High Temperature Ceramic Crucibles for Laboratory & Industrial Heating

ADCERAX is a China ceramic crucible manufacturer providing lab-grade ceramic crucibles for research laboratories and industrial heating lines. Standard sizes ship from stock, while our engineers customize shapes, materials and capacities to your drawings so you can match temperature range and chemistry, stabilize batch quality and secure reliable supply.

Working factory-direct helps you cut scrap, avoid furnace downtime and keep lead times predictable.

What is Ceramic Crucible?

Ceramic Crucible Meaning

A ceramic crucible is a refractory container made from engineering ceramics such as alumina, zirconia, boron nitride or silicon carbide, designed to hold solids or melts during high-temperature treatment. Compared with metal vessels, a ceramic crucible offers excellent resistance to heat, corrosion and thermal shock, while keeping metal ions and other impurities away from your sample.

Formation of Ceramic Crucible

💠High-purity ceramic powders such as alumina, zirconia, BN, SiC or Si₃N₄ are selected according to the target temperature range and chemistry.

💠Finely milled powders are blended with small amounts of binders, plasticizers and, where needed, sintering aids to achieve good packing and forming behaviour.

💠Pressing and molding – dry or isostatic pressing, and in some cases extrusion or injection molding, are used for standard cups, bowls and tubular shapes with uniform wall thickness.

💠Slip casting – a fluid ceramic slurry is poured into porous molds for more complex contours or thin-walled designs that need precise detail.

💠Moisture and organics are removed in a controlled drying step to prevent warping, surface blistering or early cracking when the crucible enters the kiln. This stage also stabilizes dimensions so subsequent handling and inspection are more reliable.

💠Once dry, critical surfaces, rims and interfaces can be green machined (drilled, turned or ground) to tighten tolerances, refine fit with lids or holders and correct minor shape deviations before the final firing stage.

💠The green crucible is heated along a defined temperature profile to burn out binders and sinter the ceramic matrix, so particles fuse together, porosity decreases and the body reaches its final density, mechanical strength and thermal shock resistance.

💠Depending on the composition, firing is carried out in air, inert or other controlled atmospheres to protect the material and achieve the required properties.

Properties of Ceramic Crucibles

Ceramic crucibles made from advanced ceramics such as alumina, zirconia, boron nitride and silicon carbide offer a combination of high hardness and wear resistance, excellent chemical stability and strong resistance to oxidation at elevated temperatures.

Alumina Ceramic Crucible

Alumina ceramic crucibles (Al₂O₃) combine high hardness, excellent chemical stability, good thermal shock resistance and reliable electrical insulation at elevated temperatures.

| Property | Unit | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Flexural strength | MPa | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.2 | 8.4 | – | – | – | – | – |

| Melting point | °C | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 |

Zirconia Ceramic Crucible

Zirconia ceramic crucibles (ZrO₂) provide higher maximum temperature capability, superior thermal shock resistance and greater fracture toughness than standard alumina, together with low thermal conductivity and strong corrosion resistance at elevated temperatures.

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Boron Nitride Ceramic Crucible

Boron nitride ceramic crucibles (BN) offer excellent thermal shock resistance, high-temperature stability, very low wettability to metals and molten silicon, along with good chemical inertness and electrical insulation.

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

|---|---|---|---|

| Purity | % | 99.99% | 99.50% |

| Density | g/cm³ | 2.15–2.19 | 1.96–2 |

| Hardness | HVO.5 | 651 | 62 |

| Volume resistivity | Ohm·cm | 2×10¹⁴ | 1.2×10¹⁴ |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | °C | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m·K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | 1/°C | 6×10⁻⁷ | 1.8×10⁻⁶ |

| Compressive strength | MPa | 154 (A direction) | 120 |

Silicon Carbide Ceramic Crucible

Silicon carbide ceramic crucibles (SiC) feature high thermal conductivity, excellent mechanical strength and strong thermal shock resistance, together with good oxidation and wear resistance at elevated temperatures.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

| Chemical Stability Range | pH 2–12 |

| Oxidation Stability | <1% microstructural oxidation after 50 cycles (1000°C → RT) |

Types of Ceramic Crucibles

Ceramic crucibles are chosen by both material, shape and use. Here you can quickly compare alumina, zirconia, BN, SiC and multiple forms—cylindrical, rectangular, boat, conical and others—to match your furnace, sample size and process.

Ceramic Crucible Material

Alumina Ceramic Crucible

Matched sets with consistent wall and rim geometry, making it easy to scale from tiny lab tests to larger furnace batches.

Zirconia Ceramic Crucible

Extra-tough rims and bodies tolerate tighter clamping and frequent handling in demanding R&D or pilot lines.

Quartz Ceramic Crucible

Ultra-smooth inner surface and precise flat base give clean release, clear observation and accurate fill control.

Silicon Carbon Ceramic Crucible

Rigid thin-wall design helps shorten heat-up and cool-down time while keeping the crucible stable over repeated cycles.

Silicon Nitride Ceramic Crucible

Lightweight but strong bodies reduce furnace thermal mass and make manual loading and unloading easier.

Magnesia Ceramic Crucible

Optimised for basic oxide and slag environments, helping maintain crucible shape and volume over long campaigns.

Aluminum Nitride Ceramic Crucible

Wide locating flange and high heat-spreading body help keep temperature uniform across the whole melt zone.

Beryllium Oxide Ceramic Crucible

Slim, light walls with very high heat transfer minimise thermal gradients in compact high-power test setups.

Boron Nitride Ceramic Crucible

Naturally non-wetting inner surface lets melts release cleanly, cutting scrap and simplifying post-process cleaning.

Ceramic Crucible Shape

Cylindrical Ceramic Crucible

Symmetrical walls give even heating and strong mechanical support, while straight sides make tongs handling simple and repeatable.

Ceramic Rectangular Crucible

Flat bottoms and long straight walls maximise usable surface area, ideal for spreading powders or aligning parts in rows.

Trapezoid Ceramic Crucible

Tapered sides make loading, scraping and pouring easier, and allow crucibles to nest compactly to save furnace space.

Ceramic Crucible with Spout

Curved lip focuses flow into a narrow stream, giving smoother, drip-free pouring into moulds or vials.

Semicircular Ceramic Crucible

Shallow, rounded profile spreads material in a thin layer, making heating uniform and scraping or sampling very easy.

Point Bottom Ceramic Crucible

Shallow, rounded profile spreads material in a thin layer, making heating uniform and scraping or sampling very easy.

Alumina Conical Crucible

Tapered walls concentrate material at the bottom, improving heat focus and making complete pouring and scraping easier.

Ceramic Boat Crucible

Elongated, shallow channels spread powders in a thin bed, giving very uniform gas contact along the furnace path.

Ceramic Flat Crucible

Reinforced corners and low profile support heavier loads while keeping parts stable during stacking and conveyor handling.

Ceramic Crucible Uses

TGA Ceramic Crucible

Used in thermogravimetric analyzers to hold tiny powder or film samples securely so mass change can be tracked through controlled heating.

DSC Ceramic Crucible

Used in thermogravimetric analyzers to hold tiny powder or film samples securely so mass change can be tracked through controlled heating.

Ceramic Crucible for C/S Analyzer

Matched to carbon/sulfur analyzers where its porous, shaped body promotes complete combustion of steel, alloy or coal samples for C/S determination.

❓ Not Sure Which Ceramic Crucible Fits Your Process?

Share your drawing and operating conditions—temperature range, furnace type, atmosphere, chemistry and batch volume—and we’ll recommend the most suitable ceramic crucible material and design, together with a manufacturable solution you can qualify and repeat.

Applications of Ceramic Crucible

Crucible ceramics are used anywhere materials must be heated, melted or calcined in a clean, repeatable way. Different materials and shapes support very different duties, from small analytical samples to heavier furnace loads and molten metal batches.

Laboratory & Analytical Work

Lab ceramic crucible designs focus on accuracy, low contamination and easy handling in routine tests and research labs. Typical uses include:

- Loss-on-ignition and ashing – laboratory alumina ceramic crucible for gravimetric analysis, residue determination and combustion of organics.

- Water and wastewater testing – ceramic crucibles for VSS analysis and related methods where stable mass and consistent firing behaviour are essential.

- Filtration and volatilization – ceramic filtering crucible and ceramic volatilization crucible types that combine fine porosity or shallow shapes with good thermal shock resistance.

- Sample preparation – controlled calcination, powder synthesis and pre-firing before XRF, XRD or other material-characterisation techniques.

Furnaces, Muffle Furnaces and Kilns

For continuous or batch thermal processes, robust containers are needed to survive repeated firing cycles. Typical applications include:

- Ceramic crucible for furnace use in box, tube and pit furnaces where stable geometry and wall strength matter.

- Ceramic crucible for muffle furnace for small production runs, pilot lines and laboratory-scale heat treatment.

- Kiln ceramic crucible and kiln furniture ceramic crucible where the crucible itself becomes part of the support system on shelves or props.

- Ceramic crucible tray for furnace when products must be spread in thin layers for uniform heating or when parts need guided support during firing.

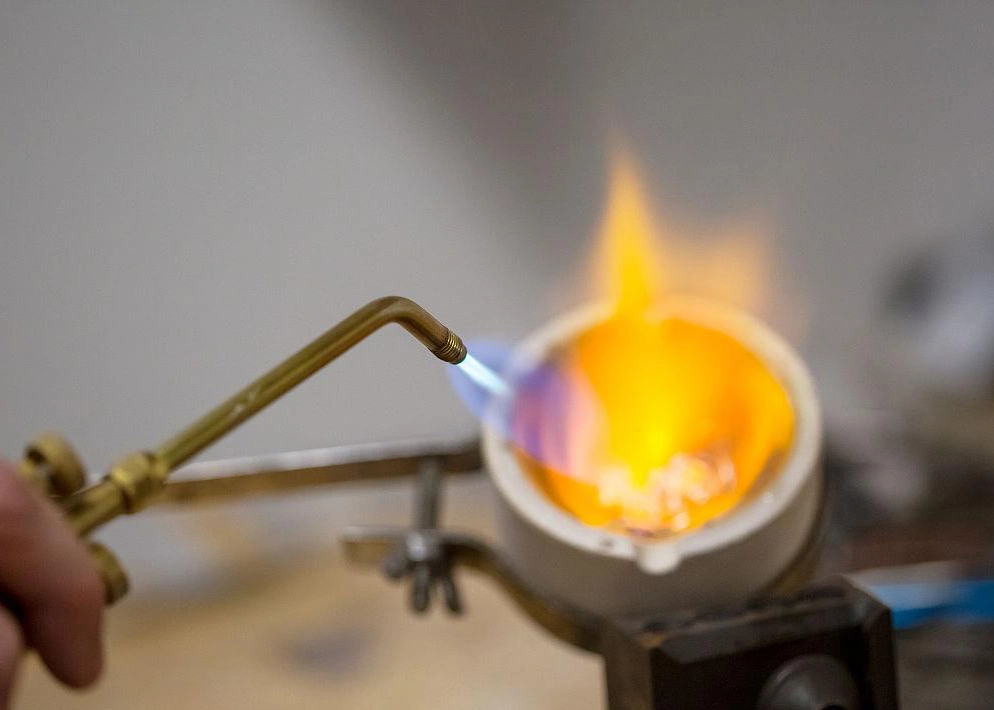

Metal and Glass Handling

When working with molten phases, crucible material and design strongly influence lifetime and contamination levels. Typical uses include:

- Ceramic melting crucible for small to medium charges of metals and alloys in R&D, test casting and sample preparation.

- Ceramic crucible molten metal duties in non-ferrous applications where oxidation resistance and dimensional stability are important.

- Ceramic crucibles for glass for frit development, colour trials and glass powder sintering under controlled temperature profiles.

Silicon and Solar-Related Processes

Special ceramic systems are required where silicon and related materials are processed at high temperature. Examples include:

- Ceramic crucibles for silicon ingot heating and intermediate holding, where thermal shock resistance and low wettability are key.

- Solar use ceramic crucible options tailored to solar-grade silicon and related materials, often based on BN or other advanced ceramics for cleaner release and stable geometry over many cycles.

China Ceramic Crucible Customized

ADCERAX is a China ceramic crucibles supplier specializing in custom-made crucibles for laboratory and industrial furnaces. We tailor capacity, shape, wall thickness and material grade to your drawings, while keeping key standard sizes in stock for urgent needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your Ceramic Crucible Manufacturer?

ADCERAX is a ceramic crucible wholesaler in China, producing custom and standard crucibles with controlled materials and tight tolerances. Experienced engineers, responsive sampling and reliable export logistics make ceramic crucible sourcing efficient, predictable and easy to support long-term.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

Professional Ceramic Crucible Factory-ADCERAX

ADCERAX has been engaged in advanced ceramics for over 20 years and has developed more than 2,000 types of high-temperature components, with a strong focus on ceramic crucibles made from alumina, zirconia, boron nitride, silicon carbide, aluminum nitride and related materials.

We supply both custom and standard ceramic crucibles for laboratory use, muffle and box furnaces, metal and glass melting and other thermal processes, exporting to more than 50 countries and supporting industrial users and OEMs that require stable, low-contamination and long-life crucible performance.

Ceramic Crucible Processing Strength

ADCERAX completes every step, from forming to diamond machining, to keep crucible walls and rims consistent. Tuned sintering profiles and 100% visual checks for cracks or chipping give you strong, thermal-shock-resistant crucibles that run reliably over many furnace cycles.

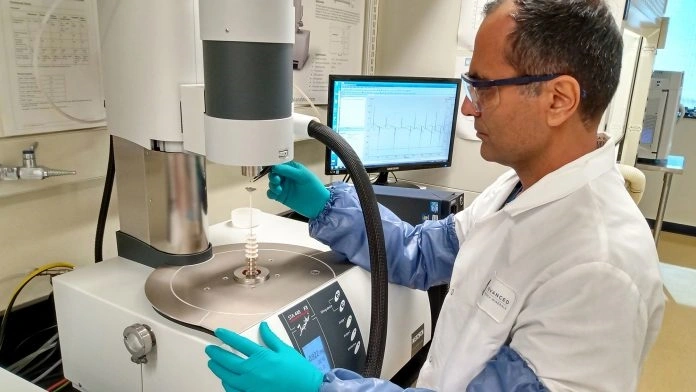

CNC Forming Stability & Wall Thickness Control

Dimensional accuracy for ceramic crucible bowl is achieved through CNC-assisted forming and machining, keeping wall thickness, roundness and base flatness within tight, repeatable tolerances for reliable furnace loading.

Holding crucible wall variation within ±0.2 mm for stable heating and cooling.

Controlling mouth roundness and base flatness to ensure smooth stacking and contact with supports.

Machining rims so lids and bodies mate correctly, improving sealing and handling strength.

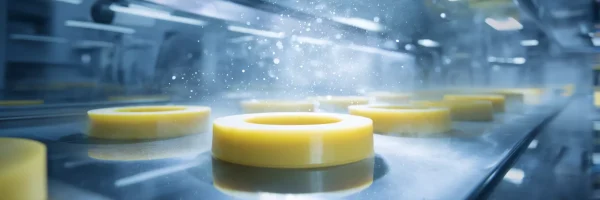

Clean, Low-Contamination Surface Finishing

Internal and external crucible surfaces are refined to reduce residue build-up, minimise contamination and limit micro-cracks, helping each firing cycle stay stable and easy to clean.

Optimised Ra reduces sample adhesion while preserving suitable wetting in melts and slurries.

Removing sharp rims and micro-chips to lower breakage risk during loading and tongs handling.

Applying selected finishes where lower porosity or easier cleaning is required.

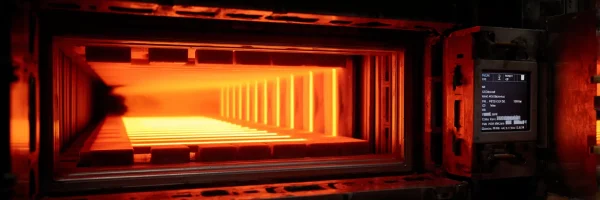

High-Temp Sintering for Service Life & Thermal Shock Resistance

Microstructure density and strength in ceramic crucibles are developed through controlled high-temperature sintering cycles, tuned to each material system for long life under repeated firing.

Matching soak times and peak temperatures to alumina, zirconia, BN or SiC crucible materials.

Managing ramp and cool-down rates to balance strength, density and resistance to cracking.

Low open porosity improves chemical stability and cuts contamination over many cycles.

FAQs About Ceramic Crucibles

A ceramic crucible is a high-temperature container used for ashing, calcination, melting, filtration and sample preparation in muffle furnaces, box furnaces and kilns, where a stable, low-contamination vessel is required.

Select the material based on temperature, atmosphere and chemistry:

Alumina ceramic crucible (Al₂O₃)

Suitable for most oxidising lab and furnace work; good balance of cost, high temperature capability and chemical stability.Zirconia ceramic crucible (ZrO₂)

Used when you need higher working temperature, better thermal shock resistance and higher toughness than alumina.Boron nitride ceramic crucible (BN)

Chosen for very low wettability to metals and molten silicon, excellent thermal shock resistance and good chemical inertness.Silicon carbide ceramic crucible (SiC)

Preferred where high thermal conductivity, strong mechanical strength and good thermal shock resistance are important.

For analytical work, small ceramic crucible volumes (for example 10–50 ml) minimise sample and energy use, while larger ceramic crucible capacities (such as 300–500 ml and above) suit furnace loads, pilot batches or metal and glass melting; always check internal dimensions and fill level against your sample mass.

A ceramic crucible with lid is preferred when you need to limit contamination, reduce evaporation or splashing, protect sensitive samples in a muffle furnace, or partially control atmosphere around the charge during heating.

Yes. For many non-ferrous metals, high-purity alumina ceramic crucible and silicon carbide ceramic crucible are commonly used; for more reactive alloys or where wetting must be very low, boron nitride ceramic crucible or zirconia ceramic crucible may be selected. In all cases, metal chemistry, fluxes, atmosphere and temperature must be checked to choose a compatible ceramic system.

Ceramic crucibles perform better in oxidizing atmospheres and many corrosive environments, while graphite crucibles offer excellent thermal shock and conductivity but are limited in air at high temperatures; choice depends on atmosphere and metal chemistry.

Service life depends on material, temperature, atmosphere, handling and thermal cycling; under well-controlled conditions, a high-purity ceramic crucible can often survive many cycles, while harsh chemistries or fast ramps shorten lifetime.

Yes, lab ceramic crucible designs in high-purity alumina are widely used for loss-on-ignition (LOI) and VSS analysis, because they offer stable mass, good thermal shock resistance and low interaction with residues during repeated firing cycles.

For an accurate ceramic crucible price, provide material (for example alumina, zirconia, BN, SiC), internal dimensions, wall thickness, whether you need a ceramic crucible with lid, required quantity, temperature range, furnace type and preferred delivery terms.

Allow the crucible to cool gradually, remove loose residues mechanically, then use a controlled burn-off or compatible chemical cleaning method; avoid quenching, hard impact and aggressive grinding that may introduce microcracks.

Ceramic crucibles generally have a higher unit cost than simple metal options but offer longer life and better chemical stability in many atmospheres; compared with graphite, they can be more cost-effective for oxidising or corrosive environments where graphite degrades quickly.

You can source China alumina ceramic crucibles directly from ADCERAX, a professional ceramic crucible factory that manufactures high-purity alumina crucibles in both standard sizes and custom designs. Send your drawing or size requirements to ADCERAX to get engineering advice, material data and a factory-direct quotation.

Yes. ADCERAX can supply ceramic crucible for melting silver in high-purity alumina and selected silicon carbide grades, suitable for non-ferrous metal melting under the correct temperature, atmosphere and flux conditions. If you share your furnace type, charge size and target temperature, we can recommend a matching material, wall thickness and crucible shape, then quote you a ceramic crucible for sale with factory-direct pricing.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.