High-Performance

Zirconia Tube Solutions for Demanding Industries

High-performance zirconia tube solutions from ADCERAX® are designed for demanding industrial environments. These tubes feature a stable microstructure that ensures excellent performance under high temperatures. By combining advanced production methods with strict process control, ADCERAX® guarantees consistent quality.

Every zirconia ceramic tube we deliver can be customized with technical drawings support for precise engineering needs. Our team focuses on dimensional accuracy, corrosion resistance, and thermal shock stability. ADCERAX® helps clients in chemical, energy, and electronic industries achieve reliable operation.

Contact ADCERAX® today for your zirconia tube requirements.

±0.2 mm

Dimensional Accuracy Control

What is a Zirconia Tube?

A Zirconia Tube is a ceramic part made from ZrO₂, designed for extreme industrial use. These zirconia ceramic tubes provide stability at very high temperatures and resist corrosion from harsh chemicals.

A zirconia ceramic pipe ensures reliable insulation and mechanical durability under stress. When processed as a yttria stabilized zirconia tube, the material offers improved fracture toughness and longer service life.

Technical Specification of Zirconia Tube

The technical specifications of a Zirconia Tube define its performance in demanding engineering applications. Each parameter is carefully controlled to meet strict industrial standards. These specifications ensure safe, reliable, and consistent use across chemical, energy, and electronic industries.

| Technical Specification Table | ||

|---|---|---|

| Parameter | Specification | |

| Material | High-purity ZrO₂ (≥ 99.9%) | |

| Available Types | Open both ends zirconia tube, one end closed zirconia tube | |

| Stabilizers | Yttria (Y₂O₃) | |

| Outer Diameter Range | 0.7mm – 100 mm (customizable) | |

| Wall Thickness Tolerance | ±0.1 – ±0.2 mm | |

| Thermal Expansion Coefficient | 10 × 10⁻⁶ /K (approx.) | |

| Maximum Working Temperature | 2200 °C | |

| Dielectric Strength | > 10 kV/mm | |

Engineered Properties of ADCERAX® Zirconia Tubes

A Zirconia Tube is manufactured through isostatic pressing and high-temperature sintering, creating a dense, smooth ceramic layer with outstanding reliability. Stabilizing agents such as yttria enhance toughness and wear resistance, making these tubes suitable for high-temperature and precision applications.

Mechanical Strength and Wear Resistance

The dense microstructure of zirconia ceramic tubes provides excellent mechanical reliability.

- High hardness ensures long service life.

- Strong fracture toughness withstands sudden stress.

- Superior wear resistance under repeated operation.

Thermal Stability and Heat Resistance

The thermal behavior of zro2 ceramic pipe supports continuous use in high-temperature systems.

- Low thermal conductivity minimizes heat loss.

- Stable function above 1000 °C with no deformation.

- Consistent performance through rapid heating cycles.

Chemical Inertness and Corrosion Protection

The inert nature of resistant zirconia ceramic tube guarantees safe use in corrosive conditions.

- Resistant to most acids and alkalis except HF.

- Strong chemical stability in aggressive atmospheres.

- Effective barrier against industrial corrosive gases.

Electrical Insulation and Functional Reliability

A yttria stabilized zirconia tube also provides dependable electrical insulation in harsh environments.

- High dielectric strength prevents voltage breakdown.

- Stable insulating behavior at elevated temperatures.

- Reliable support for thermocouple and sensor systems.

ADCERAX® Zirconia Tube Product Showcase

Zirconia Tube solutions from ADCERAX® are designed for high-temperature, corrosive, and precision engineering applications. Our range covers both standard and custom zirconia ceramic tubes, ensuring flexibility for global industrial projects.

This type of zirconia ceramic pipe is widely used for continuous flow and furnace insulation.

- Available in multiple diameters and lengths.

- Suitable for chemical and high-temperature reactors.

- Customizable for laboratory and industrial systems.

A zro2 ceramic pipe with one sealed end provides reliable protection in sensor and probe assemblies.

- Ideal as a zirconia thermocouple tube.

- Prevents contamination in sensitive measurement devices.

- Stable at elevated temperatures with long service life.

A Magnesia Stabilized Zirconia Ceramic Tube Single Bore combines high temperature endurance with stable mechanical strength.

- Enhanced resistance to thermal shock and corrosion.

- Designed for consistent performance in single-channel flow systems.

- Reliable option for industrial furnaces and heat treatment setups.

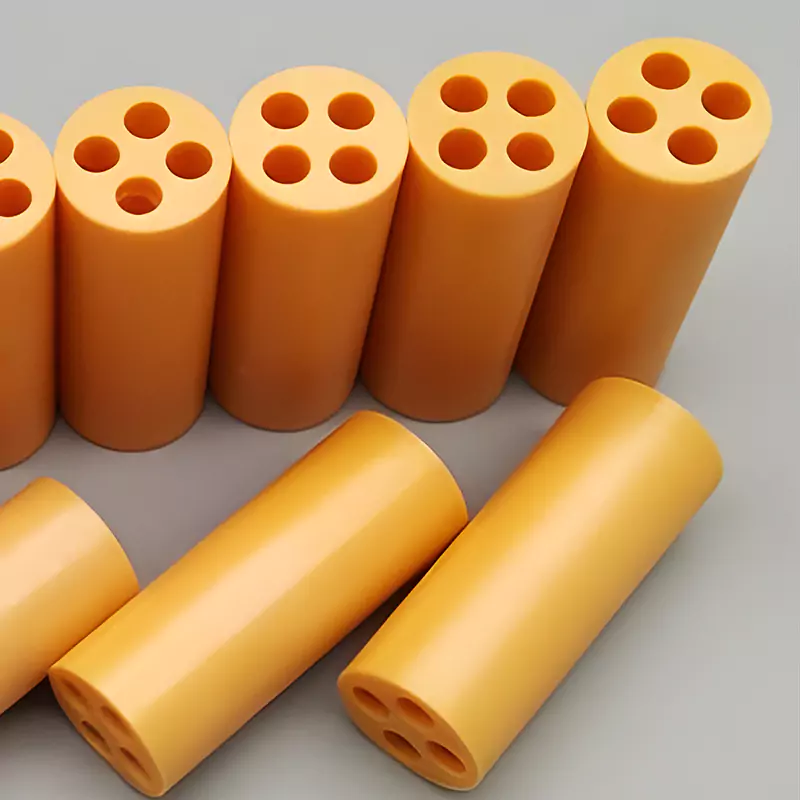

A Magnesia Stabilized Zirconia MSZ Tube Multi Bore is engineered for applications needing multiple channels in a single component.

- Allows complex fluid or gas routing within one ceramic body.

- Maintains high density and mechanical strength under stress.

- Preferred for advanced laboratory, energy, and high-temperature projects.

Ready to Discuss Your Zirconia Tube Needs?

At ADCERAX®, we are committed to providing complete solutions for your engineering projects.

Our team supports you with technical drawings, customization options, and fast delivery to meet demanding requirements.

Whether you need open both ends or one end closed Zirconia Tube, we ensure consistent quality and global supply.

Advanced Application Fields for ADCERAX® Zirconia Tubes

Zirconia Tube solutions are widely applied across industries where high temperature, chemical resistance, and durability are critical. ADCERAX® supports both standard and custom zirconia ceramic tubes to meet diverse engineering needs.

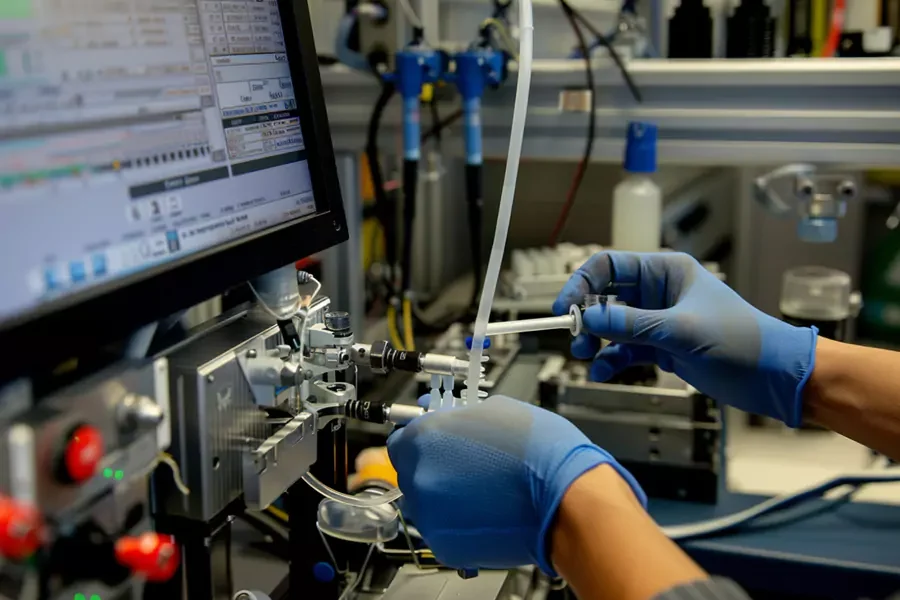

Chemical and Energy Systems

In chemical plants and energy units, zirconia ceramic tubes serve as essential thermal and corrosion barriers.

- Furnace liners protect against extreme chemical reactions.

- Resistant zirconia ceramic tube ensures stable gas flow in reactors.

- Reliable material for pipelines in aggressive atmospheres.

Metallurgy and High-Temperature Processing

A ZrO2 ceramic pipe is trusted in metallurgical and furnace applications requiring heat stability.

- Yttria stabilized zirconia furnace tube reduces cracking from thermal shock.

- High bending strength supports continuous casting equipment.

- Wear resistance lowers maintenance cost in smelters.

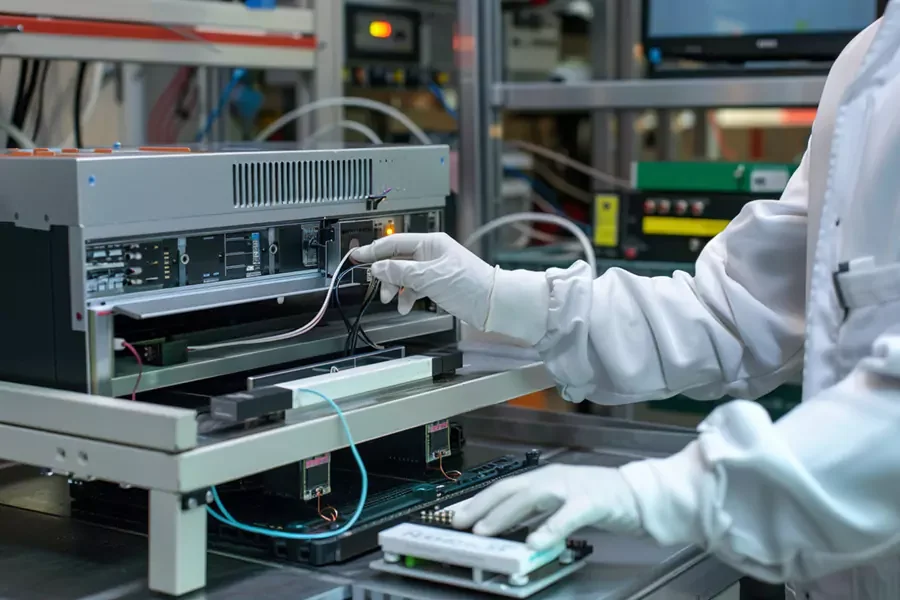

Electronics and Laboratory Equipment

Laboratory zirconia ceramic tube solutions deliver insulation and reliability in electronic systems.

- Acts as a zirconia thermocouple tube for accurate temperature sensing.

- Provides high dielectric strength for electrical devices.

- Maintains dimensional accuracy under repeated heating cycles.

Automotive and Aerospace Components

Zirconia Tube components improve monitoring and protection in transportation technologies.

- Used as oxygen sensor sheaths in exhaust systems.

- Durable protection for probes in aerospace turbines.

- Long service life in combustion and emission control systems.

ADCERAX® End-to-End Solutions for Zirconia Tube Buyers

ADCERAX® One-Stop Solutions for Zirconia Tube Supply

ADCERAX® integrates factory-direct supply with engineering expertise to reduce risks for industrial buyers. Our services focus on eliminating common pain points such as long lead times, poor dimensional control, and inconsistent quality. By offering responsive customization and assured reliability, we help customers make faster and safer procurement decisions.

- Rapid evaluation of customer drawings with precise tolerance guidance.

- Small-batch customization available to support prototype and testing needs.

- 24-hour dispatch for in-stock standard zirconia tubes.

- Strict quality inspections to minimize rejection rates and costly rework.

- Dedicated engineer support for application-specific problem solving.

- Flexible order handling without minimum order quantity restrictions.

- Clear communication and status updates to prevent project delays.

Engineering-Driven Customization and Manufacturing Strengths

At ADCERAX®, our zirconia tube production combines engineering-driven customization with advanced manufacturing strengths. We focus on achieving precise tolerances, stable quality, and reliable performance under demanding conditions. This approach ensures every order meets the specific requirements of industrial applications worldwide.

| Custom Capability and Processing Strengths | |||

|---|---|---|---|

| Category | Capability Description | ||

| Engineering Support | Dedicated engineers analyze drawings, advise on tolerance optimization, and provide solutions that reduce assembly failure rates. | ||

| Design Flexibility | Supports non-standard geometries, multi-bore designs, and closed-end tubes without MOQ, helping customers shorten R&D cycles. | ||

| Quality Assurance | Each zirconia tube is inspected with ±0.1–0.2 mm precision, minimizing rejection rates and ensuring reliable project integration. | ||

| Machining Equipment | Advanced CNC machines, precision grinders, and isostatic pressing allow consistent repeatability, reducing delays from rework. | ||

| Surface Options | Ground, polished, or as-sintered finishes improve sealing, reduce cracking risks, and extend service life in harsh conditions. | ||

customized zirconia tube supplier

We specialize in custom zirconia ceramic tubes with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Frequently Asked Questions about Zirconia Tubes

A Yttria Stabilized Zirconia Tube has yttria added as a stabilizer to improve toughness and wear resistance. This modification reduces brittleness, a common limitation of ceramics. It allows the tube to withstand thermal shock and mechanical stress more effectively.

The closed end protects the sensing element from direct exposure to corrosive gases and high temperatures. It ensures accurate readings while preventing premature sensor failure. This makes a one-end-closed Zirconia Tube ideal for probe applications.

Yttria doping transforms the crystal phase of zirconia to enhance crack resistance. This increases fracture toughness to the range of 6–8 MPa·m½. Such durability makes Y-TZP Zirconia Tubes suitable for heavy-duty use.

Yes, zirconia ceramics exhibit high dielectric strength. A Zirconia Tube maintains insulating properties even at elevated temperatures. This allows safe use in thermocouples and electronic assemblies.

The material resists most acids and alkalis except hydrofluoric acid. This ensures long-term reliability in aggressive chemical environments. A Zirconia Tube provides protection where metals would degrade.

By controlling tolerances and ensuring consistent density, failure rates are minimized. This lowers the chance of line stoppages or costly rework. Customers achieve stable operations with reliable Zirconia Tubes.

Typical tolerance control is around ±0.1–0.2 mm, depending on tube size and composition. This precision reduces assembly failure rates for critical equipment. Customers benefit from Zirconia Tubes that integrate smoothly into engineered systems.

Zirconia Tubes offer higher fracture toughness and better thermal shock resistance. They are less brittle and more durable under stress. This makes zirconia a superior option in critical applications.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Zirconia Ceramic Tubes

Looking for a reliable zirconia tube supplier? Let us help you with your next project.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours