ADCERAX® Zirconia Ceramic Gage Balls are engineered for dimensional measurement tasks that require long-term precision, chemical stability, and non-magnetic behavior. These spheres perform reliably in high-friction, corrosive, and thermally demanding environments. Commonly used in metrology equipment, aerospace tooling, and precision machining setups, they maintain shape and hardness far longer than conventional steel balls. Zirconia Ceramic Gage Balls are well-suited for manufacturers and calibration labs that demand consistent surface finish and material durability.

Features of Zirconia Ceramic Gage Balls

- Hardness over 1200 HV enables more than 10× longer lifespan than hardened steel balls in wear-intensive environments.

- Consistent performance in setups exceeding 1 million contact cycles without surface degradation has been verified in machining test beds.

- High resistance to abrasive loss makes these balls suitable for 24/7 operation in precision tooling setups with minimal replacement downtime.

- Their 100% non-magnetic composition prevents signal interference in CMMs, micrometers, and PCB testers.

- They demonstrate surface resistivity exceeding 10¹⁴ Ω·cm, far beyond the needs of electronic metrology environments.

- These properties eliminate measurement drift in capacitive and magnetic induction-based instruments used in aerospace and microelectronics sectors.

- They remain dimensionally stable up to 1000°C, suitable for integration into furnace-mounted or high-temperature calibration systems.

- Corrosion tests in 10% HCl and 10% NaOH showed <0.01% mass loss over 72 hours, outperforming alumina and steel equivalents.

- The material’s low thermal expansion coefficient of 10.5 × 10⁻⁶/K ensures structural consistency under cyclic heat exposure.

Technical Properties for Zirconia Ceramic Gage Balls

Zirconia Ceramic Gage Balls are engineered to deliver stable performance across demanding metrology conditions, including high-temperature exposure, corrosive media, and mechanical loading. Their consistent composition and microstructural density allow them to meet stringent requirements in precision calibration, especially in aerospace, machining, and cleanroom environments.

| Property |

Specification |

| Material Composition |

Yttria-Stabilized Zirconia (Y-TZP) |

| Density |

≥ 6.0 g/cm³ |

| Vickers Hardness |

≥ 1200 HV |

| Fracture Toughness (K₁c) |

≥ 7 MPa·m¹ᐟ² |

| Compressive Strength |

> 2000 MPa |

| Flexural Strength |

900–1200 MPa |

| Maximum Working Temperature |

≥ 1000°C |

| Thermal Conductivity (20°C) |

2.5 W/m·K |

| Coefficient of Thermal Expansion |

10.5 × 10⁻⁶ /K |

| Electrical Resistivity (RT) |

> 10¹⁴ Ω·cm |

| Acid Resistance (10% HCl, 72 hrs) |

< 0.01% mass loss |

| Alkali Resistance (10% NaOH, 72 hrs) |

< 0.01% mass loss |

| Water Absorption |

0% |

| Magnetic Permeability |

≈ 1.00000 (non-magnetic) |

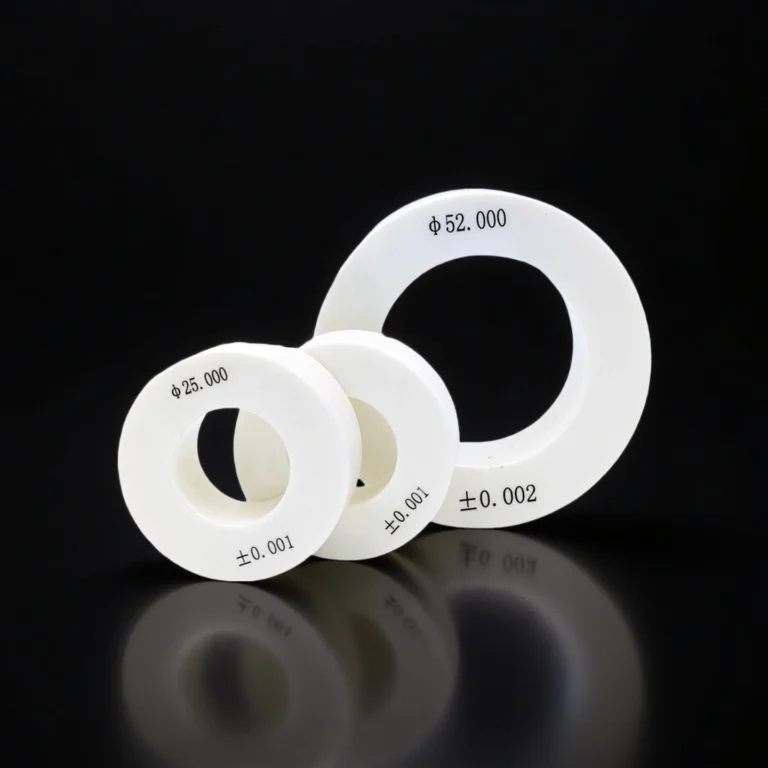

Specifications of Zirconia Ceramic Gage Balls

Packaging of Zirconia Ceramic Gage Balls

Zirconia Ceramic Gage Balls are securely packed in individual anti-static cases with foam inserts to prevent surface damage during transport. Each unit or set is labeled for traceability and arranged in compact storage boxes for easy handling. For bulk orders, They are organized in sealed wooden cases with protective inserts to ensure safe logistics and on-site calibration readiness.

Solving Dimensional Control Challenges with ADCERAX® Zirconia Ceramic Gage Balls

ADCERAX® Zirconia Ceramic Gage Balls provide stable reference geometry in specialized industrial scenarios where conventional metal balls are limited by corrosion, magnetism, or thermal distortion. These spheres help engineering teams maintain calibration integrity, especially in high-precision, high-risk measurement tasks.

-

Zirconia Ceramic Gage Balls in High‑Frequency Bore Inspection for CNC Tooling

✅Key Advantages

1. Flat‑spot resistance

Two sentences. <0.5% wear loss after 1 million cycles. Steel balls exceed 5% and lose repeatability.

2. Stable under coolant heat cycling

Two sentences. Shape change <0.2 µm after 300 thermal cycles. Steel balls often exceed 3 µm and fail contact accuracy.

3. Zero magnetic influence on probes

Two sentences. 100% non‑magnetic confirms clean signals. Inductive sensors show zero drift in long machining shifts.

✅ ️Problem Solved

Steel balls flatten after constant bore checks in a 24/7 automotive CNC line. Calibration alarms increased 15% each week due to magnetic noise and wear. ADCERAX® Zirconia Ceramic Gage Balls held geometry within ±0.2 µm for 90 days nonstop. Inspection false‑trigger rate fell below 1% and tool change frequency declined.

-

Zirconia Ceramic Gage Balls in Aerospace Fixture Calibration Under Vacuum and Heat

✅Key Advantages

1. No oxidation in high‑vacuum heat

Two sentences. <0.01% mass change after 1000°C cycles. Metal balls scale and disrupt alignment references.

2. Alignment stability under load

Two sentences. 6.0 g/cm³ density ensures rigid seating. Zero fixture drift after repeated press‑fit operations.

3. Consistent form in corrosive residue

Two sentences. Acid or alkali exposure causes no spherical deviation. Maintains calibration points in turbine assembly stages.

✅ ️Problem Solved

An aerospace jig used steel balls during vacuum firing. After 12 cycles, oxidation forced recalibration downtime of two days. ADCERAX® Zirconia Ceramic Gage Balls remained smooth and round after 50+ high‑temperature runs. Alignment variance stayed under ±0.3 µm, preventing compounded assembly errors.

-

Zirconia Ceramic Gage Balls in Electronic Probe Alignment for PCB Test Fixtures

✅Key Advantages

1. Non‑conductive signal isolation

Two sentences. Surface resistivity >10¹⁴ Ω·cm prevents leakage. Probe readings remain stable under high duty cycles.

2. Anti‑arc contact interface

Two sentences. No micro‑pits after 500k probe strikes. Contact height consistency holds alignment.

3. Sensor drift elimination

Two sentences. Zero magnetic permeability avoids EMI artifacts. Supports accurate micron‑scale pin placement.

✅ ️Problem Solved

A tablet PCB tester reported 2% false fails from arcing on metal reference spheres. Weekly maintenance was required to polish pits. ADCERAX® Zirconia Ceramic Gage Balls showed no surface damage after 0.5 million impacts. False fail rate dropped below 0.2%, with no downtime for rework.

Handling and Operational Guidelines for Zirconia Ceramic Gage Balls

To ensure optimal performance and extended service life, Zirconia Ceramic Gage Balls must be used, stored, and maintained according to application-specific guidelines. These instructions help avoid avoidable measurement drift, surface damage, and environmental degradation, especially in high-frequency or critical alignment tasks.

-

Cleanroom and Laboratory Handling Protocols

1. Always use lint-free gloves or ceramic tweezers when handling gage balls to avoid introducing oil, dust, or static discharge to the contact surface. Even slight contamination can affect dimensional referencing in high-resolution metrology. Store the balls in a clean, enclosed tray with individual compartments.

2. Before use, verify that the gage ball surface is free of debris and airborne particulate, especially in optical or laser alignment systems. Use an alcohol-based wipe or ceramic-grade compressed air if cleaning is necessary. Never use abrasive cloths or metallic tools for surface cleaning.

3. Avoid prolonged exposure to open lab environments with humidity above 65%, as condensation may attract particulates. Maintain storage temperature between 20–25°C with low ambient vibration to preserve calibration consistency.

-

Integration into Measurement and Calibration Systems

1. Ensure the gage ball seats properly into fixtures using non-metallic mounts or alignment sockets. Misaligned or forced placement may create microfractures and reduce surface integrity. Use light pressure or self-aligning holders in automated systems.

2. For dimensional reference tasks, always rotate the gage ball between uses to distribute contact wear evenly, especially in rotary or oscillating probe designs. This helps prevent flat spots on high-contact areas.

3. Periodically inspect contact points under 50× or higher magnification to detect microdamage. If surface anomalies are detected, replace the ball immediately to avoid cascading tolerance errors in multi-stage systems.

-

Short-Term and Long-Term Storage Practices

1. Store Zirconia Ceramic Gage Balls in non-metallic, chemically inert cases with cushioned padding to prevent impact chipping. Compartments should be fitted to prevent free movement during transport or drawer access.

2. Avoid stacking multiple gage balls in direct contact. If multi-size sets are stored together, use individual separation slots to avoid collision damage, especially during shipment.

3. For long-term storage, maintain relative humidity below 55%, avoid UV exposure, and label containers with traceability information such as batch number and inspection cycle date.

-

Common Misuse Scenarios and Prevention Tips

1. Never attempt to polish, sand, or rework a used gage ball. Dimensional tolerance and surface finish cannot be restored manually and such actions invalidate calibration reliability.

2. Avoid using gage balls as makeshift test weights, spacers, or contact stoppers in non-measurement applications. Misuse leads to internal stress cracks not visible to the naked eye.

3. In environments with intense electromagnetic fields, only use gage balls in shielded fixtures to maintain signal accuracy. While the ball itself is non-magnetic, external interference can still distort results if system shielding is insufficient.