Black Alumina (Aluminum Oxide for Structural Components and Wear-Resistant Applications

ADCERAX supplies black alumina ceramic components engineered for structural, mechanical and wear-resistant applications. We manufacture custom-machined rods, discs, plates and precision parts in dark alumina formulations produced under controlled atmospheres to achieve stable density, hardness and thermal performance. As a factory-based supplier, we support drawings, tight tolerances, rapid sampling and consistent mass production, helping OEMs, equipment builders and materials engineers source durable ceramic solutions with reliable lead times and responsive technical support.

🤝 If you are tired of unstable quality or suppliers who cannot keep up with your requirements, we can give you the consistency and technical support your projects need.

What is Black Aluminum Oxide?

Black Aluminum Oxide Definition

Black alumina is a dark-colored alumina ceramic material produced by adding specific metal oxides, carbon sources, or using controlled atmospheres during sintering to shift high-purity α-Al₂O₃ into a deep grey to black appearance. Unlike black fused aluminum oxide (which is an abrasive), black alumina is a structural ceramic, engineered for mechanical strength, wear resistance and thermal stability.

Why choose Black Alumina Ceramic instead of Black Fused Alumina?

| Item | Black Alumina Ceramic | Black Fused Aluminum Oxide |

|---|---|---|

| Material Type | Sintered structural ceramic (engineered α-Al₂O₃) | Electro-fused abrasive grain (bauxite-based) |

| Final Form | Machined parts: rods, discs, plates, custom components | Granular abrasive grit (F12–F220, 1–3 mm) |

| Density | 3.60–3.85 g/cm³ (fully dense) | 1.60–1.95 g/cm³ (loose bulk density) |

| Hardness | 15–18 GPa (Vickers) | Mohs ~9 (abrasive grain) |

| Thermal Performance | Operates up to ~1,400–1,650 °C as a structural part | Used in refractories/blasting but not as shaped component |

| Shape Capability | High precision machining to tight tolerances (±0.02–0.1 mm) | No machining—only grit size available |

| Typical Applications | Structural parts, wear components, high-temperature supports | Grinding wheels, sandpaper, blasting media, refractory aggregates |

Black aluminum oxide is a fully dense structural material for engineered components, while black fused alumina is an abrasive grain for cutting, grinding and blasting—with entirely different performance, applications and design parameters.

Black Alumina (Aluminum Oxide) Properties

Black alumina is a fully dense, black-colored structural alumina ceramic engineered for mechanical strength, wear resistance and high-temperature stability, making it suitable for custom precision components.

Black Alumina Technical Data

| Parameter | Typical Value / Range | Technical Notes |

|---|---|---|

| Flexural Strength | 250–380 MPa | Determines mechanical load capacity and resistance to bending failure |

| Compressive Strength | > 2,000 MPa | Critical for high-load structural components |

| Vickers Hardness | 15–18 GPa | Indicates wear resistance under abrasive or frictional conditions |

| Maximum Operating Temperature | 1,400–1,650 °C | Suitable for high-temperature assemblies and furnace components |

| Density | 3.60–3.85 g/cm³ | Near-theoretical density ensures stable ceramic performance |

| Thermal Conductivity | 18–25 W/m·K | Supports thermal stability and heat dissipation |

| Coefficient of Thermal Expansion (CTE) | 7.5–8.0 ×10⁻⁶ /K | Ensures dimensional stability under thermal cycling |

| Electrical Resistivity | >10¹² Ω·cm | Provides excellent insulation for electrical isolation parts |

| Fracture Toughness (KIC) | 2.5–3.5 MPa·m½ | Measures crack-propagation resistance under mechanical stress |

| Machining Tolerance Capability | ±0.02–0.1 mm | Tight CNC grinding tolerances suitable for precision custom parts |

- This chart displays the typical properties of black alumina used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Advantages of Black Alumina Ceramic

Delivers strong abrasion resistance against friction, impact, and particle erosion, making it ideal for durable guides and motion components in industrial equipment.

Provides reliable flexural and compressive strength, maintaining dimensional accuracy under continuous mechanical load, vibration, and repetitive assembly forces.

Its deep black, through-body ceramic matrix minimizes glare and light scatter, supporting stable performance in optical housings, sensors, and heat-affected environments.

Sintered blanks can be ground into rods, plates, discs, rings, or complex geometries with tight tolerances, enabling precise fit and consistent performance across custom assemblies.

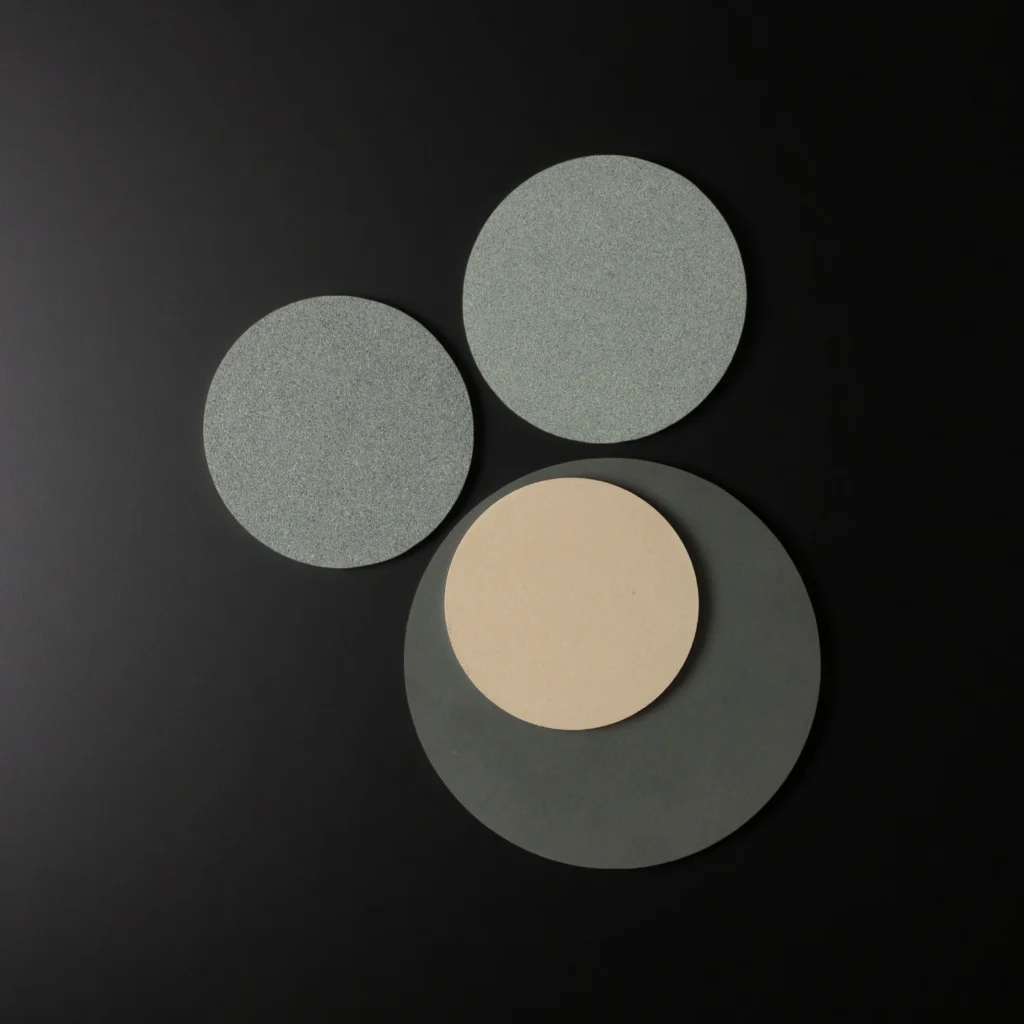

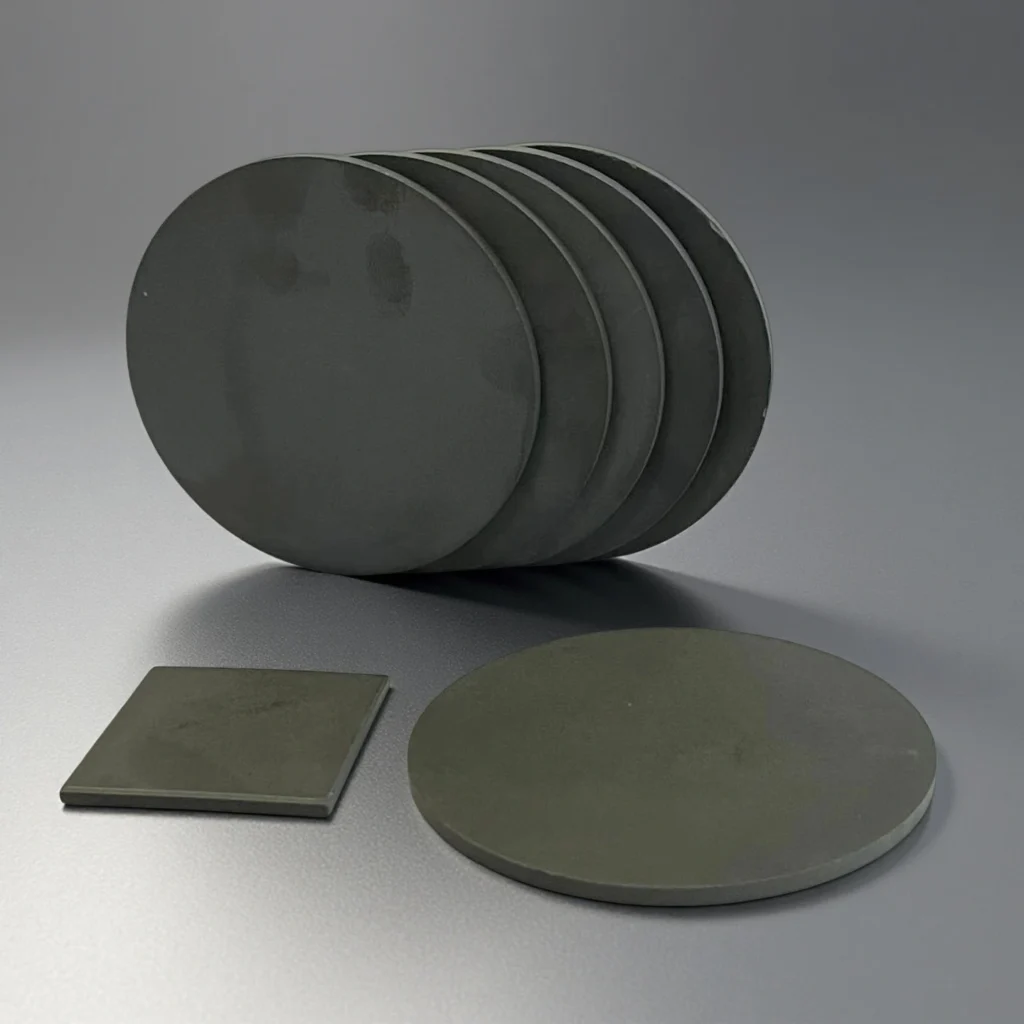

Black Alumina Products

We offer a full range of black alumina products, including discs, rods, plates, rings, blocks, and custom-machined components. All parts can be produced according to your drawings, samples, dimensions, and geometric requirements, supporting both standard shapes and complex custom designs.

Black alumina tubes serve as high-temperature insulation sleeves, protective guides, and wear-resistant liners for industrial machinery and heating systems. They provide stable performance during thermal cycling and continuous mechanical load.

- Strong abrasion resistance for sliding, guiding, and motion interfaces

- Maintains mechanical stability at elevated temperatures

- Customizable in length, inner/outer diameter, and precision-machined tolerances

Porous alumina vacuum chucks are used for uniform suction, wafer handling, and precision support in processes where stable airflow control, flatness, and thermal consistency are critical to device alignment and surface protection.

- Even air distribution and stable holding force for sensitive substrates

- High flatness and dimensional stability under heat and process load

- Custom pore size, thickness, and surface geometry options for specialized tools

Black alumina substrates are used as stable insulating bases, support layers, and wear-resistant plates in equipment where heat exposure, mechanical load, and electrical isolation must remain consistent during continuous operation.

- Reliable insulation and strength under high temperature and repeated cycles

- Low thermal expansion for dimensional accuracy in precision assemblies

- Custom thickness, surface finish, and CNC-machined shapes available

Black alumina rods are used as structural guides, insulating supports, and wear-resistant shafts in industrial equipment. They maintain stable mechanical and electrical performance under heat, friction, and continuous operational load.

- High wear resistance for sliding, guiding, and rotating interfaces

- Strong electrical insulation with stable strength at elevated temperatures

- Available in custom diameters, lengths, and precision-machined tolerances

💡 Precision Black Alumina Built for High-Heat, High-Load, and Wear-Critical Applications. Custom Sizes Ready on Request.

ADCERAX provides black alumina ceramic rods, plates, discs, and custom parts engineered for strength, durability, and stable performance under heat and mechanical load. We manufacture from dense black alumina blanks with tight machining tolerances to support industrial equipment, automation systems, and precision assemblies.

Black Alumina Applications

Black alumina ceramics are used across industrial machinery, optical devices, electronic assemblies, and laboratory equipment. They serve as structural components, alignment parts, wear surfaces, positioning elements, and insulating supports in systems that require stable geometry and long-term reliability. Their consistent appearance and low reflectivity also make them suitable for optical benches, sensor mounting, and precision-fixture environments.

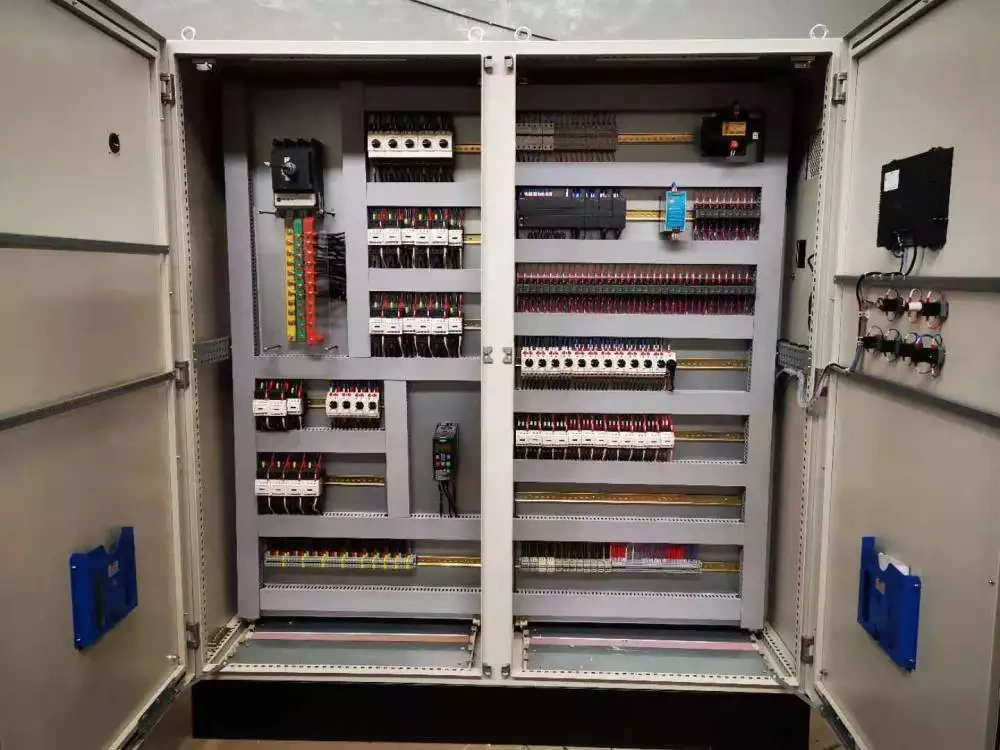

Industrial Machinery & Wear Components

📍Black alumina’s high hardness, abrasion resistance, and dimensional stability make it suitable for wear pads, guide blocks, sealing interfaces, positioning fixtures, and sliding components in heavy-duty machinery, automation systems, and material-handling equipment. It performs reliably under continuous friction, impact, and particulate erosion.

⚙️ Case: Black alumina bushings from ADCERAX have run in a German material-handling system for 11 months with only 0.018 mm wear, compared with 0.12 mm using their previous polymer bushings. This extended the maintenance interval from 4 months to 12 months, reducing annual service cost by over 50%.

— Senior Equipment Engineer, German Machinery OEM

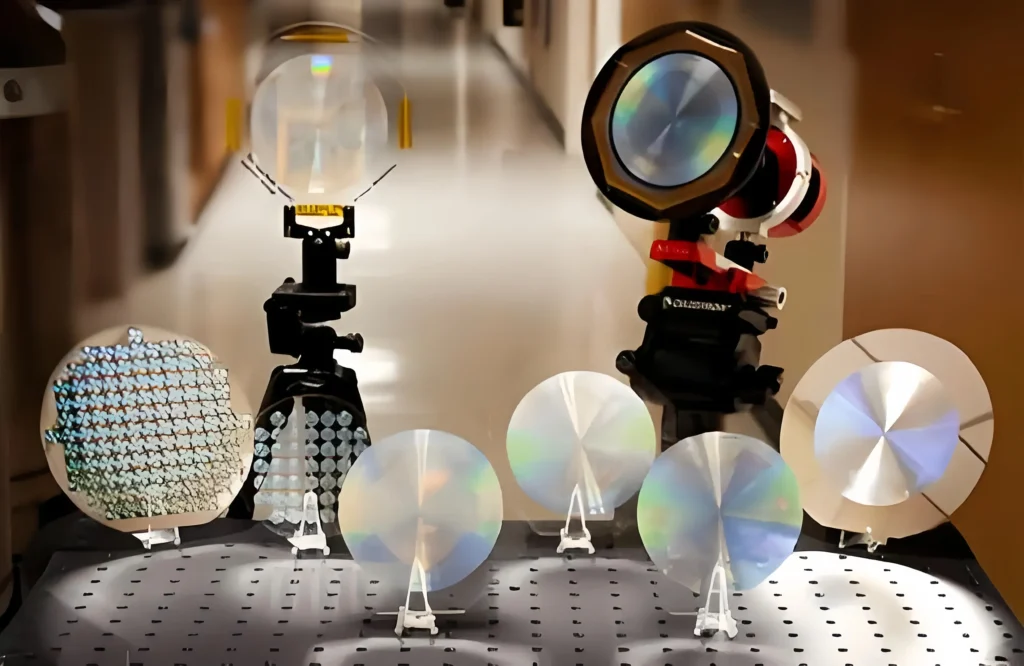

Optical, Imaging & Precision Instrumentation

📍Its low reflectivity, controlled surface finish, and stable mechanical properties enable use in optical fixtures, sensor housings, alignment blocks, beam-path structures, and precision mounting components. Black alumina minimizes stray light and maintains geometry in metrology systems, imaging devices, and photonics equipment.

⚙️ Case: Black alumina alignment blocks from ADCERAX were used in a U.S. optics lab’s laser fixture, showing <0.005 mm dimensional drift after 600 thermal cycles between 25–120°C. This reduced recalibration frequency by 40% and stabilized beam alignment in long-run tests.

— Optical Systems Engineer, U.S. Photonics Lab

Electronic & High-Temperature Insulation Systems

📍With good dielectric strength and thermal resistance, black alumina is applied in electrically insulated mounts, thermal-barrier components, coil supports, heating structures, and protective housings for RF modules, power electronics, and compact high-temperature assemblies that require stable insulating performance.

⚙️ Case: A Japanese electronics manufacturer integrated ADCERAX black alumina housings in a high-frequency sensor module. After 2,000 hours of operation, EMI leakage dropped by 18%, and unit rejection rate fell from 3.2% to 0.9%, improving production yield significantly.

— Quality Manager, Japan Sensor Manufacturing Group

Scientific Equipment, Laboratory Fixtures & Structural Parts

📍Its structural rigidity and resistance to chemical exposure allow use in laboratory jigs, support posts, vacuum-compatible parts, sample holders, furnace fixtures, and experimental hardware. Black alumina maintains consistency under heat, load, and repeated thermal cycling, supporting long-term testing and research applications.

⚙️ Case: Black alumina sample holders supplied by ADCERAX were tested in a European materials lab at up to 900°C. After 4 months of repeated cycling, surface wear measured only 0.012 mm, compared to 0.09 mm with alumina-coated steel, extending usable life by 6×.

— Lead Research Scientist, EU Materials Research Center

Customized Black Alumina Manufacturer

ADCERAX manufactures custom black alumina ceramic components in China, producing engineered parts according to your drawings, samples, or functional requirements. Engineering assistance, flexible MOQs, and typical delivery in 3–9 weeks are available for both prototypes and production orders.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Trusted china black alumina factory

ADCERAX is a black alumina manufacturer in China, producing custom-made black alumina components through advanced sintering and precision machining. With in-house production and strict quality control, we support consistent material quality, reliable dimensional accuracy, and flexible supply for both prototype development and mass-production orders.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates aluminum oxide black forming, precision machining, and inspection into a unified production workflow. Our one-stop system supports custom geometries, tight tolerances, and consistent quality—from prototypes to full-scale production.

-

Precision Machining & Dimensional Control:

Each black alumina component is produced with strict control of density, microstructure, and geometry, ensuring accurate dimensions, low reflectivity uniformity, and stable performance under mechanical load and temperature exposure. -

Batch Stability & Quality Assurance:

Every production batch is inspected for density, hardness, dimensional consistency, and surface quality. This ensures reliable material uniformity and repeatable performance for structural, insulating, and wear-related uses. -

Customization & Engineering Support:

We provide engineering assistance for custom black alumina parts, including complex shapes, tight-tolerance interfaces, and design adjustments based on your drawings or functional requirements—supporting industrial, automation, and high-temperature applications.

ADCERAX specializes in black oxidized aluminum production, combining controlled sintering and precision machining to deliver components with stable density, uniform black-through-body structure, and accurate dimensions for reliable industrial performance.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Dense black alumina ceramics formulated for uniform through-body color, stable density, and consistent sintering quality. | ||

| Precision Machining | CNC diamond grinding, ultrasonic milling, slotting, and precision trimming for tight tolerances (typically ±0.02–0.1 mm). | ||

| Forming & Shaping | Cold Isostatic Pressing (CIP), die pressing, and custom preform shaping to produce discs, rods, plates, rings, and complex geometries before final machining. | ||

| Microstructure Control | Fine powder formulation and controlled sintering cycles to achieve uniform grain structure, consistent densification, and stable mechanical properties. | ||

| Surface Treatment | Grinding, lapping, polishing, and matte finishing to achieve smooth, consistent, or low-reflectivity surfaces depending on design requirements. | ||

FAQ

In refractory and furnace environments, black alumina can operate in the 1,200–1,500 °C range when built into an appropriate matrix. For grinding and blasting operations, the working temperatures at the contact zone are much lower than its thermal stability limit, so black aluminum oxide temperature range is more than adequate for standard steel processing.

In practice, cleaning methods may involve alkaline cleaners, mild abrasives or blasting with suitable media. Black alumina can be used as a blasting media to mechanically remove coatings from steel, but when working on aluminum you must choose media and parameters carefully to avoid damaging the softer base metal.

White aluminum oxide is a high-purity, extremely hard, and brittle abrasive produced from refined alumina, making it ideal for precise grinding, polishing, and applications where contamination must be minimized. It cuts cleanly but fractures easily, generating sharp micro-edges for fine finishing work.

Black aluminum oxide, however, is tougher and slightly less brittle, produced from alumina with controlled impurities that give it a darker color. It offers stronger impact resistance, longer service life, and better performance for heavy-duty cutting, surface conditioning, and industrial wear components. For applications requiring durability, toughness, or cost-effective abrasive power, black aluminum oxide is generally preferred over its white counterpart.

Aluminum oxide appears black when trace metallic additives, carbon sources, or controlled furnace atmospheres are introduced during sintering. These elements alter the crystal structure and light-absorption behavior of α-Al₂O₃, producing a deep gray-to-black body color through the entire ceramic—not just a surface coating.

This black-through-body structure is often intentional because it improves light absorption, infrared resistance, and surface masking performance, while maintaining the mechanical strength and wear resistance typical of alumina ceramics.

You can purchase black alumina directly from ADCERAX, a ceramic manufacturer in China that produces black alumina not only for optical fixtures but also for a wide range of custom components. We supply black alumina parts machined to your drawings, with controlled surface finish and tight tolerances suitable for optical alignment blocks, sensor housings, precision mounts, and other engineered assemblies.

Yes. black aluminum oxide is inherently corrosion-resistant because it is a fully sintered, chemically stable oxide material. It does not react with moisture, most acids or alkalis, or typical industrial chemicals, and it will not rust or degrade like metals or coated surfaces. The through-body black structure also means there is no surface layer to peel, wear, or oxidize, ensuring long-term stability even in high-temperature or humid environments.

No. When formulated correctly, the black colorants or atmosphere adjustments do not significantly degrade flexural strength, hardness, or density. Mechanical performance remains comparable to conventional 95–99% alumina grades.

Typical machining tolerances range from ±0.02–0.1 mm, depending on part geometry, wall thickness, and grinding surface area. Flatness, perpendicularity, and surface finish can also be tightly controlled.

Yes. The deep black ceramic matrix provides low reflectivity and minimal light scatter, making it suitable for optical mounts, alignment blocks, sensor housings, and metrology systems requiring stray-light suppression.

With hardness around 15–18 GPa, black alumina offers excellent abrasion resistance for sliding, guiding, and contact surfaces. Although softer than Si₃N₄ or SiC, it provides superior performance compared to engineering plastics and most metals.

Black alumina is usually priced slightly higher than 95% alumina due to adjusted powder formulations and more controlled sintering conditions. However, it is still significantly more cost-effective than Si₃N₄, SiC, or ZTA for many applications.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Tel: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours