, and stable cutting forces during prolonged roughing cycles.

-

Tunable edge preparation: Customizable T-land, honed, or micro-chamfered edges allow precise control over thermal shock and notch wear behavior. Edge prep optimization enhances performance in both heavy interrupted cutting and fine finishing operations.

-

Thickness and flatness control: Manufactured with tight dimensional tolerances of ±0.025–0.05 mm, ensuring balanced tool geometry and minimal runout. This precision maintains consistent engagement with the workpiece, improving cutting stability and repeatability in automated systems.

-

SiAlON option for HRSA machining: The SiAlON composite grade (Si₃N₄–Al₂O₃ solid solution) provides improved resistance to thermal shock and oxidation compared with standard silicon nitride. It is particularly effective for roughing nickel-based superalloys and Inconel under dry or semi-dry conditions.

Silicon Nitride Cutting Tools Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

| Tolerance: |

| 1. Diameter Tolerance: ±0.003mm |

| 2. Hole Depth: ±0.005mm |

| 3. Surfance Roughness:Ra0.02 |

| 4. Cylindricity:±0.003mm |

| 5. Concentricity:±0.002mm |

| 6. Parallelism: ±0.002mm |

Si3N4 Cutting Tools Specifications

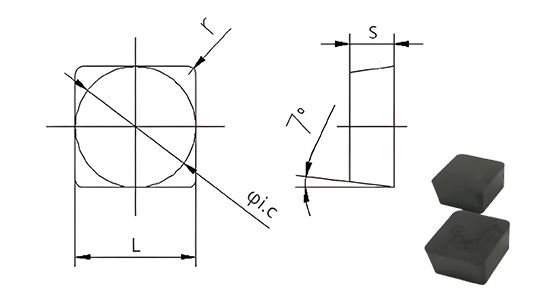

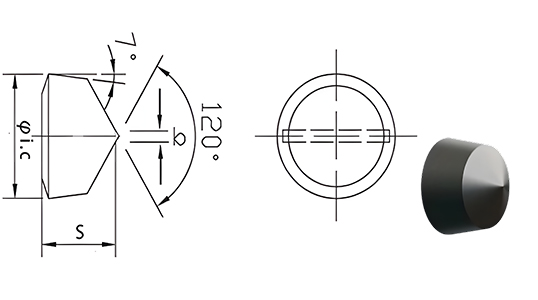

Type 1: Silicon Nitride 7° Square Blade with Relief Angle

| Type 1: Silicon Nitride 7° Square Blade with Relief Angle | |||

| Item NO. | L - Cutting Edge Length(mm) | i.c. - Inscribed Circle Diameter(mm) | S - Thickness(mm) |

| AT-SIN-SCGN0903 | 9.525 | 9.525 | 3.18 |

| AT-SIN-SCGN0904 | 9.525 | 9.525 | 4.76 |

| AT-SIN-SCGN1204 | 12.7 | 12.7 | 4.76 |

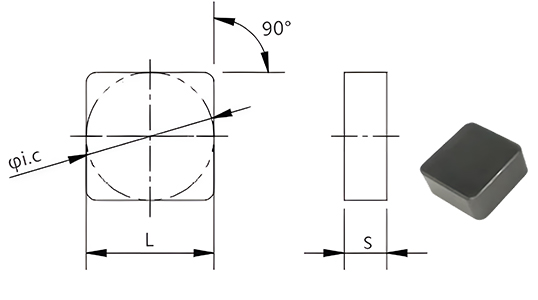

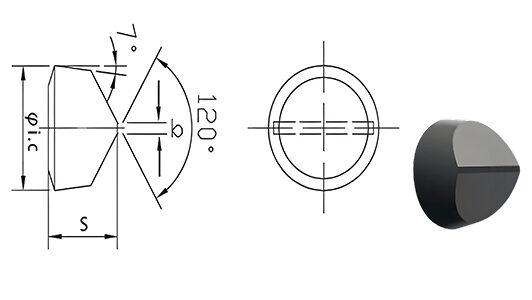

Type 2: Silicon Nitride Square CNC Cylindrical Turning Blade

| Type 2: Silicon Nitride Square CNC Cylindrical Turning Blade | |||

| Item NO. | L - Cutting Edge Length(mm) | i.c. - Inscribed Circle Diameter(mm) | S - Thickness(mm) |

| AT-SIN-SCGN0904 | 9.525 | 9.525 | 4.76 |

| AT-SIN-SCGN1204 | 12.7 | 12.7 | 4.76 |

| AT-SIN-SCGN1207 | 12.7 | 12.7 | 7.94 |

| AT-SIN-SCGN1608 | 16.0 | 16.0 | 8.0 |

| AT-SIN-SCGN2010 | 20.0 | 20.0 | 10.0 |

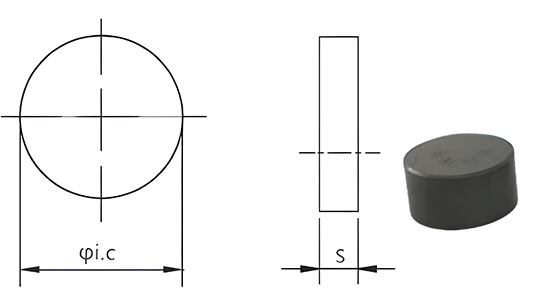

Type 3: Silicon Nitride Round Blade

| Type 3: Silicon Nitride Round Blade | ||

| Item NO. | i.c. - Inscribed Circle Diameter(mm) | S - Thickness(mm) |

| AT-SIN-RNGN0604 | 6.35 | 4.76 |

| AT-SIN-RNGN0904 | 9.525 | 4.76 |

| AT-SIN-RNGN1204 | 12.7 | 4.76 |

| AT-SIN-RNGN1207 | 12.7 | 7.94 |

| AT-SIN-RNGN1608 | 16.0 | 8.0 |

| AT-SIN-RNGN2008 | 20 | 8 |

| AT-SIN-RNGN2010 | 20.0 | 10.0 |

Type 4: Silicon Nitride Conical Hole Cutter Blade

| Type 4: Silicon Nitride Conical Hole Cutter Blade | ||

| Item NO. | i.c. - Inscribed Circle Diameter(mm) | S - Thickness(mm) |

| AT-SIN-RCGX0605 | 6.35 | 5.0 |

| AT-SIN-RCGX0907 | 9.525 | 7.94 |

| AT-SIN-RCGX1207 | 12.7 | 7.94 |

| AT-SIN-RCGX1510 | 15.875 | 10.0 |

| AT-SIN-RCGX1910 | 19.05 | 10.0 |

| AT-SIN-RCGX2010 | 20 | 10.0 |

Type 5: Silicon Nitride V-shaped Hole Cutter Blade

| Type 5: Silicon Nitride V-shaped Hole Cutter Blade | ||

| Item NO. | i.c. - Inscribed Circle Diameter(mm) | S - Thickness(mm) |

| AT-SIN-RCGV0604 | 6.35 | 4.76 |

| AT-SIN-RCGV0907 | 9.525 | 7.94 |

| AT-SIN-RCGV1207 | 12.7 | 7.94 |

| AT-SIN-RCGV1510 | 15.875 | 10.0 |

| AT-SIN-RCGV1910 | 19.05 | 10.0 |

| AT-SIN-RCGV2012 | 20.0 | 12.0 |

| AT-SIN-RCGV2512 | 25.0 | 12.0 |

Type 6: Silicon Nitride Triangle Blade

| Type 6: Silicon Nitride Triangle Blade | |||

| Item NO. | L - Cutting Edge Length(mm) | i.c. - Inscribed Circle Diameter(mm) | S - Thickness(mm) |

| AT-SIN-TNGN1103 | 11.0 | 6.35 | 3.18 |

| AT-SIN-TNGN1604 | 16.5 | 9.525 | 4.76 |

| AT-SIN-TNGN1603 | 16.5 | 9.525 | 3.18 |

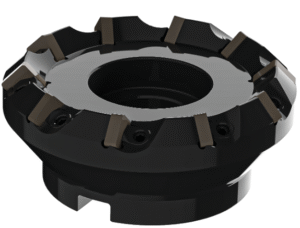

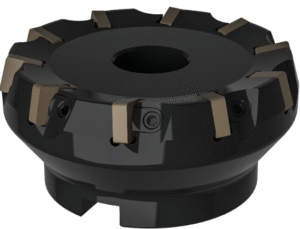

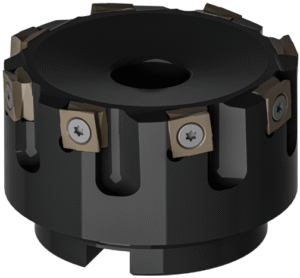

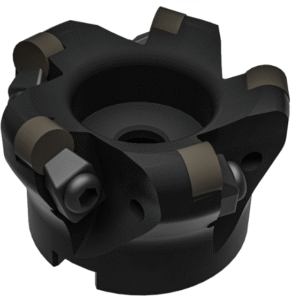

Type 7: Custom Silicon Surface Nitride Milling Cutter

| Silicon Nitride Surface Milling Cutter 43° | |||

| Item No. | Diameter (mm) | Thickness (mm) | Picture |

| AT-SIN-SK0043 | Customize |

|

|

| Silicon Nitride Surface Milling Cutter 45° | |||

| Item No. | Diameter (mm) | Thickness (mm) | Picture |

| AT-SIN-SK0045 | Customize |

|

|

| Silicon Nitride Surface Milling Cutter 75° | |||

| Item No. | Diameter (mm) | Thickness (mm) | Picture |

| AT-SIN-SK0075 | Customize |

|

|

| Silicon Nitride Surface Milling Cutter 88° | |||

| Item No. | Diameter (mm) | Thickness (mm) | Picture |

| AT-SIN-SK0088 | Customize |

|

|

| Silicon Nitride Milling Cutter 90° | |||

| AT-SIN-SK0090 | Customize |

|

|

| Silicon Nitride Square Milling Cutter | |||

| AT-SIN-SK0001 | Customize |

|

|

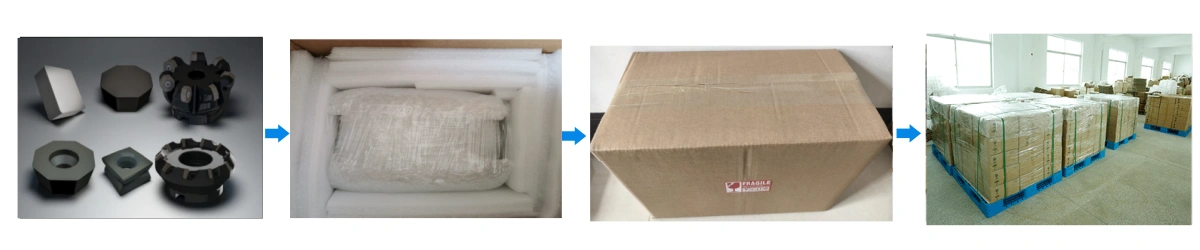

Si₃N₄ Ceramic Inserts Packaging

- Each tool is individually packed in anti-static, shock-absorbing foam boxes.