Porous Ceramic Manufacturer in China— Standard Sizes & Custom Porosity and Geometry

ADCERAX is a porous ceramic manufacturer in China, supplying porous ceramic tubes, discs, plates, core rods, and diffuser components in alumina and SiC. These engineered porous ceramics help engineers prevent the most common failure modes in filtration and flow-control duty—rapid pressure-drop rise, unstable flow distribution, premature clogging, and cracking from thermal cycling or abrasive wear.

With controlled pore structure, consistent batches, and custom-to-drawing capability, performance stays repeatable from prototype to repeat orders.

What is Ceramic Porous?

Ceramic porous refers to a ceramic material that contains a controlled network of interconnected pores. Those pores allow fluid or gas to pass through in a predictable way, so the part can function as a filter, diffuser/sparger, flow restrictor, or permeable support layer.

⚠️ Porous vs non-porous ceramic

1.Choose porous when you need controlled flow, diffusion, or filtration.

2.Choose non-porous (dense) when you need sealing, wear surfaces, or leak-tight strength.

Porous Ceramic Material Properties

Porous ceramics combine controlled open porosity with reliable mechanical strength, thermal stability, and chemical durability. Tuned pore size and porosity deliver predictable permeability while maintaining consistent performance.

Mechanical Properties of Porous Ceramic Materials

| Material | Bulk Density (g/cm³) | Open Porosity (%) | Compressive Strength (MPa) | Flexural Strength (MPa) | Young’s Modulus (GPa) | Fracture Behavior | Typical Mechanical Notes |

|---|---|---|---|---|---|---|---|

| Porous Alumina (Al₂O₃) | 2.0 – 3.2 | 20 – 50 | 20 – 150 | 10 – 60 | 80 – 200 | Brittle | Good balance of strength and permeability; stable under compression; widely used for filters, supports, and core rods |

| Porous Zirconia (ZrO₂) | 3.0 – 4.5 | 15 – 45 | 50 – 250 | 20 – 100 | 100 – 210 | Semi-toughened | Higher fracture resistance than other porous ceramics; better shock tolerance; suitable for precision and load-bearing porous parts |

| Porous Silicon Carbide (SiC) | 2.2 – 3.0 | 25 – 60 | 80 – 300 | 30 – 120 | 200 – 350 | Brittle | Very high stiffness and compressive strength; excellent wear resistance; ideal for high-temperature and abrasive environments |

| Porous Magnesium Oxide (MgO) | 1.6 – 2.5 | 30 – 65 | 10 – 80 | 5 – 40 | 30 – 120 | Brittle | Lower mechanical strength; lightweight and highly permeable; often used where insulation or chemical compatibility matters more than load capacity |

Thermal Properties of Porous Ceramic Materials

| Material | Max Service Temperature (°C) | Thermal Conductivity (W/m·K) | Thermal Expansion (×10⁻⁶ /K) | Thermal Shock Resistance | Heat Retention / Dissipation | Typical Thermal Notes |

|---|---|---|---|---|---|---|

| Porous Alumina (Al₂O₃) | 1200 – 1600 | 2 – 10 | 6.5 – 8.5 | Moderate | Balanced | Good high-temperature stability; reduced thermal conductivity due to porosity; suitable for heated filtration and hot gas flow components |

| Porous Zirconia (ZrO₂) | 900 – 1400 | 1.5 – 5 | 9.5 – 11 | Good | High heat retention | Low thermal conductivity with higher expansion; better thermal shock tolerance than most porous ceramics; suitable for precision thermal fixtures |

| Porous Silicon Carbide (SiC) | 1400 – 1800 | 15 – 60 | 4.0 – 4.8 | Excellent | Fast heat dissipation | High thermal conductivity even in porous form; outstanding thermal shock resistance; ideal for high-temperature and rapid heating/cooling environments |

| Porous Magnesium Oxide (MgO) | 1000 – 1600 | 1 – 6 | 12 – 14 | Fair | High insulation | Very low thermal conductivity; excellent thermal insulation performance; often used where heat loss must be minimized rather than controlled |

Electrical Properties of Porous Ceramic Materials

| Material | Volume Resistivity (Ω·cm) | Dielectric Strength (kV/mm) | Dielectric Constant (εr) | Electrical Insulation Stability | Typical Electrical Notes |

|---|---|---|---|---|---|

| Porous Alumina (Al₂O₃) | 10¹² – 10¹⁴ | 6 – 15 | 8 – 10 | Excellent | Strong electrical insulation even with open porosity; widely used for insulating supports, porous heaters, and vacuum systems |

| Porous Zirconia (ZrO₂) | 10⁹ – 10¹² | 4 – 10 | 20 – 30 | Good | Higher dielectric constant; suitable for applications requiring insulation with enhanced thermal compatibility |

| Porous Silicon Carbide (SiC) | 10² – 10⁶ | <1 | 10 – 40 | Limited | Semiconductive behavior; electrical resistivity decreases with temperature; suitable for heating or sensing rather than insulation |

| Porous Magnesium Oxide (MgO) | 10¹³ – 10¹⁵ | 5 – 12 | 9 – 11 | Excellent | High resistivity and low dielectric loss; preferred for high-temperature electrical insulation and heater supports |

Chemical Properties of Porous Ceramic Materials

| Material | Acid Resistance | Alkali Resistance | Solvent Resistance | Oxidation Resistance | Chemical Stability Notes |

|---|---|---|---|---|---|

| Porous Alumina (Al₂O₃) | Excellent | Good | Excellent | Excellent | Chemically inert to most inorganic acids and organic solvents; limited attack by strong alkalis at elevated temperature |

| Porous Zirconia (ZrO₂) | Excellent | Excellent | Excellent | Excellent | Outstanding chemical stability across acids, alkalis, and solvents; minimal ion leaching; suitable for aggressive chemical environments |

| Porous Silicon Carbide (SiC) | Excellent | Excellent | Excellent | Excellent | Highly resistant to acids, alkalis, and molten salts; surface oxidation possible at very high temperatures in oxidizing atmospheres |

| Porous Magnesium Oxide (MgO) | Fair | Poor | Good | Excellent | Sensitive to moisture, acids, and strong alkalis; prone to hydration; mainly used in dry or controlled chemical environments |

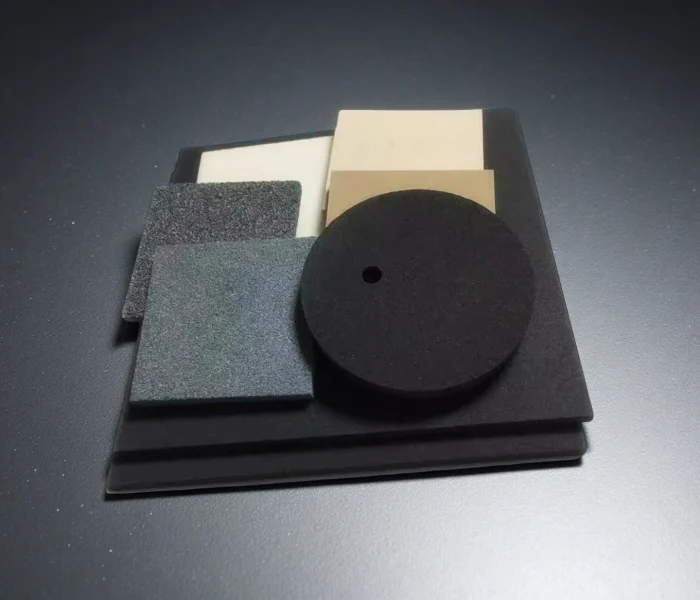

Porous Ceramic Products & Types

Explore porous ceramics in two ways: by material (alumina, zirconia, SiC, magnesia) and by product type (foam filter, balls, tube, rod, chuck, disc, plate). Use your pore size and permeability (flow/ΔP), plus temperature and chemistry, to quickly narrow to the right option.

Porous Alumina Ceramic

Cost-effective porous alumina with stable pore structure, clean chemistry, and reliable insulation.

Porous Zirconia Ceramic

Tough porous zirconia with higher crack resistance and stable permeability under cycling.

porous silicon carbide ceramic

Porous SiC for high wear and heat—high stiffness, strong permeability, excellent thermal-shock resistance.

Porous Magnesia Ceramic

Porous magnesia for insulation—low heat loss, lightweight permeability, stable at high temperature (dry service).

Ceramic Foam Filter

Ceramic foam filters capture inclusions with a 3D open-cell network while keeping flow resistance low. The foam structure helps reduce bypass under flow surges.

porous ceramic balls

Porous ceramic balls offer high surface area in a compact shape for efficient packed-bed contact. The spherical form improves flow distribution and reduces channeling.

porous ceramic tube

Porous ceramic tubes provide long, uniform flow paths and easy inline sealing. The tubular format delivers high effective area per footprint with stable pressure-drop control.

porous ceramic rod

Porous ceramic rods enable controlled diffusion or wicking along a linear core. The rod form allows precise placement inside housings without complex redesign work.

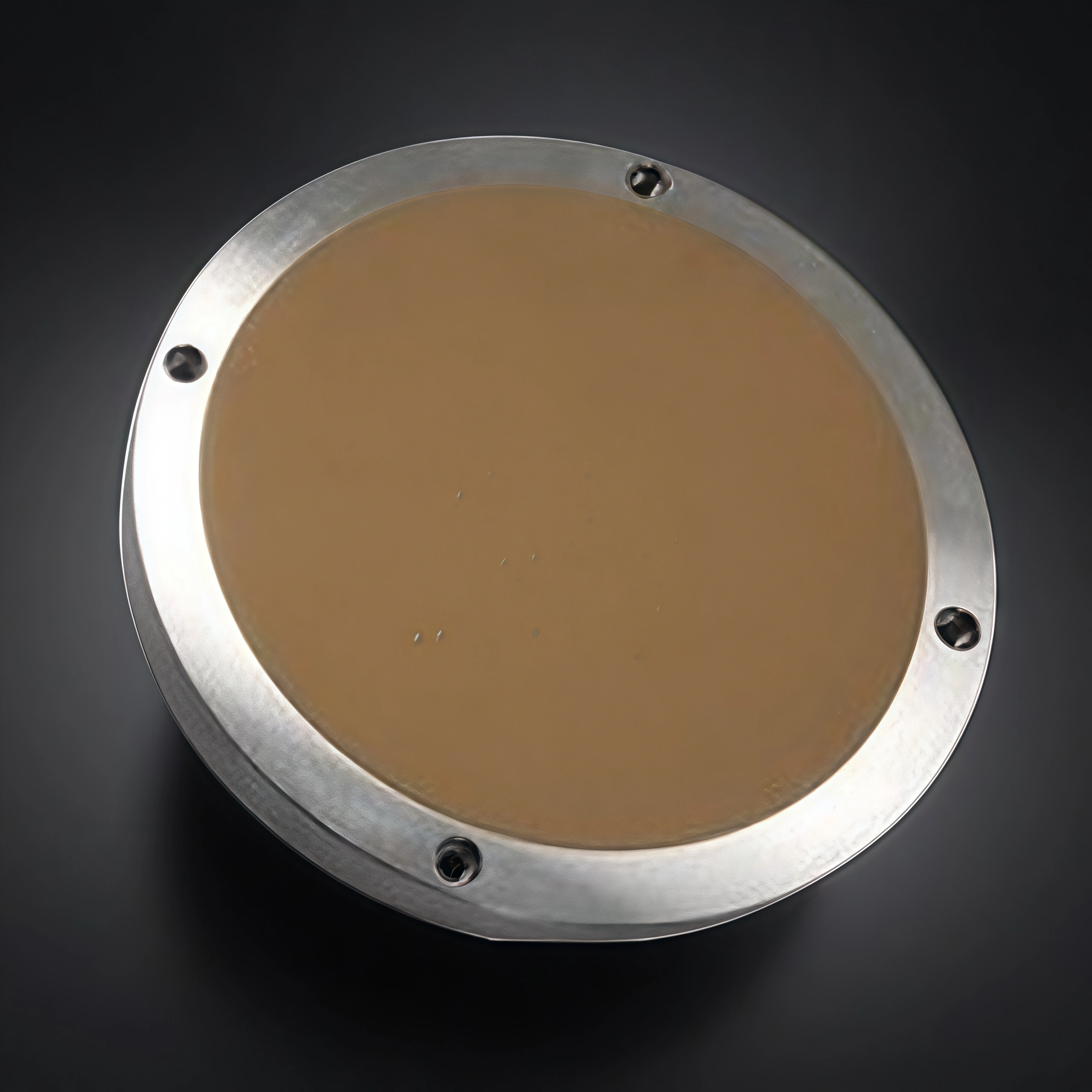

porous ceramic chuck

Porous ceramic chucks provide uniform vacuum holding through a permeable surface, reducing slip and local leakage. Stable suction helps keep positioning repeatable.

porous ceramic disc

Porous ceramic discs deliver compact, uniform through-flow with stable pressure-drop behavior. The disc shape supports easy sealing and quick replacement.

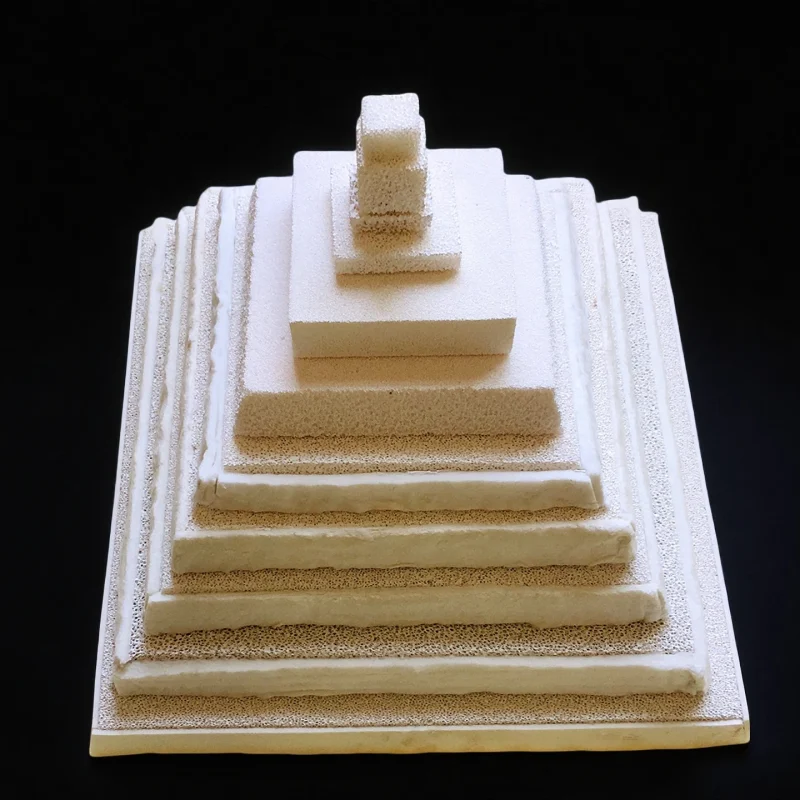

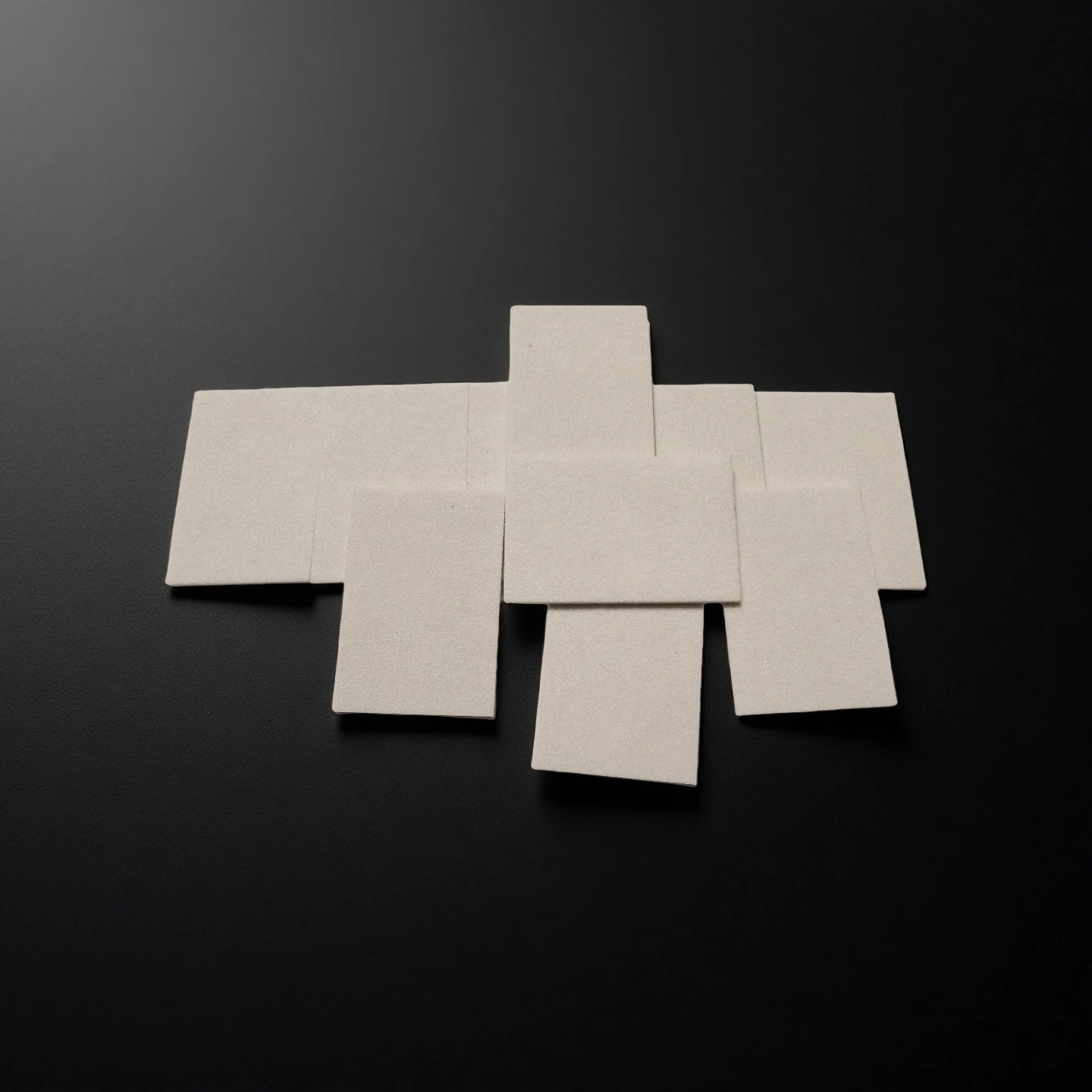

porous ceramic plate

Porous ceramic plates spread permeability across a wide area, reducing channeling and edge lift. The flat format integrates easily into fixtures.

porous ceramic membrane

Porous ceramic membranes use engineered pore size for repeatable separation performance. Rigid structure supports strong cleaning and recovery.

Porous Ceramic — Built for Stable Flow and Long Life.

Porous ceramics deliver controlled permeability and stable performance in abrasive, corrosive, or clogging-prone duty. Tuned pore size and porosity help reduce channeling, pressure-drop spikes, and output drift, while enabling repeatable batches for OEM integration.

Porous Ceramics Applications

Porous ceramics are used across industrial filtration, process equipment, chemical engineering, automation systems, thermal management, and high-temperature processing, where controlled permeability and material stability are critical.

Filtration & Separation

✍🏻Application of porous ceramics :

Porous ceramics are widely used for liquid and gas filtration where stable flow and cleanable media are required. Their rigid pore network maintains permeability under pressure, abrasion, and chemical exposure.

📍Typical products

porous ceramic tubes, discs, plates, foam filters

🧩Porous ceramics examples

In an industrial wastewater reuse system handling high-solids slurry, polymer filter media required replacement every 3–4 months due to pore collapse and chemical attack. After switching to porous alumina ceramic tubes, operating life extended to 18–24 months, while average pressure-drop increase per cycle was reduced by over 40%.

Flow Distribution & Equalization

🧩Porous ceramics examples

A chemical process skid experienced uneven inlet flow, causing localized erosion and frequent seal failures. By integrating a porous ceramic distribution plate upstream, velocity variation across the section dropped from ±25% to below ±8%, stabilizing downstream equipment.

Vacuum Holding & Workholding

✍🏻Applications of porous ceramics

Porous ceramics are used in vacuum chucks and holding tables to distribute suction evenly across a surface, improving stability for thin or delicate parts.

📍Typical products

porous ceramic chucks, porous plates

🧩Porous ceramics examples

A vacuum workholding system using drilled metal plates suffered from uneven suction, causing part slip and alignment errors. Switching to a porous ceramic vacuum chuck improved suction uniformity, cutting part movement incidents by over 70%.

High-Temperature & Abrasive Environments

✍🏻Applications of porous ceramics

In conditions where polymers soften and metals corrode or wear, porous ceramics maintain both permeability and structure.

📍Typical materials

porous silicon carbide, porous alumina

🧩Porous ceramics examples

In a hot gas handling line above 800 °C, polymer-based porous components degraded within weeks. After replacement with porous silicon carbide elements, service intervals extended to 12+ months despite abrasive particulate exposure.

Custom Porous Ceramic

ADCERAX custom porous ceramic components are made to your drawing or process specs, including pore size target, porosity/permeability range (flow/ΔP), part geometry (OD/ID/length or plate size/thickness), end-face or sealing features, and surface finish requirements. Typical customization lead time is 2–9 weeks, depending on material choice, porosity grade, tolerances, and machining complexity.

Customization Options

Define the function first—filtration, diffusion, distribution, wicking, or vacuum holding—then set the pore size window and permeability target (flow/ΔP). Clear matching reduces output drift and avoids over-restriction or unstable flow behavior.

Share your drawing and fit points for reliable integration—OD/ID/length, plate size/thickness, end-face flatness, sealing lands, and mounting features. Controlled fit reduces bypass/leak paths and simplifies replacement in service.

Match the design to your media behavior—abrasive solids, sticky fines, viscosity shifts, or particulate spikes. Specify allowable ΔP rise and cleaning method (backwash, blowback, solvent/alkali wash) to maintain permeability and stable operation.

Choose the porous ceramic material based on chemistry, wear, and temperature—Al₂O₃ / ZrO₂ / SiC / MgO. The right surface finish and pore connectivity improve durability, cleanliness, and long-term consistency under harsh service.

Customization Process

Send function, pore size, flow/ΔP target, temp/chemistry, and cleaning method. Include drawing/interface, quantity, lead time, destination.

We confirm material (Al₂O₃/ZrO₂/SiC/MgO), porosity grade, pore window, OD/ID/length or plate size, and sealing/mount details.

We produce porous ceramic parts to spec and inspect key dimensions plus pore/permeability targets by batch. Traceable marking and records available.

Parts are protected, labeled, and packed to prevent chipping/contamination, then shipped with export-ready documents.

Why Source Porous Ceramics from ADCERAX?

ADCERAX supplies export-ready porous ceramic components with controlled processing and batch inspection for consistent pore structure and reliable fit. Fast engineering support helps confirm pore size, permeability (flow/ΔP), interfaces, and lead time.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Porous Ceramic Manufacturers-ADCERAX

ADCERAX is a factory-direct porous ceramics supplier with 20+ years of advanced ceramics experience, supplying porous ceramic plates, discs, tubes, rods, chucks, balls, and foam filters for industrial duty where stable permeability and durability matter.

Standard porous ceramic parts are available for fast replacement, and custom-to-drawing builds match pore size, porosity grade, permeability (flow/ΔP), and interface features. With documented inspection and protective packing, ADCERAX helps buyers keep performance consistent and maintenance cycles predictable.

Porous Ceramics Processing

Pore-Former Sintering (Sacrificial Additives)

🔹How it’s made: ceramic powder is blended with pore formers (polymer beads, starch, graphite, etc.), formed, then fired; pore formers burn out to leave open pores.

🔹Best for: porous plates, discs, rods, blocks (uniform porosity).

🔹What it delivers: tunable porosity level and pore size band; good batch repeatability.

Partial Sintering (Necking-Control Porosity)

🔹How it’s made: the green body is sintered below full densification so particles “neck” together while keeping inter-particle voids open.

🔹Best for: fine porous structures where strength must remain acceptable (often small parts).

🔹What it delivers: interconnected pores with relatively tight pore network; stable geometry.

Extrusion + Burnout + Sintering

🔹How it’s made: plasticized ceramic mix is extruded into tubes/rods; pore former burnout creates open pores; sintering locks structure.

🔹Best for: porous ceramic tube, porous ceramic rod, long straight flow paths.

🔹What it delivers: consistent ID/OD along length; good inline sealing and assembly.

Freeze Casting (Directional Porosity)

🔹How it’s made: slurry is frozen; ice crystals template aligned channels; ice is removed (freeze-dry), then sintering fixes the structure.

🔹Best for: parts needing anisotropic flow—one-direction channels, controlled gradients.

🔹What it delivers: aligned pore channels and high directional permeability.

FAQs About Porous Ceramics

Some ceramics can be porous, but industrial porous ceramics are intentionally engineered. Pore size, porosity, and permeability are controlled during forming and sintering.

Ceramic can be either porous or non-porous depending on processing.

Porous ceramics contain an interconnected pore network and are used for flow, filtration, and diffusion.

Non-porous (dense) ceramics have negligible open porosity and are used for insulation, sealing, wear surfaces, or leak-tight parts.

Engineers differentiate them by open porosity %, permeability (flow/ΔP), and leak rate. A simple lab test is to measure flow at a small pressure differential.

Start from the function: filtration needs a pore-size window tied to particle retention, while diffusion or vacuum holding focuses more on stable permeability. Define your target flow and allowable ΔP first, then confirm pore grade.

Porous alumina: cost-effective, good chemical & thermal stability, typical filtration duties.

Porous zirconia: higher fracture toughness, better mechanical shock resistance; good when strength under stress matters.

Porous SiC: high wear resistance, high temp tolerance, excellent for abrasive or heavy solids loading duties.

You should choose by media chemistry, temp range, solids load & desired permeation stability.

Yes, critical fit zones (OD/ID, flatness, sealing lands) can be finished to drawing. The porous region is handled carefully to avoid pore blockage and edge chipping.

Porous ceramics are made as:

Plates/discs: wide area flow & distribution.

Tubes: inline filtration & sealing integration.

Rods/core rods: diffusion & wicking cores.

Chucks: vacuum holding with uniform suction.

Balls/beads & foam: packed beds & high throughput media.

Common checks include key dimensions, pore grade confirmation, and permeability verification (flow/ΔP) by batch. Traceable marking and inspection records can be provided if required.

You should send part type, drawing/interface, pore size (µm), permeability (flow/ΔP), temperature/chemistry, and quantity.

Include cleaning method and lead time target to get the most accurate build recommendation and quote.

Porous ceramic is made by forming a ceramic “green body” and then engineering an interconnected pore network during burnout and sintering to meet a target pore size, porosity, and permeability (flow/ΔP).

✅ Typical production workflow (step-by-step)

Define targets: pore size window, open porosity %, permeability (flow/ΔP), temperature/chemistry, and part geometry.

Raw material prep: select ceramic powder + binders; add pore-forming agents if required.

Mixing & de-airing: disperse uniformly to avoid pore banding and weak zones.

Forming: press/extrude/cast to create the green shape (plate/disc/tube/rod/foam).

Drying: controlled drying to prevent cracks and distortion.

Debinding & burnout: remove binders and pore formers to open the pore network.

Sintering: lock pore structure and mechanical integrity with a controlled firing profile.

Finish machining (as needed): OD/ID, flatness, sealing lands, grooves, mounting features—without blocking pores.

Cleaning: remove machining dust and residues to stabilize permeability.

Inspection: verify key dimensions plus pore grade and permeability (flow/ΔP) by batch, then pack for shipment.

Porous ceramics can be cleaned without blocking pores by:

Rinse/flush at low ΔP to remove loose solids.

Soak in compatible solvent for oils/greases.

Controlled alkali or acid wash for specific foulants.

Backwash flow for filtration parts.

Final rinse & drying.

Avoid hard brushes or high-pressure jets that can chip pore walls. Confirm success by comparing flow vs. ΔP before and after cleaning.

Porous ceramics can be engineered with pore sizes from <1 µm up to several hundred µm depending on duty. For filtration, typical ratings are 5–50 µm; for diffusion or wicking, pore sizes can be broader (10–200 µm). Permeability and ΔP targets should be specified with desired flow rate.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.