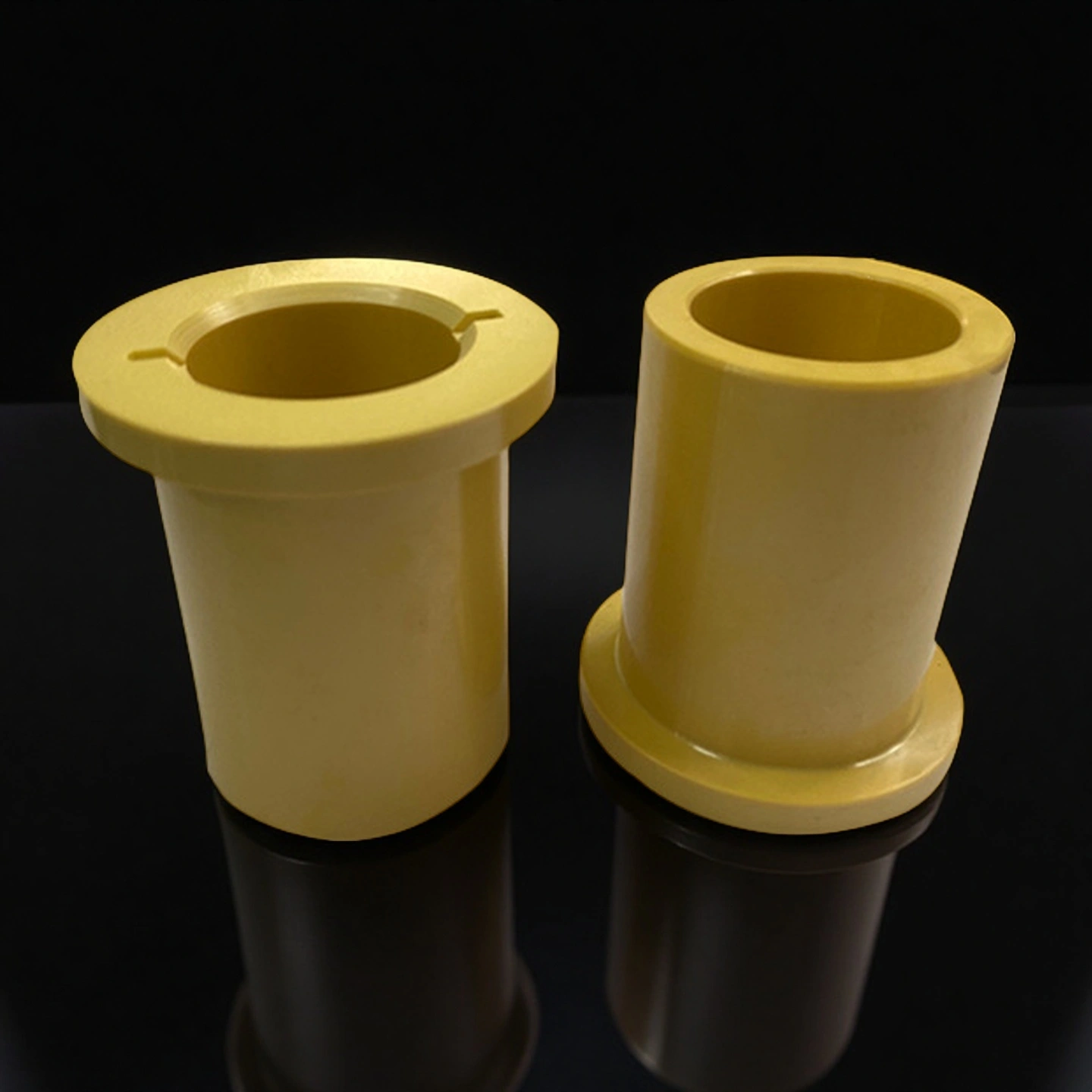

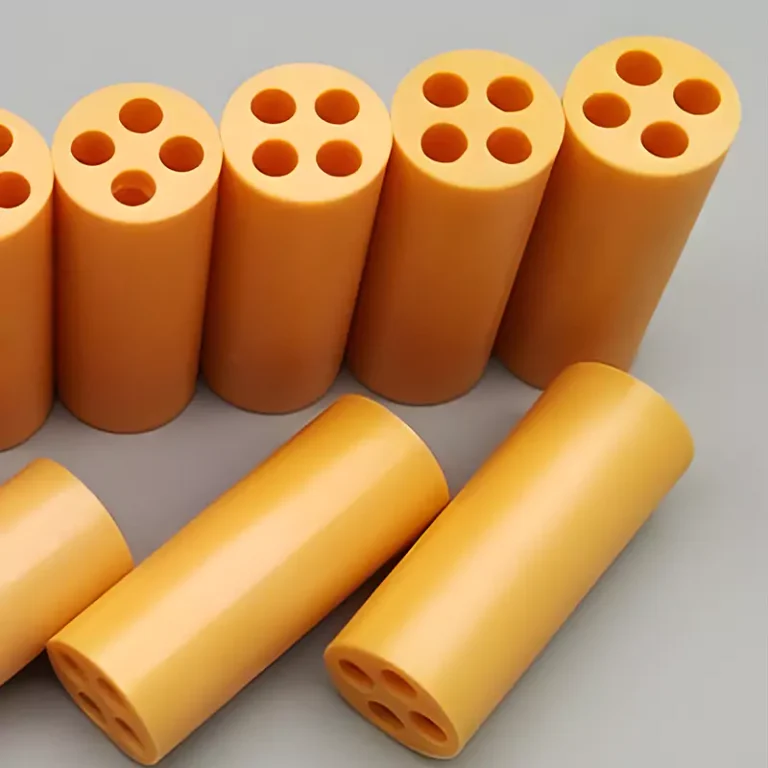

ADCERAX® Magnesia Stabilized Zirconia Ceramic Sleeve delivers a dense and stable ceramic structure designed to withstand continuous exposure to corrosive media and abrasive slurry environments. Its magnesia‑stabilized formulation supports high hardness, strong fracture resistance, and chemical inertness, allowing the sleeve to maintain performance under elevated temperatures found in chemical processing, metallurgy, pharmaceutical transfer systems, and power‑generation equipment. This stability enables long operating cycles and consistent protection of mechanical components against wear, corrosion, and process‑driven degradation.

Key Functional Properties of Magnesia Stabilized Zirconia Ceramic Sleeve

- Superior Acid & Alkali Tolerance

The material remains chemically stable in 98% sulfuric acid and 30% sodium hydroxide with no surface degradation observed after 72 hours of immersion. This ensures durability in systems carrying corrosive process fluids.

- Chloride & Oxidizer Resistance

Testing against chlorinated solvents and oxidizers shows no measurable mass loss or dimensional change after 300 hours in simulated process conditions. This performance protects pumps and valves from early failure.

- Long-Term Chemical Stability

After prolonged exposure to acidic slurries containing 10% silica, sleeves retain more than 95% of their surface hardness (Vickers HV10) over a 12-month operation cycle.

- High Surface Hardness

Magnesia-stabilized zirconia achieves a Vickers hardness of >1200 HV, outperforming stainless steel and alumina in abrasive slurry tests. This resists particle erosion during high-velocity flow.

- Abrasion Resistance in Slurry Media

In rotating equipment handling 20% solid load slurries, sleeves showed less than 0.01 mm wear depth after 1000 operational hours, ensuring longer service intervals.

- Fracture Toughness Advantage

With a fracture toughness of >6 MPa·m¹ᐟ², MSZ sleeves exhibit superior resistance to crack initiation and propagation under mechanical shocks compared to alumina-based alternatives.

- Stable Operation Above 1000°C

Thermal tests confirm dimensional and phase stability up to 1100°C in air, supporting continuous high-temperature application without degradation.

- Low Thermal Conductivity

Measured at 2.2 W/m·K, the material minimizes heat transfer to adjacent components, ideal for thermal isolation in pump housings.

- Thermal Shock Resistance

The sleeve withstands rapid heating from 25°C to 900°C in under 60 seconds without developing microcracks, reducing failure risks in fluctuating temperature cycles.

Technical Specifications of Magnesia Stabilized Zirconia Ceramic Sleeve

The Magnesia Stabilized Zirconia Ceramic Sleeve exhibits a robust balance of structural durability, thermal endurance, and chemical inertness, making it ideal for continuous use in highly corrosive and abrasive process environments.

| Property |

Specification |

| Material Composition |

MgO-Stabilized ZrO₂ (MSZ) |

| Density |

5.60 – 5.85 g/cm³ |

| Vickers Hardness |

>1200 HV |

| Compressive Strength |

>2,000 MPa |

| Flexural Strength |

800 – 1000 MPa |

| Fracture Toughness |

9 – 10 MPa·m¹ᐟ² |

| Maximum Working Temperature |

>1000°C |

| Thermal Conductivity |

2.0 – 2.3 W/m·K @ RT |

| Thermal Expansion Coefficient |

10.3 ×10⁻⁶/K (25–1000°C) |

| Electrical Resistivity |

>10¹² Ω·cm @ RT |

| Chemical Resistance |

Stable in H₂SO₄, NaOH, chlorides, oxidizers |

| Water Absorption |

<0.01% |

| Surface Finish (Ra after grinding) |

≤0.4 μm |

| Phase Stability |

No monoclinic phase detected after 72h boiling |

Dimensions of Magnesia Stabilized Zirconia Ceramic Sleeve

|

MSZ Ceramic Sleeve |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-MGO-CT001 |

Customize |

Secure Packaging of Magnesia Stabilized Zirconia Ceramic Sleeve

Magnesia Stabilized Zirconia Ceramic Sleeve is securely packed using multi-layer protection to ensure safe transit during international shipment. Each unit is first cushioned with high-density foam and then sealed in reinforced cartons. Cartons are further consolidated in fumigation-free wooden crates for stable pallet loading and moisture-resistant export handling.

Enhancing Equipment Longevity in Corrosive and Abrasive Systems with ADCERAX® Magnesia Stabilized Zirconia Ceramic Sleeve

The ADCERAX® Magnesia Stabilized Zirconia Ceramic Sleeve is engineered for long-term durability in critical wear zones of industrial systems where conventional materials often fail due to chemical attack, abrasive erosion, or thermal cycling. By targeting core pain points such as accelerated component wear, fluid leakage, and unplanned shutdowns, this advanced ceramic solution plays a vital role in stabilizing system performance and extending equipment lifecycle.

-

High-Solid Slurry Recirculation Pumps in Mineral Processing

✅Key Advantages

1. High-Load Abrasion Endurance

The sleeve maintains structural integrity in slurries containing >30% solid concentration, where metal and alumina degrade rapidly. Its >1200 HV hardness limits cutting wear from angular ore particles common in phosphate and rare‑earth circuits.

2. Stable Performance Under High Particle Velocity

The dense MSZ microstructure resists micro‑pitting even at slurry velocities exceeding 5–8 m/s, preventing progressive surface scoring. This reduces turbulence-induced vibration that typically accelerates wear in steel sleeves.

3. Extended Operating Hours in Harsh Slurry Cycles

Field tests show MSZ sleeves sustaining >4000 hours of continuous operation without dimensional loss. This contrasts with hardened steel sleeves that generally fail within 1000–1500 hours in comparable circuits.

✅ ️Problem Solved

ADCERAX® in Mineral Slurry Recirculation

A concentrator handling 32%‑solid rare-earth slurry reported that hardened steel sleeves required replacement every 1200 hours, causing recurrent pump imbalance and seal failures. After switching to ADCERAX® Magnesia Stabilized Zirconia Ceramic Sleeves, the service interval extended to 4800 hours, reducing unscheduled shutdowns by over 60%. Shaft vibration dropped by 28%, attributed to the sleeve’s stable wear profile and smooth internal geometry. Maintenance labor associated with slurry pump rebuilds decreased significantly, improving overall concentrator equipment availability.

-

Flue Gas Desulfurization (FGD) Slurry Pumps in Coal-Fired Power Plants

✅Key Advantages

1. Resistance to pH Cycling in FGD Slurries

The MSZ matrix remains chemically stable through rapid pH swings from 3 to 10 encountered in limestone–gypsum reactions. This prevents the early‑stage surface etching seen on stainless steel sleeves exposed to sulfur-containing condensates.

2. Dual Protection Against Corrosive Condensates and Abrasive Crystals

The sleeve resists both sulfite‑induced corrosion and calcium‑rich particulate abrasion present in FGD loops. This dual resistance supports extended performance despite continuous recirculation loads in absorber towers.

3. Reliability Under Boiler-Adjacent Thermal Stress

With a sustained operating capability above 1000°C, the sleeve avoids thermal swelling or deformation that commonly affects elastomeric or polymeric alternatives. This protects pump alignment and reduces MTBF decline in desulfurization cycles.

✅ ️Problem Solved

ADCERAX® in FGD Desulfurization Pumps

A coal-fired power plant operating a wet‑FGD system reported sleeve failures every 2,500–3,000 hours when using 316L stainless steel, primarily due to sulfuric condensate corrosion and abrasive gypsum crystals. After adopting ADCERAX® Magnesia Stabilized Zirconia Ceramic Sleeves, service life exceeded 6,000 hours, effectively doubling MTBF. Leakage events decreased, and vibration associated with sleeve wear dropped by 31%, improving desulfurization unit uptime. Restricted-access maintenance areas benefited significantly, reducing annual maintenance interventions by nearly 40%.

-

Caustic Transfer Pumps in Fine Chemical & Specialty Alkali Systems

✅Key Advantages

1. Zero Ion Contamination in High‑Purity Alkali Processes

The fully inert ceramic surface eliminates Fe, Cr, or Ni ion leaching—an issue prevalent in alloy sleeves. Testing in 30% NaOH at 60°C for 72 hours confirmed zero measurable contamination, supporting purity‑critical production lines.

2. Structural Integrity in Extreme High‑pH Environments

MSZ maintains fracture toughness above 9 MPa·m¹ᐟ² even under repeated exposure to pH >13 chemicals. This prevents embrittlement and surface oxidation, which often compromise alumina sleeves in closed-loop caustic systems.

3. Batch Consistency Through Corrosion-Free Operation

With corrosion rates approaching 0 mg/cm²·day, the sleeve ensures predictable operation during long production cycles. This is essential for avoiding batch rejection in detergent-grade or specialty reagent manufacturing.

✅ ️Problem Solved

ADCERAX® in Caustic Chemical Transfer

A fine‑chemical producer manufacturing high-purity alkali reagents experienced product contamination caused by trace Fe/Ni leaching from alloy sleeves, resulting in three batch rejections per quarter. After replacing metal sleeves with ADCERAX® Magnesia Stabilized Zirconia Ceramic Sleeves, contaminant levels dropped below detection limits during 30% NaOH recirculation trials, ensuring regulatory compliance. Pump uptime improved as sleeve embrittlement was eliminated, and batch rejection due to sleeve-generated impurities was reduced to zero over a six-month monitoring period.

ADCERAX® Magnesia Stabilized Zirconia Ceramic Sleeve – Safe Use, Handling, and Maintenance Guide

Proper application and care of the Magnesia Stabilized Zirconia Ceramic Sleeve is essential to fully realize its wear resistance, corrosion stability, and thermal performance in demanding industrial environments. This section provides operational insights, handling precautions, and lifecycle recommendations tailored for engineering users, ensuring reliable performance and minimal risk of premature failure during use.

-

Pre-Installation Inspection Guidelines

1. Visual integrity check is required prior to installation. All Magnesia Stabilized Zirconia Ceramic Sleeves must be visually examined for surface cracks, chips, or handling damage under adequate lighting conditions.

2. Verify correct fitment without forcing the part. Always confirm dimensional compatibility against mating components without applying excessive force or impact during placement.

3. Avoid surface contamination during handling. Use clean gloves and avoid contact with grease, metal debris, or abrasive particles during inspection and installation stages.

-

Mounting and Assembly Best Practices

1. Support the sleeve evenly during mounting. Use soft clamping fixtures or concentric press-fit supports to avoid point loading that could induce stress concentrations.

2. Do not hammer or impact fit into housing. Ceramic sleeves must be inserted with controlled force; never use hammers or rigid press tools that can fracture the structure.

3. Align shaft and housing carefully. Misalignment during pump assembly may cause vibration and sleeve wall stress, increasing the risk of edge chipping during startup.

-

Operational Considerations in Field Use

1. Avoid thermal shock during system start-up. Gradually increase temperature to prevent microcracking from sudden ΔT, especially when transitioning from ambient to >500°C.

2. Prevent fluid cavitation and dry runs. Abrupt loss of process media can lead to localized overheating and surface spalling, reducing sleeve lifespan.

3. Monitor vibration and fluid chemistry regularly. Continuous operation in high-solids or acidic conditions should include routine inspection for wear or corrosion patterns.

-

Cleaning, Storage, and Replacement Strategy

1. Clean only with non-abrasive methods. Use soft brushes or ultrasonic baths—never sandblasting or wire brushes that could degrade the sleeve surface.

2. Store in a dry, shock-protected environment. Keep unused Magnesia Stabilized Zirconia Ceramic Sleeves in original foam-padded boxes, away from vibration or impact zones.

3. Define replacement intervals based on cycle history. Track operational hours, fluid properties, and failure trends to establish predictive replacement schedules that prevent unplanned shutdowns.