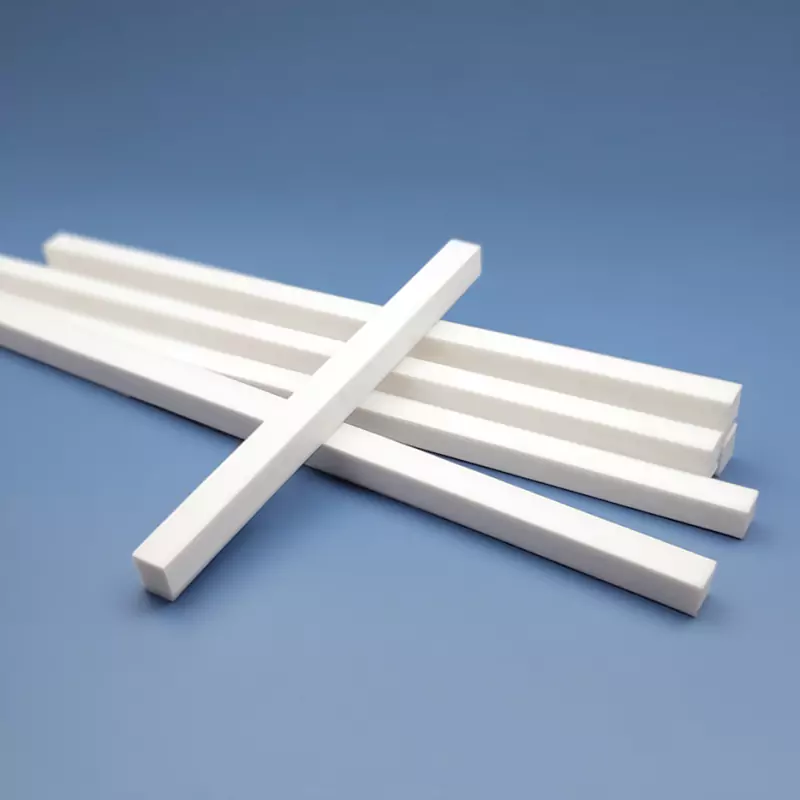

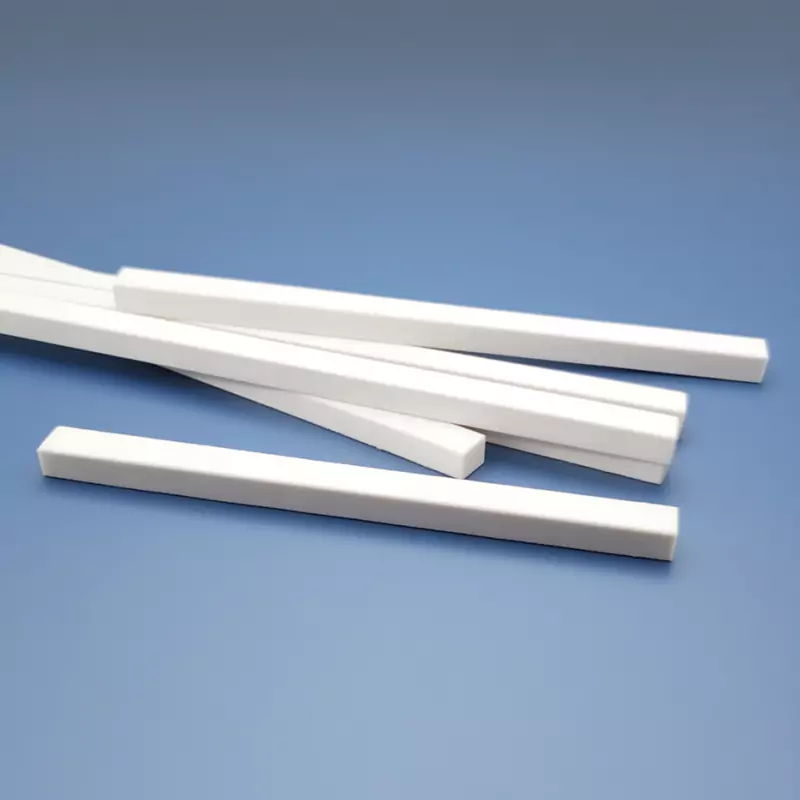

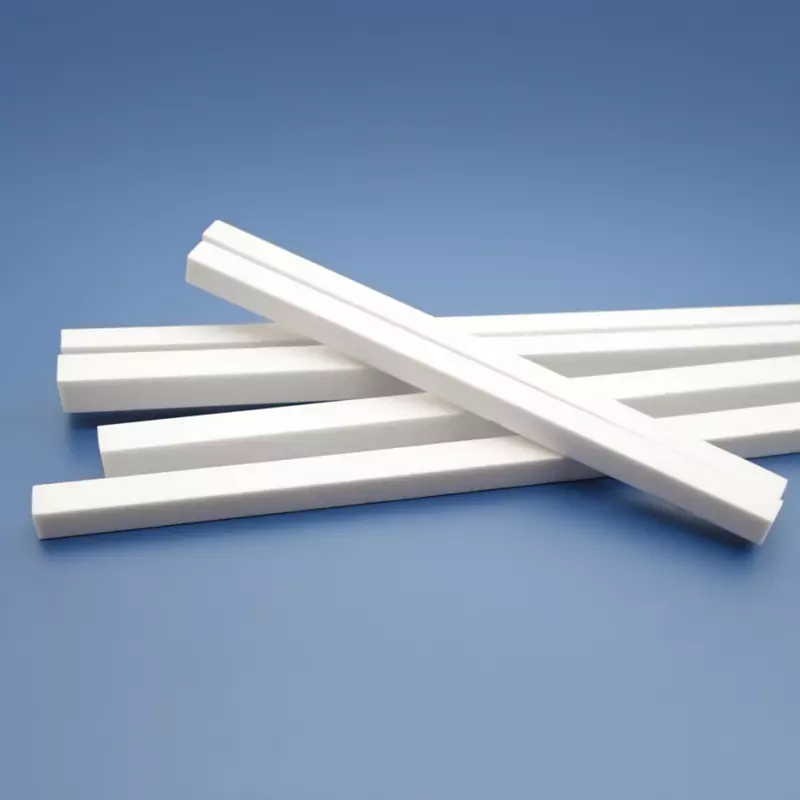

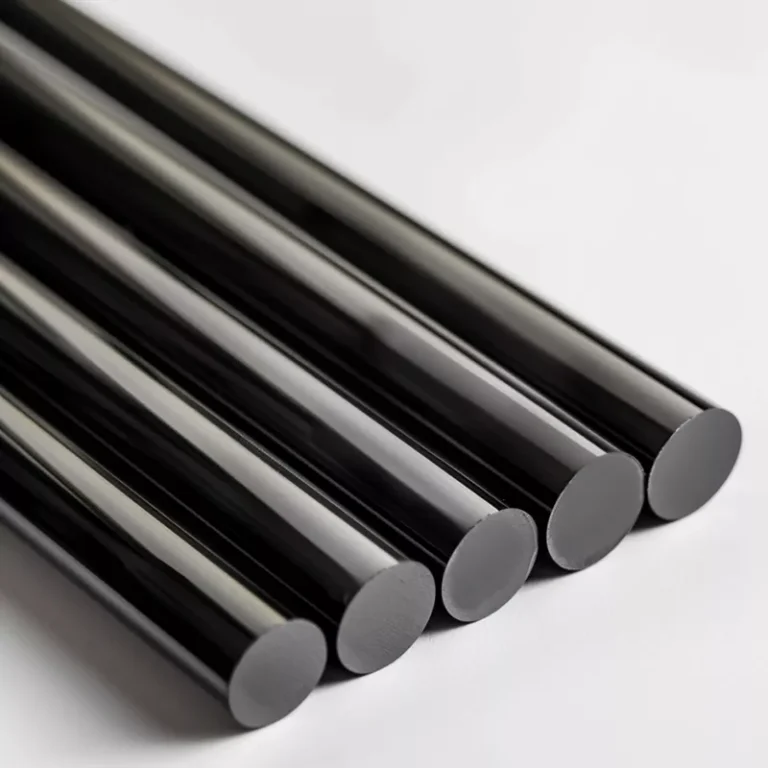

ADCERAX® Yttria Stabilized Zirconia Ceramic Square Rod is engineered for demanding industrial environments where wear resistance and toughness are critical. Produced through isostatic pressing and high-temperature sintering, it delivers a dense and uniform microstructure with excellent chemical stability. The material withstands high thermal stress, aggressive media, and extended mechanical loads without degradation. Industries such as mechanical engineering, chemical processing, and metallurgy rely on Yttria Stabilized Zirconia Ceramic Bar Square Rod to ensure consistent performance and long service life.

Features of Yttria Stabilized Zirconia Ceramic Square Rod

- Independent testing shows hardness above 1200 HV, ensuring components maintain shape even under continuous abrasion. This makes Yttria Stabilized Zirconia Ceramic Bar Square Rod suitable for heavy-duty mechanical parts.

- With a flexural strength exceeding 900 MPa, it resists bending and cracking during repeated industrial use. This level of strength directly improves uptime in high-load systems.

- Wear loss is less than 0.01 g per 1000 cycles in comparative sliding tests, demonstrating its ability to outperform alumina-based alternatives. This ensures longer service intervals for critical machinery.

- The material remains structurally stable up to 1000 °C, supporting high-temperature applications. This allows Yttria Stabilized Zirconia Ceramic Bar Square Rod to function reliably in furnaces and metallurgical systems.

- Thermal expansion is approximately 10.5 × 10⁻⁶/K, reducing stress and failure risk under fluctuating heat. This property makes it compatible with thermal cycling processes.

- Proven thermal shock resistance withstands rapid heating up to 200 °C/min without visible cracking. This durability is critical for equipment exposed to sudden temperature changes.

Properties for Yttria Stabilized Zirconia Ceramic Bar Square Rod

The Yttria Stabilized Zirconia Ceramic Square Rod is defined by strict performance metrics that support industrial applications requiring durability, stability, and long service life. This section provides a summary of its key technical parameters and links directly to the detailed property table and dimension catalog for precise engineering evaluation.

| Property |

Specification |

| Density |

6.0 g/cm³ |

| Thermal expansion |

10.5 × 10⁻⁶/K |

| Thermal conductivity |

2.5 W/m·K |

| Fracture toughness |

8–10 MPa·m¹ᐟ² |

| Compressive strength |

> 2000 MPa |

| Elastic modulus |

200 GPa |

| Stable in saline spray |

>500h |

| Thermal shock resistance |

200 °C/min |

| Max service temperature |

~1000 °C |

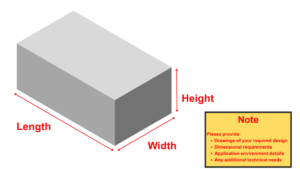

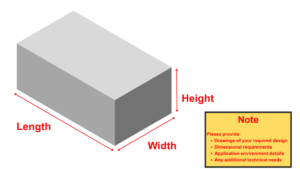

Dimension for Yttria Stabilized Zirconia Ceramic Bar

Packaging of Yttria Stabilized Zirconia Ceramic Square Rod

Each Yttria Stabilized Zirconia Ceramic Square Rod is individually protected with foam-lined wrapping to prevent edge damage during transit. Products are packed in reinforced export cartons with moisture-proof sealing. This ensures the Yttria Stabilized Zirconia Ceramic Bar arrives in perfect condition for immediate industrial use.

Addressing Industry Challenges with ADCERAX® Yttria Stabilized Zirconia Ceramic Square Rod

The Yttria Stabilized Zirconia Ceramic Bar addresses critical pain points in industries where conventional materials fail under wear, corrosion, or extreme thermal stress. By combining toughness, chemical inertness, and high-temperature stability, it provides durable solutions that extend equipment life and reduce downtime.

-

High-Temperature Furnace Fixtures and Support Spacers

✅Key Advantages

1. Thermal-shock endurance (200 °C/min) — Y-TZP resists rapid heat ramps without micro-cracking. This keeps spacer geometry stable through repeated cycles.

2. Creep resistance at 900–1000 °C — Compressive strength > 2000 MPa limits hot deformation under fixture loads. Flat faces preserve stack alignment over long runs.

3. Clean, inert contact surfaces — Ra ≤ 0.2 µm and chemical inertness minimize sample contamination. Oxidation and scale transfer are negligible versus metallic jigs.

✅ ️Problem Solved

A heat-treat line replaced alloy spacers with ADCERAX® Yttria Stabilized Zirconia Square Rod. Over 600 thermal cycles at 900–980 °C, spacer flatness drift stayed <0.05 mm, and fixture realignments dropped >40%. Scrap linked to surface contamination fell 28% versus oxidizing steel jigs. Unplanned downtime attributable to spacer failures was reduced from 9.5 h/month to 3.8 h/month.

-

Linear Guide Wear Blocks and Anti-Rotation Keys

✅Key Advantages

1. Edge retention under abrasion — Hardness > 1200 HV maintains sharp, square edges for positive stop and anti-roll. Dimensional change at edges stays minimal over high-cycle motion.

2. High load, low drift — Flexural strength > 900 MPa and modulus ~ 200 GPa support precise, repeatable guidance. Blocks resist notch propagation in reciprocating duty.

3. Chemically robust in shop environments — > 95% resistance to common acids/alkalis protects guides from coolant and cleaning chemicals. Surfaces remain smooth for predictable sliding.

✅ ️Problem Solved

On a precision assembly cell, steel guide keys wore and rounded, causing 0.12 mm positional drift every 2–3 weeks. After switching to ADCERAX® Yttria Stabilized Zirconia Ceramic Square Rod keys, edge radius growth after 1.2 million strokes was <0.03 mm and alignment stayed within ±0.02 mm. Changeover frequency dropped from weekly touch-ups to a quarterly inspection, cutting maintenance labor ~55%.

-

Corrosive Media Jigs and Scraper Bars

✅Key Advantages

1. Corrosion resistance with data — Weight loss <0.1% after 72 h in 10% H₂SO₄ at 80 °C; > 95% alkali resistance. Bars maintain mass and integrity in aggressive baths.

2. Effective scraping geometry — Square edges deliver consistent shear and wipe action. Edge integrity persists thanks to high hardness and dense microstructure.

3. Stable in harsh atmospheres — No pitting after >500 h salt-spray exposure; surfaces remain smooth. Cleaning is faster and residue buildup is reduced.

✅ ️Problem Solved

A PCB cleaning line suffered frequent steel scraper corrosion and residue carry-over, forcing bi-weekly replacements. With ADCERAX® Yttria Stabilized Zirconia Square Rod scrapers, mass loss in acid stages was <0.05%/month and visual edge wear after 8 weeks was negligible. Bath contamination events dropped 35%, and scraper changeouts moved to a 10–12 week cadence.

User Guide for Yttria Stabilized Zirconia Ceramic Square Rod

The Yttria Stabilized Zirconia Square Rod requires proper handling, storage, and operational practices to maximize service life and maintain consistent performance. This guide provides clear recommendations from multiple perspectives, ensuring customers understand how to apply, maintain, and protect the product in real-world industrial conditions.

-

Handling Guidelines

1. Always handle the bars with clean gloves to avoid surface contamination. Accumulated dust, oils, or residues may affect performance in chemical or furnace applications.

2. Avoid dropping or knocking the square rods against hard surfaces. Although strong in service, sharp edges are sensitive to impact and may chip under careless handling.

3. Use padded trays or non-metallic supports when moving rods between workstations. This practice minimizes accidental edge damage and keeps the surfaces smooth.

-

Storage Conditions

1. Store the bars in dry, temperature-stable environments free from corrosive vapors. Prolonged exposure to moisture and salts can cause surface discoloration or micro-defects.

2. Place rods horizontally on cushioned shelves or racks with non-reactive linings. Stacking without separators can create uneven stress and lead to corner damage.

3. Clearly label storage areas with part codes and usage notes. Proper inventory control helps ensure the correct material grade is selected for each application.

-

Operational Recommendations

1. Introduce rods gradually to high-temperature environments to reduce thermal stress. Controlled heating and cooling cycles extend service life under thermal cycling.

2. Avoid using rods beyond the recommended service temperature of ~1000 °C. Exceeding this range increases the risk of structural fatigue and cracking.

3. Ensure even load distribution across flat surfaces when used as spacers or supports. Unequal loading can create localized stress points that shorten product lifespan.

-

Maintenance and Inspection

1. Inspect rods regularly for surface chipping, cracks, or discoloration. Early detection of wear prevents unexpected failures in critical operations.

2. Clean rods with neutral solutions or mild detergents rather than harsh chemicals. This protects the zirconia structure and keeps surfaces consistent for repeated use.

3. Document inspection and replacement cycles based on operating conditions. Tracking performance helps customers predict service intervals and reduce downtime.