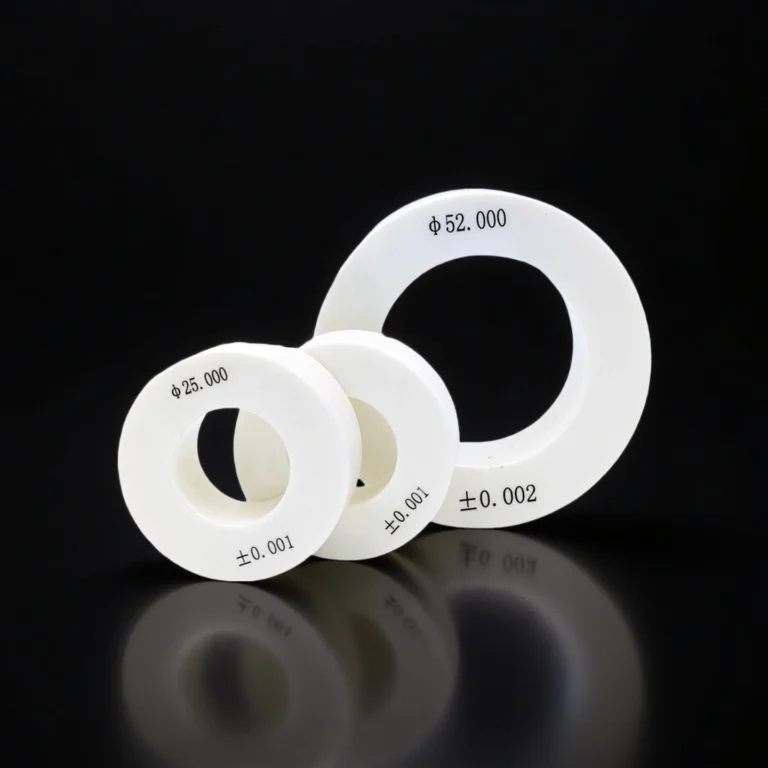

ADCERAX® MSZ Ceramic Gauge Block provides a stable length reference for precision measurement systems operating in demanding industrial environments. Its dense magnesia‑stabilized zirconia structure ensures long-term dimensional consistency under heat, abrasion, and repeated calibration cycles, allowing reliable performance where steel blocks degrade. The non‑magnetic and electrically insulating ceramic matrix supports accurate measurement near motors, magnetic fixtures, and dust‑laden production areas, creating a dependable standard for modern machining and quality‑control workflows.

Key Performance Advantages of MSZ Ceramic Gauge Block in Industrial Calibration

-

Wear Resistance for Long-Term Use

-

10× longer lifespan than standard steel gauge blocks under repeated wringing, surface contact, and industrial humidity conditions.

-

Independent lab testing shows <0.3 µm wear depth after 10,000 cycles, ensuring dimensional consistency throughout extended calibration intervals.

-

Chemical and Thermal Stability

-

Maintains full structural integrity up to 1000 °C with no phase transformation or mechanical distortion in thermal cycling applications.

-

Withstands exposure to strong acids and alkalis (pH 2–12) without surface degradation, outperforming alloy and alumina-based materials in corrosive plant environments.

-

Non-Magnetic and Electrically Insulating Properties

-

Constructed from magnesia-stabilized zirconia with zero magnetic permeability, allowing reliable use in magnetic field test environments and CMM labs.

-

Exhibits electrical resistivity above 10¹⁴ Ω·cm, enabling safe use near inductive systems, electronic modules, and sensitive measuring instruments.

Technical Specifications of MSZ Ceramic Gauge Block for High-Stability Metrology Applications

ADCERAX® MSZ Ceramic Gauge Block is engineered to maintain dimensional accuracy, mechanical strength, and surface integrity under prolonged exposure to thermal, magnetic, and chemical stress, making it highly suitable for advanced calibration laboratories and industrial quality systems.

| Property |

Specification |

| Material Type |

Magnesia Stabilized Zirconia (MSZ) |

| Density |

> 5.80 g/cm³ |

| Vickers Hardness (HV10) |

> 1300 HV |

| Bending Strength |

> 800 MPa |

| Fracture Toughness (K₁c) |

> 6.0 MPa·m¹ᐟ² |

| Thermal Conductivity |

2.5 W/m·K @ 20 °C |

| Thermal Expansion Coefficient |

10.3 ×10⁻⁶ /K @ 25–500 °C |

| Maximum Operating Temperature |

1000 °C continuous |

| Surface Finish (Ra) |

< 0.05 µm (working faces) |

| Magnetic Permeability |

≈ 0 (non-magnetic) |

| Electrical Resistivity |

> 10¹⁴ Ω·cm |

| Chemical Resistance |

Acid/alkali resistant (pH 2–12 range) |

| Moisture Absorption |

0% (fully sintered ceramic) |

| Calibration Interval |

≥ 3–5 years under controlled conditions |

| Dimensional Stability (ΔL) |

< 0.1 µm/year (standard lab conditions) |

Dimensions of MSZ Ceramic Gauge Block

|

MSZ Ceramic Gauge Block |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-MG-LJ1001 |

Customize |

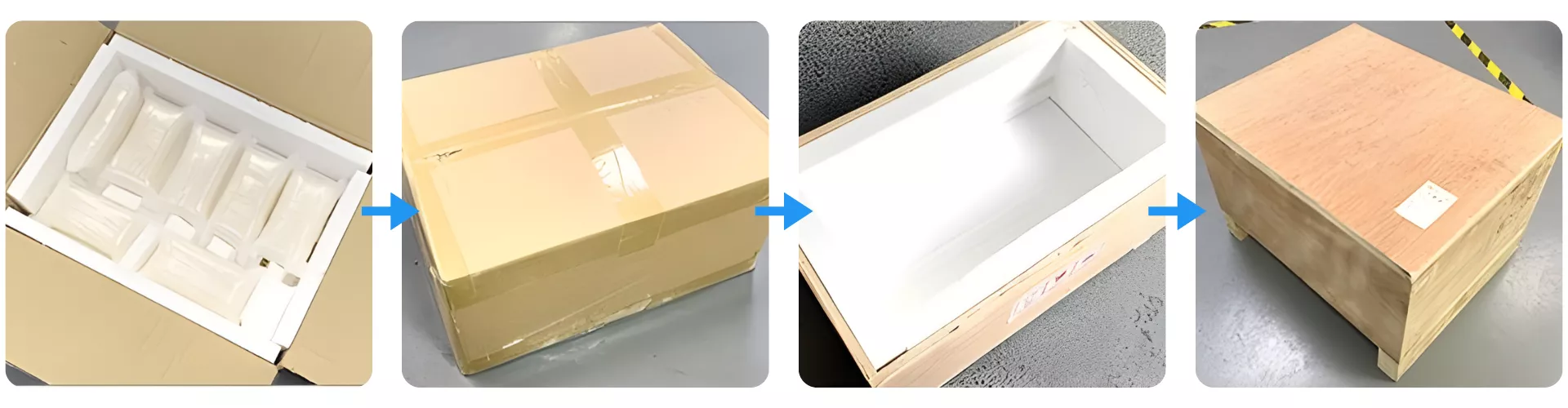

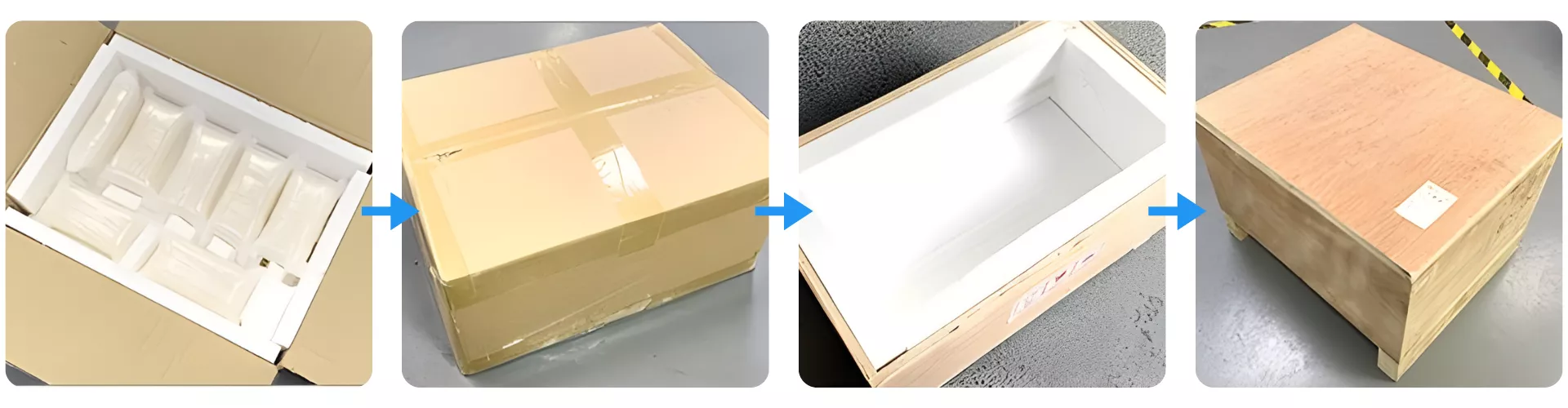

Secure Industrial Packaging for MSZ Ceramic Gauge Block

MSZ Ceramic Gauge Block is carefully packed using custom-cut foam inserts to prevent any surface contact or shift during transit. The inner carton is sealed and double-boxed before being encased in a reinforced plywood crate. This layered packaging system ensures the product arrives in perfect metrological condition, even under long-distance international shipping.

ADCERAX® MSZ Ceramic Gauge Block Resolves Precision Calibration Challenges Across Industrial Environments

ADCERAX® MSZ Ceramic Gauge Block addresses critical calibration challenges in environments affected by magnetic interference, particulate abrasion, and thermal instability, offering metrology engineers a stable and low-maintenance alternative to conventional steel blocks across automotive assembly, mold tooling, and high-throughput calibration labs.

-

MSZ Ceramic Gauge Block in Powertrain Shaft Line Precision Setup

✅Key Advantages

1. Non-Magnetic Performance in E-Motor Fields

MSZ gauge blocks exhibit magnetic permeability <0.001, ensuring undisturbed referencing near electric stator housings and e-drive assemblies. This eliminates magnetic drift during alignment on hybrid and EV powertrain lines.

2. Corrosion Resistance in Coolant-Rich Zones

Surface integrity is retained after 1000+ hours of exposure to synthetic coolants and high-humidity (>85% RH) environments. This prevents rust pitting and surface deviation seen in steel blocks after 3–6 months.

3. Stable Geometry Across Extended Shifts

Wringing flatness variation remains under 0.2 µm even after 10,000 usage cycles in shaft line setups. MSZ blocks maintain consistent Z-reference under 3-shift continuous operations.

✅ ️Problem Solved

A Tier-1 automotive supplier operating dual EV assembly lines in Michigan reported that steel gauge blocks required replacement every 4–6 months due to rust-induced height variance of ±1.5 µm, leading to frequent shaft misalignment alarms. After switching to ADCERAX® MSZ Ceramic Gauge Blocks, they extended calibration intervals to 24+ months, reducing tooling downtime by over 40% and stabilizing first-pass assembly yield.

-

MSZ Ceramic Gauge Block in CNC Fixture Alignment for High-Volume Mold Tooling

✅Key Advantages

1. Graphite and EDM Dust Resistance

The closed-pore ceramic surface repels fine graphite particles and EDM debris. Surface Ra remains <0.05 µm after 500 cycle wipe-downs without needing oil films or ultrasonic cleaning.

2. Flatness Preservation Under Particulate Abrasion

MSZ blocks showed <0.3 µm loss in face flatness after simulated 1,000 alignments in graphite-rich CNC zones, while steel blocks degraded >1.2 µm in the same test setup.

3. Reduced Wringing Variation in Dirty Shop Floors

Even in environments with airborne particles >10 µg/m³, MSZ maintains wringing consistency with <0.5 µm stack deviation. This minimizes the need for fixture height recalibration.

✅ ️Problem Solved

A precision mold company in Suzhou operating 24/7 EDM-CNC production lines reported daily misalignment rework due to steel blocks accumulating EDM residue and warping. After deploying ADCERAX® MSZ Ceramic Gauge Blocks, fixture referencing remained stable over 6 months with zero unplanned height resets, cutting mold setup times by 28% and extending tool recalibration cycles to 2× the previous average.

-

MSZ Ceramic Gauge Block for Calibration in Third-Party ISO 17025 Labs with High Throughput

✅Key Advantages

1. No Oil Film or Anti-Rust Storage Needed

MSZ blocks remain chemically inert under >90% RH storage for 12 months without oxidation. Eliminates need for protective oiling and desiccant-controlled drawers.

2. Cross-Material Compatibility Without Transfer Risk

No cross-contamination observed after 100+ cycles calibrating steel, carbide, and zirconia sets in succession. MSZ gauge blocks act as neutral standards for multi-material labs.

3. Micron-Level Drift Control Over Time

In controlled lab conditions (20±0.5 °C), MSZ blocks show dimensional drift <0.05 µm/year—2× better than equivalent-grade hardened steel standards.

✅ ️Problem Solved

A third-party ISO 17025 metrology lab in Ontario found that their oil-protected steel reference blocks developed surface oxidation during humid summer storage, affecting stack results by up to 1.2 µm across multi-block verification. After adopting ADCERAX® MSZ Ceramic Gauge Blocks, they eliminated oxidation-related variance and extended recalibration from 18 months to 4 years, while also cutting maintenance hours by 30% annually.

Comprehensive Use and Handling Guide for ADCERAX® MSZ Ceramic Gauge Block

MSZ Ceramic Gauge Block from ADCERAX® is a high-stability reference standard designed for use in precise calibration environments. To ensure long-term dimensional integrity and prevent operational deviation, users must follow key practices during handling, inspection, and storage. This guide outlines essential procedures to maximize performance and lifecycle reliability.

-

Proper Handling During Measurement and Setup

1. Avoid excessive force during wringing

Excessive pressing or twisting can create micro-scratches or dimensional wear. Always wring on a clean, flat surface using gentle and even pressure. Avoid stacking with metal blocks to reduce potential surface abrasion.

2. Use in thermally stable environments

Rapid thermal shock may compromise block performance. Allow the MSZ Ceramic Gauge Block to thermally stabilize for at least 30 minutes before use if moved between rooms. Avoid placing it directly near heating elements or drafts.

3. Limit contact with measurement oils

Although MSZ is chemically inert, oils can attract particulates, which affect surface flatness. If oils are required in the setup, clean the gauge block immediately after use using neutral pH wipes.

-

Cleaning and Maintenance Recommendations

1. Use non-abrasive cleaning materials

Only clean using soft, lint-free cloths and avoid any alcohol-based or abrasive solutions. Dry the surface using compressed air or dust-free wipes after cleaning.

2. Inspect surface finish routinely

Examine for visible pits, scratches, or residue under adequate lighting every 100 cycles. If abnormalities are found, withdraw from service and evaluate with a certified lab.

3. Avoid contact with ferrous particles

Although the block is non-magnetic, iron shavings or tool dust can embed during use. Use a non-contact air cleaner or a ceramic brush to remove such contaminants safely.

-

Calibration and Reverification Practices

1. Follow regular recalibration intervals

Even with excellent stability, recalibration should be scheduled every 3–5 years under controlled lab usage. In high-frequency production use, inspect more frequently.

2. Utilize certified metrology labs

Reverification should be performed by ISO/IEC 17025 accredited institutions. Include surface flatness and parallelism in the recalibration scope.

3. Document all traceability records

Keep a log of calibration dates, results, and usage history. This ensures traceability compliance for audits and long-term metrology certification.

-

Storage and Environmental Control

1. Store in a dry, temperature-stable cabinet

Maintain a temperature of 20 ±1 °C and humidity below 60% RH. Avoid storing with steel blocks to eliminate cross-contamination.

2. Use foam-lined ceramic trays

Use non-metallic lined holders to prevent micro-surface damage. Each block should be stored individually without direct stacking.

3. Avoid vibration and airborne dust

Store away from high-vibration equipment and dusty zones. Use sealed containers or drawers with silica packs if environmental control is not guaranteed.