Engineering-Grade Silicon Carbide Tube Solutions for High-Temperature Reliability by ADCERAX®

The Silicon Carbide Tube category is designed to enhance operational continuity across demanding thermal and corrosive industrial environments. Each tube delivers consistent dimensional stability and long service duration under elevated temperatures without structural degradation.

Contact ADCERAX® today to request engineering support for selecting the most suitable SiC Ceramic Tube for your application.

1600°C

High-Temp Stability

What Is a Silicon Carbide Tube?

A Silicon Carbide Tube is a high-performance ceramic component designed for thermal, mechanical, and corrosive environments found in industrial systems. The material enables stable operation across repeated heating cycles without compromising dimensional accuracy.

In applications requiring long-term reliability, SiC ceramic tubes provide consistent performance under extreme temperatures and corrosive media. As a non-metallic, dense ceramic material, sic silicon carbide tubes support precise integration into high-temperature process equipment.

Technical Specification of ADCERAX® Silicon Carbide Tube

Technical specifications define performance capability and provide clear reference for integration into industrial thermal and corrosive systems. The following parameters outline typical engineering requirements for Silicon Carbide Tube selection.

| Parameter | Typical Requirement | Parameter | Typical Requirement |

| Material Grades | SSiC / RBSiC / SiSiC | Hardness | > 2200 HV |

| Density | 2.90–3.15 g/cm³ | Porosity | < 17% (RBSiC lower) |

| Maximum Operating Temperature | 1300–1600 °C (grade-dependent) | Straightness Deviation | ≤ 0.5–1.0 mm per meter |

| Thermal Conductivity | 45–120 W/m·K | Wall Thickness Tolerance | ±0.3–0.5 mm |

| Thermal Expansion (25–1000 °C) | 4.0–4.8 ×10⁻⁶/K | Surface Roughness (Ra) | 0.4–1.6 μm (depending on machining) |

| Flexural Strength | 150–350 MPa | Chemical Resistance | Resistant to acids, alkalis, chlorides, bromides |

| Compressive Strength | 1800–2200 MPa | Electrical Resistivity | 0.02–0.1 Ω·cm (varies by grade) |

Product Properties of ADCERAX® Silicon Carbide Tube

Silicon carbide tubes exhibit a combination of thermal, mechanical, and chemical properties suited for complex industrial operations. Their structure allows stable performance in furnaces, kilns, chemical systems, and heat-exchange assemblies.

Thermal Performance

Thermal behavior of sic ceramic tube assemblies supports reliable operation under elevated temperatures.

- High thermal conductivity enables rapid heat transfer and uniform temperature gradients across long tube spans.

- Low thermal expansion minimizes thermal shock damage during repeated heating cycles up to 1300–1600 °C.

Mechanical Strength

Mechanical properties of silicon carbide tubes support long operating cycles under load-bearing conditions.

- High flexural strength maintains straightness and dimensional stability during continuous use in furnace and kiln systems.

- Low creep deformation ensures consistent structural alignment during prolonged exposure to high-temperature mechanical stress.

Chemical Inertness

Chemical performance of each silicon carbide tube enables safe operation in corrosive processing lines.

- Strong resistance to acids, alkalis, halogenated organics, and mixed-acid environments prevents material degradation and contamination.

- Oxidation resistance supports long service life in oxygen-rich or high-velocity combustion atmospheres.

Precision Adaptability

Dimensional stability of sic silicon carbide tubes supports precise compatibility with industrial equipment.

- Controlled tolerances ensure reliable integration into thermocouple assemblies, kiln structures, chemical reactors, and heat-exchange units.

- Multiple geometric configurations—closed-end, multi-bore, flanged, threaded—allow adaptation to non-standard engineering layouts.

ADCERAX® Silicon Carbide Tube Product Range

It shields thermocouples and sensors in molten-metal and corrosive atmospheres.

- Thermal shock resistance 1600°C rating

- Dense structure resisting infiltration

- Low expansion 4.0×10⁻⁶/K

They support kiln cars under continuous high-temperature mechanical loading.

- High bending strength >250 MPa

- Stable alignment 1380°C loading

- Rapid heat conduction 45–120 W/m·K

It ensures stable transport of ceramic and powder materials in roller-hearth kilns.

- Thermal cycling tolerance 20–1380°C

- Alkali resistance for LFP cathodes

- Straightness deviation ≤0.5 mm

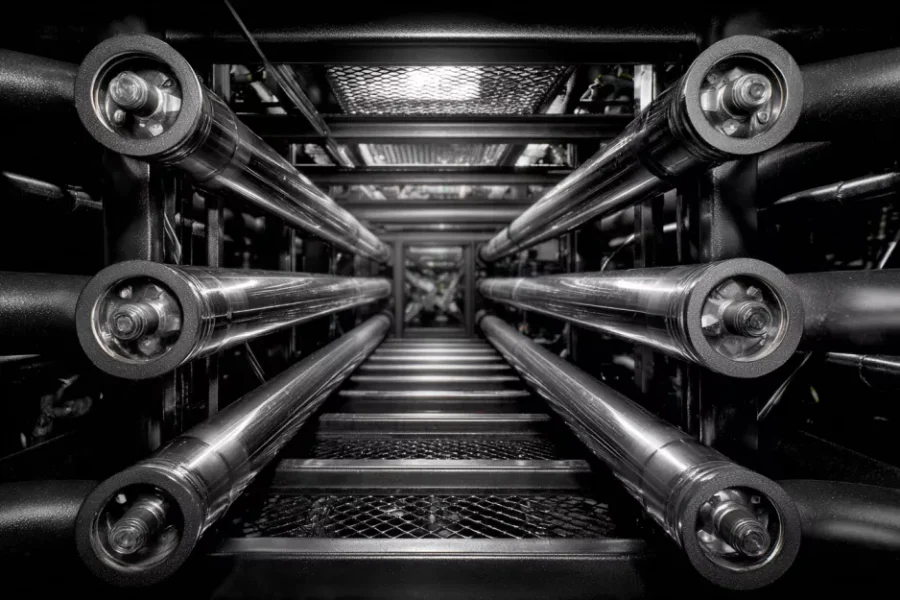

They handle corrosive chemical media and high-heat transfer loads in process industries.

- Corrosion resistance in mixed acids

- Heat load tolerance up to 1600°C

- Low porosity <17% structure

This exchanger structure withstands aggressive chemical, thermal, and particulate conditions.

- Thermal conductivity 3–5× metals

- Strength retention under gradients

- Low expansion structural control

It delivers rapid temperature response for industrial high-heat electric systems.

- Operating temperature up to 1600°C

- Service duration 2000+ hours

- Fast heating response time

Looking for the Right Silicon Carbide Tube for Your Project?

Precise component selection is critical for furnace systems, chemical equipment, and high-temperature processing lines.

Each Silicon Carbide Tube category supports different thermal, structural, and corrosion-resistant requirements essential to industrial operations.

Get in touch with ADCERAX® to obtain a detailed recommendation for your SiC Ceramic Tube requirements.

Key Silicon Carbide Tube Applications Across Industrial Systems

The Silicon Carbide Tube category supports a broad range of high-temperature, corrosive, and load-bearing engineering environments.

Its stability, material density, and thermal behavior enable reliable operation in systems requiring precise temperature control, extended lifecycle performance, and contamination-free processing.

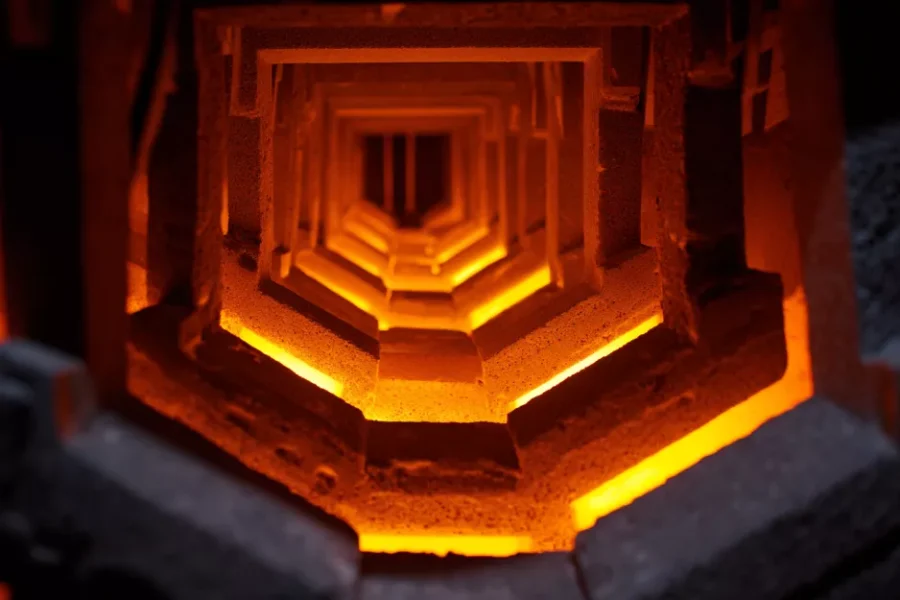

Industrial Furnace and Thermal-Processing Systems

Silicon carbide tube assemblies used in furnace thermal systems provide stable performance under continuously fluctuating temperatures. The structural integrity of silicon carbide tube components ensures reliable thermal cycling for long-duration industrial firing environments.

- Thermal cycling tolerance enabling 20–1380°C operational ranges

- Sensor lifespan extended 5–10× under molten-metal exposure

- Heat distribution improved using 45–120 W/m·K conductivity

Chemical Processing, Corrosive Media, and Acid Handling

Sic ceramic tube structures applied in corrosive chemical process equipment maintain mechanical stability under aggressive acid and alkali exposure. The material behavior of silicon carbide tubes allows uninterrupted operation where metal or graphite components typically fail prematurely.

- Replacement frequency reduced 60–80% in acid reactors

- Mechanical integrity retained across 1300–1600°C temperature loads

- Porosity below 17% preventing infiltration and media absorption

Technical Ceramics, Electronic Ceramics, and Advanced Material Production

Silicon carbide tube configurations used in advanced materials production equipment support sintering, calcination, and controlled cooling requirements. The thermal and dimensional stability of silicon carbide tubes enables predictable part geometry during continuous high-temperature processing.

- Dimensional stability improved 25–35% in ceramic firing

- Geometric integrity maintained through >500 rapid cooling cycles

- Flatness preserved under 1380°C long-duration structural loading

Metallurgy, Smelting, and Molten-Metal Measurement Systems

SiC ceramic tube protection structures incorporated in molten-metal measurement systems ensure consistent thermal shielding under severe immersion conditions. The high-temperature resilience of silicon carbide tubes safeguards measurement accuracy during repeated contact with liquid aluminum, copper, and alloy melts.

- Sensor burnout reduced 70% during 700–1200°C immersion

- Thermal expansion controlled at 4.0–4.8×10⁻⁶/K baseline levels

- Structural strength maintained under 150–350 MPa turbulent flow

One-Stop Engineering & Supply Capability by ADCERAX®

One-Stop Silicon Carbide Tube Supplier for Integrated Industrial Requirements

A complete silicon carbide tube supply chain is supported through coordinated engineering, machining, inspection, and export logistics under the unified structure of ADCERAX®.

A consolidated workflow reduces project delays, minimizes compatibility issues, and ensures stable performance across thermal, chemical, and material-processing environments.

-

End-to-End Engineering Coordination:

Consolidated engineering control reduces tolerance deviation and prevents assembly inconsistency. -

Integrated Manufacturing & Quality Control:

Unified forming and inspection keep long silicon carbide tube bodies within <1.0 mm straightness deviation. -

Stable Lead-Time & Supply Continuity:

Synchronized production scheduling avoids the 8–10 week delivery delays common in fragmented supply chains. -

High-Reliability Components for Harsh Environments:

Integrated material screening reduces failure risk and prevents furnace downtime losses.

Advanced Manufacturing Capability for Industrial-Grade Silicon Carbide Tube Production

The production system of ADCERAX® integrates high-precision forming, sintering, and inspection technologies to support consistent manufacturing of silicon carbide tube components. A factory-level workflow ensures reliable batch repeatability and dimensional stability across demanding thermal, chemical, and mechanical applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Category | Capability Description | ||

| High-Precision Forming Systems | Isostatic pressing up to 250 MPa, supporting long-body SiC tubes with wall thickness stability within ±0.3–0.5 mm. | ||

| Automated Sintering & Reaction Furnaces | RBSiC reaction furnaces handling 3,000+ tubes/month; SSiC sintering lines achieving peak stability at 2,000 °C. | ||

| CNC Machining & End-Face Processing | Multi-axis CNC centers with machining tolerance control of ±0.02 mm for interfaces, grooves, threads, and flange seats. | ||

| Dimensional Metrology & Inspection | CMM measurement accuracy of ±0.005 mm, straightness verification for long tubes ensuring deviation below 1.0 mm/m. | ||

| Material Reliability & Microstructure Testing | Batch density monitoring achieving RBSiC ≥ 2.95 g/cm³; porosity consistently maintained below 17% for industrial applications. | ||

customized silicon carbide tubes supplier

We specialize in customizing silicon carbide tube with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

FAQs About Silicon Carbide Tube

A Silicon Carbide Tube maintains structural integrity at temperatures up to 1,500–1,600 °C, while metallic alloys often soften or creep above 1,000 °C. Its low thermal expansion reduces thermal-shock-induced cracking during rapid heating and cooling. The oxidation layer remains stable, preventing scaling and contamination. These features extend service life by 5–10× compared to stainless steel or nickel alloys.

A Silicon Carbide Tube shields sensors from molten metal, carburizing atmospheres, and high-velocity particulates. The dense microstructure eliminates chemical interaction that would distort readings over long cycles. Stable thermal conductivity supports accurate response times. As a result, calibration drift is significantly reduced across repeated thermal cycles.

A Silicon Carbide Tube offers exceptional chemical inertness in chloride-, bromide-, and acid-rich conditions. The covalent bonding structure prevents ion diffusion and surface degradation. Unlike graphite, the tube does not absorb liquid or develop microcracks. This enables long service periods in acid coolers, corrosive reactors, and flue-gas systems.

A Silicon Carbide Tube features a low CTE (4.0–4.5×10⁻⁶/K) and high thermal conductivity, enabling rapid heat dissipation. This prevents crack propagation when exposed to sudden temperature jumps. Thermal shock cycles exceeding ΔT 250–300 °C are commonly tolerated. This stability is critical for roller kilns, high-speed firing lines, and rapid heating furnaces.

The straightness of a Silicon Carbide Tube depends on forming pressure, uniform sintering, and precise machining. Reaction-bonded microstructures minimize warping during firing. Dimensional inspection typically maintains deviation below 1.0 mm per meter. This consistency is essential for roller systems, heat exchanger bundles, and long process tubes.

Premature failure occurs when porous material grades are used for high-velocity corrosive gases. A dense Silicon Carbide Tube prevents erosion of internal channels. Microstructure uniformity reduces pitting and oxidation layer peeling. Long-term degradation is avoided when gas velocity and chemical concentration are within SiC thresholds.

A Silicon Carbide Tube provides flexural strength in the range of 150–350 MPa, depending on grade and geometry. This strength allows the tube to support furnace loads without creep deformation. High stiffness ensures minimal deflection during long-span support applications. Mechanical reliability contributes to long operational cycles in high-load kilns.

Thermal conductivity of a Silicon Carbide Tube (typically 45–120 W/m·K) depends on purity, porosity, and sintering technique. Dense RBSiC structures transfer heat efficiently through continuous SiC grain pathways. High conductivity reduces temperature gradients in process chambers. Improved heat uniformity shortens firing or reaction cycles.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Refractory SiC Ceramic Tubes

Looking for a reliable silicon carbide tubes supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours