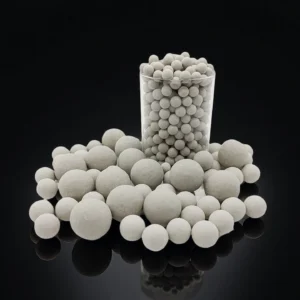

Superior Wear Resistant Alumina Balls (Al2O3) — Activated, Inert Support & Grinding Media for Industrial

ADCERAX is a trusted China manufacturer of alumina balls(Al2O3), offering purities from 68% to 99.7%. Our range includes high alumina grinding balls, inert support balls, and activated alumina balls for adsorption. Designed for petrochemical, water treatment, and advanced material industries, these balls ensure wear resistance, high density, and thermal stability.

👉 Explore our specifications and applications below, or request a quotation for bulk supply and tailored solutions.

≥1700 °C

High Thermal Stability

(Suitable for High-Temperature Reactors & Kilns)

(Standard Sizes & Custom Mini Balls Available)

High Density Alumina Ball

(Improved Wear Resistance & Longer Service Life)

(Stable Bed Support & Reliable in Heavy Load Systems)

What are Alumina Balls?

Alumina Balls Composition

Ceramic Alumina balls are manufactured from refined aluminum oxide powders, shaped and sintered under controlled conditions to achieve stable chemical and structural properties. The composition is primarily Al₂O₃, with purity grades available from 68% to 99.7%.

Medium alumina (68–80%) contains balanced proportions of Al₂O₃ and auxiliary oxides, often applied in cost-sensitive grinding operations.

High alumina (92–95%) features minimized silica and alkali content, ensuring reliable chemical inertness for catalyst and filtration uses.

Ultra-high purity (99%–99.7%) is produced with minimal impurities, offering excellent stability for thermal storage and electronic ceramics.

Extended service life and low contamination in milling and grinding.

Reliable support media for petrochemical and chemical reactors.

Proven durability in high-temperature and regenerative systems.

Resistant to acids, alkalis, and solvents, ensuring long-term stability in catalytic and filtration applications.

Alumina Ball Manufacturing Process

The manufacturing process of alumina oxide balls (Al₂O₃) follows a series of controlled steps designed to achieve consistent high density, mechanical strength, and material purity.

Alumina Ball Specification

ADCERAX supplies alumina balls (Al2O3) in multiple sizes and grades, engineered for grinding, catalyst support, adsorption, and thermal applications.

| Diameter (mm) | Purity Options | Typical Applications | Features / Highlights |

|---|---|---|---|

| 2–10 mm | 92%, 95%, 99% | Fine grinding media, catalyst support beds | High surface area, uniform sphericity, stable packing |

| 20–40 mm | 92%, 95% | Ball mill grinding, ceramic glaze milling | Wear-resistant, long service life, low contamination |

| 50–60 mm | 92%, 95%, 99%, 99.5% | Heavy-duty grinding, refractory packing | High crushing strength, excellent bulk density |

| 70–75 mm | 75%, 92%, 95%, 99%, 99.7% | Large ball mills, high-load grinding | Stable under heavy load, reliable thermal resistance |

Alumina Balls Benefits & Properties

Alumina ceramic balls are engineered to deliver a balance of high strength, heat resistance, and chemical stability. These properties make them widely adopted in petrochemical operations, ceramic production, and environmental treatment systems.

Key Benefits of Alumina Balls

⚙️ Problem: Uneven gas/liquid flow in catalyst reactors

Solution: Precisely engineered sphericity and bulk density of alumina balls ensure stable bed packing and uniform flow distribution.

🏗️ Problem: Catalyst bed collapse under high pressure

Solution: Alumina balls offer superior crushing strength, maintaining reactor integrity and minimizing downtime.

💧 Problem: Limited adsorption capacity in purification systems

Solution: Activated alumina alls provide high porosity and surface area, maximizing adsorption for water and gas treatment.

🔄 Problem: Excessive wear and contamination in grinding media

Solution: High-density alumina grinding balls deliver extended milling life with minimal contamination.

Alumina Balls Properties

| Purity Grade | Bulk Density (g/cm³) | Crushing Strength (N/ball, Ø20mm) | Max Operating Temp (°C) | Wear Resistance | Typical Applications | Relative Cost |

|---|---|---|---|---|---|---|

| 68% Al₂O₃ | 2.8–3.0 | 500–700 | ≤1100 | ★ | Ceramic grinding media, bulk milling | ★ Lowest |

| 75% Al₂O₃ | 3.0–3.2 | 800–1000 | ≤1200 | ★★ | Tile, glaze, paint, low-cost grinding | ★★ Low |

| 80% Al₂O₃ | 3.2–3.3 | 1000–1200 | ≤1300 | ★★ | Abrasives, ceramic powder milling | ★★ Low |

| 92% Al₂O₃ | 3.60–3.65 | 1500–1800 | ≤1500 | ★★★★ | Ball mill grinding media, glaze mills | ★★★ Medium |

| 95% Al₂O₃ | 3.68–3.75 | 1800–2000 | ≤1600 | ★★★★ | Catalyst support, inert packing, adsorption | ★★★★ Mid-High |

| 99% Al₂O₃ | 3.82–3.85 | 2000–2200 | ≤1680 | ★★★★★ | Fine ceramics, wear parts, high-temp systems | ★★★★★ High |

| 99.5–99.7% Al₂O₃ | 3.9–3.94 | 2200–2300 | ≤1730 | ★★★★★ | Semiconductor, electronics, advanced refractory | ★★★★★★ Premium |

📌 Notes

68–80% → Cost-effective choices for bulk grinding media and general ceramic milling.

92–95% → Most popular in catalyst beds, adsorption towers, and ball mills (balance of performance & price).

99%+ → For high-purity, high-temperature, and precision industries.

Relative Cost → Expressed as ★ rating (★ = lowest cost, ★★★★★★ = premium).

Find the Right Alumina Balls for Your Application?

From grinding media to catalyst beds and adsorption systems, we offer 68%-99.7%+ alumina balls with custom sizes and packaging.

Alumina (Al2O3)Ball Types & Function

Alumina(Al2O3) ceramic balls are designed in different types to meet diverse industrial needs—from grinding and milling to purification, catalyst support, and thermal storage. Each grade balances density, durability, and heat resistance, ensuring reliable performance across applications. Below are the main categories of alumina balls and their typical functions.

alumina grinding ball

1.Grinding media for ball mills and glaze milling

2. Applications: Ceramics, pigments, minerals

3. Long wear life, minimal contamination

inert alumina ball

1. Catalyst support media, stable bed packing

2. Applications: Petrochemical, refinery, gas/liquid distribution

3. High crushing strength, thermal resistance

activated alumina balls

1. Adsorbent and desiccant with high porosity

2. Applications: Water treatment, gas purification, air drying

3. Strong adsorption, regenerable

high alumina refractory ball

1. Thermal storage and lining for kilns and regenerative systems

2. Applications: High-temperature furnaces, heat recovery systems

3. Excellent thermal stability, spalling resistance

alumina beads

1. Multi-purpose ceramic beads

2. Applications: Grinding media, ceramic fillers, structural use

3. Durable and cost-effective

Alumina Ceramic Multi Bores

1. Flow and support media with through-holes

2. Applications: Reactor packing, fluid distribution systems

3. Enhanced flow uniformity, customizable

insulator alumina beads

1. Electrical insulation with strong dielectric properties

2. Applications: Electronics, high-voltage devices, barriers

3. Reliable insulation at high temperature

Precision Alumina Bearing Ball

1. Rolling elements for precision bearings

2.Applications: Automotive, aerospace, medical devices

3. High hardness, smooth finish, low friction

Bulk Alumina Balls, Fast Delivery, Custom Solutions

ADCERAX, an alumina ball wholesaler from China, supplies factory-direct with bulk stock and OEM customization. Backed by an integrated alumina ceramic ball supply chain, we ensure 24H fast delivery, stable quality, and competitive wholesale pricing worldwide.

Alumina Balls Uses

From petrochemical refining to environmental treatment, materials manufacturing, and high-temperature energy systems, alumina balls play a vital role. At ADCERAX, we provide both bulk supply and custom-engineered grades to ensure smooth, dependable operation across these diverse industries.

🔥 Petrochemical & Refinery

Application:Alumina balls are extensively applied as inert support media in hydrogenation reactors, desulfurization units, reforming towers, and gas-liquid separation beds. Their primary role is to stabilize catalyst layers, prevent particle migration, and improve overall reaction efficiency.

Operational Challenge:Refineries require stable catalyst beds with high strength to resist pressure and thermal cycling.

ADCERAX Solution:

To meet the demand for stable catalyst beds under high pressure and thermal cycling, ADCERAX produces high-strength alumina balls with crushing strength ≥ 8 kN/ball (Φ20 mm) and thermal shock resistance up to 1000°C quench cycles. Our engineered balls maintain bed stability and catalyst service life exceeding 3–5 years, ensuring reliable reactor operation even under extreme refining conditions.

👉 Start your project with confidence — get your pricing today.

🌍 Environmental Treatment & Gas Separation

Application: Activated alumina balls are used in industrial water treatment systems, air purification units, flue gas desulfurization towers, and VOC scrubbing processes. Their porous structure makes them ideal for fluoride removal, arsenic adsorption, and gas drying.

Operational Challenge: Treatment systems need reliable adsorption media to handle impurities and emissions effectively.

ADCERAX Solution:

To address the demand for high adsorption media in water and air treatment, ADCERAX supplies activated alumina balls with adsorption capacities up to 20% of their weight for fluoride, SO₂, and moisture. Our products ensure stable removal efficiency and extend system service life, reducing replacement frequency by over 30% in purification processes.

👉 Test first, scale later with confidence.

⚙️ Ceramics & Abrasive Manufacturing

Application: High-density alumina grinding balls are essential in ball mills and attritors for processing ceramic powders, pigments, advanced coatings, and abrasive materials. They ensure precise particle size reduction and maintain product purity.

Operational Challenge: Grinding and milling require wear-resistant media to maintain product quality and efficiency.

ADCERAX Solution:

For milling and grinding applications requiring wear resistance and efficiency, ADCERAX manufactures dense alumina grinding balls with bulk density above 3.6 g/cm³ and wear loss below 0.01% per 1000 cycles. These properties deliver uniform particle size distribution and lower media consumption, reducing production costs for abrasive and ceramic manufacturers.

👉 From prototype to mass production — we support every step.

♻️ High-Temperature Regenerative Systems

Application: Refractory alumina balls are deployed in regenerative burners, hot blast stoves, kilns, and thermal storage systems. They help retain and release heat efficiently, improving energy utilization rates.

Operational Challenge: Thermal systems demand materials that endure >1700°C without cracking or deformation.

ADCERAX Solution:

To withstand extreme thermal cycling in regenerative burners and kilns, ADCERAX offers refractory alumina balls rated for continuous use above 1700°C with thermal shock resistance of ≥10 rapid heat-cool cycles. This ensures long-term stability in heat storage units and cuts energy losses by 15–20%, supporting efficient high-temperature operations.

👉 Reduce risk, ensure consistency.

China Alumina Ball Manufacturer & Custom Supplier

ADCERAX, a China manufacturer, supplies bulk alumina balls in standard sizes and custom options. From 1 mm to 70 mm, we offer choices in purity, shape, and packaging—standard items ship within 24hours, custom orders in 3–7 weeks.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with details (purity grade, diameter range, tolerance, and quantity). Our engineers will review and provide a quotation with lead time.

Step 1

After confirming the order, we provide sample batches (1–50 pcs if required) for validation of size, strength, and surface quality.

Step 2

Once approved, bulk manufacturing begins with rolling, pressing, and high-temperature sintering. Each lot is inspected for density, crushing strength, and chemical resistance.

Step 3

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Step 4

Why Choose ADCERAX as Your Alumina Ball Supplier?

As a dedicated alumina balls manufacturer in China, ADCERAX wholesale alumina ceramic balls for grinding, adsorption, and refractory use—combining high quality, reliable solutions with strict QC and global shipping support

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Alumina Ceramic Ball Factory-ADCERAX

ADCERAX is a professional China alumina ball manufacturer and supplier, providing a complete range of grinding media, inert balls, activated balls, and refractory balls. With 10+ years of production experience, we serve clients in the USA, Germany, and Japan with verified QC standards. Through advanced forming and firing processes, we deliver products with precise size tolerance, consistent density, and long service life.

- 68% -99.7% high-purity alumina for stable performance

- Custom al2o3 ball based on your drawings or samples

- Fast prototyping (7–15 days) & flexible MOQ

- Strict QC with bulk density, crushing strength & thermal resistance tests

- Direct engineering support from design to delivery

Alumina Ball Machining & Processing

This section highlights our strengths in alumina ball production, from raw material purity and size control to forming, firing, and finishing. ADCERAX delivers customized alumina balls with high quality, meeting the diverse requirements of catalyst support, grinding media, and thermal applications.

| Technical Capabilities Overview | |

|---|---|

| Material Grades | 68%, 75%, 80%, 92%, 95% ,99%-99.7% Al₂O₃ – covering grinding, support, and thermal use |

| Diameter Range | 1 mm – 70 mm, with ±0.1 mm tolerance for consistent packing |

| Forming Methods | Rolling, pressing, and isostatic forming for uniform density |

| Processing | High-temperature sintering, surface polishing, customized sizing |

| Surface Finish | Smooth / Unglazed / Glazed, depending on application |

| Customization | OEM support with drawings or samples for tailored solutions |

Alumina Ceramic Ball Quality & Certifications

FAQ

The price of Al₂O₃ ceramic balls varies depending on purity (68%–99.7%), size, and order quantity. ADCERAX provides both a detailed alumina ball pricelist and competitive bulk pricing to meet different industrial requirements.

Alumina balls are available in 68%, 75%, 80%, 92%, 95%, and 99%+ Al₂O₃ grades. Higher purity improves thermal resistance, mechanical strength, and chemical inertness, making them suitable for more demanding industrial environments.

Refractory alumina balls withstand >1700°C without cracking, maintaining bed stability and service life in kilns, regenerative burners, and heat storage units.

Alumina grinding balls are loaded into ball mills as high-density grinding media, where they provide efficient particle size reduction through impact and friction. Their high hardness and wear resistance extend milling cycles while minimizing contamination, making them ideal for processing ceramics, minerals, pigments, and electronic materials.

nert alumina balls: Used mainly as catalyst bed support media due to high strength and chemical inertness.

Activated alumina balls: Feature a porous structure with large surface area, ideal for adsorption and drying applications in water treatment and gas purification.

Yes. ADCERAX supports customization in purity grades, diameters, density, surface finish, and packaging. Custom-engineered alumina balls can be tailored for specific reactors, mills, or regenerative systems.

Depending on application and grade, alumina balls typically last 3–5 years in catalyst beds and up to 2–3 times longer than conventional grinding media in milling operations, reducing overall operational costs.

Yes. ADCERAX is a China alumina ball manufacturer with large-scale production capacity, offering factory-direct wholesale supply for wastewater treatment projects. We provide bulk alumina ceramic balls with stable quality, fast delivery, and competitive pricing, ensuring reliable supply for distributors and industrial buyers.

Selection depends on whether you need inert balls (for catalyst support), activated balls (for adsorption), grinding balls (for milling), or refractory balls (for thermal storage). Our engineers can recommend the best alumina ball type based on your industry.

Yes. ADCERAX supplies wholesale inert alumina balls for petrochemical and refinery catalyst beds. With factory-direct bulk supply, we ensure high crushing strength, thermal stability, and timely delivery for reliable operation.

Yes. ADCERAX is aalumina balls manufacturer in china, offering bulk supply from 1 mm to 90 mm sizes. We provide factory-direct pricing, stable quality, and flexible shipping options to meet the needs of ball mill operations, ceramic glaze milling, and mineral grinding industries.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Build a Long-Term Partnership with ADCERAX?

Trusted by global buyers, ADCERAX is a China alumina ball manufacturer ensuring reliable bulk supply and cost-effective custom solutions.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours