ADCERAX® Zirconia Ferrule is a high-precision ceramic alignment component used in fiber optic connectors to ensure accurate fiber core positioning. Formed from stabilized zirconia ceramic, it provides excellent mechanical strength, thermal stability, and wear resistance in demanding optical environments. Its consistent geometry and polished end-face support low insertion loss and high return loss, making it essential in telecom, data center, and optical test systems.

Key Product Features of Zirconia Ferrule

- Insertion Loss Stability: The concentricity of the ferrule is controlled within ≤0.5 µm, enabling accurate core-to-core fiber mating. This results in consistent insertion loss <0.3 dB across repeated connections.

- End-Face Quality: End surfaces are polished to a roughness of Ra ≤ 0.02 µm, minimizing back reflection and maintaining return loss above 55 dB for APC configurations.

- Hole Accuracy: Inner bore diameters are manufactured with ±0.001 mm tolerance, ensuring stable ferrule-to-fiber interface across production batches.

- Cycle Longevity: Manufactured from Y-TZP zirconia, the ferrule withstands >5000 mating cycles without structural degradation. Tests confirm mechanical stability in high-use environments such as data centers and telecom hubs.

- Surface Hardness: With a Vickers hardness of ≥1250 HV, the ceramic resists micro-abrasions during repeated insertion and polishing processes.

- Service Life: Accelerated aging simulations confirm <0.1% strength degradation after 1000 hours at 150 °C and 85% relative humidity.

- Polishing Compatibility: The ferrule supports multiple polishing types including PC, UPC, and APC, ensuring compatibility with global connector standards.

- Custom Geometries: Conical, spherical, and angled profiles can be precisely machined without compromising end-face quality or symmetry.

- Thermal Stability: The linear thermal expansion coefficient of 10.3 × 10⁻⁶ K⁻¹ allows dimensional stability across –40 °C to +85 °C, supporting use in field-deployed optical systems.

Technical Properties of Zirconia Ferrule

The Zirconia Ferrule is engineered for demanding optical alignment applications, combining high mechanical strength, microstructural uniformity, and thermal reliability to ensure consistent performance across various fiber optic connection environments.

| Property |

Specification |

| Material Type |

Y-TZP / 3Y-TZP Zirconia |

| Density |

6.05 g/cm³ (typical) |

| Hardness |

≥1250 HV1 |

| Fracture Toughness |

6–8 MPa·m¹ᐟ² |

| Flexural Strength |

>1000 MPa |

| Compressive Strength |

1600–2300 MPa |

| Young’s Modulus |

~210 GPa |

| Thermal Conductivity |

~3 W/m·K |

| Thermal Expansion Coefficient |

10.3 × 10⁻⁶ K⁻¹ |

| Electrical Resistivity |

>10¹² Ω·cm |

| Aging Resistance |

<0.1% strength loss @150°C/1000h |

| Surface Finish (End Face) |

Ra ≤ 0.02 µm |

| Mating Durability |

>5000 cycles |

| Chemical Resistance |

Inert to acids, bases, solvents |

| RoHS Compliance |

Yes (2011/65/EU) |

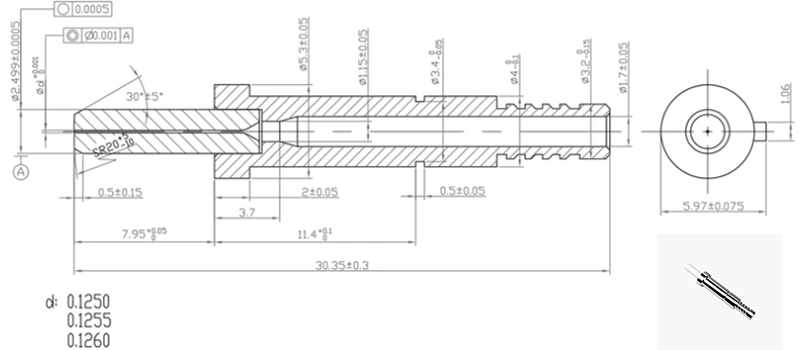

Specifications of Zirconia Ferrule

|

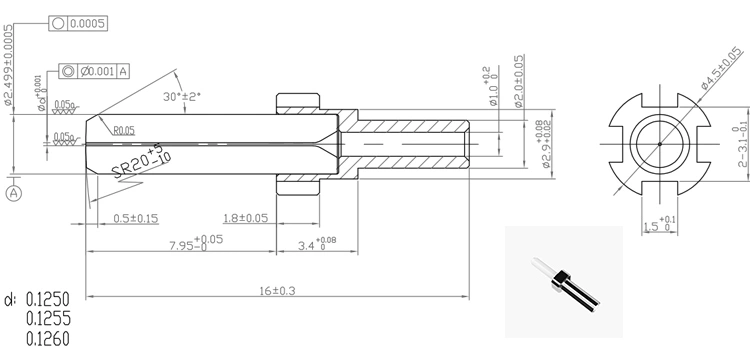

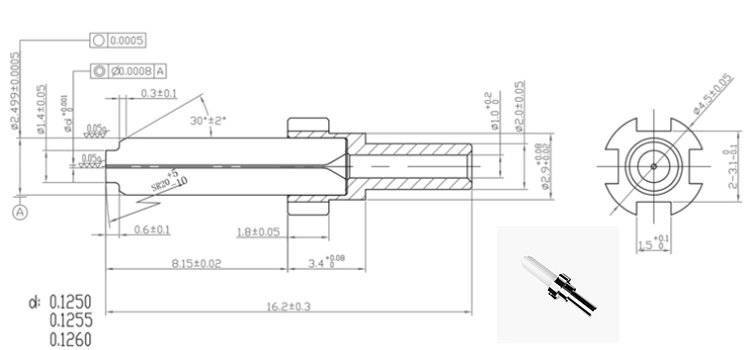

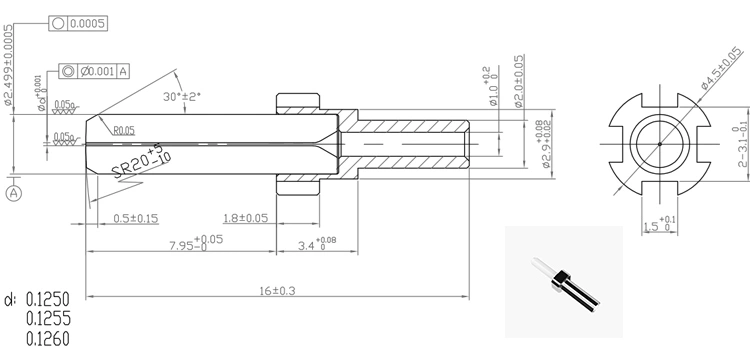

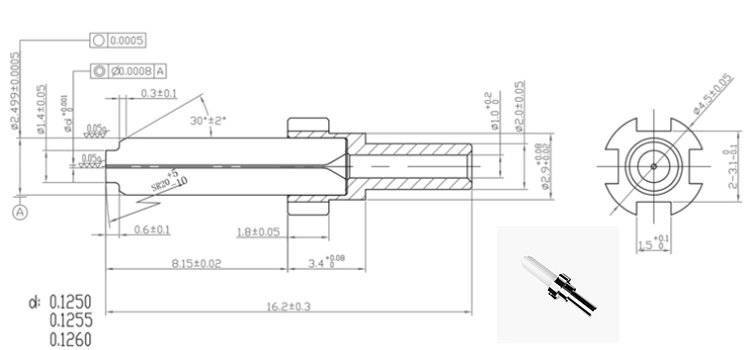

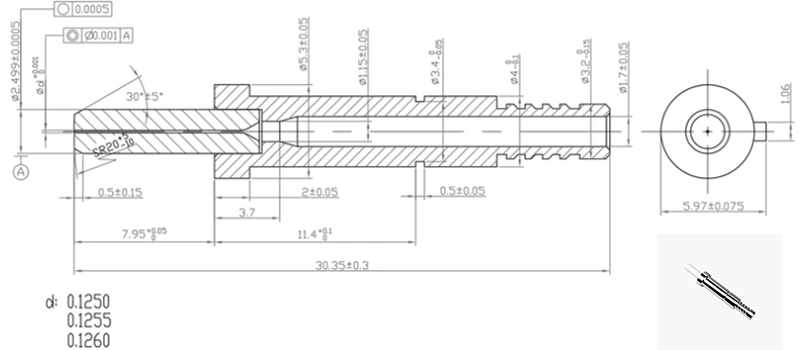

SC Single Mode |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX001 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX001-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX001-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

SC Single Mode with Flange |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX002 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX002-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX002-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

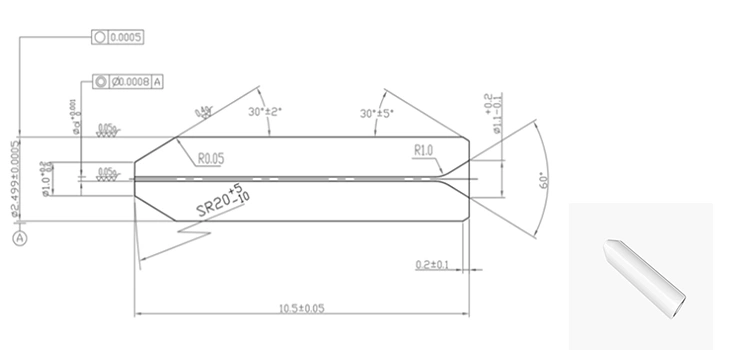

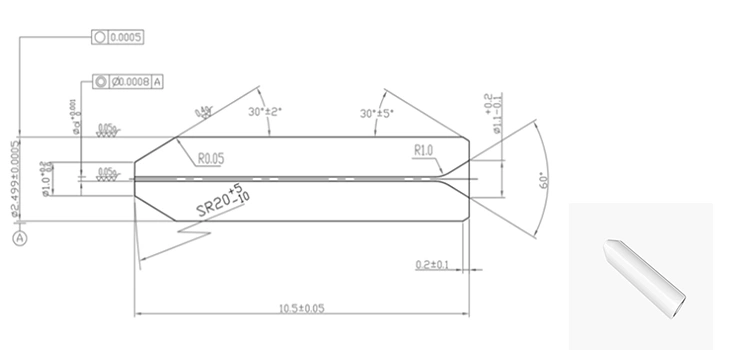

APC/SC |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX003 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX003-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX003-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

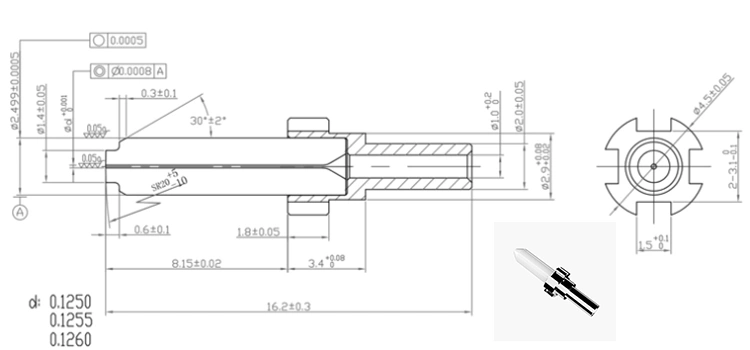

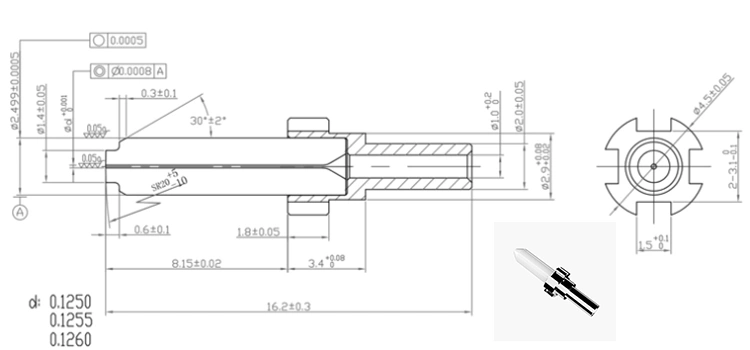

APC/SC with Flange |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX004 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX004-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX004-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

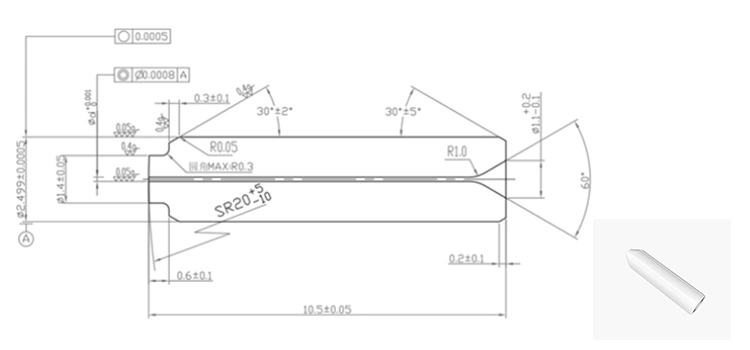

APC/SC, Stepped |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX005 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX005-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX005-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

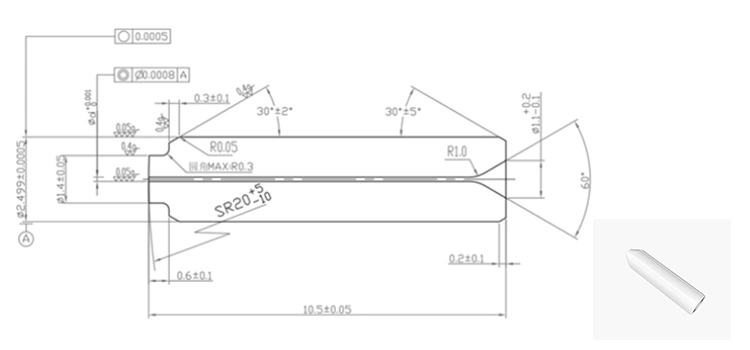

Stepped APC/SC with Flange |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX006 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX006-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX006-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

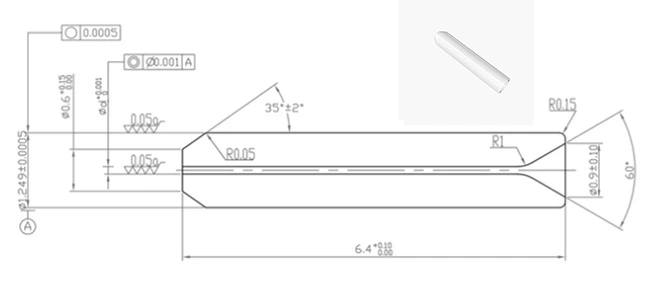

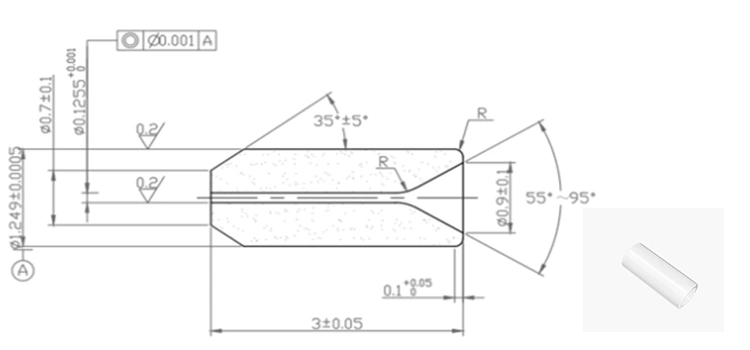

LC Single Mode |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX006 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX006-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

AT-YHG-CX006-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.0008 |

≥1200 |

≥1200 |

|

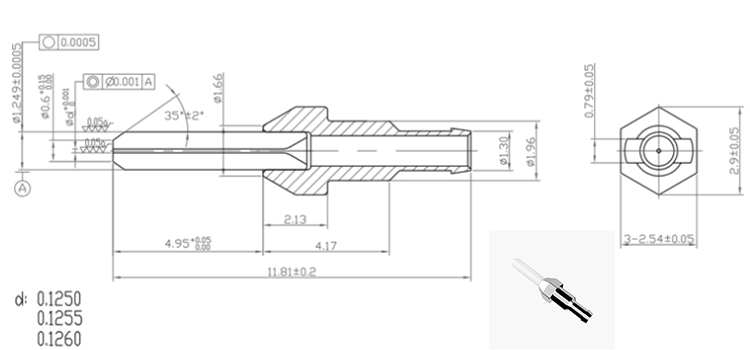

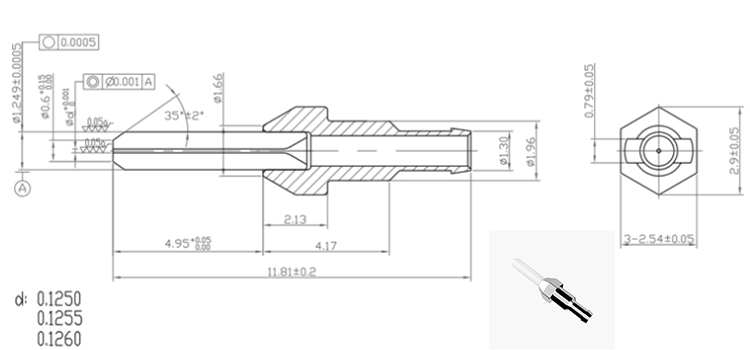

LC Single Mode with Flange |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

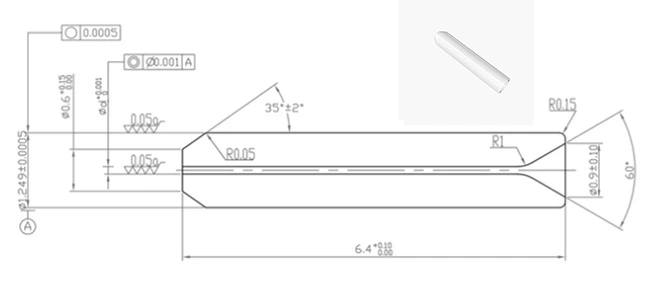

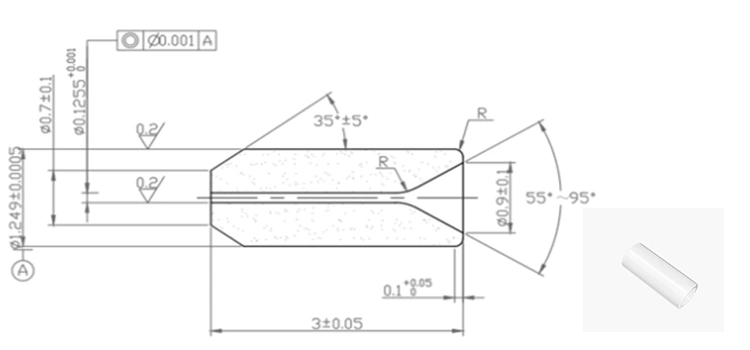

AT-YHG-CX008 |

1.249±0.0005 |

d(0.1250)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX008-1 |

1.249±0.0005 |

d(0.1255)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX008-2 |

1.249±0.0005 |

d(0.1260)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

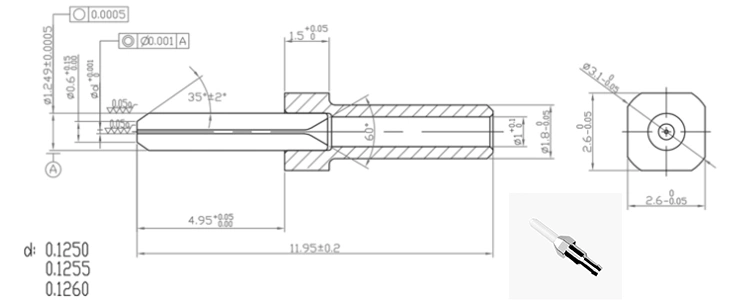

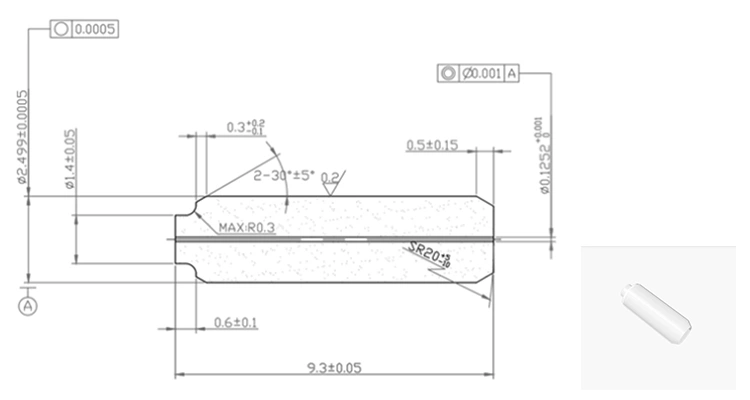

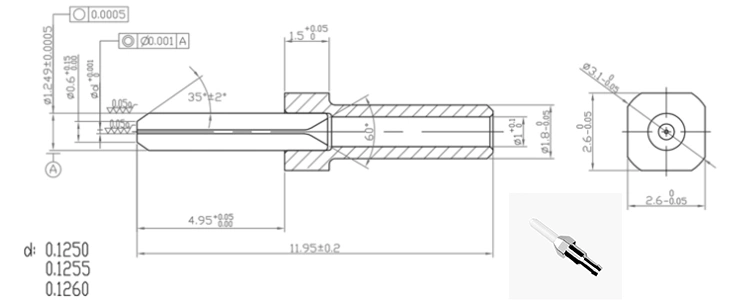

MU Single Mode with Flange |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

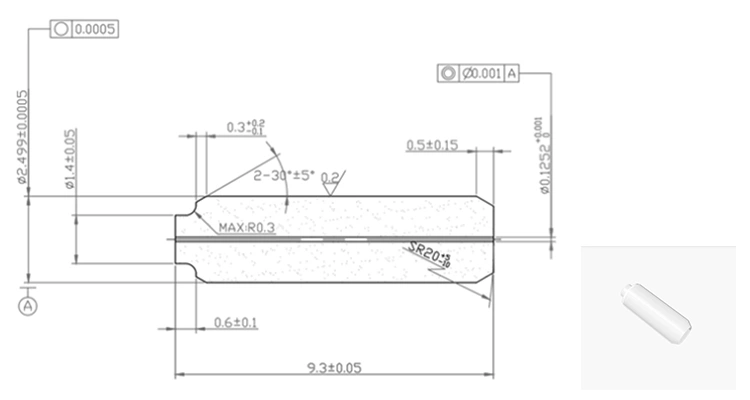

AT-YHG-CX009 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX009-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX009-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

ST with Flange |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX010 |

2.499±0.0005 |

d(0.1250)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX010-1 |

2.499±0.0005 |

d(0.1255)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

AT-YHG-CX010-2 |

2.499±0.0005 |

d(0.1260)+0.001 |

≤0.001 |

≥1200 |

≥1200 |

|

LC (Non-Standard) |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Concentricity(mm) |

Flexural Strength(mpa) |

Hardness(HV) |

|

AT-YHG-CX011 |

0.5-3.2 |

0.06-0.8 |

2.5-33 |

≥1200 |

≥1200 |

Packaging of Zirconia Ferrule

Zirconia Ferrule is packed in high-density, anti-static plastic trays to ensure geometric stability and avoid end-face contamination during transit. Each tray holds individually slotted components to prevent micro-abrasion or contact damage. The stackable design supports efficient bulk logistics for volume-based shipments.

Solving Application Challenges with ADCERAX® Zirconia Ferrule

ADCERAX® Zirconia Ferrule addresses alignment stability, repeated mating durability, and optical signal consistency across fiber-based communication and sensing environments, where long-term performance depends on precise fiber-to-fiber contact under varying mechanical and thermal conditions.

-

High‑Density Patch Panels in Telecom Backbone Networks

✅Key Advantages

1. Stable End‑Face Integrity Under Frequent Mating

The ≥1250 HV hardness of the zirconia surface prevents micro‑abrasion during thousands of insertion cycles. This preserves end‑face geometry in 400G/800G panels where even minor wear shifts optical alignment.

2. Low Signal Drift Through Consistent Fiber Core Alignment

Concentricity controlled to ≤0.5 µm maintains consistent insertion loss across repeated re‑routing operations. This stability reduces the variance range of attenuation values over long‑term patch panel usage.

3. Reduced Network Downtime Due to Extended Component Service Life

With >5000 verified mating cycles, ferrules require fewer replacements in large node environments. This directly lowers maintenance scheduling frequency during capacity expansion or network rerouting.

✅ ️Problem Solved

A Tier‑1 telecom operator reported rising attenuation and intermittent link instability in high‑density ODF bays after polymer ferrules degraded under frequent mating cycles. Replacement with ADCERAX® Zirconia Ferrules reduced insertion loss deviation to <0.15 dB variance across 3000+ connections, enabling stable 800G operation without unplanned maintenance intervals. Over a 12‑month period, patch‑panel servicing frequency decreased measurably, supporting continuous service‑level availability targets.

-

Precision Optical Calibration in Testing and Measurement Laboratories

✅Key Advantages

1. Repeatable Measurement Baselines Across Test Batches

End‑face roughness of Ra ≤0.02 µm ensures a stable optical reference surface. This minimizes reflection‑related measurement drift between sequential calibration cycles.

2. Core‑to‑Core Alignment Consistency for Sensitive DUT Evaluation

Concentricity of ≤0.5 µm reduces alignment variation when connecting multiple devices under test. This supports controlled test environments where reproducibility is essential for equipment certification workflows.

3. Reduced Calibration Time and Frequency

Low insertion loss stability of <0.3 dB minimizes re‑zeroing needs between instrument runs. This maintains traceability in labs processing high volumes of optical components daily.

✅ ️Problem Solved

A measurement laboratory conducting routine optical module certification experienced inconsistent baseline readings due to variability in connector interface surfaces. After switching to ADCERAX® Zirconia Ferrules, baseline return loss stabilized at >55 dB for APC interfaces, eliminating repeated recalibration cycles. This reduced average calibration turnaround time per instrument group by 18–22%, improving throughput without altering existing test procedures.

-

Fiber‑Based Industrial Automation and Monitoring Systems

✅Key Advantages

1. Dimensional Stability Under Thermal Cycling

The thermal expansion coefficient of 10.3 × 10⁻⁶ K⁻¹ prevents stress‑induced alignment shifts when equipment operates between widely varying temperatures. This is essential for systems that cannot be stopped for periodic realignment.

2. Mechanical Resistance in High‑Vibration Assemblies

The ~210 GPa Young’s modulus enables the ferrule to retain form under prolonged vibration. This ensures stable optical transmission integrity inside robotic, high‑speed or rotating mechanical environments.

3. Chemical and Environmental Inertness for Continuous Operation

Zirconia’s non‑reactive surface resists degradation from lubricants, humid air, dust, and airborne industrial residues. This preserves signal reliability where cleaning or handling access is limited.

✅ ️Problem Solved

An industrial plant using fiber‑optic monitoring in automated assembly lines reported signal interruptions caused by ferrule deformation and contamination exposure from lubricants and airborne particulates. After deploying ADCERAX® Zirconia Ferrules, link stability was maintained even under continuous 24/7 operation, with no measurable signal loss drift over six months of vibration and thermal cycling. Maintenance intervals were extended without requiring environmental enclosures or modified cleaning protocols.

ADCERAX® Zirconia Ferrule User Guide for Optimal Handling and Long-Term Performance

Proper usage and maintenance of the Zirconia Ferrule are essential to maintain its dimensional stability, optical interface quality, and mechanical endurance across high-cycle applications. This guide helps users prevent damage during handling, installation, and inspection, ensuring reliable performance throughout the product’s lifecycle.

-

Handling and Contamination Control

1. Always hold the component by its cylindrical body using non-metallic tweezers or gloves to prevent end-face scratches or surface oil contamination.

2. Avoid direct contact with the end-face, as fingerprints or dust may interfere with the optical interface and lead to increased signal loss.

3. Keep unused ferrules in sealed, clean trays or containers, and avoid transferring between uncontrolled environments to minimize particle exposure.

-

Installation and Mechanical Fit Precautions

1. Ensure the ferrule is inserted into connector housings with no lateral force, as side-loading may compromise concentricity alignment.

2. Confirm that mating connectors are free from misalignment or over-insertion that can lead to micro-chipping or ceramic cracking.

3. Use manufacturer-approved press-fit tools or polishing fixtures to maintain dimensional integrity during assembly processes.

-

End-Face Cleaning and Inspection Procedures

1. Clean the polished end-face using optical-grade isopropyl alcohol and lint-free wipes before measurement or mating.

2. Inspect under 400× interferometric magnification to detect scratches, pits, or polishing defects prior to deployment.

3. Replace ferrules with any visible edge damage or surface deformation, as these may lead to insertion loss drift or connector instability.

-

Storage, Environmental Exposure, and Lifecycle Management

1. Store the product in temperature-controlled, dust-free environments between 5 °C–35 °C with <60% RH for long-term reliability.

2. Avoid extended exposure to chemically active atmospheres or UV-curing adhesives, which may degrade ceramic surfaces or adhesives.

3. Track ferrule usage cycles in high-density assemblies; after >5000 mating cycles, monitor end-face condition to determine replacement needs.