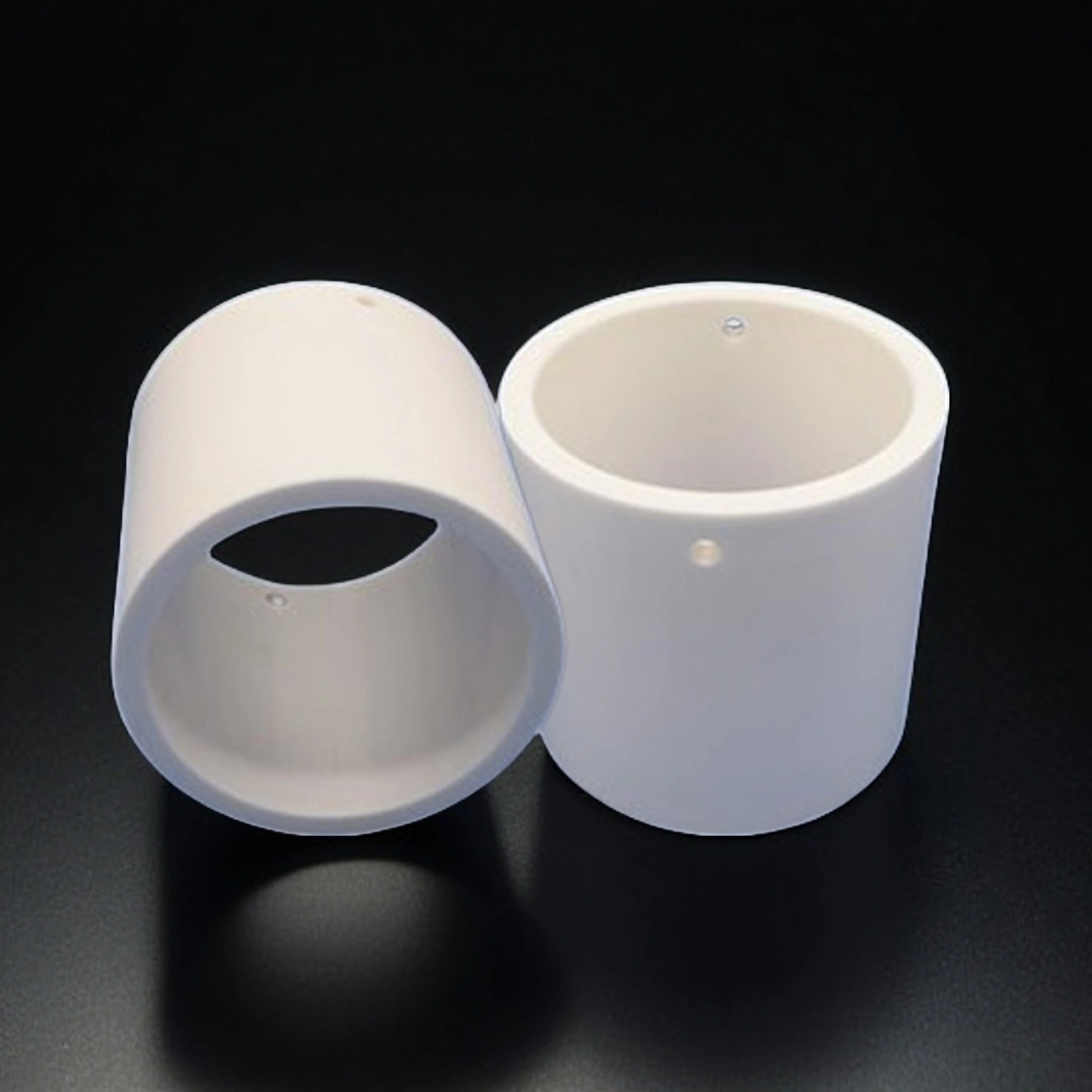

ADCERAX® Zirconia Ceramic Cylinder Sleeve is engineered for use in demanding reciprocating systems where continuous piston or plunger motion subjects components to intense mechanical stress. It plays a critical role in extending the operating life of mud pumps, plunger pumps, and hydraulic cylinders by minimizing surface wear and maintaining structural integrity under high pressure. With enhanced resistance to abrasion and chemical degradation, it ensures consistent performance even in harsh slurry and corrosive fluid environments.

Core Performance Features of Zirconia Ceramic Cylinder Sleeve in Harsh Pumping Systems

-

Corrosion and Temperature Resistance

Withstands chemically aggressive fluids including drilling muds containing >15% chloride and acidic slurries.

Remains dimensionally stable in environments exceeding 200 bar pressure and 180 °C operating temperature.

Zirconia maintains 98% mechanical integrity after 72-hour sulfuric acid immersion tests.

-

Abrasion Resistance in Slurry Media

The Vickers hardness reaches 1200 HV, offering 2.5× abrasion resistance compared to hardened steel.

Field reports show zirconia sleeves last 4,000–10,000+ hours in mud pumps with quartz sand and iron ore particulates.

Maintains sealing performance with surface roughness Ra ≤ 0.2 μm, even after long-term abrasive wear.

-

Structural Toughness and Operational Longevity

Demonstrates fracture toughness of 8–10 MPa·m¹ᐟ², reducing failure risk under cyclic pressure surges.

Achieves a compressive strength above 2000 MPa, preventing deformation during high-load reciprocation.

Proven to deliver ≥8× longer service life than standard metal liners, cutting maintenance costs by over 50%.

Technical Properties of Zirconia Ceramic Cylinder Sleeve

Zirconia Ceramic Cylinder Sleeve delivers high mechanical strength, thermal stability, and chemical inertness required for long-cycle operation in abrasive and corrosive environments. Its microstructural uniformity and surface integrity enable consistent sealing and fatigue resistance under demanding industrial conditions.

| Property |

Specification |

| Material Composition |

Yttria-Stabilized Zirconia (3Y-TZP) |

| Density |

≥ 6.0 g/cm³ |

| Vickers Hardness (HV10) |

1200 ± 50 |

| Bending Strength |

950 MPa |

| Compressive Strength |

> 2000 MPa |

| Fracture Toughness |

8–10 MPa·m¹ᐟ² |

| Surface Roughness (Ra, inner) |

≤ 0.2 µm |

| Thermal Expansion Coefficient |

10.5 × 10⁻⁶/K (25–1000 °C) |

| Maximum Operating Temperature |

2200 °C (inert atmosphere) |

| Corrosion Resistance |

Stable in pH 1–14 media |

| Porosity |

< 0.1 % |

| Electrical Insulation Strength |

≥ 10 kV/mm |

| Phase Stability |

Tetragonal (retained) |

| Wear Resistance Index (ASTM G65) |

≥ 3× over alumina |

Specifications of Zirconia Ceramic Cylinder Sleeve

| Technical Parameters of Steel Shell |

| Material: 45# Forged Steel |

| Chemical Composition |

C |

Mn |

Si |

P |

S |

Cr |

| 0.42~0.50 |

0.5~0.8 |

0.17~0.37 |

<0.06 |

<0.05 |

<0.25 |

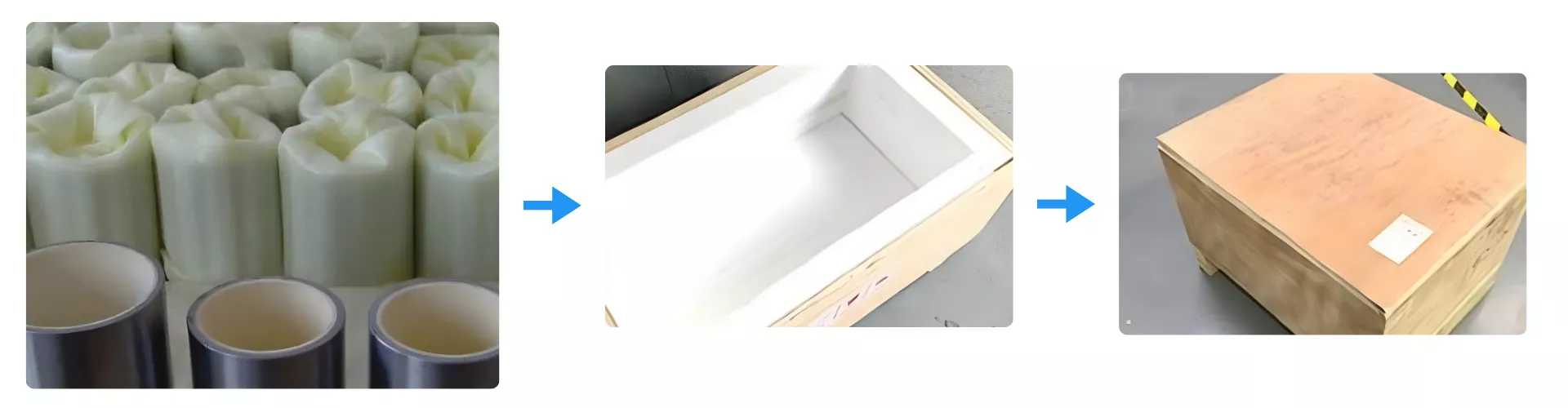

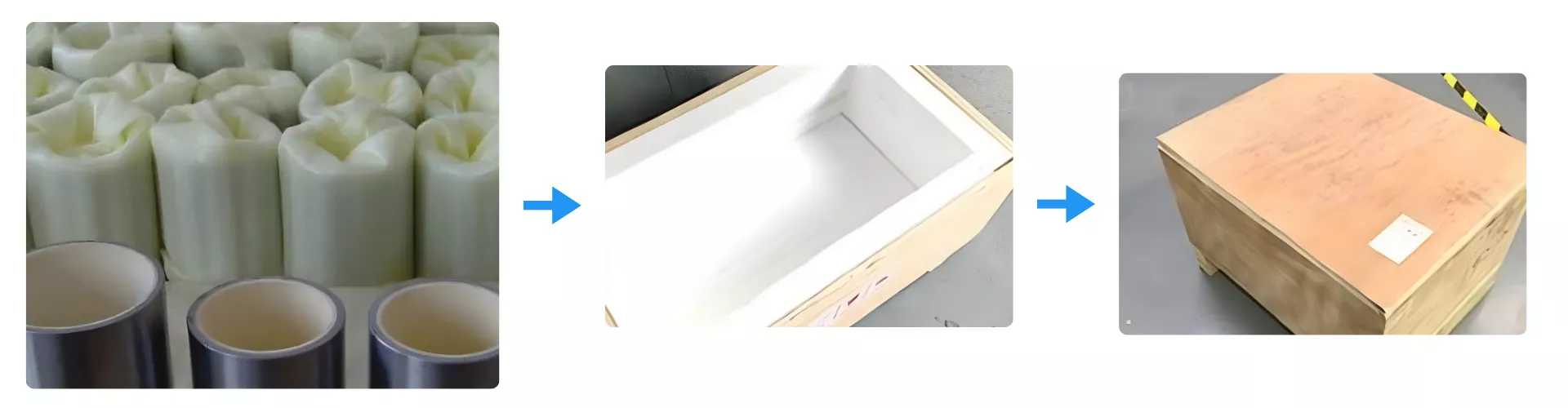

Packaging of Zirconia Ceramic Cylinder Sleeve

Zirconia Ceramic Cylinder Sleeve is individually wrapped in shock-absorbing film to prevent surface damage during handling. Each unit is placed in a high-density foam-lined wooden box to ensure full immobilization during transit. The final outer crate is reinforced and sealed for international shipping stability.

Enhancing Pumping Reliability in Harsh Industrial Environments with ADCERAX® Zirconia Ceramic Cylinder Sleeve

ADCERAX® Zirconia Ceramic Cylinder Sleeve is purpose-built to meet the mechanical stress, abrasive fluid load, and high thermal gradients found in the most demanding pump systems across oil drilling rigs, engine testing platforms, and chemical process equipment. Its dimensional integrity and wear resistance help solve chronic maintenance issues, reduce unplanned downtime, and improve fluid system longevity in complex field environments.

-

Zirconia Ceramic Cylinder Sleeve in Triplex Mud Pumps for Offshore Drilling

✅Key Advantages

1. High Abrasion Endurance Under ≥200 bar Slurry Pressure

The sleeve maintains structural stability when exposed to high‑viscosity drilling mud containing quartz sand and metal cuttings. Field wear‑rate testing indicates >3× lower surface erosion compared to hardened steel liners under identical pump load.

2. Stable Inner Surface Finish During Long‑Cycle Reciprocation

The inner bore surface retains Ra ≤ 0.2 µm even after extended operation, minimizing seal lip wear. This ensures consistent volumetric efficiency across 10,000+ reciprocating duty hours in slurry circulation.

3. Crack‑Resistance Under Pulsation-Induced Stress Variations

With fracture toughness of 8–10 MPa·m¹ᐟ², the sleeve resists crack propagation generated by fluctuating pump pressures. This reduces catastrophic failures during continuous drilling operations where pressure oscillation is frequent.

✅ ️Problem Solved

Reduced Unplanned Shutdowns in Offshore Mud Circulation

A North Sea offshore rig previously required sleeve replacement every 1,200–1,500 hours due to surface scoring and crack formation in metal liners. After switching to ADCERAX® Zirconia Ceramic Cylinder Sleeves, service intervals extended to 9,800–11,200 hours, reducing pump‑related downtime by over 40% across a 6‑month drilling campaign. This directly lowered emergency maintenance frequency and improved rig operational continuity.

-

Zirconia Ceramic Cylinder Sleeve in Engine Test Bench Hydraulic Systems

✅Key Advantages

1. Dimensional Stability Under High‑Cycle Actuator Loading

The sleeve retains internal geometry after >10⁷ reciprocation cycles, preventing performance drift. This contributes to stable actuator output and repeatable test measurements in engine calibration labs.

2. Resistance to Micro‑Scoring from Suspended Metal Particles

The 1200 HV hardness prevents abrasive scratches caused by contaminants circulating in synthetic hydraulic fluids. This directly reduces seal degradation and prevents creeping internal leakage rates.

3. Consistent Seal Interface Over Extended Operation Periods

The surface finish uniformity prevents gradually increasing friction torque. Testing shows <2% change in piston sliding resistance after continuous cycling, ensuring reliable motion characteristics.

✅ ️Problem Solved

Maintained Test Accuracy and Reduced Calibration Frequency

An automotive powertrain testing facility experienced inconsistent hydraulic actuator response due to micro‑scoring inside nitrided steel sleeves, requiring weekly recalibration. After conversion to ADCERAX® Zirconia Ceramic Cylinder Sleeves, recalibration intervals extended to five weeks, and leakage deviation decreased by >60%. This stabilized benchmarking conditions and reduced maintenance interference during engine durability validation.

-

Zirconia Ceramic Cylinder Sleeve in Abrasive Chemical Reactor Pumps

✅Key Advantages

1. Corrosion Stability Across pH 1–14 in Heated Slurry Media

The zirconia matrix remains chemically inert in acidic and alkaline conditions at up to 180 °C, preventing surface pitting and material thinning common in metal sleeves.

2. Hardness Capability for Catalyst‑Laden Recirculation Streams

With ≥1200 HV surface hardness, the sleeve resists abrasive wear caused by suspended catalysts and mineral solids. This preserves internal clearance and prevents pump efficiency reduction.

3. Thermal Stress Resistance During Reactor Temperature Cycling

Controlled thermal expansion at 10.5×10⁻⁶/K allows the sleeve to withstand repeated heating and cooling cycles without inducing internal cracking or warping.

✅ ️Problem Solved

Longer Operating Cycles in Slurry Reactor Circulation

A specialty chemicals plant using alumina‑based sleeves replaced liners every 3–4 weeks due to erosion and corrosive attack from catalyst slurries. After implementing ADCERAX® Zirconia Ceramic Cylinder Sleeves, replacement intervals reached 10–12 weeks, cutting spare part usage by over 55% and reducing unplanned pump shutdowns during batch production runs.

ADCERAX® Zirconia Ceramic Cylinder Sleeve – Best Practice User Guide for Safe and Efficient Operation

Proper handling and installation of the Zirconia Ceramic Cylinder Sleeve are essential to maximize its operational life and avoid avoidable failures during service. ADCERAX® provides the following user-centric guidelines to help ensure safety, performance stability, and cost-efficient use of this critical ceramic component across pump systems and fluid equipment.

-

Handling and Pre-Assembly Cautions

1. Avoid any form of mechanical impact such as dropping, hammering, or forced insertion. Even micro-cracks from minor impact may cause structural failure under pressure cycles.

2. Transport and store sleeves in upright positions with foam or rubber cushioning to minimize vibration stress. During bulk handling, ensure they are not stacked directly without separation.

3. Inspect surface and edges carefully before assembly for signs of chipping or abrasion. Do not use sleeves with visible cracks, as they can compromise the sealing interface or fracture during operation.

-

Installation Guidelines for Piston and Plunger Systems

1. Ensure piston and sleeve concentricity is maintained during insertion to prevent uneven wear. Misalignment may lead to frictional hotspots and increased seal degradation.

2. Use a non-metallic soft mallet with wood or rubber buffer when tapping components into place. Never strike the sleeve directly with a hard tool.

3. Apply uniform assembly torque if clamping or flanging is required, especially when sleeves interface with metallic housings that expand differently under temperature.

-

Operating Conditions and Maintenance Best Practices

1. Avoid dry-starting pumps or operating them without sufficient lubrication, as this can lead to thermal shock and micro-abrasion. Pre-lubricate contact surfaces where applicable.

2. Monitor fluid cleanliness to prevent sediment buildup and abrasion from foreign particles. High solid content accelerates liner surface fatigue.

3. Schedule visual inspections after every 2,000–3,000 operating hours in abrasive systems. Replace the sleeve if Ra values exceed tolerance or surface fatigue appears.

-

Cold Weather and Inactive Period Protection

1. Drain residual fluids before extended shutdowns in environments below 0 °C. Freezing expands slurry inside the sleeve and can lead to internal cracking.

2. Store sleeves in temperature-stable indoor conditions to avoid moisture condensation and thermal stress shock. Do not expose to direct sunlight during storage.

3. Recheck inner bore condition and seal alignment after long idle periods or equipment relocation. Ensure no warpage or seal hardening has occurred.