Advanced Silicon Carbide Ceramic Designed for Harsh Operating Conditions by ADCERAX®

Engineered to withstand extreme thermal cycling, corrosive media, and mechanical abrasion, our SiC Ceramic solutions maintain stability across high-demand industrial environments.

Built for OEMs requiring consistent performance, long service life, and predictable behavior under thermal, chemical, and abrasive stress profiles.

Partner with ADCERAX® to secure engineered ceramic components tailored to your system’s operational limits.

cuts downtime by 40%

holds shape up to 1600°C

resists pH 0–14 fluids

maintains ±0.02 mm accuracy

What Defines Advanced Silicon Carbide Ceramic Materials

Silicon Carbide Ceramic is a high-strength, high-purity engineered material designed for extreme thermal, chemical, and mechanical environments.

With its dense microstructure and low porosity, it maintains dimensional accuracy under high loads and aggressive operating conditions.

Its excellent thermal stability and resistance to oxidation make SiC Ceramic a preferred choice for kiln furniture, pump components, membrane systems, and wafer-handling devices.

These properties enable long service intervals, predictable performance, and reduced maintenance across a wide range of industrial applications.

achieves >350 MPa bending

handles 1600°C continuous load

insulates >10⁸ Ω·cm reliably

endures pH 0–14 exposure

Key Properties of ADCERAX® Silicon Carbide Ceramics

Silicon Carbide Ceramic materials maintain stability and performance across demanding thermal, chemical, electrical, and mechanical environments.

Thermal Performance of Silicon Carbide Ceramic

| Parameter | Value | Engineering Note |

|---|---|---|

| Maximum Working Temperature | 1400–1600°C | supports continuous high-temp cycles |

| Thermal Conductivity | 25–35 W/m·K | ensures rapid heat dissipation |

| Thermal Expansion (CTE) | 4.0–4.5 ×10⁻⁶/K | prevents thermal distortion |

| Thermal Shock Resistance | ΔT > 250°C | tolerates fast temperature shifts |

Electrical Properties of SiC Ceramic Materials

| Parameter | Value | Engineering Note |

|---|---|---|

| Electrical Resistivity | >10⁸ Ω·cm | stable insulation under heat |

| Dielectric Strength | 8–12 kV/mm | withstands strong electric fields |

| Permittivity (εr) | 9.5–10.5 | suitable for sensor structures |

| Insulation Stability | up to 800°C | retains dielectric reliability |

Chemical Resistance of Silicon Carbide Ceramic

| Parameter | Value | Engineering Note |

|---|---|---|

| Acid Resistance | stable in pH 0 | unaffected by strong acids |

| Alkali Resistance | stable in pH 14 | handles concentrated alkalis |

| Oxidation Resistance | up to 1200°C | suitable for hot oxidizing gas |

| Corrosion Rate | <0.02 mm/year | minimal long-term material loss |

Mechanical Properties of SiC Ceramic Components

| Parameter | Value | Engineering Note |

|---|---|---|

| Flexural Strength | >350 MPa | resists high bending loads |

| Compressive Strength | >2200 MPa | suitable for heavy structural loads |

| Hardness (Vickers) | >22 GPa | excellent wear resistance |

| Elastic Modulus | 380–420 GPa | maintains structural rigidity |

ADCERAX® Product Categories of ADCERAX® Silicon Carbide Ceramics

Each SiC Ceramic form factor is engineered to address specific thermal, mechanical, and chemical challenges across industrial applications.

SiC Tube

High-temperature tubular components for controlled heating environments.

- Maintains strength at 1600°C operation

- Ensures stable gas-flow geometry

- Provides ±0.02 mm tolerance stability

SiC Membrane

Porous filtration structures engineered for corrosive liquid treatment.

- Supports pH 0–14 filtration duty

- Delivers high-flux porous networks

- Maintains >10⁸ Ω·cm insulation

SiC Rod

Solid structural elements for wear and load-bearing applications.

- Withstands >22 GPa hardness

- Offers precise shaft alignment

- Provides 350 MPa bending strength

SiC Plate

Flat sintered plates optimized for kiln loading and high-temperature support.

- Carries loads at 1400°C firing

- Minimizes creep deformation risk

- Supports large-format ware stability

SiC Crucible

High-density melting containers for metals and thermal processing.

- Handles rapid 250°C ΔT cycling

- Resists corrosive molten alloys

- Provides long service intervals

SiC Balls

High-hardness grinding and bearing media for abrasive systems.

- Ensures >22 GPa hardness durability

- Achieves uniform particle grinding

- Reduces wear by measurable margins

SiC Nozzles

Erosion-resistant components for slurry, sandblasting, and fluid jets.

- Resists high-velocity particle impact

- Maintains ±0.02 mm orifice control

- Extends service life significantly

SiC Wafer Handling Parts

Dimensionally stable carriers designed for PV diffusion and thermal cycling.

- Maintains flatness at 1000–1200°C

- Reduces particle shedding rates

- Supports large wafer formats

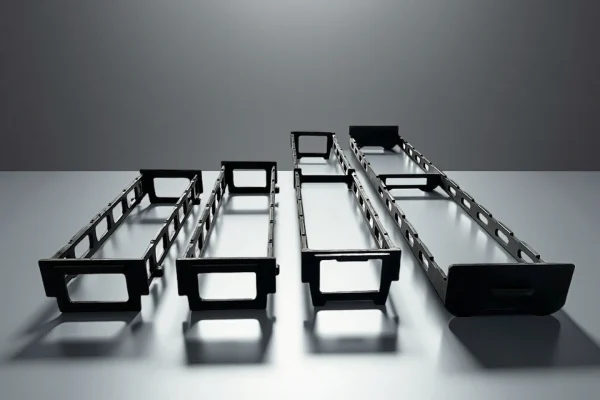

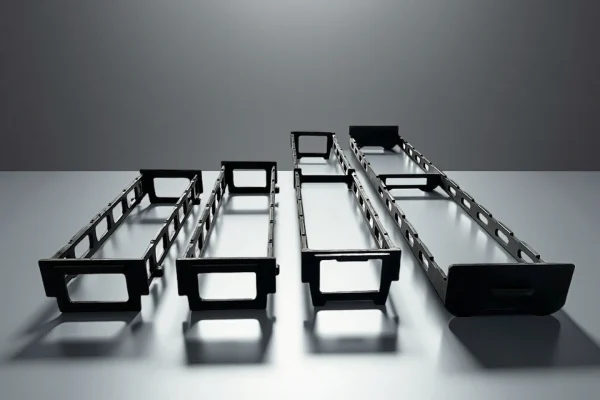

SiC Mechanical Parts

Precision-machined wear and seal surfaces for rotating equipment.

- Maintains >10⁸ Ω·cm insulation

- Provides 350 MPa flexural strength

- Controls seal-face flatness precisely

We maintain a ready stock of standard silicon carbide ceramic products, ensuring 24-hour dispatch for urgent requirements, enabling you to minimize downtime and maintain operational continuity.

Industrial Application Domains of ADCERAX® Silicon Carbide Ceramics

High-Temperature Kiln Systems

These systems rely on SiC materials to maintain dimensional stability under extreme thermal cycling.

- SiC Plate supports 1400°C kiln operations steadily

- SiC Tube provides controlled furnace atmosphere handling

- SiC Crucible endures rapid ΔT and molten alloys

Industrial Water Treatment

SiC membrane technologies deliver stable filtration performance under corrosive, high-solid, and high-temperature industrial water conditions.

- SiC Membrane Tube delivers high-flux MF performance

- Column Membrane Module ensures stable industrial filtration

- Flat Sheet Membrane maintains durability in harsh streams

Chemical Pumps & Mechanical Seals

SiC components ensure long service life and stable sealing performance in corrosive process fluids.

- SiC Mechanical Components reduce seal failure rates

- SiC Rod improves shaft wear resistance performance

- SiC Bearings support shafts in chemical pumps

Photovoltaic Furnace & Wafer Handling

These applications require SiC structures that maintain rigidity and low particle generation during high-temperature diffusion and annealing cycles.

- Cantilever Paddle maintains rigid wafer support

- Boat Bracket ensures stable multi-wafer loading

- Wafer Boat supports uniform PV diffusion heating

Industrial Wear & Structural Support

Broad industrial systems rely on SiC durability for both long-term wear resistance and high-temperature structural support.

- Silicon Carbide Balls ensure consistent grinding efficiency

- Silicon Carbide Beam supports heavy kiln loads

- Silicon Carbide Rod provides reliable load-bearing alignment

ADCERAX® Integrated Solutions for Silicon Carbide Ceramics

One-Stop Processing Services for SiC Components

ADCERAX® one-stop manufacturing workflow ensures that each Silicon Carbide Ceramic component is engineered, processed, and inspected according to industrial operating requirements. The service model minimizes lead-time risks and provides consistent quality across both standard and customized geometries.

supports complex SiC design geometry

ensures dense component structure

removes residual surface particulates

enables stable green body formation

achieves precise dimensional tolerances

validates critical engineering parameters

Technical Competence and Manufacturing Strength

ADCERAX® maintains strong engineering capability supported by stable, traceable production workflows for advanced Silicon Carbide Ceramic components. Our facility integrates controlled forming, precision machining, and multi-stage inspection to support demanding B2B industrial requirements.

| Parameter | Capability | Engineering Note |

|---|---|---|

| Cold/Isostatic Pressing | up to 200 MPa | stable uniform green density |

| Sintering Furnace | 2100°C peak range | supports RBSiC / SSiC sintering |

| Diamond Machining | ±0.02 mm tolerance | precise OD/ID/flatness control |

| CMM Measurement | 3D geometry validation | ensures drawing conformance |

Core Manufacturing Processes of ADCERAX® Silicon Carbide Ceramic Components

Isostatic Pressing for Uniform Green Density

This forming stage ensures consistent density distribution essential for stable Silicon Carbide SiC Ceramic sintering.

Isostatic press applies uniform 200 MPa

Green bodies achieve stable density uniformity

Load configuration minimizes structural defects

High-Temperature Sintering for Structural Consolidation

Controlled furnace cycles enable the ceramic microstructure to reach full strength and dimensional stability.

Sintering furnace reaches controlled 2100°C peak

Temperature ramps maintain microstructural uniformity

Atmosphere control prevents oxidation above 1200°C

Diamond Precision Machining for Tight Tolerance Control

Advanced machining equipment ensures dimensional accuracy required by high-performance industrial SiC applications.

Diamond tools achieve ±0.02 mm tolerances

CNC grinding stabilizes OD and ID geometry

Flatness calibrated through full CMM inspection

Let our advanced capabilities bring your ceramic component vision to life.

Engineering-Driven Silicon Carbide SiC Ceramic Tailoring Solutions

Engineers rely on ADCERAX® to shape Silicon Carbide Ceramic components that meet demanding thermal, mechanical, and chemical loading conditions. Each geometry is developed through controlled forming, high-temperature consolidation, and precision finishing to ensure stable performance in industrial systems.

Contact ADCERAX® engineering team to evaluate your drawing requirements.

±0.02 mm Tolerance

precision surface control

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX for Your SiC Ceramic Needs?

Choosing the right advanced ceramic supplier is crucial for the success of your industrial projects. ADCERAX stands out as a reliable and competitive partner.

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Stringent quality measures from raw material inspection to final product testing.

24-hour response guarantee with dedicated support for global clientele.

Trusted by global customers for advanced ceramic materials and precision components.

Engineering Insights into ADCERAX® Silicon Carbide SiC Ceramic

Silicon Carbide SiC Ceramic maintains structural integrity from 1400°C to 1600°C due to its stable covalent bonding. This allows components to resist deformation during rapid heat cycles. The material’s low thermal expansion prevents dimensional drift in furnace and kiln systems. Its thermal stability directly resolves failure risks in long-cycle high-temperature equipment.

Silicon Carbide SiC Ceramic exhibits a Vickers hardness above 22 GPa, allowing it to resist abrasion from powders, slurries, and high-velocity particles. Its dense microstructure minimizes material loss under repetitive mechanical contact. This property extends service intervals for grinding, sealing, and flow components. Customers experience fewer shutdowns caused by premature wear.

SiC ceramic is chemically inert in both strong acids (pH 0) and strong alkalis (pH 14), enabling stable operation in harsh processing fluids. Its corrosion rate of <0.02 mm/year significantly reduces dimensional degradation. This ensures consistent sealing and pumping performance over extended cycles. It solves the persistent issue of metal components failing due to fluid-induced corrosion.

Silicon Carbide SiC Ceramic tolerates temperature gradients exceeding ΔT 250°C without cracking. Its combination of high strength and moderate thermal conductivity prevents localized stress concentrations. This resistance makes it effective in rapid heating and quenching processes. Users benefit from greater reliability in fluctuating thermal environments.

SiC ceramic delivers flexural strength above 350 MPa and compressive strength exceeding 2200 MPa. This enables stable load-bearing even under elevated temperatures. The material’s stiffness ensures minimal creep deformation during extended service periods. As a result, structural frameworks retain alignment and geometry under demanding mechanical loads.

SiC membrane structures feature controlled pore distribution that supports high flux in UF/MF operations. The material’s hydrophilicity improves fouling resistance, reducing cleaning frequency. Its high mechanical strength withstands pressure fluctuations common in industrial filtration lines. This alleviates issues with polymer membrane deformation and early failure.

Silicon Carbide SiC Ceramic offers electrical resistivity above 10⁸ Ω·cm and dielectric strength between 8–12 kV/mm. These characteristics maintain insulation even under elevated temperature conditions. Its permittivity stability ensures predictable electrical behavior in sensor and heating applications. This reliability addresses breakdown issues often found in oxide-based ceramics.

SiC exhibits extremely low friction coefficients and excellent dimensional stability. These features prevent dry-running damage and reduce sealing face wear. The material’s thermal conductivity quickly dissipates friction heat. Engineers benefit from extended seal life and reduced leakage incidents.

Silicon Carbide SiC Ceramic resists both abrasion and chemical attack, two primary causes of pump shaft failure. Its high stiffness ensures accurate shaft alignment over long service periods. These properties maintain pump efficiency and reduce vibration-related damage. This resolves misalignment and premature wear experienced with metal alternatives.

SiC ceramic maintains rigidity at high temperatures due to its high modulus and oxidation resistance. This prevents sagging or warping during long firing cycles. Its thermal shock stability accommodates rapid loading and unloading conditions. Manufacturers benefit from stable support structures and longer fixture lifespans.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact ADCERAX for Your SiC Ceramic Solutions

Ready to elevate your industrial applications with high-performance Silicon Carbide SiC Ceramic?

Whether you need standard products or custom-engineered solutions, ADCERAX is your trusted partner.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours