Zirconia Toughened Alumina (ZTA)— Advanced Composite Ceramics for Wear & Structural Applications

ADCERAX is a global supplier of zirconia toughened alumina ceramics (ZTA) with over 20 years of manufacturing experience, specializing in next-generation materials that combine the best properties of alumina and zirconia.

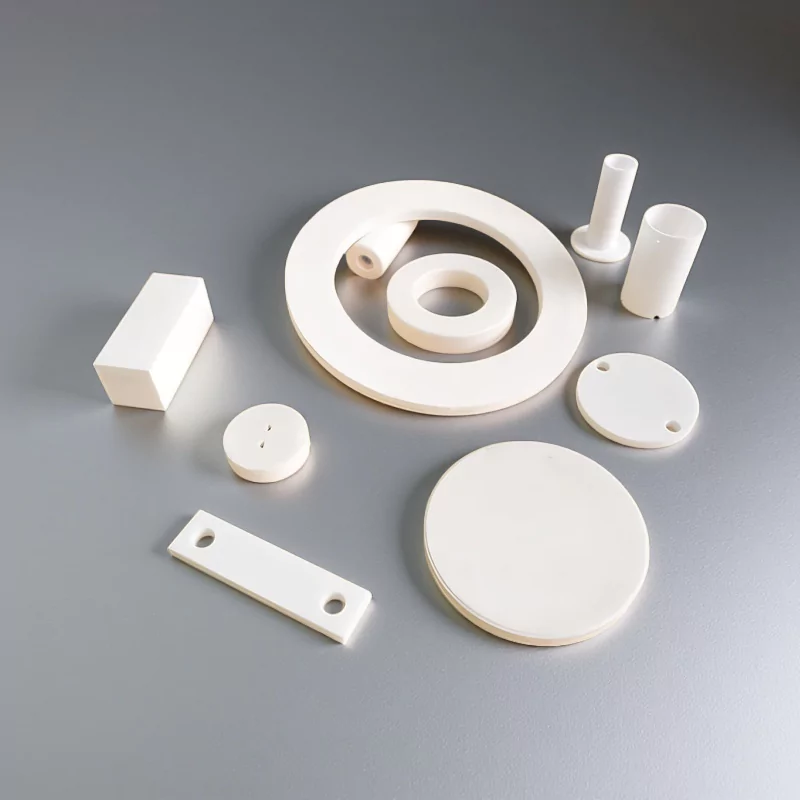

Our product portfolio includes ZTA tubes, rods, plates, beads, and custom parts, built to deliver long-lasting performance against friction, corrosion, and heat in real-world operating environments.

Through factory-direct service, fast lead times, and flexible customization, ADCERAX delivers high-performance ZTA ceramic solutions trusted by clients across the USA, Germany, Japan, and beyond.

What is Zirconia Toughened Alumina (ZTA)?

Zirconia toughened alumina (ZTA) ceramic is a composite material combining alumina (Al₂O₃) and zirconia (ZrO₂) to achieve an ideal balance of hardness, strength, and fracture toughness.By embedding fine zirconia particles into the alumina matrix, the zirconia toughening mechanism significantly increases crack resistance — making ZTA up to 3× tougher than pure alumina while remaining more cost-effective than full zirconia ceramics.

Zirconia Toughened Alumina Composition

- Alumina (Al₂O₃): Serves as the matrix material, typically accounting for 80% to 95% of the total weight. It provides the material’s fundamental hardness, wear resistance, and chemical stability.

- Zirconia (ZrO₂): Acts as the toughening agent, generally making up 5% to 20% of the total weight. This component is crucial for achieving the enhanced toughness.

General Rule:

- More Hardness/Wear Resistance = Higher Alumina %

- More Toughness/Fracture Resistance = Higher Zirconia %

ZTA Composition by Application

| Application | Alumina (Al₂O₃) % | Zirconia (ZrO₂) % | Key Performance Driver |

| Cutting Tools & Inserts | 85% – 95% | 5% – 15% | Maximum Hardness & Wear Resistance: High alumina content ensures cutting edge retention at high speeds. |

| Biomedical Implants | 80% – 85% | 15% – 20% | Maximum Toughness & Reliability: High zirconia content prevents catastrophic fracture under cyclic loading. |

| Wear-Resistant Parts | 80% – 90% | 10% – 20% | Balanced Toughness & Wear: A versatile composition for parts needing both abrasion resistance and impact strength. |

| Nozzles & Drawing Dies | 85% – 95% | 5% – 15% | High Hardness & Dimensional Stability: Prioritizes wear resistance to maintain precise orifice dimensions. |

| Semiconductor Parts | > 90% | < 10% | Hardness, Rigidity & Insulation: Focuses on wear resistance and minimal deformation, with just enough toughness to prevent chipping. |

Zirconia Toughened Alumina Manufacturing Process

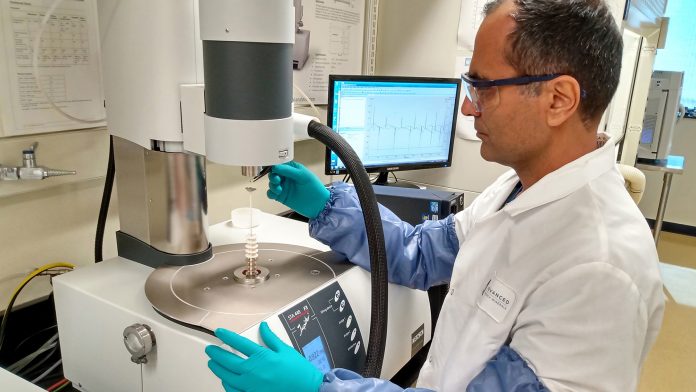

From zirconia toughened alumina powder to precision-finished components, ADCERAX controls every step of production — ensuring consistent density, strength, and reliability across all ZTA ceramic parts.

High-purity alumina and stabilized zirconia powders are precisely blended to achieve uniform dispersion and controlled particle size.

Cold isostatic pressing or uniaxial pressing ensures homogeneous compaction and high green strength for complex geometries.

Optimized sintering schedules up to 1,650 °C achieve near-theoretical density and a fine-grained microstructure with minimal porosity.

Post-sintering grinding, lapping, and laser cutting achieve tight tolerances (±0.02 mm) and smooth surfaces (Ra < 0.2 µm).

Dimensional, mechanical, and microstructural tests verify each batch for density, toughness, and phase stability.

Each part is ultrasonically cleaned, vacuum-packed, and labeled with batch traceability for global shipment.

Zirconia Toughened Alumina Mechanism

The superior toughness of ZTA compared to conventional alumina is primarily due to a unique mechanism known as “stress-induced transformation toughening,” which is enabled by the zirconia particles.

Through the addition of stabilizers (like yttria), the zirconia particles are retained within the alumina matrix in a metastable crystalline state called the tetragonal phase.

When the material is subjected to external impact or stress, microscopic cracks begin to form. The area at the very tip of a propagating crack becomes a zone of high stress concentration.

Induced by this high stress, the tetragonal zirconia particles near the crack tip instantaneously transform into the more stable monoclinic phase. This phase transformation is accompanied by a significant volume expansion of about 3-5%.

This localized volume expansion exerts a powerful compressive force on the crack tip. This force effectively "pinches" the crack shut, arresting or slowing its further propagation by absorbing the crack's energy.

Zirconia Toughened Alumina Properties

Zirconia toughened alumina (ZTA) ceramics offer an exceptional balance of hardness, strength, and fracture toughness, achieving up to three times higher crack resistance than standard alumina. They combine excellent wear, corrosion, and thermal stability, making them ideal for harsh industrial environments and precision components.

Mechanical Properties of Zirconia Toughened Alumina

With superior mechanical strength, wear resistance, and fracture toughness, zirconia toughened alumina ceramics deliver long-term durability in demanding industrial and thermal applications.

- Flexural strength: 500–700 MPa, compressive strength: up to 2000 MPa

- Vickers hardness: 1400–1600 HV providing excellent wear resistance

- Fracture toughness: 6–8 MPa·m¹/² with enhanced crack resistance

Chemical Properties of Zirconia Toughened Alumina

ADCERAX zirconia toughened alumina (ZTA) ceramics exhibit excellent chemical inertness and corrosion resistance across a wide range of aggressive media.

- High chemical stability against most acids, alkalis, and molten salts

- Excellent corrosion resistance in oxidizing and reducing atmospheres

- Minimal ionic contamination, ideal for cleanroom and vacuum applications

Thermal Performance of Zirconia Toughened Alumina (ZTA) Ceramics

ADCERAX zirconia toughened alumina (ZTA) ceramics offer outstanding thermal stability and low thermal expansion, making them ideal for high-temperature and rapid heating environments.

- Maximum working temperature: up to 1600 °C in continuous operation

- Low thermal expansion coefficient for dimensional accuracy under temperature changes

- Excellent thermal shock resistance preventing cracking or distortion

Electrical Properties of Zirconia Toughened Alumina (ZTA) Ceramics

ADCERAX zirconia toughened alumina (ZTA) ceramics deliver strong electrical insulation and reliable operation in high-voltage conditions.

- High electrical resistivity: >10¹² Ω·cm at room temperature

- Strong dielectric strength suitable for insulators and sensor housings

- Stable electrical performance under varying temperatures and humidity

Alumina Parts Zirconia Ceramic

ADCERAX zirconia toughened alumina (ZTA) ceramics deliver dependable precision solutions for high-tech industries. From tubes and rods to plates and rings, each component is crafted for engineers seeking long-lasting ceramic parts that perform consistently across demanding industrial applications.

Zirconia toughened alumina rods combine rigidity and fracture toughness, ideal for shafts and insulation pins.

- High flexural strength minimizes breakage risk

- Stable performance in high-temperature and vacuum use

- Precise grinding ensures smooth fit and alignment

Zirconia toughened alumina rings provide strong sealing and structural reliability under thermal stress.

- High toughness avoids cracking at high torque

- Excellent insulation in electrical assemblies

- Stable tolerance ensures tight sealing performance

Zirconia toughened alumina seal rings offer exceptional wear and leak resistance for pumps and valves.

- Dense microstructure resists fluid erosion

- Thermal shock stability supports repeated cycles

- Precision-lapped faces maintain smooth sealing

Zirconia toughened alumina balls deliver excellent hardness and wear resistance for grinding and bearing systems.

- High impact resistance prevents chipping

- Low wear rate ensures clean milling environment

- Works stably up to 1,500 °C under load

Zirconia toughened alumina grinding beads ensure efficient dispersion and minimal contamination.

- High density improves grinding efficiency

- Smooth surface reduces media abrasion

- Chemically inert for pure material processing

Zirconia toughened alumina substrates combine electrical insulation with mechanical durability.

- High hardness resists particle abrasion

- Corrosion-proof surface extends equipment life

- Easy to install and replace in modular setups

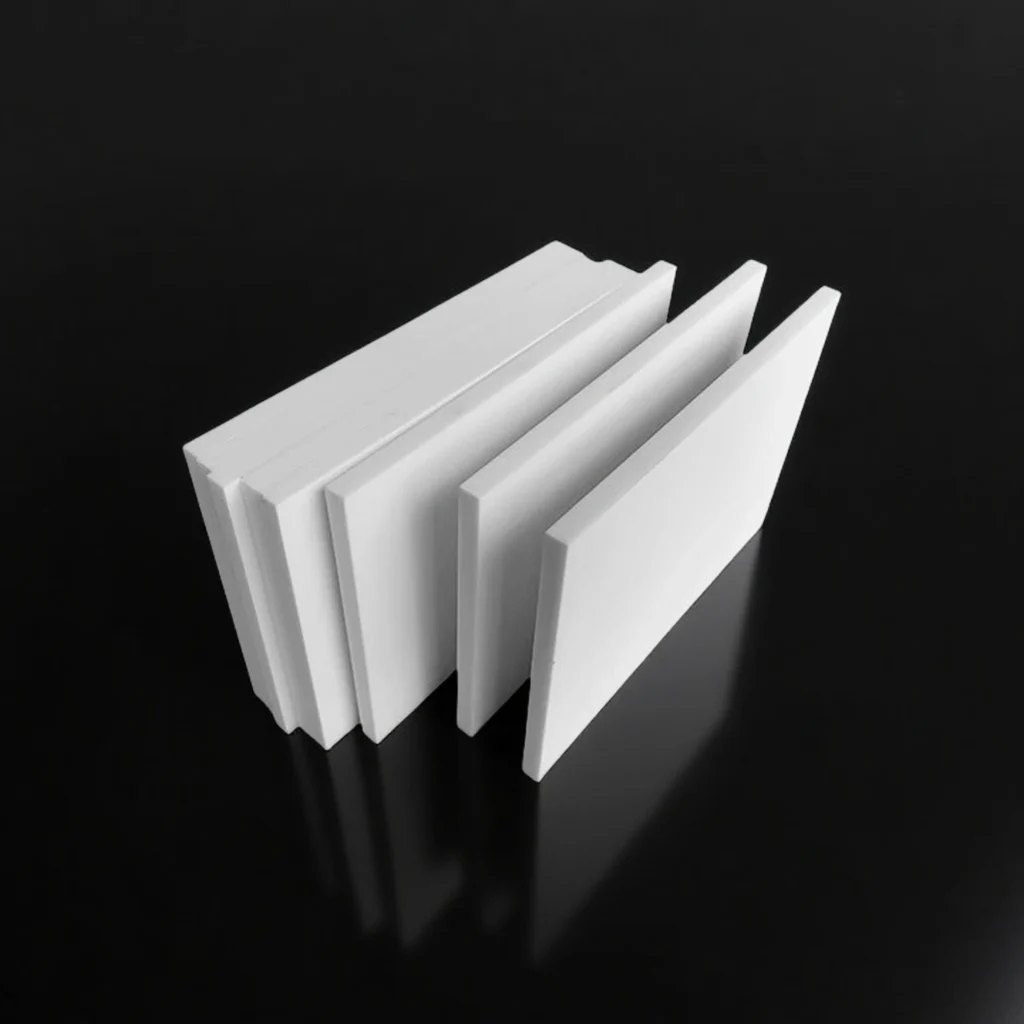

Zirconia toughened alumina plates provide enhanced strength and stability for load-bearing and insulation applications.

- High fracture toughness withstands heavy loads

- Excellent corrosion resistance in acidic or alkaline media

- Retains mechanical precision after repeated heating

Zirconia toughened alumina lining boards protect process equipment from wear and chemical attack.

- High hardness resists particle abrasion

- Corrosion-proof surface extends equipment life

- Easy to install and replace in modular setups

Zirconia toughened alumina tubes offer high strength, wear resistance, and stability under extreme heat and pressure.

- Toughened structure resists cracking and impact

- Excellent corrosion and wear resistance in harsh media

- Dimensional stability up to 1,700 °C ensures long service life

💥 Fewer Replacements. Higher Uptime. Greater Precision— ZTA Delivers

With ADCERAX ZTA ceramics, every component means less maintenance, more stability, and measurable performance gains for your operation.

Zirconia Toughened Alumina Applications

Zirconia toughened alumina ceramics are widely used in semiconductor tools, analytical instruments and precision machinery as bearings, spacers, substrates, fixtures, and insulating components, ensuring long-term reliability in chemical, vacuum, and high-temperature environments.

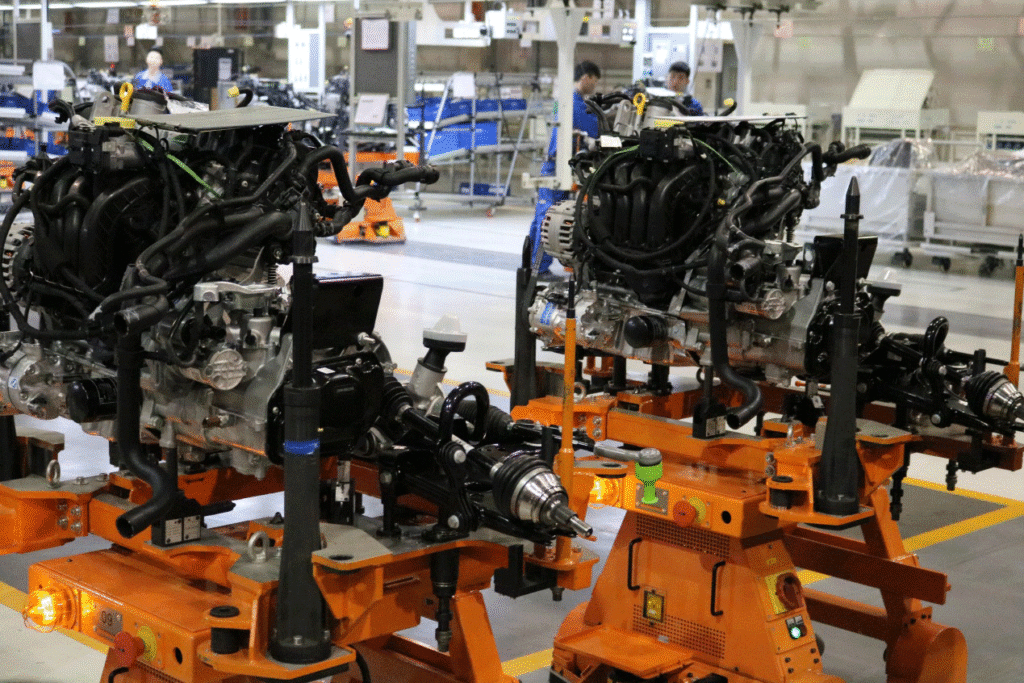

⚙️Industrial Machinery

Application:Zirconia toughened alumina ceramics are used in bearings, bushings, spacers, and liners for precision and automation machinery, ensuring stable operation and long service life under continuous motion.

Challenges: Metal parts wear or deform under high load and friction, leading to reduced accuracy, downtime, and frequent replacements.

🧩 ADCERAX Solution:

- High wear and corrosion resistance delivers up to 5× longer lifespan than metals or carbides.

- Hardness >1,600 HV and tight tolerances ensure dimensional stability under load.

- Smooth polished surfaces (Ra < 0.1 µm) reduce friction and prevent contamination.

- 🎯 ADCERAX ZTA components minimize wear, leakage, and maintenance frequency — keeping industrial machinery running efficiently and reliably.

⚗️Chemical & Petrochemical Industry

Applications: Zirconia toughened alumina ceramics are used in acid pipelines, pumps, valves, plungers, and seal rings, operating under strong chemical corrosion and pressure fluctuations.

Challenges: Metal components corrode quickly in acidic or alkaline media, polymer seals deform under heat or pressure, and frequent replacements cause costly downtime and maintenance.

🧩 ADCERAX Solution:

- High toughness and chemical resistance extend component life and prevent corrosion damage.

- Stable microstructure up to 1700 °C ensures reliability under extreme conditions.

- Controlled purity > 99% avoids contamination and maintains process integrity.

- 🎯ADCERAX ZTA products help manufacturers cut maintenance frequency, extend equipment lifespan, and keep operations stable in aggressive chemical and high-pressure environments.

💡 Semiconductor & Electronics Industry

Applications: Zirconia toughened alumina ceramics are used in wafer handling arms, vacuum chucks, heater boards, and fixture plates for deposition, etching, and lithography systems, offering precision, insulation, and stability under vacuum or plasma conditions.

Challenges:Conventional ceramics often chip, deform, or contaminate wafer processes under plasma, vacuum, or high-temperature conditions, leading to yield loss and unstable equipment performance.

🧩 ADCERAX Solution:

- High-purity ZTA ceramics combine toughness and insulation, reducing particle generation.

- Mirror-polished surfaces (Ra < 0.2 µm) prevent friction and contamination.

- Low outgassing and stable dielectric ensure reliability in vacuum and high-temperature processes.

- 🎯 ADCERAX ZTA components help semiconductor manufacturers achieve cleaner wafer handling, consistent yield, and long-term stability in demanding environments.

🧫 Laboratory & Analytical Equipment

Applications: Zirconia toughened alumina ceramics are used in crucibles, sample trays, reaction tubes, and support fixtures for furnaces, reactors, and analytical systems that face frequent heating, cooling, and corrosive conditions.

Challenges: Conventional ceramics like alumina and zirconia often crack, deform, or release contaminants under thermal or mechanical stress, reducing precision and reliability in high-performance equipment.

🧩 ADCERAX Solution:

- High-toughness ZTA ceramics resist cracking and thermal shock up to 1700 °C.

- High purity > 99% ensures clean testing without sample contamination.

- Smooth, precision-finished surfaces extend fixture life and maintain measurement consistency.

- 🎯 ADCERAX ZTA ceramics help laboratories achieve stable, accurate results with longer-lasting components under repeated high-temperature cycles.

Customize zirconia toughened alumina Supplier

ADCERAX is a professional zirconia toughened alumina (ZTA) ceramics manufacturer, specializing in customized components with complex geometries, tight tolerances, and tailored zirconia-to-alumina ratios for enhanced strength and toughness. Each part is precisely produced according to your drawings or samples, and custom ZTA ceramics are typically manufactured and delivered within 3–7 weeks.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Precision ZTA Supplier from China

ADCERAX is a trusted zirconia toughened alumina manufacturer in China, providing standard and customized ZTA components for global OEM clients. We also offer both wholesale and custom ZTA solutions, ensuring reliable performance and cost efficiency for industrial applications worldwide.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates design, machining, quality control, and logistics into one seamless manufacturing workflow. Our one-stop approach for zirconia toughened alumina ceramics streamlines coordination, shortens lead time, and ensures stable quality from prototype to mass production.

-

Precision Machining Assurance:

Each ZTA product is precisely processed according to customer drawings, with dimensional accuracy up to ±0.05 mm, ensuring a perfect fit and stable assembly in complex mechanical or electronic systems. -

Batch Quality Consistency:

Every production batch of ZTA components undergoes strict QC on density, toughness, and surface finish to guarantee uniform performance across high-stress and high-temperature applications. -

Technical Engineering Support:

ADCERAX engineers assist OEM clients with material optimization, tolerance design, and surface engineering, helping enhance part reliability and extend service life in demanding industrial environments.

ADCERAX specializes in the production of zirconia toughened alumina ceramics, combining advanced forming technologies with precision CNC machining and strict quality control. Each ZTA product is engineered for superior toughness, dimensional stability, and long-term reliability across demanding industrial applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Zirconia-toughened alumina (ZTA) composites with zirconia content typically 10–30%, achieving excellent toughness, hardness > 1,500 HV, and flexural strength up to 800 MPa. | ||

| Dimension Range | Custom ZTA parts from small precision insulators to large structural components, with machining tolerances of ±0.05–0.2 mm depending on geometry. | ||

| Forming Methods | Isostatic pressing, CNC machining, fine grinding, and hot sintering ensure uniform microstructure, high density, and repeatable dimensional accuracy. | ||

| Processing | Controlled sintering up to 1,700 °C achieves full densification; optional precision lapping and polishing enhance surface quality and component fit. | ||

| Surface Finish | Polished ZTA surfaces can reach Ra < 0.2 µm, providing low friction, smooth sealing contact, and stable performance in high-stress environments. | ||

FAQ

Yes. ZTA maintains stability up to 1,500°C (2,732°F), outperforming many metals and polymers. Its low thermal expansion minimizes cracking during rapid temperature changes, critical for furnace components or aerospace applications.

ZTA’s high hardness and toughness demand specialized machining techniques. Below are the core challenges and advantages of common methods:

1. Diamond Grinding

✔️ Advantages:

- Delivers ultra-smooth surfaces (Ra <0.2 μm), ideal for medical implants.

- Cost-efficient for medium-scale production.

❌ Challenges:

- Rapid diamond tool wear increases long-term costs.

- Limited efficiency for complex 3D shapes.

2. Laser Machining

✔️ Advantages:

- No physical contact eliminates mechanical stress.

- Cuts intricate designs (e.g., micro-features) with high precision.

❌ Challenges:

Expensive equipment and energy consumption.

Heat-affected zones may require post-polishing.

3. Ultrasonic Machining (USM)

✔️ Advantages:

- Minimal subsurface damage, perfect for brittle ZTA.

- Handles tiny holes (as small as 0.3 mm).

❌ Challenges:

- Slow material removal rate.

- Limited to small-scale or delicate components.

4. Electrical Discharge Machining (EDM)

✔️ Advantages:

- Machines complex 3D shapes without mechanical force.

❌ Challenges:

- Only works with conductive ZTA (modified with additives like TiC).

- Leaves a recast layer requiring extra finishing.

Quick Decision Guide

Choose Diamond Grinding for precision surfaces or cylindrical parts.

Opt for Laser Machining if designing complex, thin components.

Use USM for fragile parts or micro-features.

Consider EDM only if using conductive ZTA.

Key Factors Influencing ZTA Lifespan:

1️⃣ Operational Load Type

Continuous Impact Loads (e.g., mining crusher plates):

Risk: Microcracks develop faster under repetitive impacts exceeding 50 MPa.

Solution: Design ZTA components with ≥5 mm thickness to absorb energy.Static/Pressure Loads (e.g., valve seats):

Advantage: ZTA maintains integrity under constant pressure up to 300 MPa.

2️⃣ Temperature Cycling Range

Rapid Quenching (e.g., from 1,200°C to 25°C in seconds):

Limit: ≤3 cycles/day to avoid grain boundary stress accumulation.Steady High Temp (e.g., 1,000°C furnace parts):

Lifespan: 5-8 years due to ZTA’s phase stability.

3️⃣ Abrasion Intensity

Sliding Abrasion (e.g., pump seals vs. sand slurry):

Wear Rate: 0.02 mm³/N·m (ZTA) vs. 0.15 mm³/N·m (pure alumina).Particle Size Impact:

Tip: Pair ZTA with <100 μm abrasive media to reduce surface pitting.

Proven Strategies to Extend ZTA Durability:

Surface Optimization:

Laser polishing (Ra <0.1 μm) reduces friction by 30% in biomedical bearings.Edge Design:

Round sharp edges (radius >0.5 mm) to prevent chipping in cutting tools.Environmental Control:

Add protective coatings if used in pH <2 or >12 environments.

ZTA vs. Other Ceramics: Comparison Table for Material Selection:

| Property | ZTA | Silicon Carbide (SiC) | Silicon Nitride (Si3N4) | Y-TZP Zirconia |

|---|---|---|---|---|

| Hardness | High (18-20 GPa) | Very High (25-28 GPa) | Moderate (14-16 GPa) | Moderate (12-14 GPa) |

| Toughness | Excellent (6-8 MPa√m) | Low (3-4 MPa√m) | High (6-7 MPa√m) | High (10-12 MPa√m) |

| Thermal Resistance | Up to 1,500°C | Extreme (1,600°C+) | High (1,400°C) | Moderate (800-1,200°C) |

| Wear Resistance | Excellent (Abrasive) | Extreme (Sliding/Erosive) | Good (Impact) | Good (Low Friction) |

| Thermal Conductivity | Low | Very High | Low | Very Low |

| Corrosion Resistance | Strong (Acid/Alkali) | Moderate (Weak in strong bases) | Good (Oxidation) | Excellent (Bio-inert) |

| Cost | $$ (Moderate) | $$$ (High) | $$$$ (Very High) | $$$ (High) |

| Key Applications | Industrial wear parts, valves | High-temp kilns, heat exchangers | Bearings, engine components | Dental implants, cutting tools |

How to Choose Based on Your Needs:

Pick ZTA If You Need:

Balanced cost-performance for abrasive wear or thermal shock resistance (e.g., mining equipment, pump seals).

Hydrothermal stability in wet/steam environments.

Choose Silicon Carbide (SiC) If You Need:

Extreme heat resistance + thermal conductivity (e.g., semiconductor furnaces, rocket nozzles).

Budget is less critical.

Opt for Silicon Nitride (Si3N4) If You Need:

High impact strength for dynamic loads (e.g., ball bearings, turbocharger rotors).

Select Y-TZP Zirconia If You Need:

Maximum flexural strength + aesthetics (e.g., dental crowns, decorative components).

Summary:

Cost-Saving + Toughness → ZTA.

Extreme Heat + Conductivity → SiC.

Impact Loads → Si3N4.

Strength + Aesthetics → Y-TZP.

Zirconia Toughened Alumina (ZTA) vs. Alumina vs. Zirconia

| Property / Aspect | Alumina (Al₂O₃) | Zirconia Toughened Alumina (ZTA) | Zirconia (ZrO₂) |

|---|---|---|---|

| Fracture Toughness | Low (≈3 MPa·m½) | ⭐ Medium–High (6–8 MPa·m½) | Very High (8–12 MPa·m½) |

| Hardness (HV) | Very High (≈1800 HV) | High (≈1600 HV) | Medium (≈1200 HV) |

| Wear Resistance | Excellent in dry conditions | ⭐ Superior under impact or abrasion | Good but lower hardness |

| Thermal Stability | Up to 1700 °C | ⭐ Up to 1600 °C | Limited (~1000 °C) |

| Electrical Insulation | Excellent | ⭐ Excellent | Moderate |

| Corrosion Resistance | Excellent | ⭐ Excellent | Good |

| Cost Level | Low | ⭐ Medium | High |

| Best For | General insulators, plates, crucibles | ⭐ High-stress, precision, or hybrid applications | High-toughness structural parts |

| Typical Industries | Laboratory • Furnace • Electronic insulation | ⭐ Semiconductor • Analytical • Machinery | Medical • Bearing • Valve systems |

ZTA bridges the performance gap between alumina and zirconia — combining alumina’s hardness and insulation with zirconia’s toughness.

It’s ideal when alumina is too brittle or zirconia is too expensive or soft for your application.

Yes. ZTA can replace both in many cases — it’s chosen when alumina is too brittle or zirconia is too soft or costly while maintaining similar machining tolerances.

Yes. ADCERAX offers zirconia toughened alumina for sale directly from our advanced production facility in China. As a professional zirconia toughened alumina factory, we provide both standard and custom parts with short lead times, ensuring consistent quality and cost efficiency for OEM and industrial buyers.

Yes. We support ±0.05–0.2 mm tolerance, mirror finish (Ra < 0.2 µm), and geometry optimization for bearings, spacers, liners, substrates, and fixtures.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Reliable ZTA Manufacturing

Submit your drawings or 3D models, and our engineers will provide a personalised quotation within 24–48 hours, ensuring you get the right ZTA solution faster.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours