Alumina crucibles are essential tools in high-temperature laboratory and industrial environments. However, incorrect selection often results in sample loss, contamination, or premature failure, which directly undermines experimental reliability.

This article presents an application-driven framework for selecting alumina crucibles. Instead of classifying products by appearance alone, it explains how geometry, height, lid configuration, and purity levels determine real-world thermal performance and operational stability.

To ensure continuity, the guide progresses from fundamental selection logic to application-specific geometry matching, thereby helping engineers and procurement professionals systematically reduce trial-and-error risks.

Before comparing individual crucible designs, it is necessary to clarify why alumina crucible types must be interpreted through application demands rather than generic catalog classification.

Understanding Alumina Crucible Types: Why Application Comes First

Alumina crucible types are practical responses to thermal, chemical, and mechanical constraints encountered during high-temperature processes. Therefore, application conditions should always be evaluated before shape, height, or purity are compared.

In laboratory and industrial operations, crucible failure rarely stems from insufficient temperature ratings alone. Instead, mismatches between geometry, openness, and sample behavior frequently disrupt heat flow and handling stability. Consequently, application mapping must precede product selection to avoid structural or procedural conflicts.

Moreover, when alumina crucibles are evaluated without reference to their intended use, even high-purity variants may underperform. For this reason, an application-first approach consistently delivers more reliable and repeatable experimental outcomes.

-

Shape, height, and structure influence thermal behavior directly.

Crucible geometry governs heat distribution, thermal gradients, and stress concentration during heating cycles. Flat-bottom designs distribute loads evenly, whereas pointed or curved bases intentionally localize heat, which alters reaction dynamics.

In practice, laboratories operating above 1000 °C often encounter cracking or deformation when geometry-induced stress is ignored, with observed stress concentration increases exceeding 25% during rapid thermal cycling.

Therefore, structure should be considered part of the thermal system rather than a passive container. -

Improper crucible selection leads to recurring operational failures.

Selection errors typically appear as spillage, contamination, or premature cracking, which are rarely caused by alumina purity alone. Low-form crucibles used in volatile ashing may lose over 10% of sample mass, whereas overly tall crucibles in tube furnaces can obstruct airflow and create uneven heating.

Consequently, both under-design and over-design introduce measurable risks.

In many cases, switching to a more suitable crucible type resolves these issues without changing furnace parameters. -

Modern workflows increasingly require application-specific crucibles.

Historically, cylindrical alumina crucibles were treated as universal solutions. However, as experimental precision requirements tighten, laboratories increasingly adopt trapezoid, boat-type, or point-bottom designs to control heat flow and sample handling.

Facilities that transitioned to application-specific crucibles have reported reductions of up to 30% in repeated experiments due to improved consistency.

Thus, crucible types should be understood as functional tools rather than interchangeable vessels.

Application-Driven Selection Logic for Alumina Crucibles

| Selection Dimension | Key Options | Typical Operating Conditions | Primary Benefits | Common Risks if Misapplied | Recommended Application Scenarios |

|---|---|---|---|---|---|

| Crucible Shape | Cylindrical | 800–1200 °C, moderate heating rates (3–10 °C/min) | Uniform radial heating, easy handling | Vertical thermal gradients >15% with volatile samples | Routine heating, gravimetric analysis, general laboratory use |

| Crucible Shape | Rectangular | Flat furnace platforms, layered samples | Maximized surface area, orderly sample layout | Stress concentration at corners, crack risk ↑ ~20% | Thin-layer treatments, chamber furnaces |

| Crucible Shape | Conical | ≥1100 °C melting and transfer operations | Controlled pouring, reduced wall adhesion | Local stress from uneven heating | Melting tests, residue transfer experiments |

| Crucible Shape | Trapezoid | ≥900 °C ashing and pre-treatment | Reduced splashing, improved visibility, residue removal | Restricted airflow in narrow furnaces | Ash determination, chamber furnaces |

| Crucible Shape | Point Bottom | Small samples <5 g, rapid activation | Heat concentration ↑ >18%, predictable reaction onset | Apex cracking at high ramp rates | Kinetic studies, small-scale reactions |

| Crucible Shape | Flat Bottom Boat | Tube furnaces, 1000–1300 °C | Positional stability, temperature uniformity ±3% | Edge stress during rapid ramps | Batch processing, comparative tube furnace studies |

| Crucible Shape | Round Bottom Boat | High-temperature or rapid cycling | Stress concentration ↓ up to 22%, improved heat flow | Requires compatible supports | Advanced gas-phase reactions |

| Height Configuration | High Form | Volatile or foaming samples ≥900 °C | Splash prevention, mass loss ↓ 10–15% | Slower heat equilibration | Ashing, combustion analysis |

| Height Configuration | Low Form | Stable samples, high throughput | Faster heating, time-to-target ↓ 8–12% | Increased splash risk | Calcination, routine pre-heating |

| Lid Configuration | With Lid | Atmosphere-sensitive processes | Volatilization control, mass deviation ↓ 12–18% | Slower reaction kinetics | Ashing, contamination-sensitive tests |

| Lid Configuration | Without Lid | Gas-exchange-dependent reactions | Faster heat transfer, efficiency ↑ ~10% | Higher contamination or loss risk | Oxidation, open-air calcination |

| Alumina Purity | ≥99.7% Al₂O₃ | ≥1200 °C, trace-sensitive R&D | Impurity transfer ↓ >30%, chemical stability | Higher brittleness, careful handling | Advanced materials research |

| Alumina Purity | 95–99% Al₂O₃ | 800–1100 °C routine testing | Balanced durability and performance | Background interference in sensitive tests | Teaching labs, quality control |

| Application-Based Selection | Integrated geometry + height + lid + purity | Defined by sample behavior and furnace type | Reduced variability, fewer repeat tests | Over-reliance on single parameter | Ashing, tube furnace treatment, small-sample melting |

| Customization Threshold | Non-standard geometry | Atypical furnaces, persistent failures | Stress reduction, service life extension | Higher upfront design effort | Pilot-scale trials, specialized equipment |

| Customization Strategy | Direct manufacturer collaboration | Real operating conditions defined | Predictable performance, fewer interruptions | Poor specs lead to iteration | Long-term reliable laboratory or production use |

Before selecting dimensions or material grades, crucible geometry must be evaluated first, since shape directly determines heat transfer behavior, stress distribution, and sample stability under high-temperature conditions.

Crucible Shape Categories: Matching Geometry to Thermal Tasks

Crucible shape is the most influential variable in alumina crucible performance, because geometry dictates how heat enters, circulates, and exits the sample system. Consequently, shape selection often determines whether a process remains stable or repeatedly fails.

In practical laboratory operations, shape-related mismatches account for a significant proportion of crucible damage and data inconsistency. Therefore, each geometry should be assessed according to its thermal task before height, lid configuration, or purity level is considered.

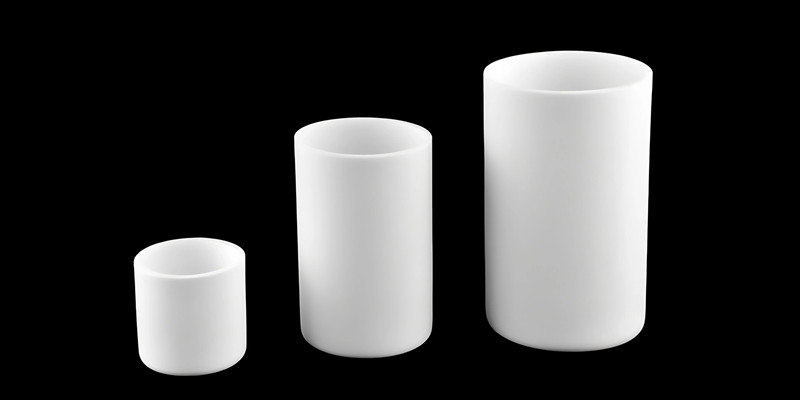

Cylindrical Alumina Crucibles

Cylindrical alumina crucibles are widely regarded as the baseline choice for routine heating and general laboratory work. Their rotational symmetry creates predictable thermal behavior that suits a broad range of standard experiments.

In daily laboratory practice, these crucibles are frequently observed in muffle furnaces operating between 800 °C and 1200 °C, where heating rates typically range from 3–10 °C/min. Moreover, the straight vertical walls simplify sample loading and residue removal, which reduces handling variability during repetitive workflows. As a result, cylindrical designs are often chosen for ash content1 determination, gravimetric analysis2, and routine material conditioning tasks.

However, experienced users often note that cylindrical crucibles can develop vertical temperature gradients exceeding 15% when volatile samples or uneven particle distributions are present. Therefore, while cylindrical alumina crucibles are versatile, they should be treated as reliable starting points rather than universal solutions.

Rectangular Alumina Crucibles

Rectangular alumina crucibles are typically selected when surface area utilization and geometric alignment with flat furnace platforms are critical. Their straight edges and flat bases support orderly sample arrangement and efficient space usage.

In applications where samples must be spread in thin layers, such as coating studies or distributed thermal treatments, rectangular crucibles improve exposure uniformity and reduce stacking-related variability. Additionally, operators often find that rectangular geometry simplifies placement on furnace plates and trays, which enhances repeatability across batches. Consequently, these crucibles are commonly used in chamber furnaces and laboratory ovens.

Nevertheless, laboratory experience shows that sharp internal corners may concentrate thermal stress during rapid heating, increasing crack initiation risk by approximately 20% compared with rounded geometries. Accordingly, rectangular alumina crucibles perform best under controlled ramp rates and steady-state heating conditions.

Conical Alumina Crucibles

Conical alumina crucibles are designed with tapered walls that guide material flow toward the bottom apex. This geometry is especially useful in experiments involving melting, pouring, or residue transfer.

During high-temperature melting above 1100 °C, conical designs encourage molten material to collect centrally, which improves transfer efficiency and minimizes material adherence to sidewalls. Furthermore, operators often report easier post-process cleaning due to reduced residue spread along the walls. As a result, conical crucibles are frequently chosen for metallurgical tests and controlled discharge experiments.

However, uneven wall thickness along the taper can introduce localized stress zones if heating is non-uniform. Therefore, conical alumina crucibles are best applied in processes where controlled discharge is prioritized over long static holding periods.

Trapezoid Alumina Crucibles

Trapezoid alumina crucibles feature wide openings combined with narrower bases, a geometry that directly influences sample behavior during heating. This shape balances accessibility, visibility, and bottom stability in demanding workflows.

In ashing and pre-treatment operations above 900 °C, laboratory technicians often observe reduced splashing and improved visual monitoring when trapezoid crucibles are used. For example, facilities conducting routine ash determination report material loss reductions approaching 20% compared with straight-wall containers. Moreover, the tapered profile facilitates residue removal after cooling, which shortens turnaround time between tests.

However, sufficient furnace clearance is required to accommodate the wider upper section and maintain airflow. Consequently, trapezoid alumina crucibles perform most effectively in chamber furnaces3 rather than confined tube furnace4 environments.

Point Bottom Alumina Crucibles

Point bottom alumina crucibles are engineered to concentrate heat at a single focal point at the base. This design is particularly advantageous for small-volume reactions requiring rapid thermal activation.

In experiments involving sample masses below 5 g, researchers often find that point-bottom designs accelerate melting or reaction onset. Specifically, localized thermal concentration at the apex can increase heating efficiency by more than 18% under identical furnace conditions. As a result, reaction timing becomes more predictable, which benefits kinetic studies and small-scale synthesis.

Nevertheless, the same concentration effect increases thermal stress at the tip. Therefore, experienced operators typically limit heating rates to below 5 °C/min to prevent cracking, ensuring reliable performance when precision is required.

Flat Bottomed Boat Alumina Crucibles

Flat bottomed boat alumina crucibles are optimized for horizontal placement, making them particularly suitable for tube furnace applications. Their flat bases provide consistent contact with furnace supports throughout thermal cycling.

Operational data from tube furnace use show that flat-bottom boats maintain temperature uniformity within ±3% across their length at operating temperatures of 1000–1300 °C. Additionally, stable base contact reduces tipping risks during loading and unloading, which enhances operator safety and batch consistency. Consequently, these crucibles are widely used for comparative studies and batch processing.

However, users often observe higher edge stress during rapid heating due to flat contact surfaces. Therefore, gradual ramping remains essential to preserve structural integrity and prolong service life.

Round Bottomed Boat Alumina Crucibles

Round bottomed boat alumina crucibles incorporate curved bases that redistribute contact points and thermal stress. This geometry improves heat circulation and reduces localized stress concentrations.

Compared with flat-bottom boats, round-bottom designs demonstrate up to 22% lower stress concentration at support interfaces. Furthermore, enhanced airflow beneath the curved base promotes more uniform thermal exposure during gas-phase reactions. As a result, these crucibles are frequently selected for high-temperature or rapid-cycling research applications.

However, compatible support fixtures are required to prevent rolling during operation. Therefore, successful use of round bottomed boat alumina crucibles depends on coordinated furnace hardware and careful placement.

Before evaluating lid configuration or material purity, crucible height must be considered carefully, because vertical geometry directly affects vapor control, heat exposure, and sample stability during high-temperature processing.

High Form vs Low Form Alumina Crucibles: Height-Driven Performance Differences

Crucible height is often underestimated, yet it plays a decisive role in how samples behave under thermal load. Consequently, selecting between high form and low form alumina crucibles should be based on volatility, reaction dynamics, and handling frequency rather than habit.

In laboratory practice, height-related mismatches frequently lead to splashing losses, uneven heating, or inefficient processing. Therefore, understanding how crucible height interacts with sample behavior is essential before finalizing a crucible type.

High Form Alumina Crucibles: Containing Volatile Samples and Preventing Splashing

High form alumina crucibles are designed with taller walls that provide increased containment during heating. This structure is particularly valuable when samples release gases, vapors, or molten phases at elevated temperatures.

In ash determination, combustion analysis, and decomposition tests above 900 °C, operators often observe that high form crucibles significantly reduce material ejection. For instance, laboratories processing organic or hydrated samples report splash-related mass losses reduced by 10–15% when switching from low form to high form designs. Moreover, the additional wall height improves containment during sudden gas release events, which stabilizes test results across repeated runs.

However, the taller geometry can slightly reduce heat transfer efficiency to the upper sample layers. Therefore, high form alumina crucibles are best applied when containment and data integrity are prioritized over rapid thermal equilibration.

Low Form Alumina Crucibles: Faster Heat Transfer and Operational Efficiency

Low form alumina crucibles feature shorter walls that expose samples more directly to radiant and convective heat. This geometry supports faster temperature equilibration and easier sample access during processing.

In routine calcination and pre-heating workflows, laboratories frequently select low form crucibles to shorten heating cycles. Empirical observations indicate that low form designs can reduce time-to-target temperature by approximately 8–12% compared with high form alternatives under identical furnace settings. Additionally, shorter walls simplify loading, unloading, and inspection, which improves efficiency during high-throughput testing.

Nevertheless, reduced wall height increases the risk of splashing or sample loss when volatile reactions occur. Consequently, low form alumina crucibles are most effective for stable, non-foaming samples where speed and accessibility outweigh containment concerns.

Before assessing purity grades or customization options, lid configuration must be evaluated, because openness directly affects atmosphere exchange, volatilization behavior, and sample integrity during thermal treatment.

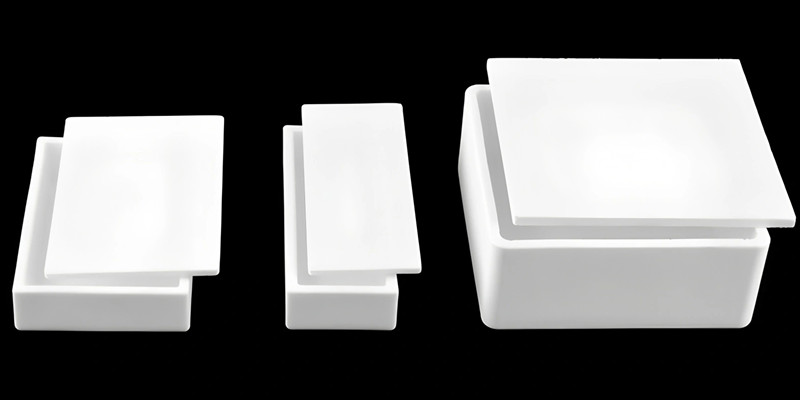

With Lid or Without Lid: Atmosphere Control and Sample Protection

The presence or absence of a lid fundamentally changes how an alumina crucible interacts with its surrounding environment. Therefore, lid selection should be driven by atmosphere sensitivity, volatility, and experimental control requirements rather than convenience.

In practical laboratory workflows, improper lid choice often results in mass loss, contamination, or inconsistent results. Consequently, understanding when to enclose or expose a sample is critical for achieving reproducible outcomes.

Alumina Crucibles with Lid: When Sample Integrity Is Critical

Alumina crucibles with lids are designed to partially isolate samples from the furnace atmosphere. This configuration is particularly important when volatilization, oxidation, or contamination must be controlled.

In combustion and ashing experiments above 800 °C, laboratories frequently observe improved mass consistency when lidded crucibles are used. For example, controlled trials indicate that covered crucibles can reduce volatile-driven mass deviation by 12–18% compared with open designs under identical heating programs. Moreover, the lid acts as a physical barrier against airborne contaminants, which improves data repeatability in shared furnace environments.

However, lids also restrict gas exchange and may slow reaction kinetics in processes requiring active oxygen flow. Therefore, alumina crucibles with lids are best applied when sample preservation outweighs reaction speed.

Open Alumina Crucibles: Accessibility and Process Efficiency

Open alumina crucibles allow unrestricted exposure to the furnace atmosphere, which supports rapid heat transfer and efficient gas interaction. This configuration is favored when reaction completeness and operational speed are priorities.

In routine calcination and oxidation processes, operators often select open crucibles to facilitate faster temperature equilibration. Observations show that open designs can shorten effective reaction time by approximately 10% due to enhanced convection and radiant heat access. Additionally, the absence of a lid simplifies handling during frequent sample inspection or staged processing.

Nevertheless, open crucibles offer minimal protection against splashing or volatilization. Consequently, they should be reserved for stable samples where atmosphere exposure is intentional and controlled.

Before finalizing crucible geometry and configuration, alumina purity must be examined, because material composition directly influences chemical stability, contamination risk, and long-term performance at elevated temperatures.

Alumina Purity Grades: Application Boundaries and Material Considerations

Alumina purity is not merely a specification number but a functional boundary that defines where a crucible can be reliably used. Consequently, purity selection should be aligned with chemical sensitivity, operating temperature, and data accuracy requirements.

In laboratory practice, inappropriate purity choices often lead to subtle yet persistent issues such as sample contamination or gradual crucible degradation. Therefore, understanding how different purity grades behave under real conditions is essential for consistent results.

High-Purity Alumina Crucibles (≥99.7% Al₂O₃): For Sensitive and High-Precision R&D

High-purity alumina crucibles are engineered to minimize chemical interaction between the container and the sample. This characteristic is critical in research environments where trace contamination can invalidate results.

In advanced material synthesis and catalyst development above 1200 °C, researchers frequently report improved compositional stability when using ≥99.7% Al₂O₃ crucibles. Experimental observations show that impurity transfer into samples can be reduced by more than 30% compared with lower-purity alternatives under prolonged heat exposure. Moreover, higher purity alumina exhibits improved grain stability, which enhances resistance to chemical attack over repeated thermal cycles.

However, high-purity crucibles typically require more controlled handling to avoid mechanical damage. Therefore, they are best reserved for applications where analytical precision outweighs handling convenience.

Standard Alumina Crucibles (95–99% Al₂O₃): Reliable Choices for Routine Laboratory Use

Standard alumina crucibles with 95–99% Al₂O₃ content provide a balanced combination of performance and durability. This range is widely adopted for routine laboratory and industrial testing.

In teaching laboratories and quality-control environments operating between 800 °C and 1100 °C, standard-purity crucibles consistently demonstrate stable behavior. Field experience indicates that these crucibles maintain structural integrity across hundreds of heating cycles, while keeping impurity influence within acceptable limits for non-trace-sensitive analyses. Additionally, their slightly higher tolerance to thermal shock improves survivability during frequent handling.

Nevertheless, when experiments involve highly reactive compounds or strict compositional control, standard alumina may introduce measurable background interference. Consequently, these crucibles are most suitable where robustness and repeatability are prioritized over ultra-high analytical sensitivity.

After geometry, height, lid configuration, and purity have been evaluated individually, the final step is to integrate these variables into application-specific selection decisions.

Application-Based Selection Guide: Choosing the Right Alumina Crucible Type

Application-based selection connects crucible design features directly to real operating conditions. Therefore, the most reliable alumina crucible choice emerges only when thermal task, sample behavior, and operational constraints are considered together.

In practice, laboratories that follow application-driven selection logic consistently reduce experimental variability and crucible replacement frequency. Consequently, this section consolidates typical use cases into practical selection pathways.

Ashing and Combustion Analysis Applications

Ashing5 and combustion processes impose simultaneous demands on containment, thermal stability, and mass consistency. Accordingly, crucible selection in these applications must prioritize splash control and volatilization management.

In routine ash determination above 800 °C, laboratories frequently observe that high form alumina crucibles with lids deliver the most stable results. Empirical data show that combining taller walls with partial enclosure can reduce sample mass deviation by 12–20% compared with low form open crucibles. Moreover, trapezoid or cylindrical shapes with sufficient wall height improve visibility while maintaining containment during gas release phases.

However, excessive enclosure may slow oxidation reactions. Therefore, ashing applications benefit from crucibles that balance containment with controlled atmosphere exchange rather than fully sealed designs.

Tube Furnace Heat Treatment Processes

Tube furnace environments introduce directional heat flow and controlled gas atmospheres, which strongly influence crucible behavior. Consequently, horizontal stability and gas accessibility become primary selection factors.

In material synthesis and surface treatment processes conducted between 900 °C and 1300 °C, flat bottomed boat alumina crucibles are commonly selected for their positional stability. Measurements indicate that these boats maintain temperature uniformity within ±3% along their length under steady gas flow. Additionally, open boat designs allow efficient atmosphere exchange, which is essential for oxidation or reduction reactions.

Nevertheless, in rapid thermal cycling or high-temperature regimes, round bottomed boat alumina crucibles may outperform flat-bottom designs by reducing stress concentration. Therefore, tube furnace selection should consider both thermal cycling intensity and furnace support geometry.

Small-Sample Melting and Reaction Studies

Small-sample melting and reaction studies demand precise thermal control and rapid response. In such cases, crucible geometry plays a decisive role in reaction initiation and repeatability.

For sample masses below 5 g, point bottom alumina crucibles are frequently chosen to concentrate heat and accelerate melting. Experimental comparisons show that reaction onset can occur up to 18% faster than with flat-bottom crucibles under identical heating conditions. Furthermore, localized heating improves reproducibility in kinetic measurements.

However, concentrated thermal stress requires conservative ramp rates to avoid cracking. Consequently, small-sample studies benefit from careful coordination between crucible geometry and furnace programming rather than aggressive heating alone.

When standard crucible geometries no longer align with furnace constraints or process realities, customization becomes a logical extension of application-driven selection rather than an exceptional measure.

Beyond Standard Types: When Custom Alumina Crucibles Become Necessary

Standard alumina crucible types are engineered to satisfy the majority of laboratory use cases. However, in real operating environments, even small geometric mismatches can introduce disproportionate risks under high-temperature conditions. Consequently, customization should be considered whenever recurring issues persist despite correct selection and handling of standard products.

In practice, laboratories often discover that performance limitations are imposed not by material purity, but by incompatibility between crucible geometry and equipment layout. Therefore, recognizing the boundary between “acceptable standard” and “necessary customization” is critical for maintaining long-term process reliability.

-

Equipment-driven geometric constraints

Non-standard crucible requirements frequently originate from furnace design rather than sample characteristics. For example, atypical chamber dimensions, custom support fixtures, or restricted airflow paths may prevent standard crucible footprints from seating evenly.

In pilot-scale or semi-industrial trials, researchers often observe that standard crucibles contact furnace walls or supports unevenly, which increases localized thermal stress and accelerates wear. As a result, service life can be reduced significantly even when temperature limits are respected.

Under these circumstances, geometry adjustments become a functional necessity rather than a design preference. -

Sample-driven stability and positioning challenges

Certain samples, such as elongated pellets, layered substrates, or asymmetrical test pieces, cannot be stabilized effectively within standard crucible interiors. During heating, uncontrolled movement may introduce uneven exposure or mechanical damage.

Laboratory experience shows that tailored internal dimensions can prevent sample shifting, thereby improving repeatability and reducing handling-related variability. Consequently, custom internal geometry often resolves issues that cannot be addressed through operational adjustments alone.

This illustrates why customization is sometimes the most direct path to process stability. -

Persistent failures despite correct standard usage

Repeated cracking, uneven heating, or handling instability that persists across multiple standard crucible types signals a systemic mismatch rather than operator error. In such cases, continued reliance on catalog items typically leads to repeated trial-and-error cycles.

By contrast, targeted customization addresses the root cause by aligning geometry with actual operating conditions. Therefore, customization becomes essential when standard options fail to eliminate recurring inconsistencies.

This transition marks a shift from reactive troubleshooting to proactive engineering control.

Reliable high-temperature performance depends not only on correct selection but also on effective translation of application knowledge into manufacturable geometry.

Engineering Reliability Through Direct Customization with ADCERAX

Direct collaboration with a manufacturing source allows application requirements to be converted accurately into crucible geometry and material choices. As a result, customization functions as a method of risk reduction rather than a last-resort solution.

In engineering practice, seemingly minor adjustments—such as modifying wall angle, base curvature, or overall height—can significantly reduce thermal stress and improve handling stability. Facilities that move from off-the-shelf selection to direct customization frequently report extended service life and fewer unplanned interruptions. Therefore, working directly with a manufacturer enables these refinements to be implemented efficiently and consistently.

By aligning real application conditions with manufacturing expertise, customized alumina crucibles can deliver predictable performance across repeated thermal cycles. Ultimately, this coordination supports long-term experimental reliability and production continuity without forcing procedural compromises.

Conclusion: Selecting Alumina Crucibles by Application, Not by Habit

Ultimately, alumina crucibles perform reliably only when their design parameters align with real thermal tasks. In conclusion, application-driven selection consistently reduces failure risk, improves data repeatability, and extends crucible service life.

When standard options no longer provide sufficient reliability, direct engineering collaboration becomes the most effective path forward.

If your application involves non-standard furnaces, sensitive materials, or recurring crucible failures, direct customization with ADCERAX enables geometry and material choices to be engineered around real operating conditions rather than assumptions.

Frequently Asked Questions

Does crucible shape significantly affect thermal shock resistance?

Yes, crucible shape directly influences stress distribution during rapid heating and cooling. For example, curved or rounded geometries typically reduce localized stress concentration compared with sharp corners or flat interfaces, thereby improving thermal shock resistance.

How should I choose between flat bottom and round bottom boat alumina crucibles?

Flat bottom boats provide higher positional stability in tube furnaces, while round bottom boats reduce thermal stress and improve heat circulation. Therefore, the choice depends on whether mechanical stability or thermal uniformity is the dominant requirement.

When is a lid necessary for alumina crucibles?

A lid is recommended when volatilization, oxidation control, or contamination prevention is critical. In contrast, open crucibles are preferred when rapid heat transfer and atmosphere exchange are required.

Can alumina purity influence experimental contamination?

Yes, higher alumina purity significantly reduces the risk of impurity transfer into samples, especially at temperatures above 1200 °C. Consequently, high-purity crucibles are essential for trace-sensitive and high-precision research applications.

References:

-

Discover the importance and methods of ash content determination to improve accuracy in material analysis and quality control. ↩

-

Discover the principles and applications of gravimetric analysis to understand its importance in accurate laboratory measurements and material testing. ↩

-

Discover how chamber furnaces provide optimal space and airflow for trapezoid alumina crucibles, enhancing performance and efficiency. ↩

-

Discover the unique features and applications of tube furnaces to understand why certain crucibles may not be suitable for their design. ↩

-

Learn the fundamentals of ashing, its role in analytical chemistry, and how it impacts sample preparation and accuracy in lab results. ↩