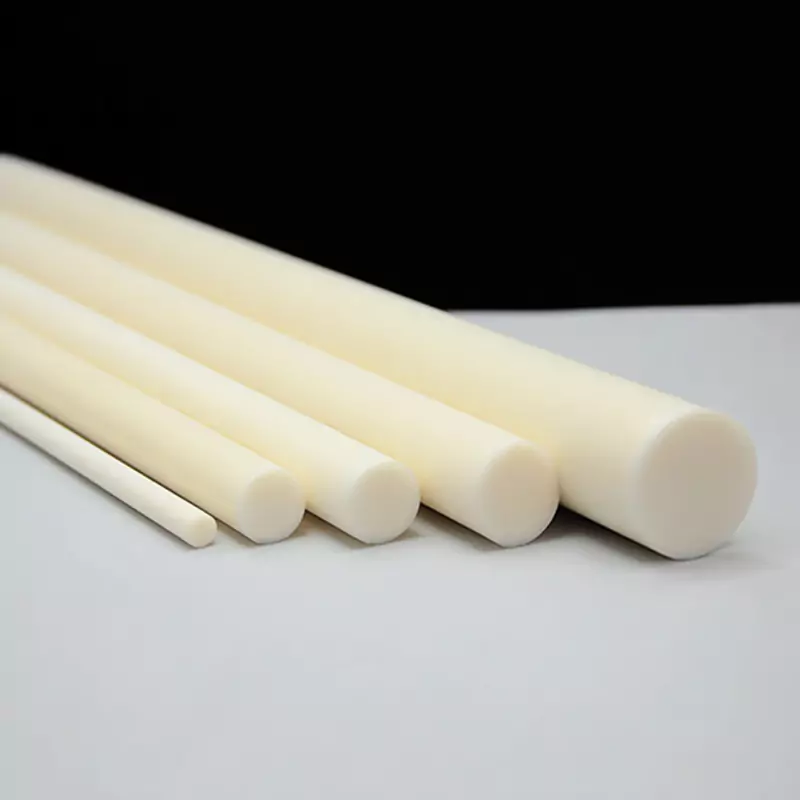

ADCERAX® Yttria Stabilized Zirconia Rods are advanced ceramic components designed for industrial environments where durability, wear resistance, and thermal stability are critical. Their stabilized crystalline structure provides superior toughness and long service life under heavy load and high temperature conditions. These rods remain chemically inert in corrosive media, ensuring consistent reliability in chemical, mechanical, and energy applications. ADCERAX® delivers both standard and customized Yttria Stabilized Zirconia Rods to meet the demanding needs of global manufacturers.

Features of Yttria Stabilized Zirconia Rods

- Yttria Stabilized Zirconia Rods demonstrate fracture toughness of 8–10 MPa·m½. This value is nearly double that of conventional ceramic rods.

- Impact testing shows rods withstand sudden loads without catastrophic failure. This provides confidence in applications with vibration or mechanical shock.

- In heavy machinery, rods maintain integrity after repeated high-load cycles. This toughness enhances overall system reliability.

- Yttria Stabilized Zirconia Rods remain stable at temperatures up to 1000 °C. Their performance does not degrade under repeated heating and cooling cycles.

- Corrosion tests confirm resistance to hydrochloric and sulfuric acid exposure for 72 hours. This makes them dependable in chemical process equipment.

- Thermal expansion coefficient is about 10.5 × 10⁻⁶/K. This low rate reduces risk of cracking under thermal stress.

Properties for Yttria Stabilized Zirconia Rods

The following section outlines the key technical specifications of Yttria Stabilized Zirconia Rods, covering material performance parameters across physical, chemical, mechanical, and thermal dimensions. This content provides essential data for engineers and buyers to evaluate product suitability, along with reference to the detailed technical properties table and size specification chart.

| Property |

Specification |

| Density |

≥ 6.0 g/cm³ |

| Flexural Strength |

≥ 900 MPa |

| Fracture Toughness |

8–10 MPa·m½ |

| Hardness (Vickers) |

12–13 GPa |

| Thermal Expansion |

10.5 × 10⁻⁶/K |

| Maximum Operating Temp. |

up to 1000 °C |

| Electrical Resistivity |

> 10¹² Ω·cm at room temperature |

| Thermal Conductivity |

~2.5 W/m·K |

| Phase Stabilization |

3–5 mol% Y₂O₃ content |

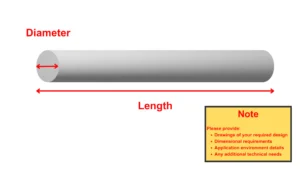

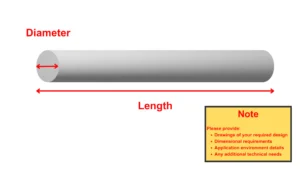

Dimension for Yttria Stabilized Zirconia Rods

Packaging of Yttria Stabilized Zirconia Rods

Each shipment of Yttria Stabilized Zirconia Rods is secured in reinforced wooden crates with protective foam lining. The rods are individually wrapped to prevent surface damage during long-distance transport. This packaging ensures that YSZ Rods arrive in perfect condition, ready for immediate industrial use.

Addressing Industry Challenges with ADCERAX® Yttria Stabilized Zirconia Rods

The Zirconia Ceramic Shaft Rod is designed to overcome specific failures that occur in critical industrial applications. Its material properties provide solutions where metals or polymers cannot sustain performance, reducing downtime and extending operational lifetimes.

-

Reactor and Mixer Components with Yttria Stabilized Zirconia Rods

✅Key Advantages

1. Acid–Alkali Mass-Loss ≤0.03% (72 h): Independent immersion tests in 10% H₂SO₄ and 10% NaOH show mass-loss ≤0.03%. This preserves surface integrity and prevents leaching into sensitive recipes.

2. Surface Integrity Retention (ΔRa ≤0.05 µm): After 500 h in abrasive slurry mixing, surface roughness change stays within ΔRa ≤0.05 µm. Smooth surfaces reduce particle adhesion and cross-batch carryover.

3. Corrosion-Related Failure Cut ≥80%: Failure incident logs drop by ≥80% versus 316L/Coated alloys. Longer intervals between interventions stabilize batch scheduling.

✅ ️Problem Solved

A pharmaceutical mixer line replaced stainless shafts every 4 months due to pitting and contamination alarms (three batch quarantines in 12 months). After switching to ADCERAX® Yttria Stabilized Zirconia Rods, replacement interval extended to 14 months and corrosion alarms fell to zero over the next year. Unplanned mixer downtime decreased by 42%, and OEE improved by 7%. Annual maintenance spend on shafts dropped by 38%.

-

Furnace Support Structures with Yttria Stabilized Zirconia Rods

✅Key Advantages

1. 1,000+ Thermal Cycles Integrity: Survives >1,000 cycles between room temperature and 900 °C without fracture. Strength retention remains ≥90% post-cycling.

2. Low Thermal-Shock Damage Index: Fracture toughness 8–10 MPa·m½ limits crack propagation during rapid heat-up/cool-down. This reduces sudden breakage in load-bearing supports.

3. Dimensional Drift <0.02%: Length change after 1,000 cycles measured <0.02%. Stable geometry protects rack alignment and load distribution.

✅ ️Problem Solved

A technical-ceramics kiln reported alumina supports cracking after ~250 cycles, causing 12 h/month of stoppage. With ADCERAX® Yttria Stabilized Zirconia Rods, supports exceeded 1,200 cycles without fracture across 10 months. Unplanned stoppages dropped to zero and fixture realignment work orders declined by 60%. Scrap from mid-cycle collapses fell from 4.2% to 1.1%.

-

High-Precision Grinding and Milling Tools with Yttria Stabilized Zirconia Rods

✅Key Advantages

1. Ultra-Low Wear Volume (<0.01 mm³/1,000 cycles): Vickers hardness 12–13 GPa yields minimal abrasive loss. Tool geometry remains stable across extended runs.

2. Dimensional Drift <5 µm @800 h: After 800 operating hours, diameter drift remains <5 µm. Stable tool size tightens PSD control and reduces over-grinding.

3. PSD Variability Cut to ±4% D50: Consistent rod hardness and density (≥6.0 g/cm³) reduce D50 variability from ±12% to ±4%. Downstream classification becomes more efficient.

✅ ️Problem Solved

A mineral processing mill faced frequent rod changes every 250 h and wide particle-size swings. After adopting ADCERAX® Yttria Stabilized Zirconia Rods, average tool life reached ~880 h and D50 variability narrowed to ±4%. Line interruptions for tool swaps fell by 65%, while grinding energy per ton dropped 3% due to steadier residence time. Finished-grade yield rose by 2.6%.

User Guide for Yttria Stabilized Zirconia Rods

Proper use and handling of Yttria Stabilized Zirconia Rods ensures maximum service life and consistent performance across demanding industrial environments. This guide offers practical instructions for installation, operation, maintenance, and storage, helping customers minimize risks and achieve reliable results.

-

Installation and Handling

1. Always transport rods in protective packaging to avoid accidental chipping or surface scratches. Each rod should be lifted using non-metallic supports to reduce localized stress points. Handle with gloves to prevent contamination of the rod surface.

2. During installation, align rods carefully with mechanical housings to avoid uneven stress distribution. Misalignment can lead to premature wear or cracking under load. Use calibrated tools to secure rods without applying excessive force.

3. Check all rod contact points for cleanliness before assembly. Any trapped dust, metal particles, or abrasive residues can accelerate wear and compromise sealing performance.

-

Operating Guidelines

1. Operate rods within recommended temperature limits up to 1000 °C to maintain phase stability. Exceeding this limit may reduce strength and increase crack propagation. Ensure gradual heating and cooling cycles where possible.

2. Avoid exposure to sharp mechanical shocks or uncontrolled vibration. While fracture toughness is high, sudden impact loads may cause surface flaws. Use vibration-damping supports when operating in dynamic systems.

3. Monitor rods under continuous use for signs of surface wear or discoloration. Early detection allows timely replacement and prevents unexpected equipment downtime.

-

Storage and Safety Precautions

1. Store rods in a dry, stable environment at room temperature. Avoid condensation or high humidity that may interact with surrounding metal fixtures.

2. Keep rods separated using foam or padded dividers. Direct contact between rods can cause micro-cracks during handling or transport.

3. Clearly label stored rods with batch information and inspection dates. This practice helps track service life, ensures traceability, and prevents mix-ups in production environments.

-

Maintenance Recommendations

1. Inspect rods periodically using visual checks and surface roughness measurements. A ΔRa increase beyond 0.05 µm indicates progressive wear and may reduce component efficiency.

2. Clean rods with neutral pH solutions or deionized water after exposure to corrosive chemicals. Avoid abrasive brushes or harsh solvents that could damage the surface finish.

3. Document maintenance intervals and performance changes. A structured log helps predict replacement needs and ensures rods remain within safety and performance thresholds.