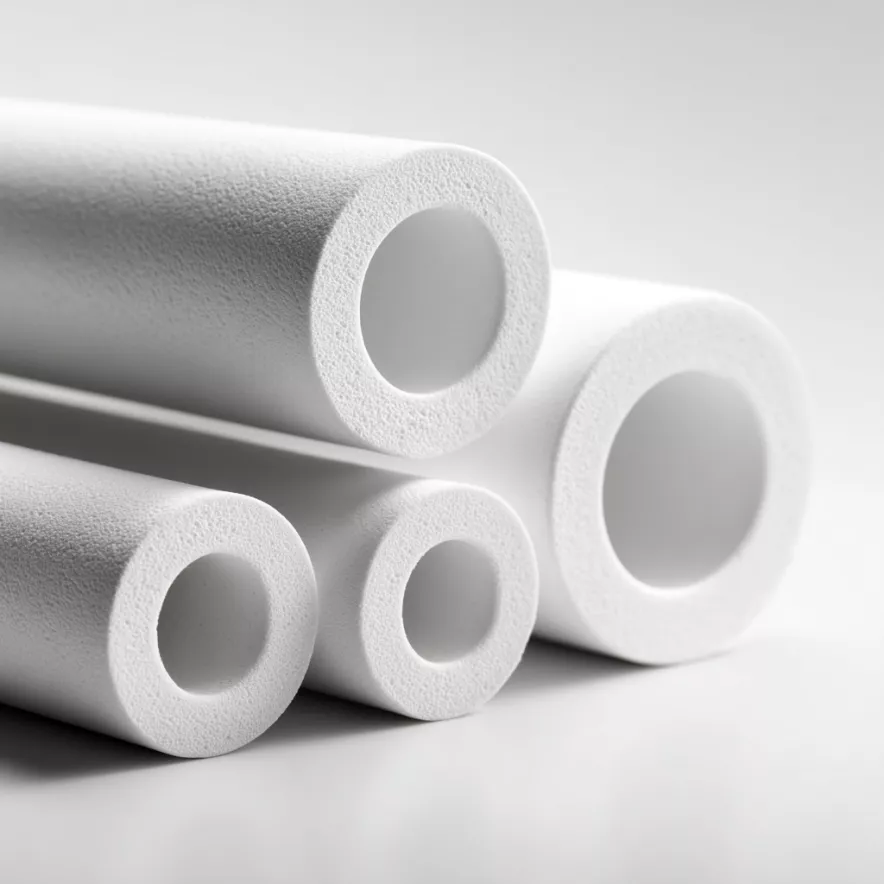

ADCERAX® Zirconia Porous Filter Tube is designed for demanding industrial filtration where chemical resistance and thermal stability are critical. It provides reliable microfiltration and ultrafiltration performance across wastewater treatment, chemical processing, and food and beverage clarification. With uniform pore distribution and durable structure, Zirconia Ceramic Membrane Tube ensures long service life and reduced maintenance cycles. This product supports both standard stock availability and tailored configurations for diverse application needs.

Features of Zirconia Porous Filter Tube

- Independent tests show >95% retention of mechanical strength after 500 hours in acidic media. This minimizes unexpected downtime and replacement needs.

- Resistance to solvents provides up to 3× longer lifetime compared to polymeric membranes. This significantly lowers annual operating expenses for users.

- Thermal shock resistance demonstrated survival of >50 heating–cooling cycles without cracking. This prevents costly failures in cyclic industrial processes.

- Field data indicate a 3–5 year average lifespan in wastewater applications. This is more than double the typical life of alumina membranes.

- Filtration performance remains stable with <10% flux decline after 1000 operating hours. This consistency improves productivity for end users.

- Replacement frequency is reduced by over 40%, leading to fewer shutdowns and lower maintenance costs.

Technical Properties for Zirconia Porous Filter Tube

The following specifications highlight the essential physical, chemical, mechanical, and optical properties of the Zirconia Porous Filter Tube.

| Property |

Specification |

| Density |

5.6–5.9 g/cm³ (measured bulk density of stabilized zirconia) |

| Flexural Strength |

≥900 MPa (tested under three-point bending) |

| Fracture Toughness |

8–10 MPa·m¹/² (higher than alumina membranes) |

| Maximum Operating Temperature |

600°C continuous, short-term ≤800°C |

| Thermal Expansion Coefficient |

10.5 ×10⁻⁶ /K (25–600°C range) |

| Chemical Resistance |

Stable in pH 2–12, >95% strength retention after 500 h acid exposure |

| Acid/Base Durability |

Survives >200 cleaning cycles with HCl/NaOH solutions |

| Porosity |

35–40% open porosity, enabling efficient fluid flux |

Packaging for Zirconia Porous Filter Tube

The Zirconia Porous Filter Tube is packaged in reinforced cartons with protective cushioning to minimize surface damage. Each carton is then secured inside wooden crates to ensure stability during long-distance transportation. This packaging approach ensures the ZrO2 filter tube reaches customers in perfect condition and ready for direct use.

Addressing Industry Challenges with ADCERAX® Zirconia Porous Filter Tube

Zirconia Porous Filter Tube is applied in demanding industrial processes where chemical stability, thermal resistance, and long service life are critical. The following sectors highlight specific challenges and demonstrate how this material provides measurable solutions.

-

Electroplating Wastewater Treatment

✅Key Advantages

1. Acid-Resistant Structure — Withstands pH 2–12 and retains >95% strength after 500 h in acidic media. This prevents metal-ion corrosion damage and extends runtime between CIP events.

2. Low Fouling Under Metals Load — Flux decline stays <10% over 1000 h with Ni/Cr-bearing effluents at 0.1–0.2 µm cut-off. Stable pore architecture limits cake buildup and keeps TMP growth predictable.

3. CIP Endurance — Survives >200 cycles with 0.5–2% HCl/NaOH at elevated temperature. Cleaning recovery is >90% of baseline flux after each cycle.

✅ ️Problem Solved

A plating line treating 80 m³/day of Ni/Cr wastewater replaced polymeric modules that failed every 4–6 months. ADCERAX® Zirconia Porous Filter Tube held flux within ±8% over 12 months, cut changeovers by >50%, and reduced chemical membrane spend by ~35%. Compliance sampling met discharge limits with stable solids removal at 0.2 µm. Recorded downtime for membrane service decreased from 18 h/month to <7 h/month.

-

Brewery Clarification Systems

✅Key Advantages

1. Tight Yeast Cut-Off — Controlled pores at 0.1–0.2 µm deliver final beer turbidity of ≤0.5 NTU. Clarification consistency protects flavor and foam stability.

2. Long-Run Stability — Flux decline <10% after 1000 h continuous operation on fermentation beer. Predictable runs reduce unplanned stops during peak demand.

3. Heat-Sanitization Endurance — Tolerates >150 hot-water cycles at 80–90 °C with >90% flux recovery. Thermal robustness lowers media replacement frequency.

✅ ️Problem Solved

A 200 hL/day brewery reported filter fouling that forced 2×/day CIP and variable clarity. With ADCERAX® Zirconia Porous Filter Tube, run length increased to 72–96 h between CIP, and CIP frequency dropped to 1× every 2–3 days. Final turbidity stabilized at 0.4–0.6 NTU, while packaging downtime fell by ~30%. Annual membrane replacement costs decreased by ~25% due to extended service life.

-

Precision Thermocouple Sheaths

✅Key Advantages

1. Solvent Attack Resistance — Maintains integrity in solvent-rich streams (e.g., DMF/DMSO) with flux variation ≤12% over 900 h. Zirconia matrix resists swelling and embrittlement seen in polymers.

2. High-Porosity Throughput — Open porosity 35–40% supports elevated permeate flux at 0.1–0.5 µm grades. Stable TMP slope enables predictable batch timelines.

3. Alkali-CIP Robustness — Endures >200 CIP cycles at 1–3% NaOH, 50–60 °C, with >90% flux recovery. Persistent colorant fouling is cleared without pore damage.

✅ ️Problem Solved

A pigment plant processing 50 m³/day solvent-laden effluent faced weekly filter swaps and high COD carryover. After deploying ADCERAX® Zirconia Porous Filter Tube, permeate COD dropped by 40–60% pre-RO, weekly swaps were eliminated, and flux held within ±10% across variable batches. CIP time per week declined from 10 h to 4 h, yielding ~20% lower OPEX for the filtration step and more stable environmental compliance.

User Guide for Zirconia Porous Filter Tube

The Zirconia Porous Filter Tube requires correct handling and maintenance to achieve its full lifespan and stable performance. This guide provides clear recommendations that help buyers and operators reduce operating costs, minimize downtime, and maintain efficiency across industrial applications.

-

Installation Recommendations

1. Inspect Before Use — Always check for visible cracks or surface defects. Minor damages can lead to leakage and shorten the 3–5 year service life.

2. Proper Orientation — Install the tube according to system design flow direction. Reversed installation may cause >15% flux reduction in the first 100 hours.

3. Secure Fittings — Ensure connectors and seals are tightened evenly. Uneven pressure can create stress points and reduce mechanical strength by up to 20%.

-

Operating Guidelines

1. Maintain pH Range — Operate strictly within pH 2–12 to prevent chemical attack. Exposure beyond this range reduces structural stability by >30%.

2. Control Pressure — Keep transmembrane pressure below the recommended limit. Exceeding pressure may cause flux decline of 25% within 200 hours.

3. Monitor Temperature — Continuous operation should not exceed 600°C. Short-term higher loads risk thermal shock and surface microcracking.

-

Cleaning and Maintenance

1. Scheduled Cleaning — Perform backwash or chemical cleaning after every 500–800 hours of operation. This maintains flux recovery above 90%.

2. Use Approved Agents — Clean only with recommended acids or alkalis. Aggressive solvents can degrade the pore structure, lowering lifetime by up to 40%.

3. Record Performance — Track flux and pressure data during each cycle. A sudden >10% drop may indicate fouling requiring immediate cleaning.

-

Storage and Handling

1. Dry and Cool Storage — Keep tubes in a humidity-controlled environment. High moisture may cause bacterial fouling and increase startup cleaning time by 20%.

2. Protective Packaging — Store in original reinforced cartons with wooden crates. This packaging prevents surface damage during long-distance transport.

3. Avoid Sudden Impact — Handle with care during loading and unloading. A fall from >0.5 m can cause microcracks that are invisible but reduce strength significantly.