Alumina Plates (Al2O3 Ceramic Plate ) — Sizes, High Purity and Custom Machining for Industrial Use

ADCERAX is a China alumina plate manufacturer and supplier delivering factory-direct alumina ceramic plate products with engineering support. Our alumina plates are trusted for electrical insulation, heat treatment, and laboratory use. Standard sizes and custom machining are available in 96%, 99%, 99.5%, and 99.7% Al₂O₃, with thickness from 0.5–20 mm and formats up to 1000 × 1000 mm.

Fast delivery, competitive pricing, and reliable quality make ADCERAX a dependable alumina plate factory partner for international buyers.

1730°C

Max Operating Temp

(99.7% Purity)

with Custom Thickness

Tolerance and Precision Machining (Cutting, Drilling, Chamfering)

Factory Direct Supply

What are Alumina Ceramic Plates?

Alumina Plate Definition

An alumina plate is a ceramic flat component made from sintered aluminum oxide (Al₂O₃). It is widely used for its high density, strong electrical insulation, and resistance to thermal and chemical attack. In industrial and research environments, alumina ceramic plates serve as lining plate, insulation plates, setter boards, and laboratory carriers.

Superior wear resistance for demanding applications

Operates reliably up to 1750°C

Outstanding dielectric properties

Inert to acids, alkalis, and corrosive media

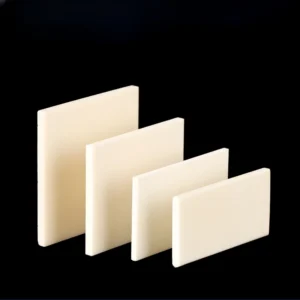

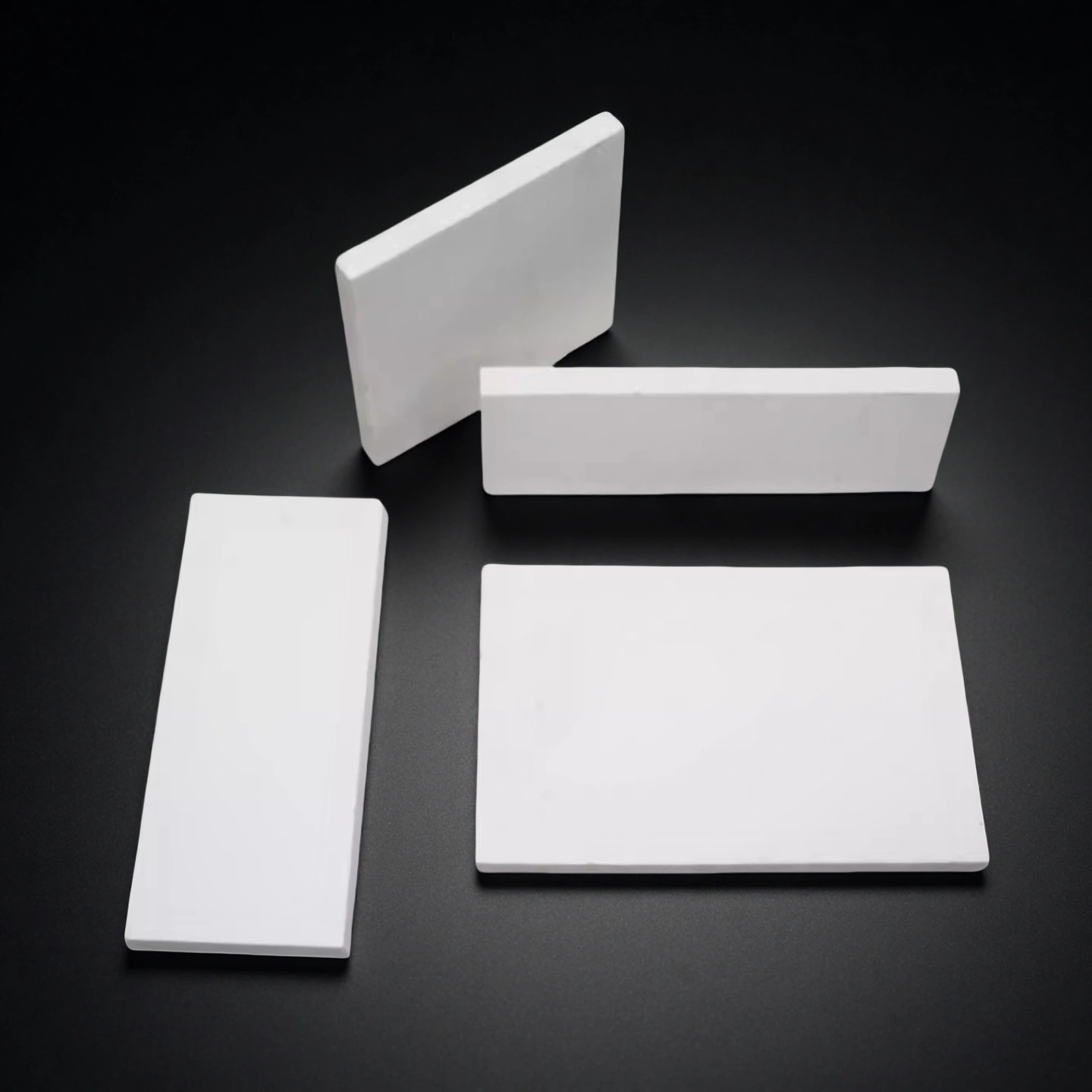

Alumina Plate Size

ADCERAX supplies alumina ceramic plates in both square and round formats, thicknesses ranging from 0.5 mm to 20 mm, with sizes up to 1000 × 1000 mm. Multiple purity grades are available to match electrical insulation, furnace lining, or laboratory applications.

| Plate Type | Shape | Dimensions (mm) | Thickness Range (mm) | Typical Applications |

|---|---|---|---|---|

| Thin Plate | Square / Rectangular | 50 × 50 / 100 × 100 | 0.5 / 1.0 / 2.0 | Electronics, insulating pads |

| Medium Plate | Square / Rectangular | 150 × 150 / 200 × 200 | 2.0–5.0 | Laboratory carriers, R&D test fixtures |

| Large Plate | Square / Rectangular | 300 × 300 / 500 × 500 | 5.0–10.0 | Furnace setter plates, thermal shields |

| Extra-Large Board | Square / Rectangular | up to 1000 × 1000 | 10–20 | Industrial kilns, heavy load supports |

| Alumina Disc | Round | Ø10–Ø300 | 1.0–10 | Sample carriers, substrate holders, insulation discs |

Alumina Ceramic Plate Benefits & Technical Data

📏 Dimensional Stability

Flatness and thickness uniformity up to 1000 × 1000 mm ensure reliable support during furnace cycles without warping.

🔩 Load-Bearing Strength

Alumina oxide ceramic plates withstand repeated kiln loading, making them ideal as setter plates and furnace boards under high stress.

🔍 Precision Machining

Custom options include laser cutting, drilling, polishing, and slotting. Thin 1 mm alumina ceramic plates serve as insulation, while thicker boards integrate with furnace racks.

⚙️ Industrial Efficiency

Large-area boards reduce the number of supports, improving throughput and enabling smooth scale-up from lab to production.

| Property | 99.7% Al₂O₃ | 99.5% Al₂O₃ | 99% Al₂O₃ | 96% Al₂O₃ |

| Density(g/cm³) | 3.94 | 3.9 | 3.83 | 3.6-3.75 |

| Hardness(Mohs) | 9.1 | 9 | 9 | 8.8 |

| Flexural Strength (Mpa) | 330 | 320 | 300 | 260 |

| Compressive Strength (Mpa) | 2300 | 2300 | 2210 | 1910 |

| Maximum Operating Temperature(°C) | 1730 | 1700 | 1680 | 1450 |

| Thermal Expansion Coefficient(10⁻⁶/°C) | 7.6 | 7.6 | 7.6 | 7.6 |

| Thermal Conductivity (25°C)W/(m·K) | 29 | 27 | 24 | 22 |

| Dielectric Strength (AC-kv/mm) | 22 | 21 | 19 | 15 |

| Volume Resistivity (20°C) | >10¹⁴ | >10¹⁴ | >10¹⁴ | >10¹⁴ |

Need Custom Alumina Plates?

Our engineers provide drawings, machining, and fast quotes.

Alumina Plate Products

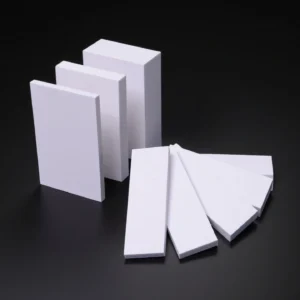

ADCERAX supplies alumina ceramic plates in square, rectangular, and round formats for insulation, wear resistance, and furnace lining. Available in 96%–99.7% Al₂O₃, with standard sizes in stock and custom machining for special dimensions. As a China alumina plate manufacturer, we offer factory-direct pricing and reliable quality for long-term industrial use.

Alumina Ceramic Disc

Alumina ceramic discs, with exceptional flatness and thermal stability, are perfect for electronic substrates or as durable alumina plates in high-wear settings.

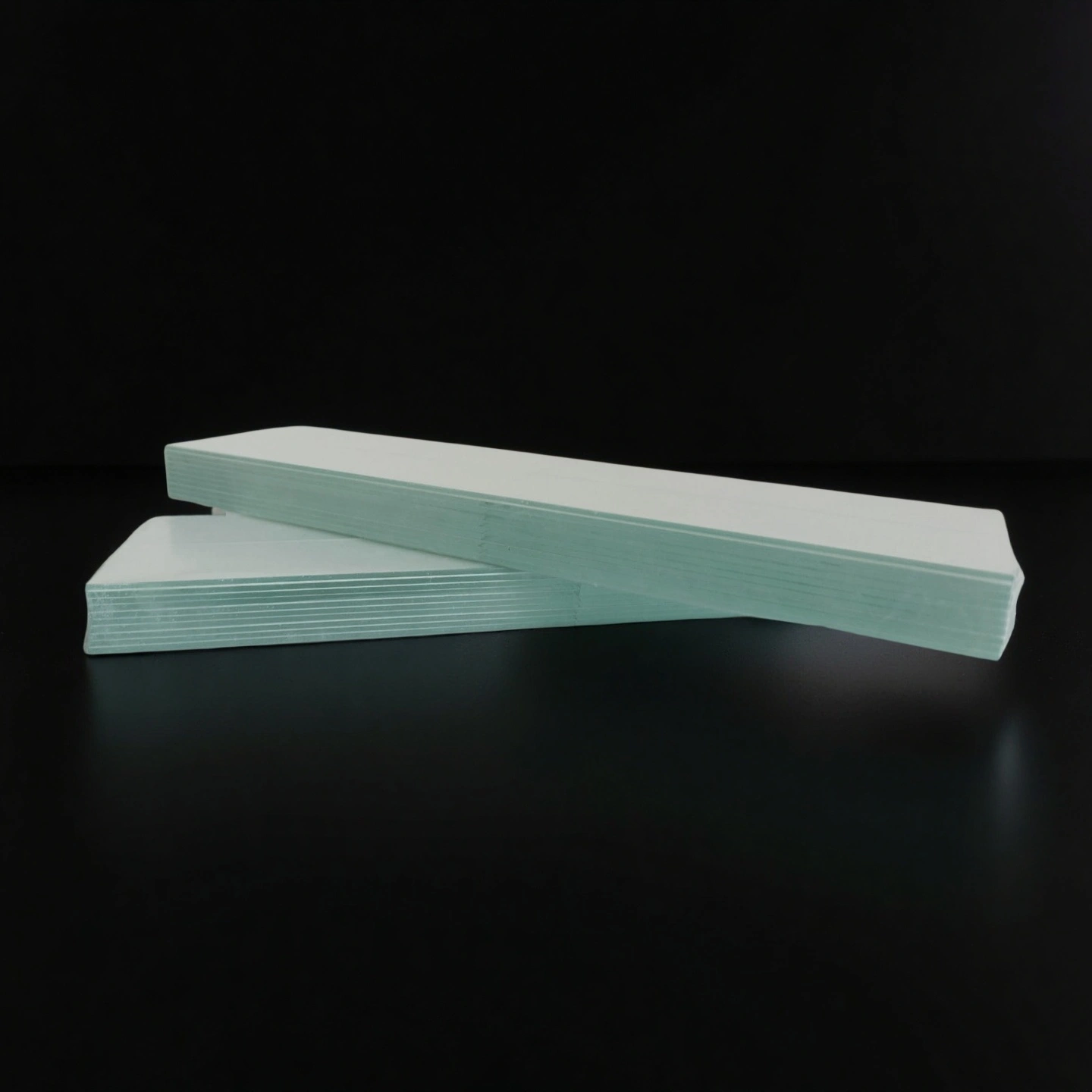

Alumina Sheet

Our versatile alumina sheets provide superior electrical insulation and chemical resistance, serving as ideal protective alumina plates for linings or harsh environments.

alumina insulation board/ Plate

Lightweight alumina insulation boards with superior thermal insulation and structural integrity for furnace linings and high-temperature applications.

alumina ceramic slice

For microelectronics and sensors, expertly cut alumina ceramic slices are vital, providing high purity and tight tolerances for compact, high-performance designs.

porous alumina plate

Excelling in filtration and gas distribution, porous alumina plates are perfect for catalyst support or specialized separation processes.

Alumina Lining Plate/ Board

Designed for extreme wear, alumina lining plates provide superior protection for industrial equipment, extending lifespan as robust alumina plates in abrasive environments.

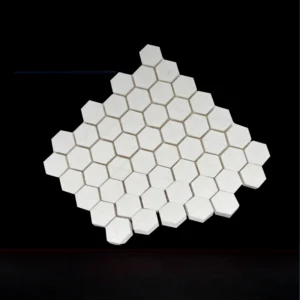

alumina mosaic plate

Alumina mosaic plates offer exceptional wear resistance in a flexible format, perfect for protecting chutes and hoppers as durable alumina plates in high-impact areas.

alumina tlc plates

Specialized alumina TLC plates are crucial for precise chromatographic separations in laboratories, offering consistent performance as high-purity alumina plates for analytical chemistry.

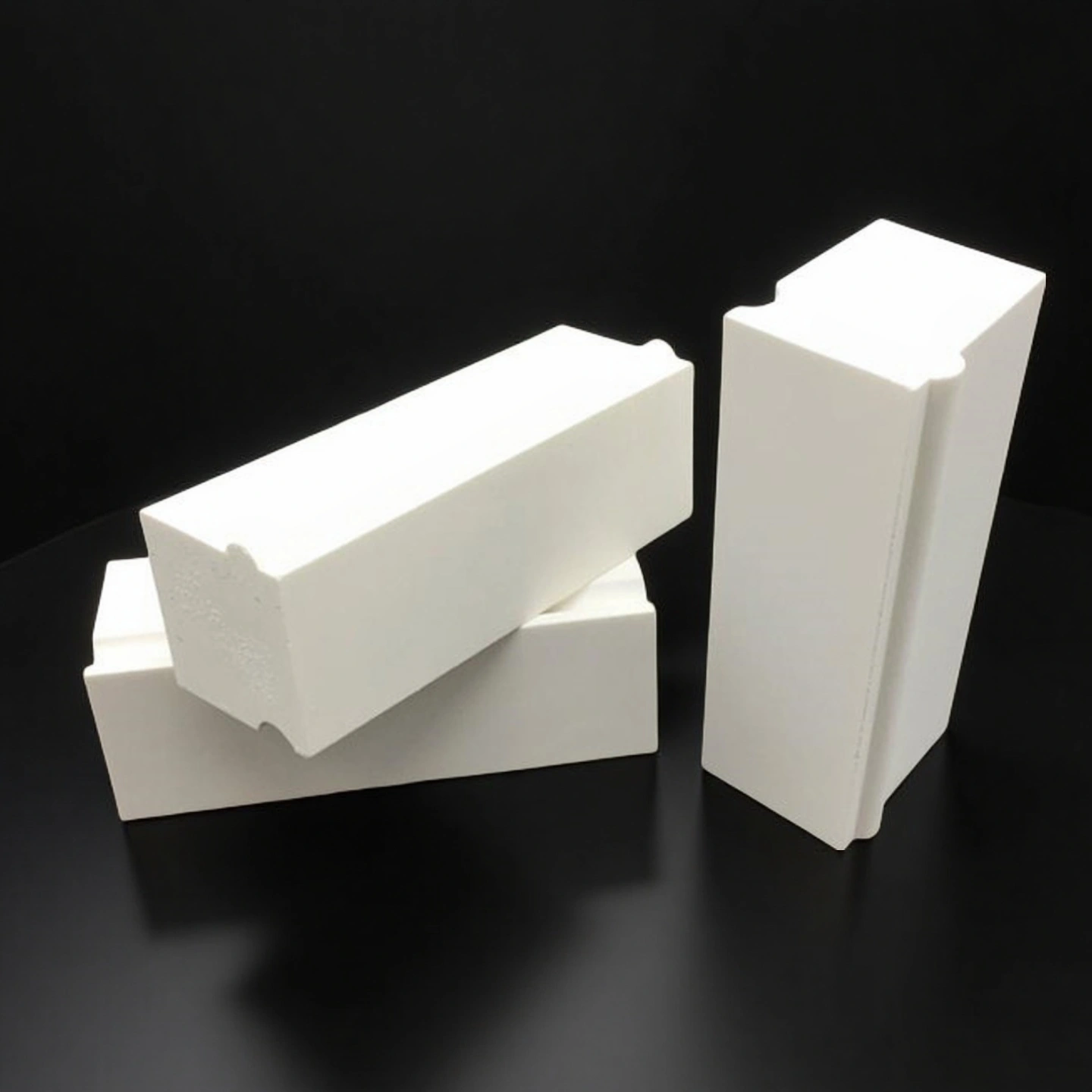

alumina ceramic block/ brick

These robust alumina ceramic blocks/bricks provide exceptional structural integrity and thermal stability, serving as essential components or alumina plates in high-temperature furnace construction.

Alumina Ceramic Foam Filter

Designed for molten metal filtration, alumina ceramic foam filters ensure high purity and efficiency. They act as advanced alumina plates for removing impurities in casting processes.

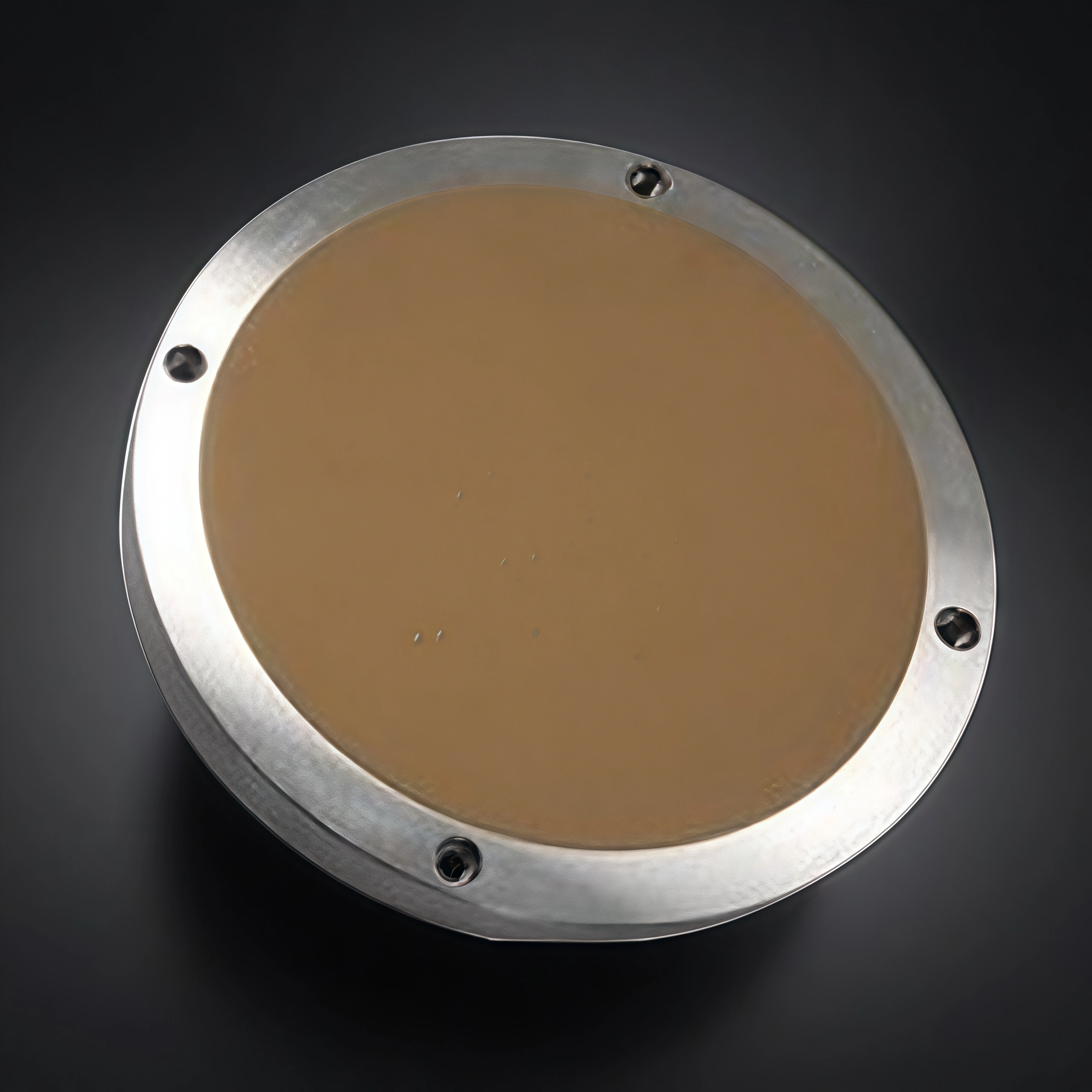

Porous Alumina Vacuum Chuck

Porous alumina vacuum chucks are for precise, non-damaging handling of delicate materials. They provide superior grip, making these alumina vacuum chucks indispensable in semiconductor and optics manufacturing.

alumina fiber board

Lightweight and highly insulating, alumina fiber boards are perfect for high-temperature furnace linings and thermal barriers. They function as versatile alumina plates where excellent heat resistance and low thermal conductivity are critical.

ADCERAX Supply Factory-Direct Price Alumina Plate and Solve Your Sourcing Challenges

As a China alumina plate manufacturer, ADCERAX offers both stock sizes and drawing-based customization. From 1 mm thin plates to large 1000 × 1000 mm boards, all products are delivered with strict tolerance control. Get a fast quotation directly from our engineering team.

Alumina Plate Applications

Whether you need an alumina plate for electrical insulation, an alumina plate for wear parts, or an alumina plate for furnace lining, our alumina plates adapt to your exact application needs. Their exceptional properties make them indispensable across a wide range of demanding industrial sectors.

🔌Alumina Plates in High-Temperature Industry

Our alumina plates serve as circuit board for microelectronics, providing excellent electrical insulation and heat dissipation. They are vital as insulators in high-voltage systems and are used in the production of heating elements, ensuring reliable performance in sensitive electrical applications.

Ready to Order Alumina Plate for Industrial Applications?

✅ 24h quotations

✅ Custom machining per drawings

✅ Fast delivery worldwide

👉 Start your project with confidence — get your pricing today.

⚙️Alumina Plates in Mechanical Engineering

In mechanical systems, our alumina ceramic plates are widely used as wear parts, significantly extending the life of components like pump components, seals, bearings, and cutting tool inserts.Their superior hardness and wear resistance make them ideal for abrasive environments.

Need Al2o3 Plate with Samples and Fast Delivery?

✅ Standard sizes available for 24h dispatch

✅ Samples for testing before bulk orders

✅ Global delivery support

👉 Test first, scale later with confidence.

🔬al2o3 Plates for Chemical & Metallurgical

The exceptional corrosion resistance of our al2o3 ceramic plate makes them suitable for components exposed to aggressive chemicals. They are frequently used for crucibles and labware in high-temperature chemical reactions and material processing.

Do You Require Custom Alumina Oxide Ceramic Plate?

✅ Laser cutting, drilling, polishing, chamfering

✅ Tolerance control up to ±0.05 mm

✅ Engineering team support for your project

👉 From prototype to mass production — we support every step.

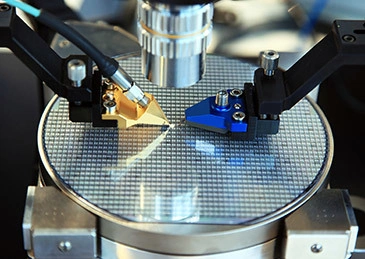

🧱 Alumina Plate in Semiconductor Manufacturing

In the precision-demanding semiconductor industry, alumina oxide ceramic plate are utilized for wafer processing equipment and vacuum components, where their purity and stability are paramount.

Tired of Delays and Quality Issues from Traders?

✅ Work directly with ADCERAX as your alumina ceramic plates manufacturer

✅ Stable lead times, strict tolerance control

✅Long-term supply for industrial projects

👉 Reduce risk, ensure consistency.

China Alumina Plates Customized supplier

ADCERAX is a China alumina plate factory offering factory-direct pricing and customized solutions. From 1 mm thin plates to large 1000 × 1000 mm boards, we provide custom machining—cutting, drilling, and polishing—to match your exact application needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your Alumina Ceramic Plate Wholesale?

ADCERAX is a dedicated manufacturer and supplier of alumina ceramic plates, focused on delivering factory-direct quality, fast lead times, and flexible customization. With strict tolerance control and global shipping support, we make it easy for you to source the right Al₂O₃ plates with confidence.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Alumina Ceramic Plate Manufacturers-ADCERAX

ADCERAX is a professional China alumina corundum plate factory and wholesaler that offers high-performance components with tight tolerances (±0.1mm) and custom geometries. Using advanced forming methods and CNC machining, we deliver precision-engineered solutions for electronics, chemical, and high-temperature applications.

- 99.7% high-purity alumina for stable performance

- Custom parts based on your drawings or samples

- Fast prototyping (7–15 days) & flexible MOQ

- ISO-compliant quality control & inspection reports

- Direct engineering support from design to delivery

Alumina Plate Machining

This section outlines our core machining strengths, from material grades and tolerance control to advanced forming and finishing methods. We deliver customized alumina plate solutions to meet diverse industrial needs with precision and reliability.

| Technical Capabilities Overview | |

|---|---|

| Material Grades | 96%, 99%, 99.5%, 99.7% Al₂O₃ – high purity for demanding applications |

| Tolerances | Up to ±0.1mm – suitable for precision assemblies |

| Forming Methods | Dry pressing, isostatic pressing, extrusion, casting, injection molding |

| Processing | CNC machining, fine grinding, polishing |

| Surface Finish | Polished / Unglazed / Glazed |

| Customization | Drawings, CAD files, or samples accepted for custom parts |

Alumina Plates Quality & Certifications

FAQ

ADCERAX supplies al2o3 alumina ceramic plate in 96%, 99%, 99.5%, and 99.7% Al₂O₃, covering both standard and high-purity requirements for insulation, wear resistance, and high-temperature use.

The choice of alumina plates quality depends on your technical needs and budget. Lower purities are more cost-effective, while higher purities deliver maximum thermal and chemical stability for advanced processes. See the comparison below:

| Purity Level (Al₂O₃) | Key Advantages | Typical Applications | Cost Level |

|---|---|---|---|

| 96% | Good mechanical strength, stable performance | General industrial use, kiln furniture, wear parts | ★ Low |

| 99% | High hardness, improved corrosion resistance | Electrical insulation plates, structural components | ★★ Medium |

| 99.5% | High density, low impurities, stable at high load | Furnace lining boards, technical ceramics, carriers | ★★★ Mid-High |

| 99.7% | Excellent thermal resistance up to 1700 °C, dielectric strength >10 kV/mm | Semiconductor manufacturing, precision lab substrates, advanced R&D | ★★★★ Premium |

👉 Need advice on selecting the right alumina purity grade? Share your drawings or specifications with ADCERAX, your China alumina plate manufacturer, and get a 24h quotation with factory-direct pricing.

Yes. ADCERAX has alumina plate for sale in 96%–99.7% purity grades, engineered for furnace lining with excellent wear resistance, high thermal stability up to 1730 °C, and reliable electrical insulation. Custom machining and fast delivery are available

The cost depends on purity (96%–99.7% Al₂O₃), size, thickness, and machining complexity. Standard alumina plates range from low-cost stock items to high-precision custom plates. Send us your drawing or specifications for a quick quotation.

Yes, we support drawing-based customization from 1 mm thin plates to 1000 × 1000 mm large boards, with machining options such as laser cutting, drilling, and polishing.

Alumina ceramic plates are very hard and brittle, making them difficult to cut with standard tools. For precise results, they should be processed using diamond cutting wheels, laser machining, or CNC grinding under professional equipment. Attempting to cut them manually often leads to cracks or breakage. ADCERAX provides custom cutting, drilling, and polishing services, ensuring tight tolerance control and clean edges for your specific application.

Alumina ceramic plates are machined using specialized equipment such as CNC grinding, laser cutting, drilling, and polishing. These methods ensure precise tolerance control, typically within ±0.05–0.1 mm, and clean surface finishes. Because alumina is extremely hard and brittle, machining requires diamond tools and advanced processing techniques. At ADCERAX, we provide custom machining services based on your drawings or CAD files to deliver alumina plates that meet exact industrial requirements.

At ADCERAX, we ensure alumina plates quality through strict raw material selection (96%–99.7% Al₂O₃), advanced isostatic pressing and high-temperature sintering, and precise machining with ±0.05–0.1 mm tolerance. Every batch is inspected for density, flatness, and surface finish to guarantee consistent performance in industrial and laboratory applications.

Standard alumina plates are produced with ±0.1 mm thickness tolerance. For custom machining, we can achieve tighter control depending on plate size. Typical options include hole or slot tolerance ±0.1–0.2 mm, chamfer and edge polish customization, and surface roughness (Ra) ≤ 1.2 μm. These tolerances ensure reliable fit in assemblies and precise integration into industrial equipment.

ADCERAX provides datasheets with details of tolerances, machining options (laser cutting, drilling, slotting), and surface roughness values upon request. This helps engineers compare alumina plate quality and select the right grade for their project.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Ready to Partner with ADCERAX?

Whether you need a standard alumina plate or a complex customized al2o3 plate, our team is ready to assist. Get in touch today to discuss your requirements.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours